ASTM E997-11

(Test Method)Standard Test Method for Structural Performance of Glass in Exterior Windows, Curtain Walls, and Doors Under the Influence of Uniform Static Loads by Destructive Methods

Standard Test Method for Structural Performance of Glass in Exterior Windows, Curtain Walls, and Doors Under the Influence of Uniform Static Loads by Destructive Methods

SIGNIFICANCE AND USE

Glass specimens to be tested shall be mounted in a standard test frame with four sides supported, or in a test frame designed to represent specific glazing conditions.

A standard test frame shall be used when it is desired to evaluate the probability of breakage of glass specimens with edge support conditions held constant.

A test frame designed to represent a specific glazing condition shall be used when it is desired to evaluate the probability of breakage of glass specimens in the specified glazing system.

Loads on glass in windows, curtain walls, and doors may vary greatly in magnitude, direction, and duration. Any load (wind, snow, etc.) that can be transformed into a 60-s duration equivalent uniform design load can be considered. Load transformation techniques are addressed in the literature (1, 2, 3).

The strength of glass varies with many different factors including surface condition, load duration, geometry, relative humidity, and temperature (4). A thorough understanding of those strength variations is required to interpret results of this test method.

SCOPE

1.1 This test method is a procedure to determine if the probability of breakage of glass specimens tested is significantly greater than, significantly less than, or not significantly different than the specified probability of breakage when exposed to a specified design load. It is not intended to be a design standard for determining the load resistance of glass. Practice E1300 shall be used for this purpose.

1.2 This test method describes apparatus and procedures to select and apply a proof load to glass specimens, to determine the number of glass specimens to be tested, and to evaluate statistically the probability of breakage. This test method may be conducted using the standard test frame specified herein or a test frame of the user's design.

1.3 Proper use of this test method requires a knowledge of the principles of pressure measurement and an understanding of recommended glazing practices.

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E997 – 11

Standard Test Method for

Structural Performance of Glass in Exterior Windows,

Curtain Walls, and Doors Under the Influence of Uniform

1

Static Loads by Destructive Methods

This standard is issued under the fixed designation E997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method is a procedure to determine if the 2.1 ASTM Standards:

probability of breakage of glass specimens tested is signifi- E1300 Practice for Determining Load Resistance of Glass

cantly greater than, significantly less than, or not significantly in Buildings

different than the specified probability of breakage when

3. Terminology

exposed to a specified design load. It is not intended to be a

3.1 Definitions:

design standard for determining the load resistance of glass.

Practice E1300 shall be used for this purpose. 3.1.1 coeffıcient of variation, n—ratioofthestandarddevia-

tion of the breakage load to the mean breakage load.

1.2 This test method describes apparatus and procedures to

select and apply a proof load to glass specimens, to determine 3.1.2 equivalent design load, n—the specified uniform de-

sign load converted to specified duration (see 4.2).

the number of glass specimens to be tested, and to evaluate

statistically the probability of breakage. This test method may 3.1.3 glass specimen, n—theglasstobetested,forexample,

a single pane, an insulating glass unit, laminated glass, etc.

be conducted using the standard test frame specified herein or

a test frame of the user’s design. (does not include test frame).

3.1.4 glass specimen breakage, n—the fracture or cracking

1.3 Proper use of this test method requires a knowledge of

the principles of pressure measurement and an understanding of any glass component of a glass specimen.

3.1.5 negative load, n—an outward-acting load that results

of recommended glazing practices.

1.4 The values stated in inch-pound units are to be regarded in the indoor side of a glass specimen being the high-pressure

as standard. side.

3.1.6 positive load, n—an inward-acting load that results in

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the the outdoor side of a glass specimen being the high-pressure

side.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.1.7 probability of breakage, n—theprobabilitythataglass

specimen will break when tested at a given load. General

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Section 7. industry practice is to express the probability of breakage as

lites per 1000 lites.

3.1.8 proof load, n—a magnitude of uniform load at which

glass specimens shall be tested.

