ASTM B224-04

(Classification)Standard Classification of Coppers

Standard Classification of Coppers

SIGNIFICANCE AND USE

This classification lists the types of copper available from refineries or fabricators, or both, defines the common terms used, and gives the characteristics of many of the coppers available. It is useful to the neophyte looking for the appropriate copper for a particular application.

SCOPE

1.1 This is a classification of the various types of copper currently available in refinery shapes and wrought products in commercial quantities. It is not a specification for the various types of copper.

1.2 In this classification, use is made of the standard copper designations in use by the copper industry.

1.3 Although this classification includes certain UNS designations as described in Practice E 527, these designations are for cross-reference only and are not requirements. Therefore, in case of conflict, this ASTM classification shall govern.

1.4 This classification does not attempt to differentiate between all compositions that could be termed either coppers or copper-base alloys, but in conformance with general usage in the trade, includes those coppers in which the copper is specified as 99.85 % or more, silver being counted as copper.

Note 1—Coppers may contain small amounts of certain elements intentionally permitted to impart specific properties, without excessively lowering electrical conductivity. The total copper plus specific permitted elements is usually specified as 99.85 % or more. These intentionally permitted elements normally include, but are not limited to, arsenic, cadmium, chromium, lead, magnesium, silver, sulfur, tellurium, tin, zinc, and zirconium, plus deoxidizers, up to specific levels adopted by the International Standards Organization.

1.5 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B224 – 04

Standard Classification of

1

Coppers

This standard is issued under the fixed designation B224; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* B5 Specification for High Conductivity Tough-Pitch Cop-

per Refinery Shapes

1.1 This is a classification of the various types of copper

B115 Specification for Electrolytic Copper Cathode

currently available in refinery shapes and wrought products in

B170 Specification for Oxygen-Free Electrolytic Copper—

commercial quantities. It is not a specification for the various

Refinery Shapes

types of copper.

B216 Specification for Tough-Pitch Fire-Refined Copper—

1.2 In this classification, use is made of the standard copper

Refinery Shapes

designations in use by the copper industry.

B379 Specification for Phosphorized Coppers—Refinery

1.3 Although this classification includes certain UNS des-

Shapes

ignations as described in Practice E527, these designations are

E527 Practice for Numbering Metals and Alloys in the

forcross-referenceonlyandarenotrequirements.Therefore,in

Unified Numbering System (UNS)

case of conflict, this ASTM classification shall govern.

