ASTM F710-11

(Practice)Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring

Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring

ABSTRACT

This practice covers the procedure for determining the acceptability of concrete floors for the installation of resilient flooring. It also includes suggestions for ensuring that the constructed concrete floor is acceptable for such installations but does not cover tests for adequacy of the concrete floor to perform structural requirements. A permanent, effective moisture vapor retarder, of the specified thickness and permeance, is required under all on- or below-grade concrete floors. Concrete floors for resilient floorings should be permanently dry, clean, smooth, structurally sound, and free of substances that may prevent adhesive bonding. Surface cracks, grooves, depression, control joints or other non-moving joints, and other irregularities should be filled or smoothed with latex patching or a recommended underlayment compound. The surface of the floor should be cleaned by scraping, brushing, vacuuming, or any other method. All concrete slabs should be tested for moisture regardless of age or grade level while all concrete floors should be tested for pH before installing resilient flooring.

SCOPE

1.1 This practice covers the determination of the acceptability of a concrete floor for the installation of resilient flooring.

1.2 This practice includes suggestions for the construction of a concrete floor to ensure its acceptability for installation of resilient flooring.

1.3 This practice does not cover the adequacy of the concrete floor to perform its structural requirements.

1.4 This practice covers the necessary preparation of concrete floors prior to the installation of resilient flooring.

1.5 This practice does not supersede in any manner the resilient flooring or adhesive manufacturer's written instructions. Consult the individual manufacturer for specific recommendations.

1.6 Although carpet tiles, carpet, wood flooring, coatings, films, and paints ae not specifically intended to be included in the category of resilient floor coverings, the procedures included in this practice may be useful for preparing concrete floors to receive such finishes.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See , 7.1.1, and 7.1.2 for specific warning statements.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F710 − 11

Standard Practice for

1

Preparing Concrete Floors to Receive Resilient Flooring

ThisstandardisissuedunderthefixeddesignationF710;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C109/C109M Test Method for Compressive Strength of

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

1.1 This practice covers the determination of the acceptabil-

Specimens)

ity of a concrete floor for the installation of resilient flooring.

C472 Test Methods for Physical Testing of Gypsum, Gyp-

1.2 This practice includes suggestions for the construction

sum Plasters and Gypsum Concrete

of a concrete floor to ensure its acceptability for installation of

D4259 Practice for Abrading Concrete

resilient flooring.

D4263 Test Method for Indicating Moisture in Concrete by

1.3 This practice does not cover the adequacy of the

the Plastic Sheet Method

concrete floor to perform its structural requirements.

D4397 Specification for Polyethylene Sheeting for

1.4 This practice covers the necessary preparation of con- Construction, Industrial, and Agricultural Applications

crete floors prior to the installation of resilient flooring.

E1155 Test Method for Determining F Floor Flatness and

F

F Floor Levelness Numbers

L

1.5 This practice does not supersede in any manner the

E1486 Test Method for Determining Floor Tolerances Using

resilient flooring or adhesive manufacturer’s written instruc-

Waviness, Wheel Path and Levelness Criteria

tions. Consult the individual manufacturer for specific recom-

E1745 Specification for Plastic Water Vapor Retarders Used

mendations.

in Contact with Soil or Granular Fill under Concrete Slabs

1.6 Although carpet tiles, carpet, wood flooring, coatings,

F141 Terminology Relating to Resilient Floor Coverings

films, and paints ae not specifically intended to be included in

F710 Practice for Preparing Concrete Floors to Receive

the category of resilient floor coverings, the procedures in-

Resilient Flooring

cluded in this practice may be useful for preparing concrete

F1869 Test Method for Measuring Moisture Vapor Emission

floors to receive such finishes.

Rate of Concrete Subfloor Using Anhydrous Calcium

1.7 This standard does not purport to address all of the

Chloride

safety concerns, if any, associated with its use. It is the

F2170 Test Method for Determining Relative Humidity in

responsibility of the user of this standard to establish appro-

Concrete Floor Slabs Using in situ Probes

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. See 7.1, 7.1.1, and

NOTE 1—Specifications and test methods for cements and other related

7.1.2 for specific warning statements.

materials are found in ASTM Volume 04.01. Specifications and test

1.8 The values stated in inch-pound units are to be regarded methods for concretes and related materials are found in ASTM Volume

04.02.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3

2.2 ACI Guides:

and are not considered standard.

302.1R-06 Guide for Concrete Floor and Slab Construction

117R Standard Tolerances for Concrete Construction and

2. Referenced Documents

2 Materials

2.1 ASTM Standards:

4

2.3 Resilient Floor Covering Institute (RFCI):

1 Recommended Work Practices for the Removal of Resilient

This practice is under the jurisdiction of ASTM Committee F06 on Resilient

Floor Coverings and is the direct responsibility of Subcommittee F06.40 on Floor Coverings

Practices.

Current edition approved May 15, 2011. Published June 2011. Originally

approved in 1981. Last previous edition approved in 2008 as F710 – 08. DOI:

10.1520/F0710-11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Concrete Institute, 19150 Redford Station, Detroit,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM MI 48219.

4

Standards volume information, refer to the standard’s Document Summary page on Resilient Floor Covering Institute, 966 Hungerford Drive, Rockville, MD

the ASTM website. 20850.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F710 − 11

2.4 Other Standards: compressive strength after 28 days, when tested in accordance

MASTERSPEC Guide Spec Section 03 30 00 “Cast-In- with Test Method C109/C109M or Test Method C472, which-

5

Place Concrete” ever is appropriate.