1

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of E06.51 on Performance

2

of Windows, Doors, Skylights and Curtain Walls. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2011. Published December 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2009 as E997–01(2009). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0997-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E997 – 11

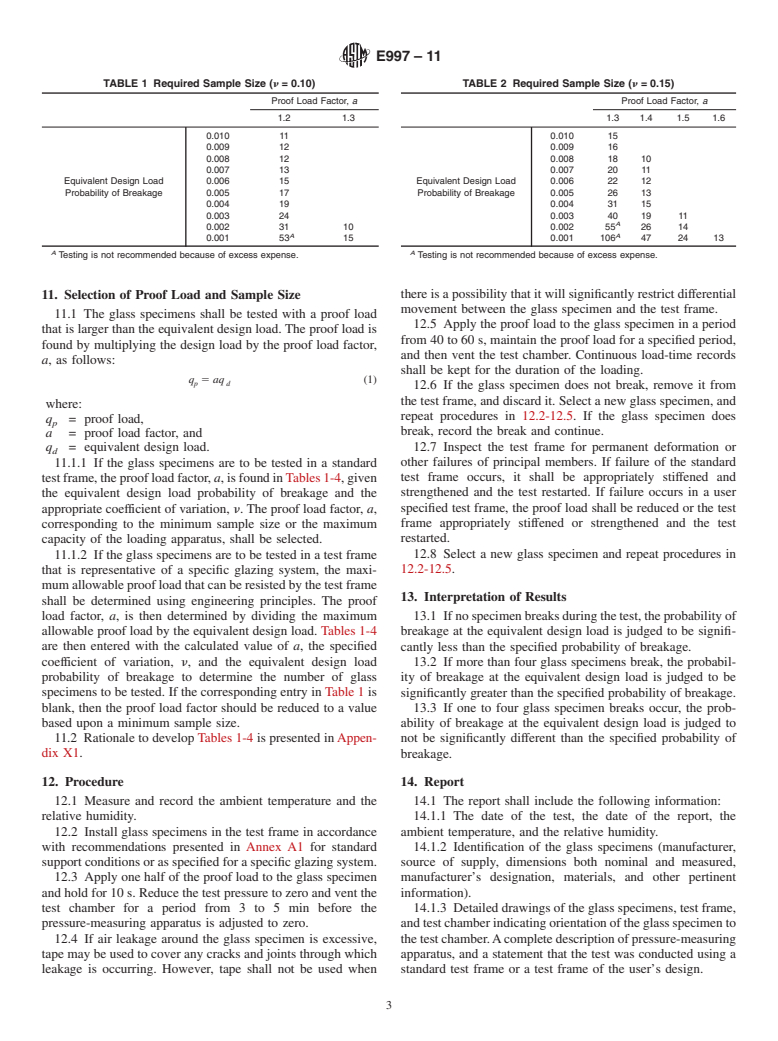

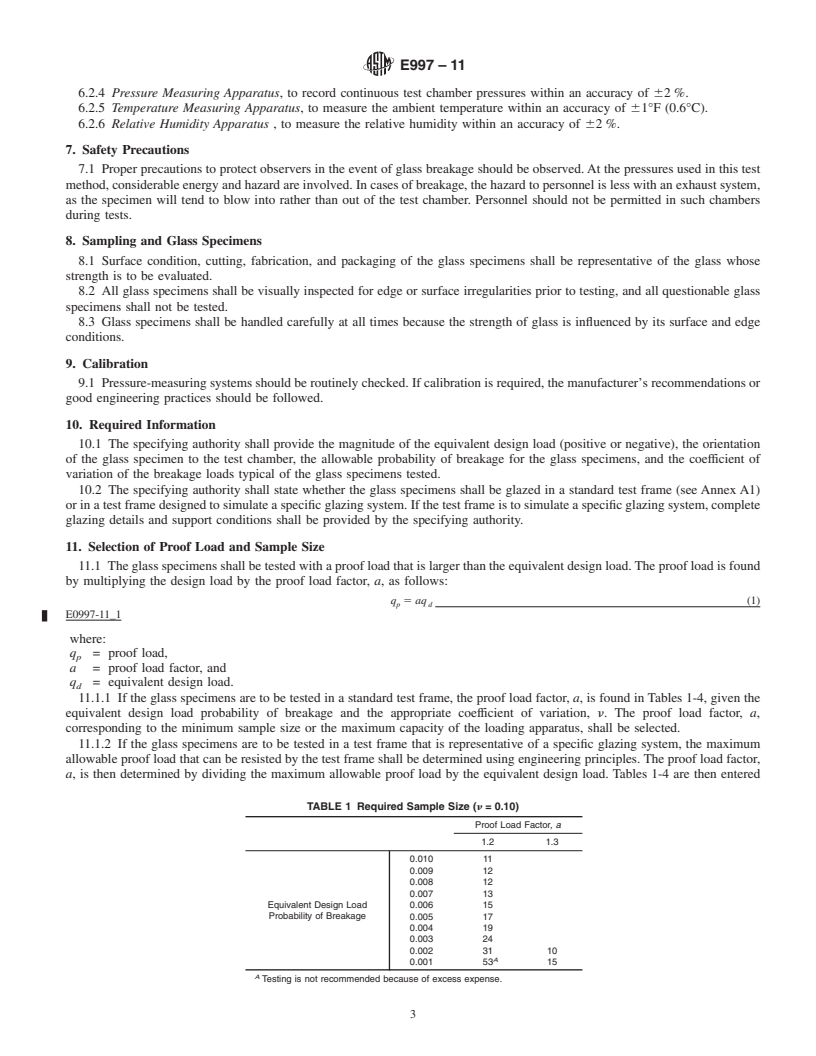

3.1.9 proof load factor, a, n—the constant which, when affected by the velocity of the air supply to or from the test

multiplied by the design load, determines the proof load. chamber or any air movement.The air supply opening into the

