ASTM F1375-92(2020)

(Test Method)Standard Test Method for Energy Dispersive X-Ray Spectrometer (EDX) Analysis of Metallic Surface Condition for Gas Distribution System Components (Withdrawn 2023)

Standard Test Method for Energy Dispersive X-Ray Spectrometer (EDX) Analysis of Metallic Surface Condition for Gas Distribution System Components (Withdrawn 2023)

SIGNIFICANCE AND USE

4.1 The purpose of this test method is to define a procedure for testing components being considered for installation into a high-purity gas distribution system. Application of this test method is expected to yield comparable data among components tested for purposes of qualification for this installation.

SCOPE

1.1 This test method establishes a procedure for comparing the elemental composition of normal surfaces with any defects found on the surfaces of metal tubing, fittings, valves, or any metal component.

1.2 This test method applies to all steel surfaces of components such as tubings, connectors, regulators, and valves, regardless of size, style, or type.

1.3 Limitations:

1.3.1 This test method is intended for use by scanning electron microscope/energy dispersive x-ray spectrometer (SEM/EDX) operators with skill level typically achieved over a twelve-month period.

1.3.2 SEM used for this study should conform to those limitations outlined in Test Method F1372 and should have a minimum point-to-point resolution of 30 nm.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

WITHDRAWN RATIONALE

This test method establishes a procedure for comparing the elemental composition of normal surfaces with any defects found on the surfaces of metal tubing, fittings, valves, or any metal component.

Formerly under the jurisdiction of Committee F01 on Electronics, this test method was withdrawn in November 2023. This standard is being withdrawn without replacement because Committee F01 was disbanded.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1375 − 92 (Reapproved 2020)

Standard Test Method for

Energy Dispersive X-Ray Spectrometer (EDX) Analysis of

Metallic Surface Condition for Gas Distribution System

Components

This standard is issued under the fixed designation F1375; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This test method

presents a procedure that may be applied for the evaluation of one or more components considered for

use in such systems.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method establishes a procedure for comparing

mendations issued by the World Trade Organization Technical

the elemental composition of normal surfaces with any defects

Barriers to Trade (TBT) Committee.

found on the surfaces of metal tubing, fittings, valves, or any

metal component.

2. Referenced Documents

1.2 This test method applies to all steel surfaces of compo- 2

2.1 ASTM Standards:

nents such as tubings, connectors, regulators, and valves,

F1372 Test Method for Scanning Electron Microscope

regardless of size, style, or type.

(SEM) Analysis of Metallic Surface Condition for Gas

1.3 Limitations: Distribution System Components

1.3.1 This test method is intended for use by scanning

3. Terminology

electron microscope/energy dispersive x-ray spectrometer

(SEM/EDX) operators with skill level typically achieved over

3.1 Definitions of Terms Specific to This Standard:

a twelve-month period. 3.1.1 normal surface—an area of the sample that does not

1.3.2 SEM used for this study should conform to those

exhibit any visible defect when viewed under the stipulated

limitations outlined in Test Method F1372 and should have a SEM magnification. Normal surface is used to provide a

minimum point-to-point resolution of 30 nm.

baseline for comparison with any area exhibiting a defect.

3.1.2 sample angle—the angle measured normal to the

1.4 The values stated in SI units are to be regarded as the

standard. The inch-pound units given in parentheses are for incoming electron beam.

information only.

3.1.3 standard conditions—101.3 kPa, 0.0°C (14.73 psia,

1.5 This standard does not purport to address all of the 32.0°F).

safety concerns, if any, associated with its use. It is the

3.1.4 working distance—the measured distance from the

responsibility of the user of this standard to establish appro-

bottom of the objective lens to the sample.

priate safety, health, and environmental practices and deter-

4. Significance and Use

mine the applicability of regulatory limitations prior to use.

Specific hazard statements are given in Section 6.

4.1 The purpose of this test method is to define a procedure

1.6 This international standard was developed in accor-

for testing components being considered for installation into a

dance with internationally recognized principles on standard-

high-purity gas distribution system. Application of this test

method is expected to yield comparable data among compo-

nents tested for purposes of qualification for this installation.

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.10 on Contamina-

tion Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2020. Published May 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin1992.Lastpreviouseditionapprovedin2012asF1375–92(2012).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1375-92R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

