ASTM D6470-99(2015)

(Test Method)Standard Test Method for Salt in Crude Oils (Potentiometric Method)

Standard Test Method for Salt in Crude Oils (Potentiometric Method)

SIGNIFICANCE AND USE

4.1 A knowledge of water extractable inorganic halides in oil is important when deciding whether or not the oils need desalting. Excessive halide, especially in crude oil, frequently results in higher corrosion rates in refining units.

SCOPE

1.1 This test method covers the determination of salt in crude oils. For the purpose of this test method, salt is expressed as % (m/m) NaCl (sodium chloride) and covers the range from 0.0005 % to 0.15 % (m/m).

1.2 The limit of detection is 0.0002 % (m/m) for salt (as NaCl).

1.3 The test method is applicable to nearly all of the heavier petroleum products, such as crude oils, residues, and fuel oils. It may also be applied to used turbine oil and marine diesel fuel to estimate seawater contamination. Water extractable salts, originating from additives present in oils, are codetermined.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6470 − 99 (Reapproved 2015)

Standard Test Method for

Salt in Crude Oils (Potentiometric Method)

This standard is issued under the fixed designation D6470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4928 Test Method for Water in Crude Oils by Coulometric

Karl Fischer Titration

1.1 This test method covers the determination of salt in

E200 Practice for Preparation, Standardization, and Storage

crudeoils.Forthepurposeofthistestmethod,saltisexpressed

of Standard and Reagent Solutions for ChemicalAnalysis

as % (m/m) NaCl (sodium chloride) and covers the range from

0.0005 % to 0.15 % (m/m).

3. Summary of Test Method

1.2 The limit of detection is 0.0002 % (m/m) for salt (as

3.1 After homogenizing the crude oil with a mixer, a

NaCl).

weighed aliquot is dissolved in xylene at 65 °C and extracted

1.3 The test method is applicable to nearly all of the heavier

with specified volumes of alcohol, acetone, and water in an

petroleum products, such as crude oils, residues, and fuel oils.

electrically heated extraction apparatus. A portion of the

Itmayalsobeappliedtousedturbineoilandmarinedieselfuel

aqueous extract is analyzed for total halides by potentiometric

to estimate seawater contamination. Water extractable salts,

titration.

originating from additives present in oils, are codetermined.

1.4 The values stated in SI units are to be regarded as the

4. Significance and Use

standard.

4.1 A knowledge of water extractable inorganic halides in

1.5 This standard does not purport to address all of the

oil is important when deciding whether or not the oils need

safety concerns, if any, associated with its use. It is the

desalting. Excessive halide, especially in crude oil, frequently

responsibility of the user of this standard to establish appro-

results in higher corrosion rates in refining units.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Apparatus

