ASTM D6095-12(2018)

(Test Method)Standard Test Method for Longitudinal Measurement of Volume Resistivity for Extruded Crosslinked and Thermoplastic Semiconducting Conductor and Insulation Shielding Materials

Standard Test Method for Longitudinal Measurement of Volume Resistivity for Extruded Crosslinked and Thermoplastic Semiconducting Conductor and Insulation Shielding Materials

SIGNIFICANCE AND USE

4.1 The electrical behavior of semiconducting extruded shielding materials is important for a variety of reasons, such as safety, static charges, and current transmission. This test method is useful in predicting the behavior of such semiconducting compounds. Also see Test Method D4496.

SCOPE

1.1 This test method covers the procedure for determining the volume resistivity, measured longitudinally, of extruded crosslinked and thermoplastic semiconducting, conductor and insulation shields for wire and cable.

1.2 In common practice the conductor shield is often referred to as the strand shield.

1.3 Technically, this test method is the measurement of a resistance between two electrodes on a single surface and modifying that value using dimensions of the specimen geometry to calculate a resistivity. However, the geometry of the specimen is such as to support the assumption of a current path primarily throughout the volume of the material between the electrodes, thus justifying the use of the term “longitudinal volume resistivity.” (See 3.1.2.1.)

1.4 Whenever two sets of values are presented, in different units, the values in the first set are the standard, while those in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.1.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6095 − 12 (Reapproved 2018)

Standard Test Method for

Longitudinal Measurement of Volume Resistivity for

Extruded Crosslinked and Thermoplastic Semiconducting

Conductor and Insulation Shielding Materials

This standard is issued under the fixed designation D6095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This test method covers the procedure for determining 2.1 ASTM Standards:

the volume resistivity, measured longitudinally, of extruded D257 Test Methods for DC Resistance or Conductance of

crosslinked and thermoplastic semiconducting, conductor and Insulating Materials

insulation shields for wire and cable. D1711 Terminology Relating to Electrical Insulation

D4496 Test Method for D-C Resistance or Conductance of

1.2 In common practice the conductor shield is often re-

Moderately Conductive Materials

ferred to as the strand shield.

1.3 Technically, this test method is the measurement of a 3. Terminology

resistance between two electrodes on a single surface and

3.1 Definitions of Terms Specific to This Standard:

modifying that value using dimensions of the specimen geom-

3.1.1 semiconducting, adj—moderately conductive, see Ter-

etry to calculate a resistivity. However, the geometry of the

minology D1711 and Test Method D4496.

specimen is such as to support the assumption of a current path

3.1.2 longitudinal volume resistivity, n—an electrical resis-

primarily throughout the volume of the material between the

tance multiplied by a factor calculated from the geometry of a

electrodes, thus justifying the use of the term “longitudinal

specimen volume between electrodes in contact with one, and

volume resistivity.” (See 3.1.2.1.)

only one, surface of the specimen.

1.4 Whenever two sets of values are presented, in different

3.1.2.1 Discussion—In normal wire and cable usage, the

units, the values in the first set are the standard, while those in

longitudinal volume resistivity is simply referred to as “volume

parentheses are for information only.

resistivity.” This usage is at variance with terminology in Test

1.5 This standard does not purport to address all of the Methods D257, Terminology D1711, and Test Method D4496.

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.1 The electrical behavior of semiconducting extruded

mine the applicability of regulatory limitations prior to use.

shielding materials is important for a variety of reasons, such

For a specific hazard statement, see 7.1.

as safety, static charges, and current transmission. This test

1.6 This international standard was developed in accor-

method is useful in predicting the behavior of such semicon-

dance with internationally recognized principles on standard-

ducting compounds. Also see Test Method D4496.

ization established in the Decision on Principles for the

5. Apparatus

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.1 See Test Method D4496 for a description of the

Barriers to Trade (TBT) Committee.

apparatus, except the electrode system which is described in

7.2.

This test method is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Electrical Insulating Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2018. Published November 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1997. Last previous edition approved in 2012 as D6095 – 12. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6095-12R18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