3.1.10 specifying authority, n—professional(s) responsible test chamber shall be arranged so that the air does not impinge

fordeterminingandfurnishinginformationrequiredtoperform directly on the glass specimen with any significant velocity.A

the test. means of access into the test chamber may be provided to

facilitate adjustments and observations after the specimen has

4. Summary of Test Method

been installed.

4.1 This test method consists of individually glazing glass

6.2.3 Air System, a controllable blower, compressed air

specimens in a test frame that is mounted into or against one

supply, exhaust system, reversible blower, or other device

face of a test chamber and supplying air to, or exhausting air

designed to apply the proof

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E997–01(Reapproved2009) Designation: E997 – 11

Standard Test Method for

Structural Performance of Glass in Exterior Windows,

Curtain Walls, and Doors Under the Influence of Uniform

1

Static Loads by Destructive Methods

This standard is issued under the fixed designation E997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is a procedure to determine if the probability of breakage of glass specimens tested is significantly greater

than, significantly less than, or not significantly different than the specified probability of breakage when exposed to a specified

60-sdurationequivalentdesignload.Itisnotintendedtobeadesignstandardfordeterminingtheloadresistanceofglass.Practice

E1300 shall be used for this purpose.

1.2 This test method describes apparatus and procedures to select and apply a 60-s duration proof load to glass specimens, to

determine the number of glass specimens to be tested, and to evaluate statistically the probability of breakage. This test method

may be conducted using the standard test frame specified herein or a test frame of the user’s design.

1.3 Proper use of this test method requires a knowledge of the principles of pressure measurement and an understanding of

recommended glazing practices.

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in Section 7.

1

This test method is under the jurisdiction ofASTM Committee E06 on Performance of Buildings and is the direct responsibility of E06.51 on Performance ofWindows,

Doors, Skylights and Curtain Walls.

Current edition approved Nov. 1, 2009.15, 2011. Published January 2010.December 2011. Originally approved in 1984. Last previous edition approved in 20012009 as

E997–01(2009). DOI: 10.1520/E0997-01R09.10.1520/E0997-11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E997 – 11

2. Referenced Documents

2

2.1 ASTM Standards:

E1300 Practice for Determining Load Resistance of Glass in Buildings

3. Terminology

3.1 Definitions:

3.1.1 coeffıcient of variation, n—ratio of the standard deviation of the breakage load to the mean breakage load.

3.1.2 equivalent design load, n—the specified uniform design load converted to a 60-sspecified duration (see 4.2).

3.1.3 glass specimen, n—the glass to be tested, for example, a single pane, an insulating glass unit, laminated glass, etc. (does

not include test frame).

3.1.4 glass specimen breakage, n—the fracture or cracking of any glass component of a glass specimen.

3.1.5 negative load, n—an outward-acting load that results in the indoor side of a glass specimen being the high-pressure side.

3.1.6 positive load, n—an inward-acting load that results in the outdoor side of a glass specimen being the high-pressure side.

3.1.7 probability of breakage, n—the probability that a glass specimen will break when tested at a given load. General industry

practice is to express the probability of breakage as lites per 1000 lites.

3.1.8 proof load, n—a magnitude of uniform load at which glass specimens shall be tested.

3.1.9 proof load factor, a, n—the constant which, when multiplied by the equivalent design load, determines the proof load.

3.1.10 specifying authority, n—professional(s) responsible for determining and furnishing information required to perform the

test.

4. Summary of Test Method

4.1 This test method consists of individually glazing glass specimens in a test frame that is mounted into or against one face

of a test chamber and supplying air to, or exhausting air from, the test chamber so that each glass specimen is exposed to a

60-sspecified duration proof load. Load-time records shall be kept for each glass specimen. Each glass specimen break shall be

recorded.

4.2 Aftertestingtherequirednumberofglassspecimens,itisdeterminediftheprobabilityofbreakageissignificantlylessthan,

significantly greater than, or not significantly different

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.