ASTM D3333-95

(Practice)Standard Practice for Sampling Manufactured Staple Fibers, Sliver, or Tow for Testing

Standard Practice for Sampling Manufactured Staple Fibers, Sliver, or Tow for Testing

SCOPE

1.1 This practice covers a procedure for the division of shipments of man-made staple fiber, sliver (or top) or tow into lots and the sampling of such lots for testing.

Note 1--For sampling yarns, refer to Practice D2258.

Note 2--This practice differs from BISFA rules for staple fibers in the lot sampling, by the elimination of separate sampling of outer versus inner container areas, in the reduction of number of strata from 6 to 5, and by the elimination of compositing to obtain a single laboratory sample for the lot when testing properties which do not depend on as-received moisture content.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3333 – 95

Standard Practice for

Sampling Man-Made Staple Fibers, Sliver, or Tow for

Testing

This standard is issued under the fixed designation D 3333; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope the laboratory as a source of test specimens.

3.1.3 lot, n—in acceptance testing, that part of a consign-

1.1 This practice covers a procedure for the division of

ment or shipment consisting of material from one production

shipments of man-made staple fiber, sliver (or top) or tow into

lot.

lots and the sampling of such lots for testing.

3.1.4 lot sample, n—one or more shipping units taken at

NOTE 1—For sampling yarns, refer to Practice D 2258.

random to represent an acceptance sampling lot and used as a

NOTE 2—This practice differs from BISFA rules for staple fibers in the

source of laboratory samples.

lot sampling, by the elimination of separate sampling of outer versus inner

3.1.5 man-made staple fiber, n—fiber of spinnable length

container areas, in the reduction of number of strata from 6 to 5, and by

manufactured directly or by cutting filaments.

the elimination of compositing to obtain a single laboratory sample for the

3.1.6 primary sampling unit, n—the sampling unit contain-

lot when testing properties which do not depend on as-received moisture

content.

ing all of the sources of variability which should be considered

in acceptance testing; the sampling unit taken in first stage of

1.2 This standard does not purport to address all of the

selection in any procedure for sampling a lot or shipment.

safety concerns, if any, associated with its use. It is the

3.1.7 sample, n—(1) a portion of material which is taken for

responsibility of the user of this standard to establish appro-

testing or for record purposes. (2) a group of specimens used,

priate safety and health practices and determine the applica-

or of observations made, which provide information that can be

bility of regulatory limitations prior to use.

used for making statistical inferences about the population(s)

2. Referenced Documents

from which the specimens are drawn. (See also lot sample,

laboratory sample, and specimen.)

2.1 ASTM Standards:

3.1.8 sampling unit, n—an identifiable, discrete unit or

D 123 Terminology Relating to Textiles

subunit of material that could be taken as part of a sample.

D 2258 Practice for Sampling Yarn for Testing

3.1.9 shipping unit, n—in textiles, any type of packaging

D 2494 Test Method for Commercial Mass of a Shipment of

used to facilitate the handling and shipping of fibers, yarns and

Yarn or Man-Made Staple Fiber or Tow

fabrics.

D 4271 Practice for Writing Statements on Sampling in Test

3.1.9.1 Discussion—For the purposes of this practice, pack-

Methods for Textiles

aging includes bales, cartons, and other such containers.

3. Terminology

3.1.10 specimen, n—a specific portion of a material or

laboratory sample upon which a test is performed or which is

3.1 Definitions:

taken for that purpose. (Syn. test specimen.)

3.1.1 container, n—a receptacle designed to hold a material,

3.1.11 For definitions of other textile terms used in this

or to give integrity to the material.

practice, refer to Terminology D 123.

3.1.1.1 Discussion—for the purposes of this standard, the

term container includes bales, cartons and other shipping units.

4. Summary of Practice

3.1.2 laboratory sample, n—a portion of material taken to

4.1 Instructions are given for dividing containers into lots,

represent the lot sample, or the original material, and used in

for determining the number of containers to be selected from

each lot as the lot sample, and for determining the number of

This practice is under the jurisdiction of ASTM Committee D-13 on Textiles

containers taken from the lot sample as a laboratory sample.

and is the direct responsibility of Subcommittee D13.57 on Fiber Test Methods,

See Practice D 4271.

General.

Current edition approved May 15, 1995. Published July 1995. Originally

4.2 Separate laboratory samples are taken for commercial

published as D 3333 – 74 T. Last previous edition D 3333 – 94.

weight measurement and for other testing, for example, physi-

BISFA Internationally Agreed Methods for Testing Polyamide Staple Fibers,

cal or chemical tests.

