ASTM D3636-00

(Practice)Standard Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

Standard Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

SCOPE

1.1 This practice covers procedures for obtaining data pertaining to the quality of a lot of electrical insulating material and for making a judgement whether the lot meets the requirements of a material specification.

1.2 This practice is not intended to define a producer's internal quality control procedures but is designed to determine the acceptability of all, or some portion, of a quantity of electrical insulating material that is available for inspection by the user of the material.

1.3 This practice is intended to be used in conjunction with an existing material specification that specifies property characteristic limits, acceptable quality level (AQL), standard test methods, and specific sampling instructions.

1.4 In the absence of a specification as described in 1.3, this practice may be used as a guide, after establishment of agreed-upon property characteristics, limits, AQL, standard test methods, and specific sampling instructions.

1.5 It is intended that this be a practice for inspection by attributes.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3636–00

Standard Practice for

Sampling and Judging Quality of Solid Electrical Insulating

Materials

This standard is issued under the fixed designation D 3636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ANSI/ASQC A2 -1987

1.1 This practice covers procedures for obtaining data

3. Terminology

pertainingtothequalityofalotofelectricalinsulatingmaterial

3.1 Definitions:

and for making a judgement whether the lot meets the

3.1.1 acceptance number, n—themaximumallowablenum-

requirements of a material specification.

ber of nonconformities for a given AQL and sample size

1.2 This practice is not intended to define a producer’s

(lot-sample size).

internalqualitycontrolproceduresbutisdesignedtodetermine

3.1.2 acceptable quality level (AQL), n— the maximum

the acceptability of all, or some portion, of a quantity of

percent nonconforming which, for purposes of sampling in-

electrical insulating material that is available for inspection by

spection, is considered satisfactory as a process average.

the user of the material.

3.1.3 critical property, n—aquantitativelymeasurablechar-

1.3 This practice is intended to be used in conjunction with

acteristic which is absolutely necessary to be met if a material

an existing material specification that specifies property char-

or product is to provide satisfactory performance for the

acteristic limits, acceptable quality level (AQL), standard test

intended use.

methods, and specific sampling instructions.

3.1.3.1 Discussion—In some situations, specification re-

1.4 In the absence of a specification as described in 1.3, this

quirements coincide with customer usage requirements. In

practice may be used as a guide, after establishment of

other situations, they may not coincide, being either more or

agreed-upon property characteristics, limits, AQL, standard

less stringent. More stringent sampling (for example, smaller

test methods, and specific sampling instructions.

AQLvalues)isusuallyusedformeasurementofcharacteristics

1.5 It is intended that this be a practice for inspection by

which are considered critical. The selection of sampling plans

attributes.

is independent of whether the term defect or nonconformity is

1.6 This standard does not purport to address all of the

appropriate.

safety concerns, if any, associated with its use. It is the

3.1.4 defect, n—a departure of a quality characteristic from

responsibility of the user of this standard to establish appro-

its intended level, or state, that occurs with a severity sufficient

priate safety and health practices and determine the applica-

tocauseanassociatedproductorservicenottosatisfyintended

bility of regulatory limitations prior to use.

normal, or reasonably foreseeable, usage requirements.

2. Referenced Documents 3.1.4.1 Discussion—The terms defect and nonconformity

and their derivatives are used somewhat interchangeably in the

2.1 ASTM Standards:

historical and current literature. Nonconformity objectively

E 300 Practice for Sampling Industrial Chemicals

describesthecomparisonoftestresultstospecificationrequire-

2.2 Military Standard:

ments,whiletheterm defecthasaconnotationofpredictingthe

MIL-STD-105D Sampling Procedures and Tables for In-

failure of a product or service to perform its intended function

spection by Attributes

in use. Since this latter connotation is often unintended, the

2.3 Other Document:

term nonconformity is preferred in full consensus standards.

The selection of any sample plan is independent of whether the

term defect or nonconformity is appropriate.

This practice is under the jurisdiction of ASTM Committee D09 on Electrical

and Electronic Insulating Materials and is the direct responsibility of Subcommittee

The term defect may be appropriate for specifications mutually

D09.94 on Editorial.