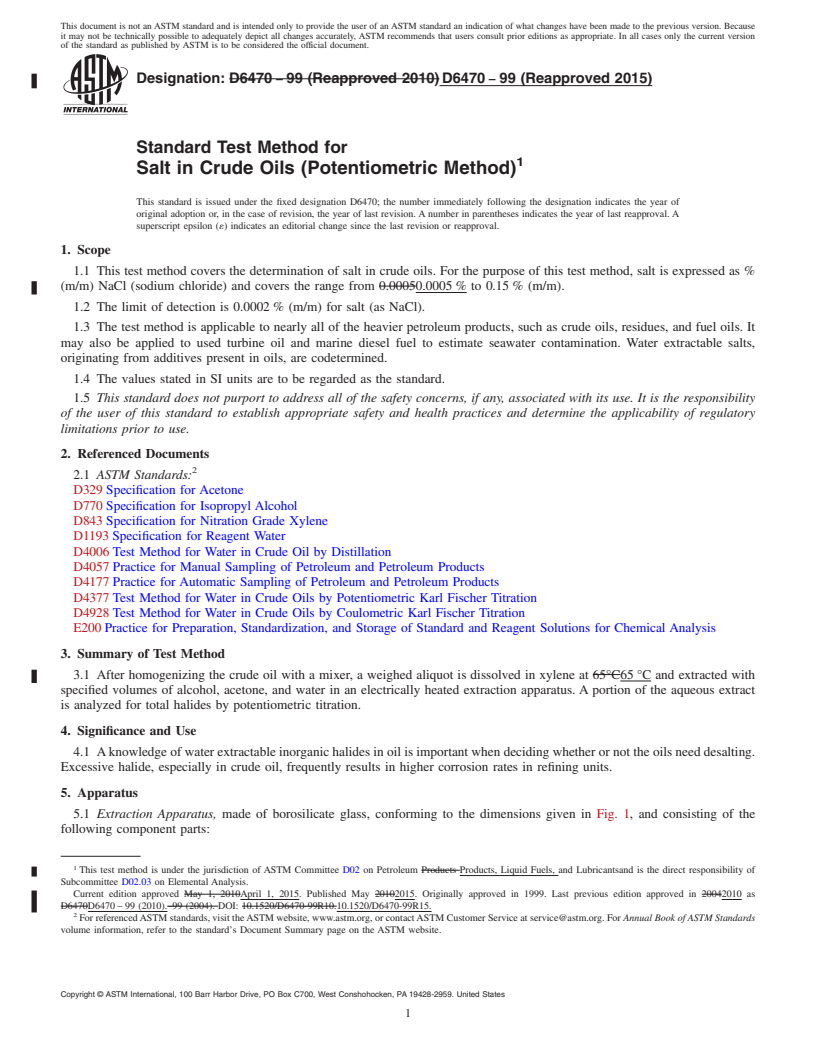

5.1 Extraction Apparatus, made of borosilicate glass, con-

2. Referenced Documents

formingtothedimensionsgiveninFig.1,andconsistingofthe

2.1 ASTM Standards:

following component parts:

D329 Specification for Acetone

5.1.1 Boiling Flask, 500 mL capacity.

D770 Specification for Isopropyl Alcohol

5.1.2 Hopkins Reflux Condenser, having a vapor outlet

D843 Specification for Nitration Grade Xylene

connected by a rubber tube to an outside vent or to a suction

D1193 Specification for Reagent Water

hood.

D4006 Test Method for Water in Crude Oil by Distillation

5.1.3 Thistle Tube, approximately 70 mL capacity, with a

D4057 Practice for Manual Sampling of Petroleum and

line to indicate approximately the 50 mL level.

Petroleum Products

5.1.4 Heating Tube, containing a chimney for increasing

D4177 Practice for Automatic Sampling of Petroleum and

convection in the liquid.

Petroleum Products

5.1.5 Heating Coil, 250 W, consisting of a suitable gage of

D4377 Test Method forWater in Crude Oils by Potentiomet-

Nichrome wire.

ric Karl Fischer Titration

5.1.6 Rheostat, of suitable resistance and capacity, for

regulating the heater.

This test method is under the jurisdiction of ASTM Committee D02 on

5.2 Safety Shield, colorless safety glass, or equivalent, to be

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

mounted in front of the extraction apparatus (see 5.1).

Current edition approved April 1, 2015. Published May 2015. Originally

5.3 Sampling Tube, glass, length approximately 600 mm,

approved in 1999. Last previous edition approved in 2010 as D6470 – 99 (2010).

DOI: 10.1520/D6470-99R15.

I.D. approximately 5 mm, with a bulb having a volume of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

100 mL, or more, and drawn out at one end to an opening of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

inside diameter (I.D.) 2 mm to 3 mm.Apipette with cut-off tip

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. makes a suitable sample tube.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6470 − 99 (2015)

NOTE 1—Hopkins-type condenser is used.

FIG. 1 Extraction Apparatus

5.4 Potentiometric Titration Equipment, with a measuring 6. Reagents and Materials

accuracy of 62 mV, or better, provided with a silver indicating

6.1 Purity of Reagents—Unless otherwise indicated, it is

and a glass reference electrode and 10 mL burette, preferably

intended that all reagents shall conform to the specifications of

pistontype.Ifanautomatictitratorisused,thisshallbecapable

theCommitteeonAnalyticalReagentsoftheAmericanChemi-

of adding fixed increments of titrant (see 9.3.3.2). 3

cal Society where such specifications are available.

5.5 Magnetic Stirrer, with polytetrafluoroethylene (PTFE)-

6.2 Purity of Water—For all purposes where water is

coated stirring bar.

mentioned, reagent water of a suitable purity shall be used.