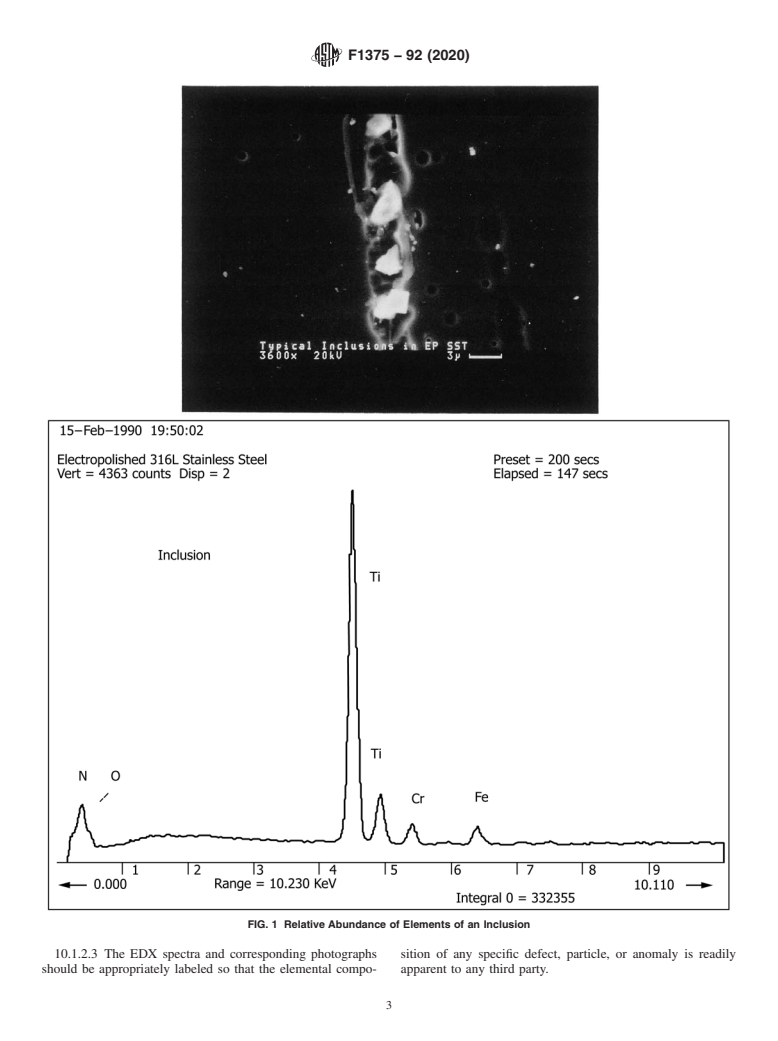

F1375 − 92 (2020)

5. Apparatus brate EDX spectrometers according to the manufacturer’s

specifications so that the energy calibration falls within 6 1

5.1 Materials:

channel.

5.1.1 Mounting Stubs, specific to the instrument used are

required. 8.2 Magnification for qualitative and quantitative analysis

5.1.1.1 Samples shall not be coated with a conductive thin shall result in incident beam concentration on the surface

layer (for example, gold or carbon). anomaly, minimizing stray X-ray signal from the background.

5.1.2 Conductive Paste/Tape, that will provide a conductive

9. Procedure

path.Useanymeansoffixingthesampletoastub.Careshould

be taken not to contaminate the area of interest.

9.1 Follow sample preparation of this test method (7.1)to

5.1.3 Adhesives, used to attach samples to sample stubs are

expose the surface.

to be vacuum stable.

9.2 Introduce the sample stub into the SEM vacuum cham-

5.2 Instrumentation:

ber.

5.2.1 Scanning Electron Microscope (SEM)—Any high

9.3 Activate the electron beam when vacuum conditions

resolution commercially available SEM with photographic

meet those recommended by the manufacturer:

capabilities of a 100 cm image may be used for these

9.4 Move the sample until an area of interest on the

analyses.

sample’s surface comes into focus. The area of interest should

5.2.2 Instrument Operating Parameters , shall be as fol-

be representative of a normal surface, avoiding gross deformi-

lows: accelerating voltage, 20 KeV; final aperture size nominal

ties.

200 µm or less; and working

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1375 − 92 (Reapproved 2020)

Standard Test Method for

Energy Dispersive X-Ray Spectrometer (EDX) Analysis of

Metallic Surface Condition for Gas Distribution System

Components

This standard is issued under the fixed designation F1375; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This test method

presents a procedure that may be applied for the evaluation of one or more components considered for

use in such systems.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method establishes a procedure for comparing

mendations issued by the World Trade Organization Technical

the elemental composition of normal surfaces with any defects

Barriers to Trade (TBT) Committee.

found on the surfaces of metal tubing, fittings, valves, or any

metal component.

2. Referenced Documents

1.2 This test method applies to all steel surfaces of compo- 2

2.1 ASTM Standards:

nents such as tubings, connectors, regulators, and valves,

F1372 Test Method for Scanning Electron Microscope

regardless of size, style, or type.

(SEM) Analysis of Metallic Surface Condition for Gas

1.3 Limitations: Distribution System Components

1.3.1 This test method is intended for use by scanning

3. Terminology

electron microscope/energy dispersive x-ray spectrometer

(SEM/EDX) operators with skill level typically achieved over 3.1 Definitions of Terms Specific to This Standard:

a twelve-month period.

3.1.1 normal surface—an area of the sample that does not

1.3.2 SEM used for this study should conform to those exhibit any visible defect when viewed under the stipulated

limitations outlined in Test Method F1372 and should have a

SEM magnification. Normal surface is used to provide a

minimum point-to-point resolution of 30 nm. baseline for comparison with any area exhibiting a defect.

1.4 The values stated in SI units are to be regarded as the 3.1.2 sample angle—the angle measured normal to the

incoming electron beam.

standard. The inch-pound units given in parentheses are for

information only.