Current edition approved Sept. 10, 2000. Published December 2000. Originally agreed upon by a producer and a user where specific use conditions are

published as D 3636 – 77. Last previous edition D 3636 – 99.

Annual Book of ASTM Standards, Vol 15.05.

Available from the U.S. Government Printing Office, Superintendent of

Available from American National Standards Institute, 11 W. 42nd St., 13th

Documents, 732 North Capitol Street, NW, Mail Stop: SDE, Washington, D.C.

Floor, New York, NY 10036 or American Society for Quality Control, 310 W.

20401.

Wisconsin Ave., Milwaukee, WI 53203.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3636

clearly understood. Even in these cases however, use the term defect

3.1.16.1 Discussion—This standard uses only lot sample

with caution and consider substituting the term nonconformity.

sizes and not lot sizes since the discriminatory power of any

For additional comments, seeANSI/ASQCA2-1987 that also states:

sampling plan is independent essentially of the size of the lot.

“When a quality characteristic of a product or service is “evaluated” in

The sample size selected by the user for a given acceptable

terms of conformance to specification requirements, the use of the term

quality level (AQL) is optional depending upon the degree of

nonconformity is appropriate.”

protection desired by the user against the acceptance of

3.1.5 group AQL—theAQL assigned to a group of material

nonconforming lots.

properties.

3.1.17 test measurement, n—a quantitative expression of

3.1.5.1 Discussion—See 5.2 for additional information

one value determined for a property of interest by a single

about the meaning of AQL.

application of a specified test procedure.

3.1.6 lot, n—an entity of electrical insulating material or

3.1.18 test result, n—the value that expresses the level of a

product which, insofar as is practicable, consists of a single

property of the test unit.

type, grade, class, size, or composition that was manufactured

3.1.18.1 Discussion—A test result may sometimes be a

under essentially the same conditions and is available to the

single test measurement but usually a test result is computed

user for sampling at one time.

from several test measurements.

3.1.7 lot number, n—the number used by a producer to

3.1.19 test specimen, n—a portion of a test unit upon which

identify an entity of electrical insulating material or product.

one or more test measurements are made.

3.1.8 major property, n—a quantitatively measurable char-

3.1.20 test unit, n—a fraction of a unit of product from

acteristic which, if not met, is likely to seriously impair the

which one or more test specimens are taken for each property.

performance of a material or product for the intended use.

3.1.20.1 Discussion—If the unit of product is of insufficient

3.1.8.1 Discussion—In some situations, specification re-

size to meet the requirements of a testing method: (1) sample

quirements coincide with customer usage requirements. In

adjacent units of product and aggregate units of product for the

other situations, they may not coincide, being either more or

test unit or, (2) obtain a test unit of sufficient size, and

less stringent. More stringent sampling (for example, smaller

representative of the unit of product, from the producer.

AQLvalues)isusuallyusedformeasurementofcharacteristics

3.1.21 unit of product, n—an entity of electrical insulating

that are considered important. The selection of sampling plans

materialorproductforinspectiontodetermineitsclassification

is independent of whether the term defect or nonconformity is

as conforming or non-conforming.

appropriate.

3.1.21.1 Discussion—Aunit of product is established by the

3.1.9 minor property, n—a characteristic which, if not met,

user and may or may not be the same as a unit of purchase,

is not likely to materially reduce the performance of a material

supply, production, or shipment. Some examples of a unit of

or product for the intended use.

product are:

3.1.9.1 Discussion—In some situations, specification re-

Bag Case Reel

quirements coincide with customer usage requirements. In

Barrel Container Roll

Bin Cop Sheet

other situations, they may not coincide, being either more or

Bobbin Drum Skid

less stringent. More stringent sampling (for example, smaller

Box Length Spool

AQLvalues)isusuallyusedformeasurementofcharacteristics

Bundle Pad Tank

Car Pail Tank compartment

that are considered important. The selection of sampling plans

Carton Pallet Truckload

is independent of whether the term defect or nonconformity is

4. Summary of Practice

appropriate.