5.6 Homogenizer. A mixer with counter-rotating blades Various types of reagent water are described in Specification

D1193.

operating at approximately 3000 r⁄min (50/s) is usually suit-

able for homogenization of samples up to 500 mL. Other

designscanalsobeusedprovidedtheperformanceconformsto

the requirements described in Annex A1.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

5.7 Oven, explosion-proof, temperature 65 °C 6 5 °C.

listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

5.8 Filter Paper, Whatman No. 41, or equivalent.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

5.9 Stopwatch. MD.

D6470 − 99 (2015)

6.3 Acetone (2-propanone) , conforming to Specification 7.3 Test Sample—The sample aliquot obtained from the

D329.(Warning—Extremely flammable. Vapors may cause laboratory sample for analysis by this test method. Once

flashfire.) drawn, the entire portion of the test sample will be used in the

analysis. Mix the laboratory sample properly, as described in

6.4 Alcohol, for example, 95 % (V/V) ethanol, or propan-

7.4, prior to drawing the test sample.

2–ol (isopropyl alcohol), conforming to Specification D770.

(Warning—Flammable.) 7.4 Homogenize the laboratory sample of crude oil imme-

diately (within 15 min) before drawing the test sample to

6.5 Barium Nitrate, A.R., crystals. (Warning—Barium

ensure complete homogeneity. Mix the sample at room tem-

compounds and their solutions present a health risk if incor-

perature (15 °C to 25 °C), or less, in the laboratory sample

rectly handled. Prevent all contact.)

container, and record the temperature of the sample in degrees

6.6 Hydrochloric Acid, 0.1 mol⁄L, aqueous. Add 9 mL of

Celsius immediately before mixing. Heat waxy samples, solid

A.R. concentrated hydrochloric acid (density 1.19 g⁄mL) to

at room temperature, to 3 °C above their pour point in order to

1 L with water. (Warning—Corrosive. Causes skin burns.)

facilitate test sample withdrawal. Select the type of mixer

related to the quantity of crude oil in the laboratory sample

6.7 Nitric Acid, 5 mol⁄L, aqueous. Cautiously add 325 mL

container. Before any unknown mixer is used, the specifica-

of A.R. concentrated nitric acid (density 1.42 g⁄mL) to 1 L

tions for the homogenization test (see AnnexA1) shall be met.

water, while stirring. (Warning—Corrosive. Causes skin

Reevaluate the mixer for any changes in the type of crude, the

burns.)

quantity of crude, the shape of the sample container, or the

6.8 Silver Nitrate Solution, standard, c(AgNO)=

mixing conditions (such as mixing speed and time of mixing).

0.1 mol⁄L, aqueous. Prepare, standardize and store as de-

7.5 For small laboratory sample containers and volumes,

scribed in Practice E200 for 0.1 N aqueous solution, reading

50 mL to 500 mL, a nonaerating, high speed (3000 r⁄min),

concentrations in mol/L in place of normality. Restandardize

shear mixer is required. Use the mixing time, mixing speed,

regularly, but in any case before preparation of the standard

and height above the bottom of the container found to be

0.01 mol⁄L solution (see 6.9)

satisfactory to Annex A1. For larger containers and volumes,

NOTE 1—Alternatively, ampoules containing concentrated solutions for

appropriate mixing conditions shall be defined by following a

preparation of standard volumetric solutions are available from various

set of procedures similar to those outlined in Annex A1 and

suppliers. (Warning—Silver compounds and their solutions present a

Practice D4177 but modified for application to the larger

health risk if incorrectly handled. Prevent all contact.)

containers and volumes. Clean and dry the mixer between

6.9 Silver Nitrate Solution, standard, c(AgNO)=

samples.

0.01 mol⁄L, aqueous. Prepare shortly before use by accurately

7.6 Record the temperature of the sample immediately after

diluting one volume of the recently restandardized 0.1 mol⁄L

homogenization. The rise in temperature between this reading

silver nitrate solution (Warning —see 6.8) to a tenfold volume

andtheinitialreadingpriortomixing(see7.4)shallnotexceed

with water.

10 °C, otherwise excessive loss of volatile vapors can occur or

6.10 Sodium Chloride Solution, approximately 1 mmol⁄L,

the dispersion can become unstable.

aqueous.Dissolve59 mg 61 mgsodiumchloridein1 Lwater.