1974 edition, BISFA Internationally Agreed Methods for Testing Polyester Staple

Fibers, 1972 edition, and BISFA Rules for Testing Regenerated Cellulose and 4.3 The manner of preparing laboratory sampling units for

Acetate Staple Fibers, 1970 edition, available from the Bureau International pour la

commercial weight, and the manner of collecting laboratory

Standardisation de la Rayonne et des Fibres Synthetiques.

sampling units for other testing are based on the following:

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

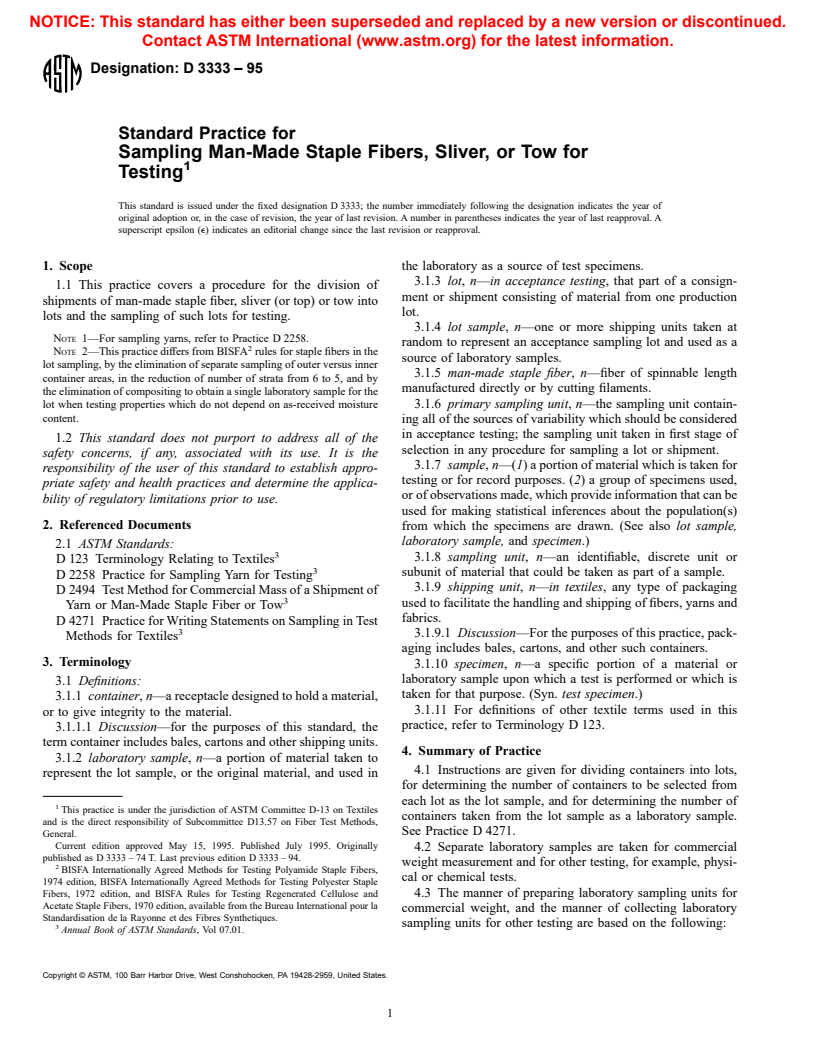

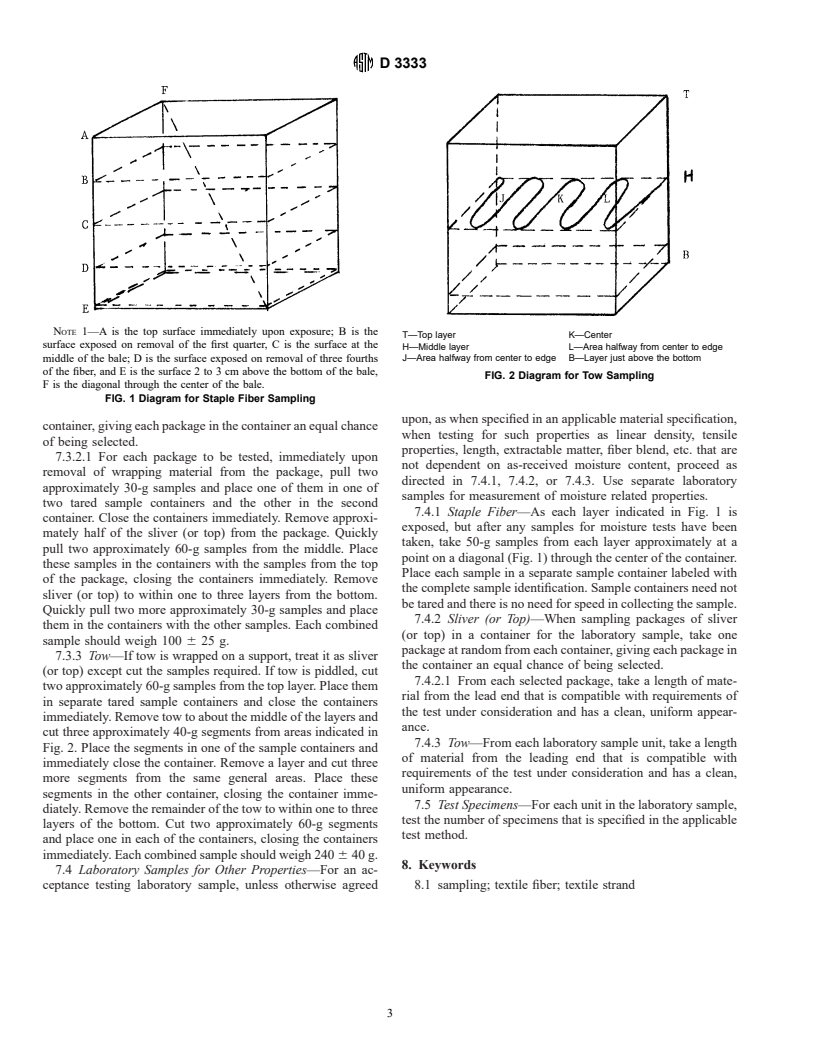

D 3333

4.3.1 Present knowledge of the systematic variation of material to a precision of 60.1 %.

moisture within the container, and 6.3 Bale-Weighing Device, capable of weighing the entire

4.3.2 The variability of the properties for which the practice container to a precision of 60.1 %.

is to be used.

7. Procedure

5. Significance and Use

7.1 Division into Lots—Instructions for the division of

5.1 Assigning a value to any property of the material in a

product into lots is best given in the appropriate specification.

container or in a lot, consignment, or delivery involves a

In the absence of such instructions, sample and test as a

measurement process that includes both sampling and testing

separate lot any portion of a shipment or order that differs from

procedures. The correctness of the value assigned depends

other portions in specifications, or physical characteristics, or

upon the variability due to testing. Even when the variability

that is billed or designated by the supplier as a separate lot. If

due to testing is minimized by carefully developed procedures,

portions of a larger order are shipped on different dates, from

correct and consistent estimates of the true value of the

plants or warehouses, or in more than one carload or truckload;