3.1.10 nonconforming unit, n—a unit of product containing

4.1 Instructions are given for obtaining a sample from

at least one nonconformity.

which specimens are then taken for testing. The test data are

3.1.11 nonconformities per hundred units, n— a calculated

compared to the material specification and a judgement is then

ratio of nonconforming units to the number of units inspected,

made as to whether the material meets the requirements of said

the quotient being multiplied by 100 (See 3.1.13.)

material specification.

3.1.12 nonconformity, n—a departure of a quality charac-

4.2 This practice has been modeled after MIL-STD105D.

teristic from its intended level or state that occurs with a

5. Procedure

severity sufficient to cause a test result not to meet a specifi-

cation requirement.

5.1 General Considerations:

3.1.13 percent nonconforming, n—a calculated ratio of 5.1.1 Assemble the lot of electrical insulating material so

nonconforming units to the number of units inspected, the

that a lot sample may be obtained in a manner that will

quotient being multiplied by 100. minimize bias in the selection of the units of product that will

3.1.14 rejection number, n—the minimum number of non- be inspected. A scheme that offers a good chance of minimiz-

conformitiesforagivenAQLandsamplesize(lot-samplesize) ing bias is the assignment of numbers to each unit of product

which will subject a lot to rejection.

and then using a table of random numbers to select those units

3.1.15 sample, n—one or more units of product taken from of product from which test units are taken.

a lot without regard to the quality of the unit. (Also often 5.1.2 For a lot of electrical insulating material which is in

termed lot sample). bulk form (for example, a tank car of powdered resin) take the

3.1.16 sample size, n—the number of units of product taken lot sample from the unit of product in accordance with Practice

to make up the sample. E 300.

D3636

5.1.3 Take the material to be removed from any unit of 5.2.2 When a user designates some specific value of AQL

product in a random manner. It will sometimes be impracti- for a single nonconformity, it indicates that the user’s accep-

cabletomeetthisrequirement(forexample,inthecaseoflong tance sampling plan will accept the great majority of the lots

lengths of material wound onto rolls or large, thick, heavy submitted by the producer if the process average level of

sheets packed on pallets or skids). In such situations economy percent nonconforming in the lots is no greater than the

will dictate the removal of material from the end of a roll, or designated value ofAQL. The preceding statement is also true

the top of a pile, etc. in which cases the selection cannot be for a group AQL value designated for a group of nonconfor-

described as “random.” mities.

5.1.4 Take the necessary amount of material from the test 5.2.2.1 The sampling plans of this standard are so arranged

unitsoastomeetthespecimenrequirementsofthevarioustest thattheprobabilityofacceptance,atthedesignatedAQLvalue,

methods that will be used to evaluate the material. depends upon the sample size. For a givenAQL, the probabil-

5.1.5 Refer to the material specification for the allowable ityofacceptancewillbegenerallyhigherforlargesamplesizes

maximum elapsed time between the assembly of the lot for than for small sample sizes. The AQL alone does not describe

inspection and the disposition of the lot. If the material the user protection for individual lots, but more directly relates

specification (or other pertinent document) does not cover this to what a user might expect from a series of lots. Refer to the

matter, the maximum allowable time is 30 calendar days. operating characteristic curve to determine what protection the

5.1.6 Exercise care to protect the electrical insulating mate- user will have for a specific AQL.

rial contained in the test unit from which specimens are to be 5.2.3 The designation of an AQL shall not imply that a

prepared. This protection may take the form of packaging in producerhastherighttoknowinglysupplyanynonconforming

metal foil or glass containers so as to prevent or minimize unit of product.

contamination of the material from the effects of the environ- 5.2.4 The values of AQL listed in the accompanying tables

menttowhichsuchmaterialissubjectedbetweensamplingand (see Section 8) are known as preferred AQL’s. If any AQL is

testing. designated other than a preferred AQL, these tables are not

5.1.7 Test units assembled as described above shall be applicable.

deemed to be representative of the lot of material being 5.3 Sampling Plan Selection:

inspected. Disposition of the lot, or portions thereof will be 5.3.1 Use the designated AQL and the sample size code