7.7 In order to ensure that crude oils with rapidly settling

6.11 Xylene, conforming to Specification D843.

impurities are properly sampled, withdraw the test sample

(Warning—Xylene presents a health risk if incorrectly

container immediately after homogenization by lowering the

handled.Avoid inhalation. Extract vapor by working in a fume

tip of the sample tube (see 5.3) almost to the bottom of the

cupboard.)

container, and withdrawing the test sample as quickly as

possible. Clean and dry the sample tube before and after

6.12 Lead Acetate Paper.

sampling.

6.13 Polishing Paper, 800 grit, or finer, to polish the silver

electrode.

8. Preparation of Apparatus

8.1 Extraction Apparatus—To reduce the risk of superheat-

7. Sampling and Sample Preparation

ing and the resulting hazards, introduce a gentle stream of air

7.1 Sampling is defined as all the steps required to obtain an

intothebottomoftheextractionapparatus.Thiscanbedoneby

aliquotrepresentativeofthecontentsofanypipe,tank,orother passing a length of hypodermic tubing through the bore of the

system, and to place the sample into the laboratory sample

tap so that the lower end reaches the bottom of the heating

container. The laboratory sample container and sample volume tube, while the upper end of the tubing is passed through a

shall be of sufficient dimensions and volume to allow mixing,

rubber bung in the top of the thistle tube. Place the extraction

as described in 7.4.(Warning—The results of the round robin

apparatus behind a safety screen. Shield all electrical resis-

have shown that for reliable results, strict adherence to the

tances and devices; alternatively, remove them from the

sampling and mixing procedure is of the utmost importance.)

immediate vicinity of the extraction apparatus.

7.2 Laboratory Sample—The sample of crude oil presented 8.2 Potentiometric Titration Equipment:

tothelaboratoryortestfacilityforanalysisbythistestmethod. 8.2.1 Glass Electrode—Before each titration (or each series

Only representative samples obtained as specified in Practices of titrations), rinse the electrode with water and soak it for at

D4057 and D4177 shall be used for this test method. least 10 min in 0.1 mol⁄L hydrochloric acid (see 6.6). Then

D6470 − 99 (2015)

rinse again with water. After titrations store the electrode approximately 25 mm below the liquid surface, and adjust the

immersed in reagent water. magnetic stirrer to produce vigorous stirring without spatter-

ing.

8.2.2 Silver Electrode—Polish the silver electrode before

9.3.3 Titrate as follows:

each set of titrations with polishing paper (see 6.13) until a

9.3.3.1 When applying manual titration, record the initial

clean, polished metal surface is obtained.

burettereadingandthepH/millivoltmeterreading.Titratewith

standard silver nitrate solution, adding the titrant in small

9. Procedure

portions.Aftereachaddition,waituntilaconstantpotentialhas

9.1 Extraction:

been established and record the burette and meter readings (see

9.1.1 Weigh about 40 g of sample, to the nearest 0.1 g, into

Note 4). In regions between inflections where the potential

a 250 mL beaker and heat on a water bath or in an oven to

change is small for each increment of silver nitrate used, add

65 °C 6 5 °C. Heat 40 mL 6 1 mL of xylene to the same

volumes as large as 0.5 mL. When the rate of change of

temperature and add slowly to the sample while stirring

potential becomes greater than 5 mV per 0.1 mL, use 0.1 mL

constantly until dissolution is complete. Transfer the solution

increments of silver nitrate solution. Construct a graph by

quantitatively to the extraction apparatus, rinsing the beaker

plotting the meter readings versus the volumes of standard

with two separate portions of 15 mL 6 1 mLof hot xylene and

silver nitrate solution used in the titration.

adding these rinsings also to the extraction apparatus.

NOTE4—Ifsilverhalidesareprecipitatedonthesilverelectrode,tapthe

9.1.2 While the solution is still hot, add 25 mL 61mLof

electrode gently to dislodge the clinging precipitate and ensure that an

ethanol or isopropyl alcohol and 15 mL 6 1 mL of acetone,

equilibrium has been reached before taking a meter reading.

usingtheseportionsforfurtherrinsingofthebeaker.Switchon

9.3.3.2 When using an automatic recording titrator, titrate

theheatingelementoftheextractionapparatustofullheatuntil

with standard silver nitrate solution, adding fixed increments.

boiling begins, then adjust the rheostat to regulate the heat to

maintain boiling at a vigorous rate, but not at such a rate to

NOTE5—Itisessentialthatincrementaltitrationisapplied,asdescribed

cause bumping in the flask or to cause the condenser to flood. in 9.3.3, to ensure that complete precipitation occurs between additions.