F68 Specification for Oxygen-Free Copper in Wrought

1.4 This classification does not attempt to differentiate

Forms for Electron Devices

between all compositions that could be termed either coppers

or copper-base alloys, but in conformance with general usage

3. Terminology

in the trade, includes those coppers in which the copper is

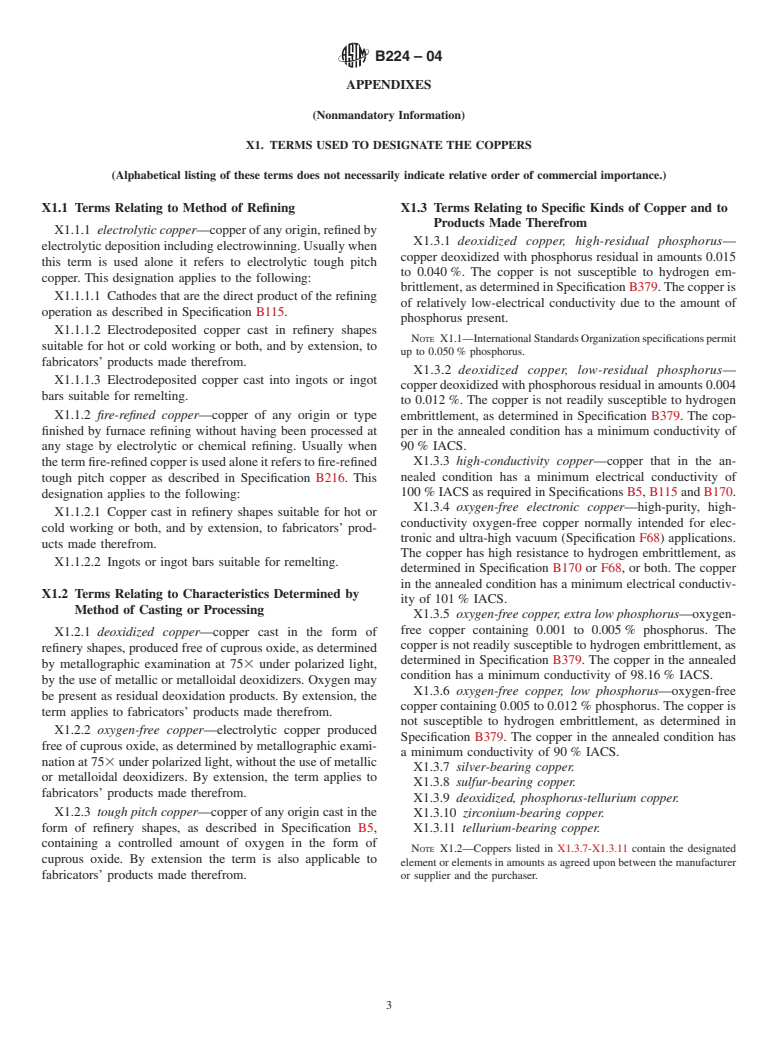

3.1 Appendix X1 describes the terms used in designating

specified as 99.85 % or more, silver being counted as copper.

the various coppers listed.

NOTE 1—Coppers may contain small amounts of certain elements

3.2 Appendix X2 describes the refinery shapes.

intentionally permitted to impart specific properties, without excessively

3.3 Appendix X3 describes the fabricators’ forms.

lowering electrical conductivity. The total copper plus specific permitted

elements is usually specified as 99.85 % or more. These intentionally

4. Significance and Use

permitted elements normally include, but are not limited to, arsenic,

4.1 This classification lists the types of copper available

cadmium, chromium, lead, magnesium, silver, sulfur, tellurium, tin, zinc,

and zirconium, plus deoxidizers, up to specific levels adopted by the from refineries or fabricators, or both, defines the common

International Standards Organization.

terms used, and gives the characteristics of many of the

coppers available. It is useful to the neophyte looking for the

1.5 Units—The values stated in inch-pound units are to be

appropriate copper for a particular application.

regarded as standard. The values given in parentheses are

mathematical conversions to SI units, which are provided for

5. Basis of Classification

information only and are not considered standard.

5.1 Table 1 lists the standard designations, and the refinery

2. Referenced Documents

shapes and fabricators’ products currently produced.The listed

2

coppers are not necessarily available in the complete range of

2.1 ASTM Standards:

sizesintheformshown,norfromanyonesupplierinallforms.

5.2 Existing ASTM specifications for refinery copper and

1

This classification is under the jurisdiction of ASTM Committee B05 on

for wrought copper products may cover more than one of the

Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.07

coppers listed in Table 1 or may include only part of the range

on Refined Copper.

covered by any one of the coppers shown in this classification.

Current edition approved May 1, 2004. Published June 2004. Originally

approved in 1948. Last previous edition approved in 1998 as B224 – 98. DOI:

10.1520/B0224-04.

6. Keywords

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 classification, coppers

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B224 – 04

TABLE 1 Classification of Coppers

NOTE 1—Table 1 lists the standard designations, refinery shapes, and fabricator’s products.

C

Form in which Copper is Available

D E

From Refiners From Fabricators

A B

DesignationsType of Copper UNS Nos. Ingots

Pipe Rod

and Flat Prod-

Wire Bars Billets Cakes and and Shapes

Ingot ucts

Tube Wire

Bars

CATH Electrolytic cathode Cathodes only

Tough-Pitch Coppers

ETP Ele

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.