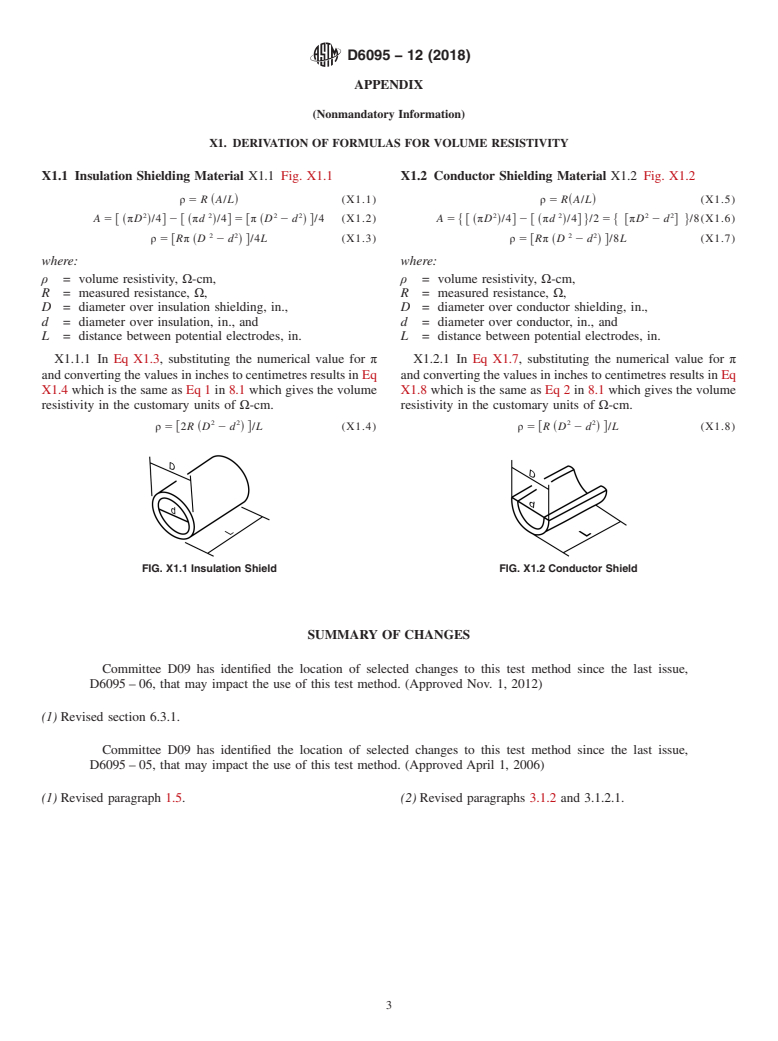

D6095 − 12 (2018)

6. Sampling and Test Specimens at 23 6 2°C (73 6 4°F) and one at the rated operating

temperature of the insulation material.

6.1 Take one 2-ft (600-mm) sample from each lot, or from

each 25000 ft (7600 m) of completed cable, whichever is less.

8. Calculation

6.2 The specimen consists of a 10 in. (250 mm) length of

8.1 For each shielding material and each temperature, cal-

cable core with all layers external to the semi-conducting

culate the volume resistivity by using the following equations:

insulation shield removed. Use this specimen to test the

Insulation Shielding:

insulation shield. To test the conductor shield, bisect the

2 2

sample longitudinally and remove the conductor. Use only one

ρ 5 2R D 2 d /L (1)

@ ~ ! #

b b

piece of the conductor shield as the test specimen.

Conductor Shielding:

6.3 Condition the specimens in accordance with Test

2 2

ρ 5 R D 2 d /L (2)

@ ~ ! #

a a

Method D4496.

where:

6.3.1 If the shielding materials are crosslinked, condition

the cable core (jacket removed) overnight at 50°C to eliminate

ρ = volume resistivity, Ω-cm,

any acetophenone that is potentially present. Then proceed R = measured resistance, Ω,

L = distance between potential electrodes, in.,

with the conditioning in accordance with Test Method D4496.

D = diameter over conductor shielding, in.,

a

7. Procedure

d = diameter over conductor, in.,

a

D = diameter over insulation shielding, in., and

b

7.1 Warning—Thoroughly instruct all operators as to the

d = diameter over insulation, in.

b

correct procedures for performing tests safely.

NOTE 1—Even though the dimensions are measured in inches, the value

7.2 Apply an electrode system consisting of four annular of the volume resistivity is reported in Ω-cm.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6095 − 12 D6095 − 12 (Reapproved 2018)

Standard Test Method for

Longitudinal Measurement of Volume Resistivity for

Extruded Crosslinked and Thermoplastic Semiconducting

Conductor and Insulation Shielding Materials

This standard is issued under the fixed designation D6095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure for determining the volume resistivity, measured longitudinally, of extruded

crosslinked and thermoplastic semiconducting, conductor and insulation shields for wire and cable.

1.2 In common practice the conductor shield is often referred to as the strand shield.

1.3 Technically, this test method is the measurement of a resistance between two electrodes on a single surface and modifying

that value using dimensions of the specimen geometry to calculate a resistivity. However, the geometry of the specimen is such

as to support the assumption of a current path primarily throughout the volume of the material between the electrodes, thus

justifying the use of the term “longitudinal volume resistivity.” (See 3.1.2.1)3.1.2.1.)

1.4 Whenever two sets of values are presented, in different units, the values in the first set are the standard, while those in

parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For a specific hazard statement, see 7.1.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D1711 Terminology Relating to Electrical Insulation

D4496 Test Method for D-C Resistance or Conductance of Moderately Conductive Materials

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 semiconducting, adj—moderately conductive, see Terminology D1711 and Test Method D4496.

3.1.2 longitudinal volume resistivity, n—an electrical resistance multiplied by a factor calculated from the geometry of a

specimen volume between electrodes in contact with one, and only one, surface of the specimen.

3.1.2.1 Discussion—

In normal wire and cable usage, the longitudinal volume resistivity is simply referred to as “volume resistivity.” This usage is at

variance with terminology in Test Methods D257, Terminology D1711, and Test Method D4496.