property are possible only when the sampling procedure avoids

treat each shipment as a separate lot. If the containers in a

systematic bias, minimizes variations due to sampling, and

shipment do not have consecutive numbers, divide the ship-

provides a laboratory sample of adequate size.

ment into groups of containers having consecutive numbers

5.2 This practice may not give the most efficient sampling

and treat each group as a separate lot if it is separated from the

plan that might be devised in special situations but it does

adjacent group by as many as ten container numbers.

present a general procedure that gives satisfactory precision

7.2 Lot Sample—As a lot sample for acceptance testing,

with an economical amount of sampling and one which does

unless otherwise agreed upon, as when specified in an appli-

not require elaborate statistical computation based on previous

cable material specification, take containers which have been

knowledge of the amount of variation between lot samples,

designated by drawing numbers from a recepticle in which the

between laboratory samples, and between test specimens.

numbers have been thoroughly mixed or by use of a table of

5.3 The smallest number of specimens required for a given

random numbers. As applicable, consider containers to be the

variability in the average result will usually be obtained by (1)

primary sampling unit. Take the number of containers specified

minimizing the number of shipping units in the lot sample, (2)

in Table 1.

taking one of the shipping units in the laboratory sample, and

7.3 Laboratory Samples for Moisture Related Properties—

(3) taking the prescribed specimen(s) from the selected labo-

For acceptance testing, unless otherwise agreed upon, as when

ratory sample shipping unit. (See 7.3 an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.