ASTM F1837M-97

(Specification)Standard Specification for Heat-Shrink Cable Entry Seals (Metric)

Standard Specification for Heat-Shrink Cable Entry Seals (Metric)

SCOPE

1.1 This specification covers the general requirements for heat-shrink cable entry seals. Cable entry seals are intended for making electrical cable penetrations into connection boxes, bulkheads, or other enclosures. These devices are suitable for both thin wall enclosures up to 5 mm (3/16 in.) thick and thick-wall enclosures of 5 to 19 mm (3/16 to 3/4 in.) thick.

1.2 Cable entry seals shall have factory-applied adhesive that provides the seal to wire and cable jackets.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: F 1837M – 97 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Heat-Shrink Cable Entry Seals (Metric)

This standard is issued under the fixed designation F 1837M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2671 Test Methods for Heat-Shrinkable Tubing for Elec-

5

trical Use

1.1 This specification covers the general requirements for

D 2863 Test Method for Measuring the Minimum Oxygen

heat-shrink cable entry seals. Cable entry seals are intended for

Concentration to Support Candle-Like Combustion of

making electrical cable penetrations into connection boxes,

6

Plastics (Oxygen Index)

bulkheads, or other enclosures. These devices are suitable for

3 D 3149 Specification for Crosslinked Polyolefin Heat-

both thin wall enclosures up to 5 mm ( ⁄16 in.) thick and

5

3 3 Shrinkable Tubing for Electrical Insulation

thick-wall enclosures of 5 to 19 mm ( ⁄16 to ⁄4 in.) thick.

D 4066 Specification for Nylon Injection and Extrusion

1.2 Cable entry seals shall have factory-applied adhesive

6

Materials

that provides the seal to wire and cable jackets.

D 4507 Specification for Thermoplastic Polyester (TPES)

1.3 The values stated in SI units are to be regarded as the

7

Materials

standard. The values given in parentheses are for information

D 4732 Specification for Cool-Application Filling Com-

only.

5

pounds for Telecommunication Wire and Cable

1.4 This standard does not purport to address all of the

2.2 ASME Standard

safety concerns, if any, associated with its use. It is the

ASME B1.1 Unified Inch Screw Threads (UN and UNR

responsibility of the user of this standard to establish appro-

8

Thread Form)

priate safety and health practices and determine the applica-

2.3 NEMA Standards:

bility of regulatory limitations prior to its use.

NEMA 250 Enclosures for Electrical Equipment (1000

9

2. Referenced Documents

Volts Max)

2.4 IEC Standard:

2.1 ASTM Standards:

IEC 68-2-6 Environmental Testing–Part 2: Tests–Test FC:

D 149 Test Method for Dielectric Breakdown Voltage and

10

Vibration (Sinusoidal) Sixth Edition

Dielectric Strength of Solid Electrical Insulating Materials

2

at Commercial Power Frequencies

3. Terminology

D 257 Test Methods for D-C Resistance or Conductance of

2

3.1 Definitions of Terms Specific to This Standard:

Insulating Materials

3.1.1 heat-shrink cable entry seal, n—heat-shrinkable tube

D 412 Test Methods for Vulcanized Rubber and Thermo-

3

making a watertight, fume-tight seal where cables enter con-

plastic Rubbers and Thermoplastic Elastomers

4

nection boxes, bulkheads, or other enclosures.

D 570 Test Method for Water Absorption of Plastics

3.1.2 polyolefin, n—polymer made by the polymerization of

D 635 Test Method for Rate of Burning and/or Extent and

hydrocarbon olefins or copolymerization olefins.