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.07 on Electrical Insulating Materials.

Current edition approved Nov. 1, 2012Nov. 1, 2018. Published November 2012November 2018. Originally approved in 1997. Last previous edition approved in 20062012

as D6095 – 06.D6095 – 12. DOI: 10.1520/D6095-12.10.1520/D6095-12R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6095 − 12 (2018)

4. Significance and Use

4.1 The electrical behavior of semiconducting extruded shielding materials is important for a variety of reasons, such as safety,

static charges, and current transmission. This test method is useful in predicting the behavior of such semiconducting compounds.

Also see Test Method D4496.

5. Apparatus

5.1 See Test Method D4496 for a description of the apparatus, except the electrode system which is described in 7.2.

6. Sampling and Test Specimens

6.1 Take one 2-ft (600-mm) sample from each lot, or from each 25000 ft (7600 m) of completed cable, whichever is less.

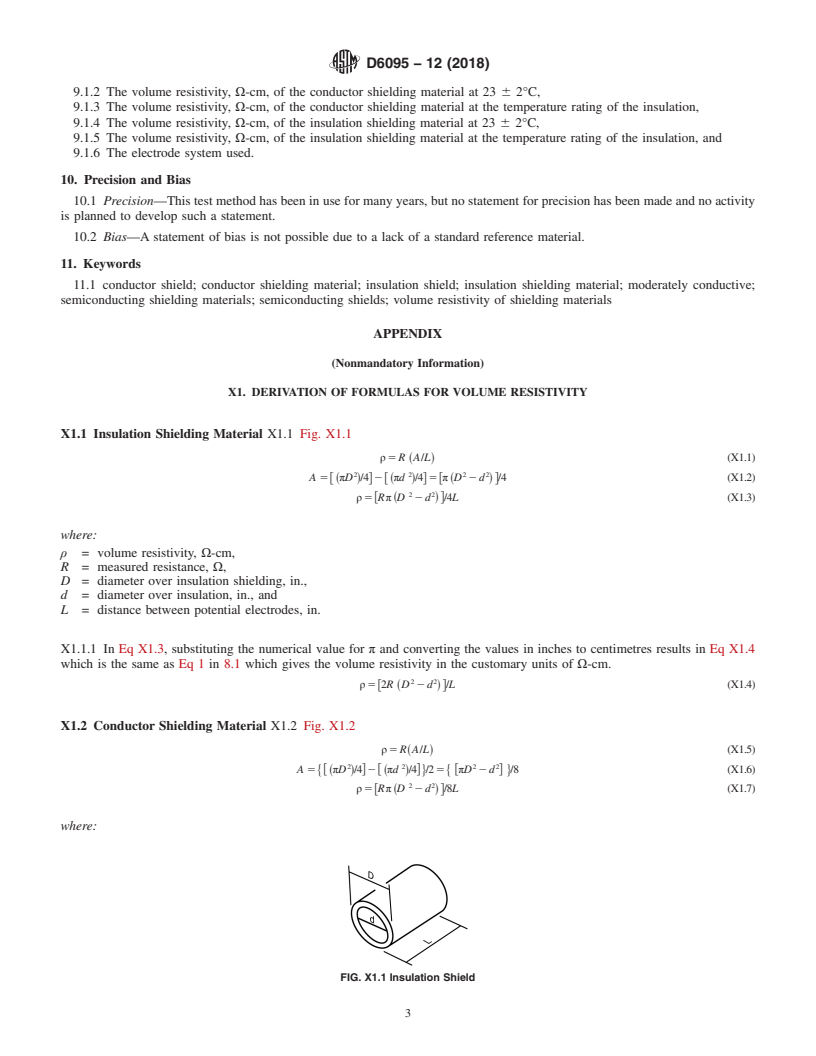

6.2 The specimen consists of a 10 in. (250 mm) length of cable core with all layers external to the semi-conducting insulation

shield removed. Use this specimen to test the insulation shield. To test the conductor shield, bisect the sample longitudinally and

remove the conductor. Use only one piece of the conductor shield as the test specimen.

6.3 Condition the specimens in accordance with Test Method D4496.

6.3.1 If the shielding materials are crosslinked, condition the cable core (jacket removed) overnight at 50°C to eliminate any

acetophenone that is potentially present. Then proceed with the conditioning in accordance with Test Method D4496.

7. Procedure

7.1 Warning—Thoroughly instruct all operators as to the correct procedures for performing tests safely.

7.2 Apply an electrode system consisting of four annular bands of silver paint approximately 0.25 in. (6.5 mm) wide to the

insulation shield. There must be a distance of at least 2 in. (50 mm) of shield between the potential electrodes (the two inner bands)

and a distance of 1 in. of shield between the current electrodes (the outer bands) and the potential electrodes. See Annex A1 of

Test Method D4496.

7.3 For measurement of the conductor shield, bisect the sample longitudinally and remove the conductor. Then, using only one

piece of the bisected shield, apply the silver paint electrode system as described in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.