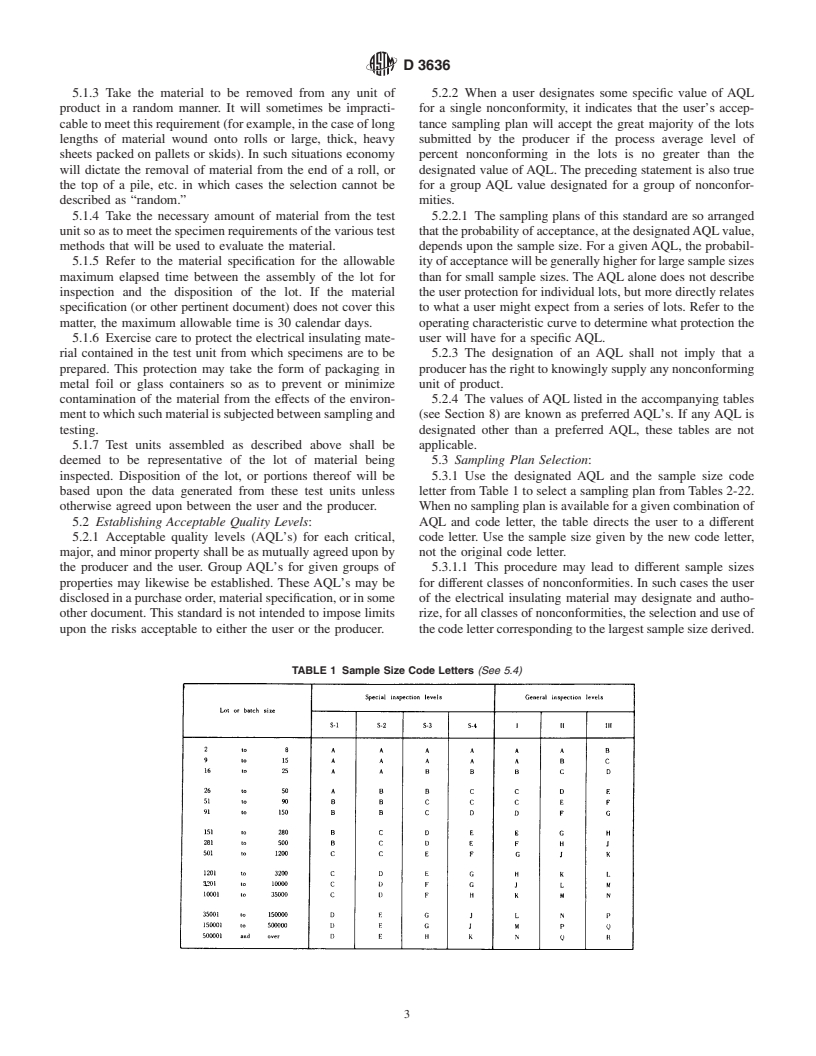

based upon the data generated from these test units unless letter from Table 1 to select a sampling plan from Tables 2-22.

otherwise agreed upon between the user and the producer. When no sampling plan is available for a given combination of

5.2 Establishing Acceptable Quality Levels: AQL and code letter, the table directs the user to a different

5.2.1 Acceptable quality levels (AQL’s) for each critical, code letter. Use the sample size given by the new code letter,

major, and minor property shall be as mutually agreed upon by not the original code letter.

the producer and the user. Group AQL’s for given groups of 5.3.1.1 This procedure may lead to different sample sizes

properties may likewise be established. These AQL’s may be for different classes of nonconformities. In such cases the user

disclosedinapurchaseorder,materialspecification,orinsome of the electrical insulating material may designate and autho-

other document. This standard is not intended to impose limits rize, for all classes of nonconformities, the selection and use of

upon the risks acceptable to either the user or the producer. thecodelettercorrespondingtothelargestsamplesizederived.

TABLE 1 Sample Size Code Letters (See 5.4)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.