Allow to reflux for 2 min after the liquid starts boiling (see

9.3.3.3 After each titration, clean the electrodes with water

8.1).Switchofftheheater.Whenboilingceases,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6470 − 99 (Reapproved 2010) D6470 − 99 (Reapproved 2015)

Standard Test Method for

Salt in Crude Oils (Potentiometric Method)

This standard is issued under the fixed designation D6470; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of salt in crude oils. For the purpose of this test method, salt is expressed as %

(m/m) NaCl (sodium chloride) and covers the range from 0.00050.0005 % to 0.15 % (m/m).

1.2 The limit of detection is 0.0002 % (m/m) for salt (as NaCl).

1.3 The test method is applicable to nearly all of the heavier petroleum products, such as crude oils, residues, and fuel oils. It

may also be applied to used turbine oil and marine diesel fuel to estimate seawater contamination. Water extractable salts,

originating from additives present in oils, are codetermined.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D329 Specification for Acetone

D770 Specification for Isopropyl Alcohol

D843 Specification for Nitration Grade Xylene

D1193 Specification for Reagent Water

D4006 Test Method for Water in Crude Oil by Distillation

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4377 Test Method for Water in Crude Oils by Potentiometric Karl Fischer Titration

D4928 Test Method for Water in Crude Oils by Coulometric Karl Fischer Titration

E200 Practice for Preparation, Standardization, and Storage of Standard and Reagent Solutions for Chemical Analysis

3. Summary of Test Method

3.1 After homogenizing the crude oil with a mixer, a weighed aliquot is dissolved in xylene at 65°C65 °C and extracted with

specified volumes of alcohol, acetone, and water in an electrically heated extraction apparatus. A portion of the aqueous extract

is analyzed for total halides by potentiometric titration.

4. Significance and Use

4.1 A knowledge of water extractable inorganic halides in oil is important when deciding whether or not the oils need desalting.

Excessive halide, especially in crude oil, frequently results in higher corrosion rates in refining units.

5. Apparatus

5.1 Extraction Apparatus, made of borosilicate glass, conforming to the dimensions given in Fig. 1, and consisting of the

following component parts:

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved May 1, 2010April 1, 2015. Published May 20102015. Originally approved in 1999. Last previous edition approved in 20042010 as

D6470D6470 – 99 (2010).–99 (2004). DOI: 10.1520/D6470-99R10.10.1520/D6470-99R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6470 − 99 (2015)

NOTE 1—Hopkins-type condenser is used.

FIG. 1 Extraction Apparatus

5.1.1 Boiling Flask, 500 mL 500 mL capacity.

5.1.2 Hopkins Reflux Condenser, having a vapor outlet connected by a rubber tube to an outside vent or to a suction hood.

5.1.3 Thistle Tube, approximately 70 mL 70 mL capacity, with a line to indicate approximately the 50 mL 50 mL level.

5.1.4 Heating Tube, containing a chimney for increasing convection in the liquid.

5.1.5 Heating Coil, 250 W, 250 W, consisting of a suitable gage of Nichrome wire.

5.1.6 Rheostat, of suitable resistance and capacity, for regulating the heater.

5.2 Safety Shield, colorless safety glass, or equivalent, to be mounted in front of the extraction apparatus (see 5.1).

5.3 Sampling Tube, glass, length approximately 600 mm, 600 mm, I.D. approximately 5 mm, 5 mm, with a bulb having a

volume of 100 mL, 100 mL, or more, and drawn out at one end to an opening of inside diameter (I.D.) 22 mm to 3 mm. 3 mm.

A pipette with cut-off tip makes a suitable sample tube.

5.4 Potentiometric Titration Equipment, with a measuring accuracy of 6 2 mV, 62 mV, or better, provided with a silver

indicating and a glass reference electrode and 10 mL 10 mL burette, preferably piston type. If an automatic titrator is used, this

shall be capable of adding fixed increments of titrant (see 9.3.3.2).

5.5 Magnetic Stirrer, with polytetrafluoroethylene (PTFE)-coated stirring bar.

5.6 Homogenizer. A mixer with counter-rotating blades operating at approximately 30003000 r ⁄ r/min min (50/s) is usually

suitable for homogenization of samples up to 500 mL. 500 mL. Other designs can also be used provided the performance conforms

to the requirements described in Annex A1.

