ASTM C165-00

(Test Method)Standard Test Method for Measuring Compressive Properties of Thermal Insulations

Standard Test Method for Measuring Compressive Properties of Thermal Insulations

SCOPE

1.1 This test method covers two procedures for determining the compressive resistance of thermal insulations.

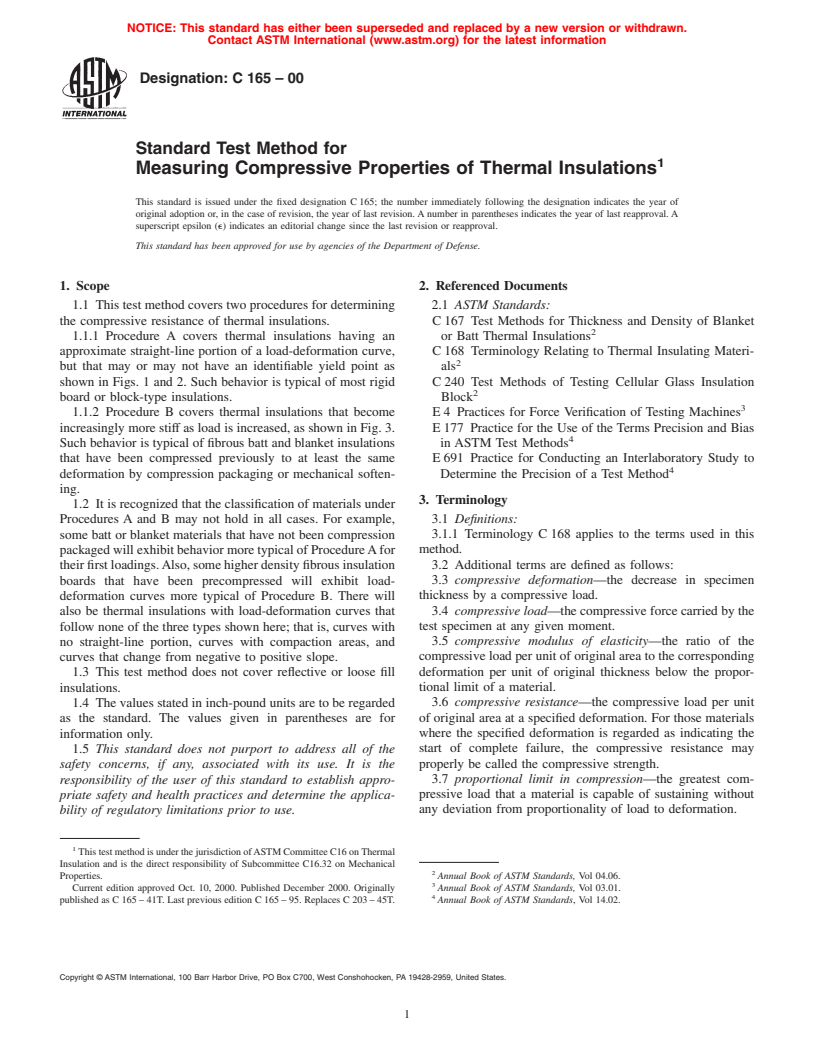

1.1.1 Procedure A covers thermal insulations having an approximate straight-line portion of a load-deformation curve, but that may or may not have an identifiable yield point as shown in Figs. 1 and 2. Such behavior is typical of most rigid board or block-type insulations.