3.1.3 standard conditions—101.3 kPa, 0.0°C (14.73 psia,

32.0°F).

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1.4 working distance—the measured distance from the

responsibility of the user of this standard to establish appro-

bottom of the objective lens to the sample.

priate safety, health, and environmental practices and deter-

4. Significance and Use

mine the applicability of regulatory limitations prior to use.

Specific hazard statements are given in Section 6.

4.1 The purpose of this test method is to define a procedure

1.6 This international standard was developed in accor-

for testing components being considered for installation into a

dance with internationally recognized principles on standard-

high-purity gas distribution system. Application of this test

method is expected to yield comparable data among compo-

nents tested for purposes of qualification for this installation.

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.10 on Contamina-

tion Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2020. Published May 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1992. Last previous edition approved in 2012 as F1375–92(2012). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1375-92R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

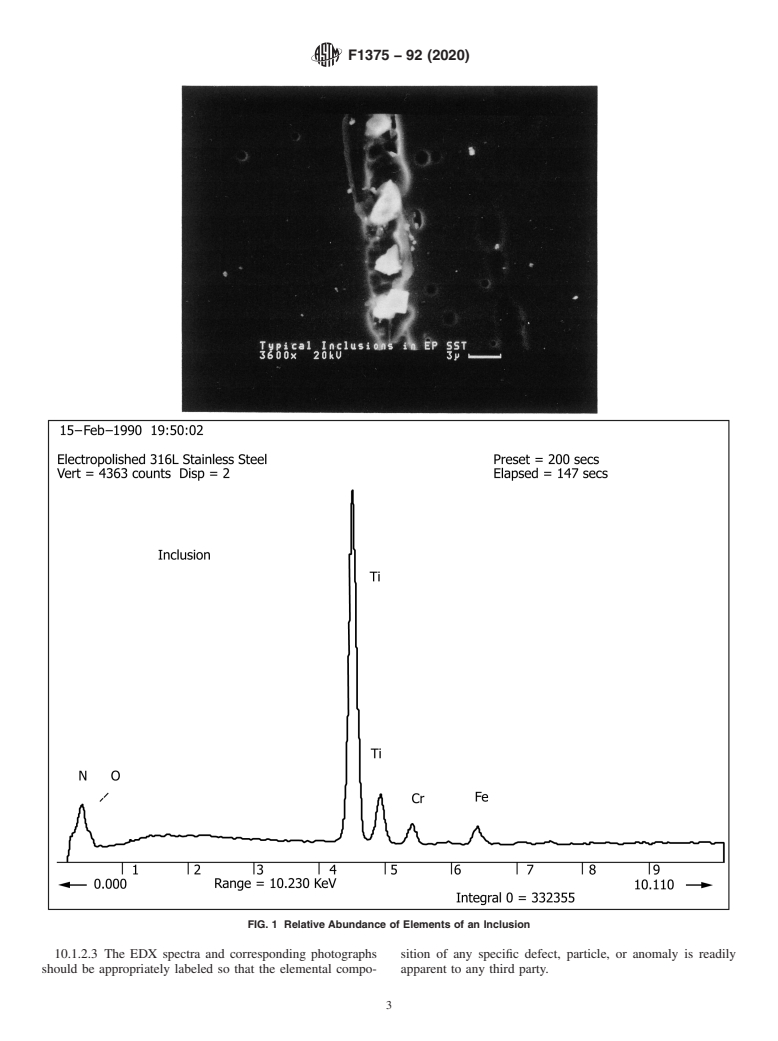

F1375 − 92 (2020)

5. Apparatus brate EDX spectrometers according to the manufacturer’s

specifications so that the energy calibration falls within 6 1

5.1 Materials:

channel.

5.1.1 Mounting Stubs, specific to the instrument used are

required. 8.2 Magnification for qualitative and quantitative analysis

5.1.1.1 Samples shall not be coated with a conductive thin shall result in incident beam concentration on the surface

layer (for example, gold or carbon). anomaly, minimizing stray X-ray signal from the background.

5.1.2 Conductive Paste/Tape, that will provide a conductive

9. Procedure

path. Use any means of fixing the sample to a stub. Care should

be taken not to contaminate the area of interest.

9.1 Follow sample preparation of this test method (7.1) to

5.1.3 Adhesives, used to attach samples to sample stubs are

expose the surface.

to be vacuum stable.

9.2 Introduce the sample stub into the SEM vacuum cham-

5.2 Instrumentation:

ber.

5.2.1 Scanning Electron Microscope (SEM)—Any high

9.3 Activate the electron beam when vacuum conditions

resolution commercially available SEM with photographic

meet those recommended by the manufacturer:

capabilities of a 100 cm image may be used for these

9.4 Move the sample until an area of interest on the

analyses.

sample’s surface comes into focus. The area of interest should

5.2.2 Instrument Operating Parameters , shall be as fol-

be representative of a normal surface, avoiding gross deformi-

lows: accelerating voltage, 20 KeV; final aperture size nominal

ties.

200 µm or less; and working distance and sample tilt, as

appropriate to the EDX detector.

9.5 Orient the sample (with r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.