D6470 − 99 (2015)

5.7 Oven, explosion-proof, temperature 6565 °C 6 5°C.5 °C.

5.8 Filter Paper, Whatman No. 41, or equivalent.

5.9 Stopwatch.

6. Reagents and Materials

6.1 Purity of Reagents—Unless otherwise indicated, it is intended that all reagents shall conform to the specifications of the

Committee on Analytical Reagents of the American Chemical Society where such specifications are available.

6.2 Purity of Water—For all purposes where water is mentioned, reagent water of a suitable purity shall be used. Various types

of reagent water are described in Specification D1193.

6.3 Acetone (2-propanone) , conforming to Specification D329. (Warning—Extremely flammable. Vapors may cause flashfire.)

6.4 Alcohol, for example, 95 % (V/V) ethanol, or propan-2–ol (isopropyl alcohol), conforming to Specification D770.

(Warning—Flammable.)

6.5 Barium Nitrate, A.R., crystals. (Warning—Barium compounds and their solutions present a health risk if incorrectly

handled. Prevent all contact.)

6.6 Hydrochloric Acid, 0.10.1 mol ⁄ mol/L, L, aqueous. Add 9 mL 9 mL of A.R. concentrated hydrochloric acid (density

1.191.19 g ⁄ g/mL) to 1 L mL) to 1 L with water. (Warning—Corrosive. Causes skin burns.)

6.7 Nitric Acid, 55 mol ⁄ mol/L, L, aqueous. Cautiously add 325 mL 325 mL of A.R. concentrated nitric acid (density

1.421.42 g ⁄ g/mL) to 1 L mL) to 1 L water, while stirring. (Warning—Corrosive. Causes skin burns.)

6.8 Silver Nitrate Solution, standard, c(AgNO ) = 0.10.1 mol ⁄ mol/L, L, aqueous. Prepare, standardize and store as described

in Practice E200 for 0.1 N 0.1 N aqueous solution, reading concentrations in mol/L in place of normality. Restandardize regularly,

but in any case before preparation of the standard 0.010.01 mol ⁄ mol/L L solution (see 6.9)

NOTE 1—Alternatively, ampoules containing concentrated solutions for preparation of standard volumetric solutions are available from various

suppliers. (Warning—Silver compounds and their solutions present a health risk if incorrectly handled. Prevent all contact.)

6.9 Silver Nitrate Solution, standard, c(AgNO ) = 0.010.01 mol ⁄ mol/L, L, aqueous. Prepare shortly before use by accurately

diluting one volume of the recently restandardized 0.10.1 mol ⁄ mol/L L silver nitrate solution (Warning —see 6.8) to a tenfold

volume with water.

6.10 Sodium Chloride Solution, approximately 11 mmol ⁄ mmol/L, L, aqueous. Dissolve 5959 mg 6 1 mg 1 mg sodium chloride

in 1 L 1 L water.

6.11 Xylene, conforming to Specification D843. (Warning—Xylene presents a health risk if incorrectly handled. Avoid

inhalation. Extract vapor by working in a fume cupboard.)

6.12 Lead Acetate Paper.

6.13 Polishing Paper, 800 grit, or finer, to polish the silver electrode.

7. Sampling and Sample Preparation

7.1 Sampling is defined as all the steps required to obtain an aliquot representative of the contents of any pipe, tank, or other

system, and to place the sample into the laboratory sample container. The laboratory sample container and sample volume shall

be of sufficient dimensions and volume to allow mixing, as described in 7.4. (Warning—The results of the round robin have shown

that for reliable results, strict adherence to the sampling and mixing procedure is of the utmost importance.)

7.2 Laboratory Sample—The sample of crude oil presented to the laboratory or test facility for analysis by this test method.

Only representative samples obtained as specified in Practices D4057 and D4177 shall be used for this test method.

7.3 Test Sample—The sample aliquot obtained from the laboratory sample for analysis by this test method. Once drawn, the

entire portion of the test sample will be used in the analysis. Mix the laboratory sample properly, as described in 7.4, prior to

drawing the test sample.