Time of Burning of Self-Supporting Plastics in a Horizon-

4

tal Position

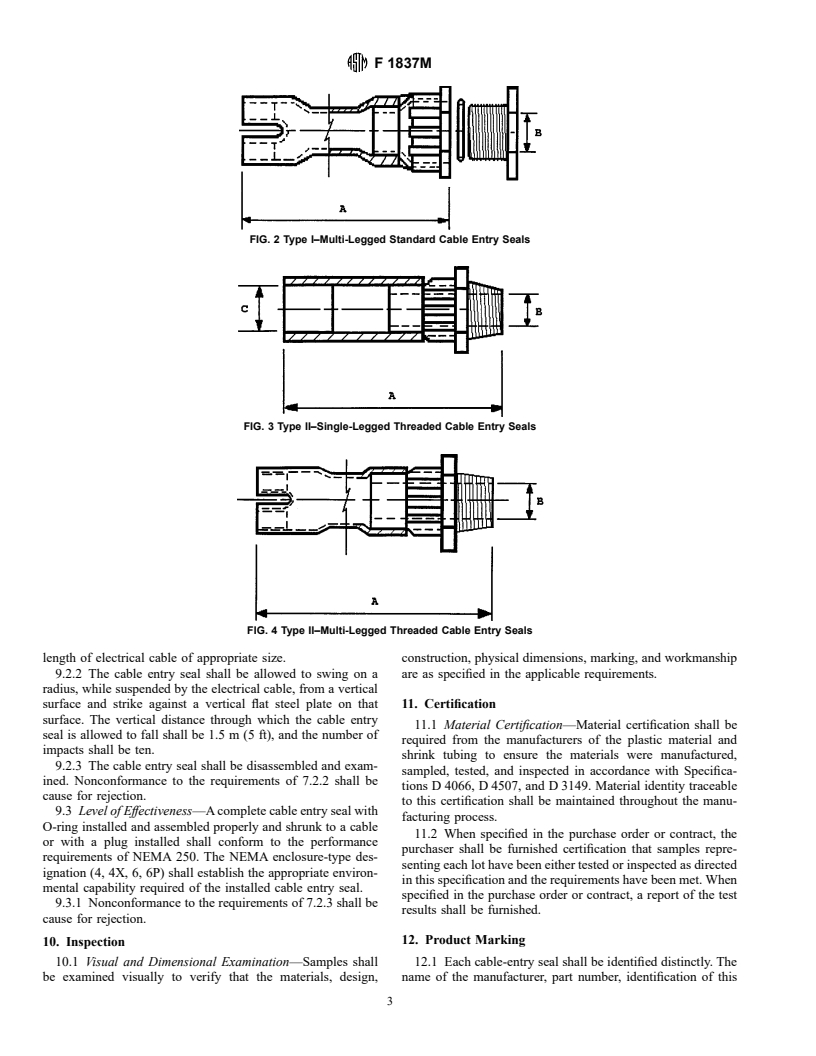

4. Classification

D 747 Test Method for Apparent Bending Modulus of

4 4.1 Heat-shrink cable entry seals shall be of the following

Plastics by Means of a Cantilever Beam

types:

D 792 Test Methods for Density and Specific Gravity (Rela-

4 4.1.1 Type 1, standard cable entry seals for thin-wall enclo-

tive Density) of Plastics by Displacement

sures shall consist of the three-part assembly; a rigid plastic

D 2240 Test Methods for Rubber Property—Durometer

3 nut, O-ring, and heat-shrinkable molded area.

Hardness

5

Annual Book of ASTM Standards, Vol 10.02.

6

Annual Book of ASTM Standards, Vol 08.02.

1

7

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

Annual Book of ASTM Standards, Vol. 08.03.

8 th

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

Available from the American Society of Mechanical Engineers, 345 E. 47 St.,

Electrical.

New York, NY 10017.

9

Current edition approved Nov. 10, 1997. Published September 1998.

Available from the National Electrical Manufacturers Association, 1300 N.

2

Annual Book of ASTM Standards, Vol 10.01.

17th St., Suite 1847, Rosslyn, VA 22209.

3

10

Annual Book of ASTM Standards, Vol 09.01.

Available from the International Electrotechnical Commission, 1 rue de

4

Annual Book of ASTM Standards, Vol 08.01.

Varembe, Geneva, Switzerland.

1

---------------------- Page: 1 ----------------------

F 1837M

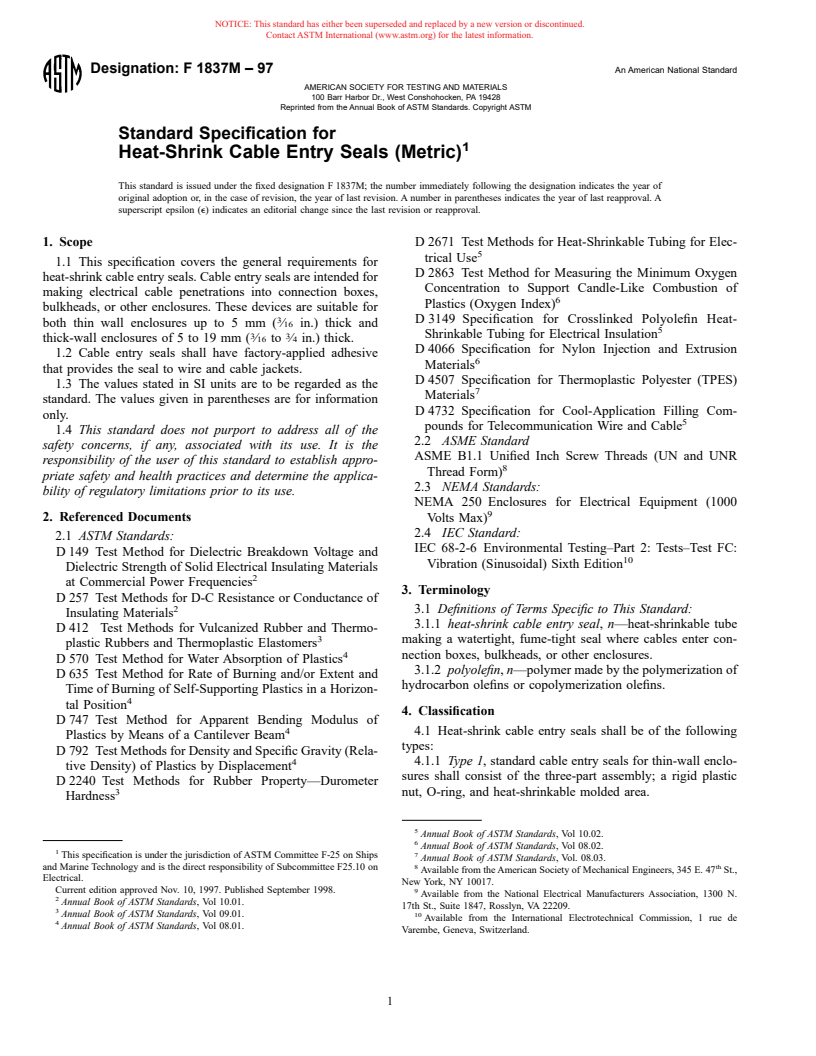

4.1.1.1 Type I–1, molded area configured with one opening 6.3 The adhesive shall be general purpose high-bond-

for a single wire or cable entry. strength adhesive sealant that provides stain relief and envi-

4.1.1.2 Type I–2, molded area configured with two equal ronmental sealing of heat-shrink tubing to cable jackets.

size openings to seal tw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.