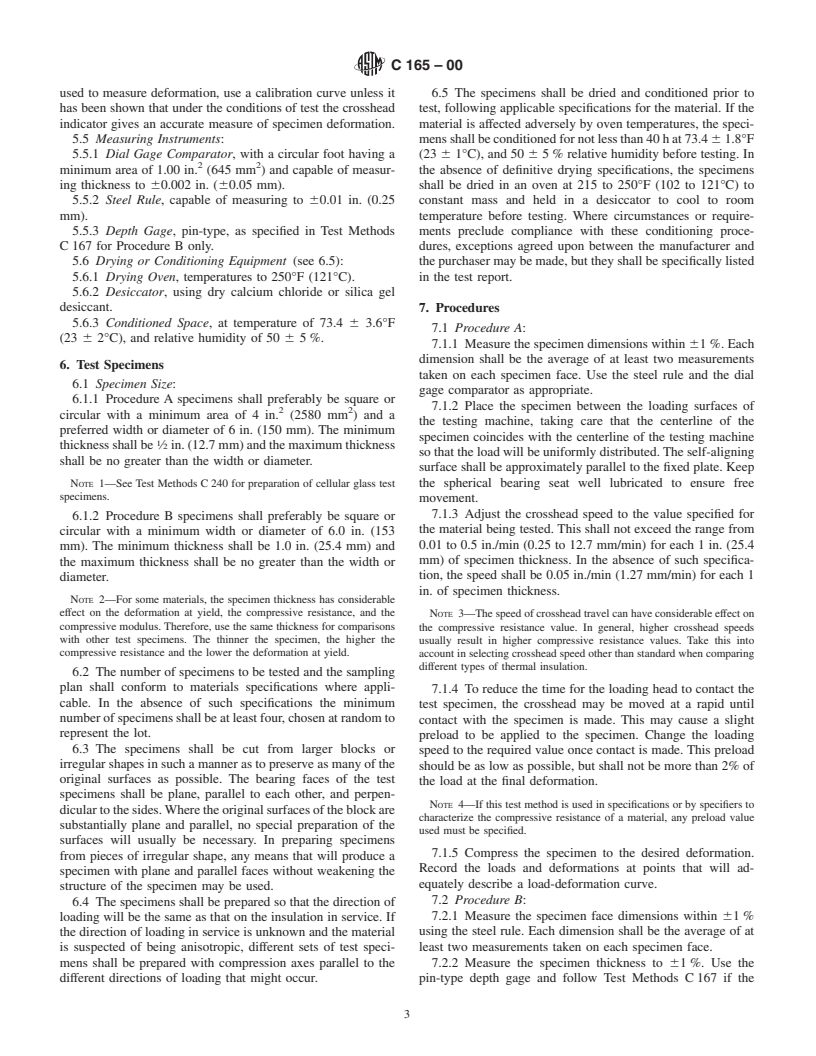

1.1.2 Procedure B covers thermal insulations that become increasingly more stiff as load is increased, as shown in . Such behavior is typical of fibrous batt and blanket insulations that have been compressed previously to at least the same deformation by compression packaging or mechanical softening.

1.2 It is recognized that the classification of materials under Procedures A and B may not hold in all cases. For example, some batt or blanket materials that have not been compression packaged will exhibit behavior more typical of Procedure A for their first loadings. Also, some higher density fibrous insulation boards that have been precompressed will exhibit load-deformation curves more typical of Procedure B. There will also be thermal insulations with load-deformation curves that follow none of the three types shown here; that is, curves with no straight-line portion, curves with compaction areas, and curves that change from negative to positive slope.

1.3 This test method does not cover reflective or loose fill insulations.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 165 – 00

Standard Test Method for

1

Measuring Compressive Properties of Thermal Insulations

This standard is issued under the fixed designation C 165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This test method covers two procedures for determining 2.1 ASTM Standards:

the compressive resistance of thermal insulations. C 167 Test Methods for Thickness and Density of Blanket

2

1.1.1 Procedure A covers thermal insulations having an or Batt Thermal Insulations

approximate straight-line portion of a load-deformation curve, C 168 Terminology Relating to Thermal Insulating Materi-

2

but that may or may not have an identifiable yield point as als

shown in Figs. 1 and 2. Such behavior is typical of most rigid C 240 Test Methods of Testing Cellular Glass Insulation

2

board or block-type insulations. Block

3

1.1.2 Procedure B covers thermal insulations that become E 4 Practices for Force Verification of Testing Machines

increasingly more stiff as load is increased, as shown in Fig. 3. E 177 Practice for the Use of the Terms Precision and Bias

4

Such behavior is typical of fibrous batt and blanket insulations in ASTM Test Methods

that have been compressed previously to at least the same E 691 Practice for Conducting an Interlaboratory Study to

4

deformation by compression packaging or mechanical soften- Determine the Precision of a Test Method

ing.

3. Terminology

1.2 It is recognized that the classification of materials under

Procedures A and B may not hold in all cases. For example, 3.1 Definitions:

3.1.1 Terminology C 168 applies to the terms used in this

some batt or blanket materials that have not been compression

packaged will exhibit behavior more typical of ProcedureAfor method.

3.2 Additional terms are defined as follows:

theirfirstloadings.Also,somehigherdensityfibrousinsulation

3.3 compressive deformation—the decrease in specimen

boards that have been precompressed will exhibit load-

deformation curves more typical of Procedure B. There will thickness by a compressive load.

3.4 compressive load—the compressive force carried by the

also be thermal insulations with load-deformation curves that

follow none of the three types shown here; that is, curves with test specimen at any given moment.

3.5 compressive modulus of elasticity—the ratio of the

no straight-line portion, curves with compaction areas, and

curves that change from negative to positive slope. compressive load per unit of original area to the corresponding

deformation per unit of original thickness below the propor-

1.3 This test method does not cover reflective or loose fill

insulations. tional limit of a material.

3.6 compressive resistance—the compressive load per unit

1.4 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for of original area at a specified deformation. For those materials

where the specified deformation is regarded as indicating the

information only.

1.5 This standard does not purport to address all of the start of complete failure, the compressive resistance may

properly be called the compressive strength.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.7 proportional limit in compression—the greatest com-

pressive load that a material is capable of sustaining without

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. any deviation from proportionality of load to deformation.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

Insulation and is the direct responsibility of Subcommittee C16.32 on Mechanical

2

Properties. Annual Book of ASTM Standards, Vol 04.06.

3

Current edition approved Oct. 10, 2000. Published December 2000. Originally Annual Book of ASTM Standards, Vol 03.01.

4

published as C 165 – 41T. Last previous edition C 165 – 95. Replaces C 203 – 45T. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C165–00

FIG. 3 Procedure B—Increasing Stiffness

considered. All load-deformation data should be reviewed

FIG. 1 Procedure A—Straight Line Portion with Definite Yield

Point carefully for applicability prior to acceptance for use in

engineering designs differing widely in load, load application

rate, and material dimensi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.