7.4 Homogenize the laboratory sample of crude oil immediately (within 15 min) 15 min) before drawing the test sample to

ensure complete homogeneity. Mix the sample at room temperature (15(15 °C to 25°C),25 °C), or less, in the laboratory sample

container, and record the temperature of the sample in degrees Celsius immediately before mixing. Heat waxy samples, solid at

room temperature, to 3°C3 °C above their pour point in order to facilitate test sample withdrawal. Select the type of mixer related

to the quantity of crude oil in the laboratory sample container. Before any unknown mixer is used, the specifications for the

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D6470 − 99 (2015)

homogenization test (see Annex A1) shall be met. Reevaluate the mixer for any changes in the type of crude, the quantity of crude,

the shape of the sample container, or the mixing conditions (such as mixing speed and time of mixing).

7.5 For small laboratory sample containers and volumes, 5050 mL to 500 mL, 500 mL, a nonaerating, high speed (3000(3000 r ⁄

r/min), min), shear mixer is required. Use the mixing time, mixing speed, and height above the bottom of the container found to

be satisfactory to Annex A1. For larger containers and volumes, appropriate mixing conditions shall be defined by following a set

of procedures similar to those outlined in Annex A1 and Practice D4177 but modified for application to the larger containers and

volumes. Clean and dry the mixer between samples.

7.6 Record the temperature of the sample immediately after homogenization. The rise in temperature between this reading and

the initial reading prior to mixing (see 7.4) shall not exceed 10°C,10 °C, otherwise excessive loss of volatile vapors can occur or

the dispersion can become unstable.

7.7 In order to ensure that crude oils with rapidly settling impurities are properly sampled, withdraw the test sample container

immediately after homogenization by lowering the tip of the sample tube (see 5.3) almost to the bottom of the container, and

withdrawing the test sample as quickly as possible. Clean and dry the sample tube before and after sampling.

8. Preparation of Apparatus

8.1 Extraction Apparatus—To reduce the risk of superheating and the resulting hazards, introduce a gentle stream of air into

the bottom of the extraction apparatus. This can be done by passing a length of hypodermic tubing through the bore of the tap so

that the lower end reaches the bottom of the heating tube, while the upper end of the tubing is passed through a rubber bung in

the top of the thistle tube. Place the extraction apparatus behind a safety screen. Shield all electrical resistances and devices;

alternatively, remove them from the immediate vicinity of the extraction apparatus.

8.2 Potentiometric Titration Equipment:

8.2.1 Glass Electrode—Before each titration (or each series of titrations), rinse the electrode with water and soak it for at least

10 min 10 min in 0.10.1 mol ⁄ mol/L L hydrochloric acid (see 6.6). Then rinse again with water. After titrations store the electrode

immersed in reagent water.

8.2.2 Silver Electrode—Polish the silver electrode before each set of titrations with polishing paper (see 6.13) until a clean,

polished metal surface is obtained.

9. Procedure

9.1 Extraction:

9.1.1 Weigh about 40 g 40 g of sample, to the nearest 0.1 g, 0.1 g, into a 250 mL 250 mL beaker and heat on a water bath or

in an oven to 6565 °C 6 5°C.5 °C. Heat 4040 mL 6 1 mL 1 mL of xylene to the same temperature and add slowly to the sample

while stirring constantly until dissolution is complete. Transfer the solution quantitatively to the extraction apparatus, rinsing the

beaker with two separate portions of 1515 mL 6 1 mL 1 mL of hot xylene and adding these rinsings also to the extraction

apparatus.

9.1.2 While the solution is still hot, add 2525 mL 6 1 mL 1 mL of ethanol or isopropyl alcohol and 1515 mL 6 1 mL 1 mL

of acetone, using these portions for further rinsing of the beaker. Switch on the heating element of the extraction apparatus to full

heat until boiling begins, then adjust the rheostat to regulate the heat to maintain boiling at a vigorous rate, but not at such a rate

to cause bumping in the flask or to cause the condenser to flood. Allow to reflux for 2 min 2 min after the liquid starts boiling (see

8.1). Switch off the heater. When boiling ceases, add 125125 mL 6 1 mL 1 mL of water and again bring the liquid to the boil and

reflux for a further 15 min.15 min.

9.1.3 Switch off the heater, and allow the two phases to separate for 55 min to 10 min. 10 min. Draw off the aqueous phase,

filtering through a filter paper into a conical flask of suitable capacity, stopper the flask, and retain the contents for the total halide

determination as described in 9.2 and 9.3.

9.2 Removal of Sulfur-Containing Compounds—Pipet 50.0 mL 50.0 mL of the aqueous e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.