4.3.1 Joints such as expansion joints, isolation joints, or

3. Terminology

other moving joints in concrete slabs

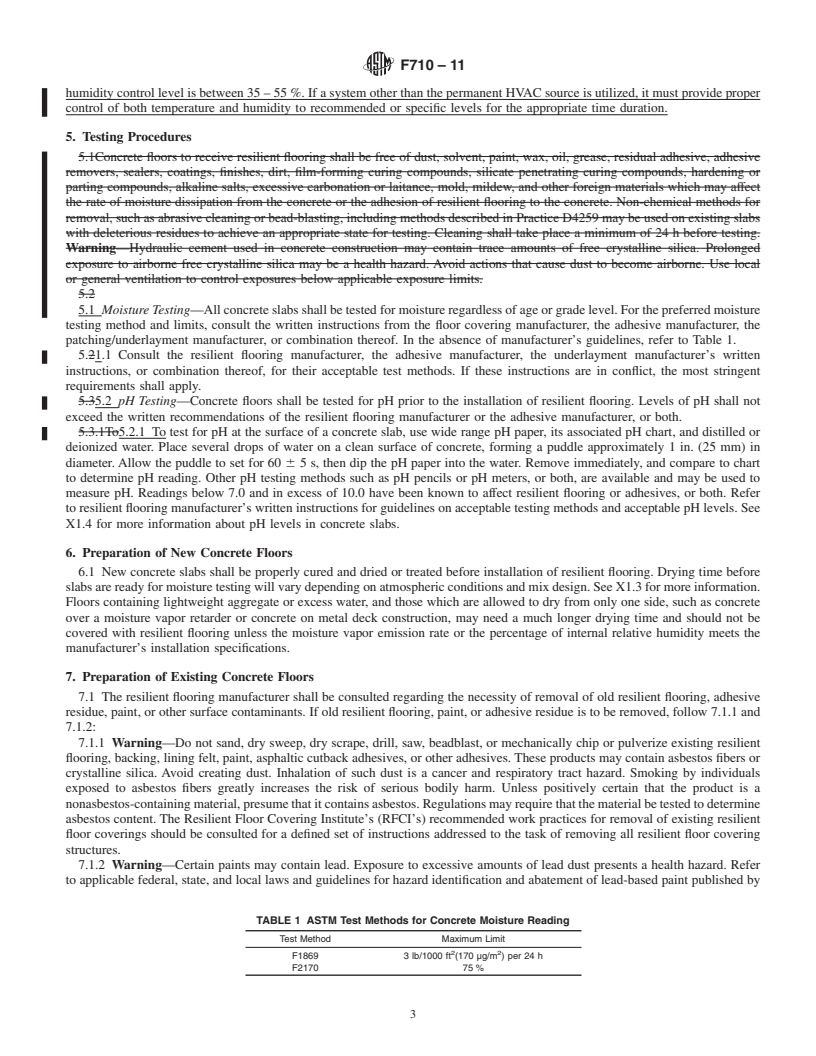

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F710–08 Designation:F710–11

Standard Practice for

1

Preparing Concrete Floors to Receive Resilient Flooring

ThisstandardisissuedunderthefixeddesignationF710;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the determination of the acceptability of a concrete floor for the installation of resilient flooring.

1.2 This practice includes suggestions for the construction of a concrete floor to ensure its acceptability for installation of

resilient flooring.

1.3 This practice does not cover the adequacy of the concrete floor to perform its structural requirements.

1.4 This practice covers the necessary preparation of concrete floors prior to the installation of resilient flooring.

1.5 This practice does not supersede in any manner the resilient flooring or adhesive manufacturer’s written instructions.

Consult the individual manufacturer for specific recommendations.

1.6 Although carpet tiles, carpet, wood flooring, coatings, films, and paints ae not specifically intended to be included in the

category of resilient floor coverings, the procedures included in this practice may be useful for preparing concrete floors to receive

such finishes.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See 5.1See , 7.1.1, and 7.1.2 for specific warning statements.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units andthat are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete

D4259 Practice for Abrading Concrete

D4263 Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method

D4397 Specification for Polyethylene Sheeting for Construction, Industrial, and Agricultural Applications

E1155 Test Method for Determining F Floor Flatness and F Floor Levelness Numbers

F L

E1486 Test Method for Determining Floor Tolerances Using Waviness, Wheel Path and Levelness Criteria

E1745 Specification for Plastic Water Vapor Retarders Used in Contact with Soil or Granular Fill under Concrete Slabs

F141 Terminology Relating to Resilient Floor Coverings

F710 Practice for Preparing Concrete Floors to Receive Resilient Flooring

F1869 Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride

F2170 Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes

NOTE 1—Specifications and test methods for cements and other related materials are found in ASTM Volume 04.01. Specifications and test methods

for concretes and related materials are found in ASTM Volume 04.02.

3

2.2 ACI Guides:

302.1R-06 Guide for Concrete Floor and Slab Construction

117R Standard Tolerances for Concrete Construction and Materials

4

2.3 Resilient Floor Covering Institute (RFCI):

Recommended Work Practices for the Removal of Resilient Floor Coverings

1

This practice is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.40 on Practices.

Current edition approved Jan. 1, 2008.May 15, 2011. Published January 2008.June 2011. Originally approved in 1981. Last previous edition approved in 20052008 as

F710–05. DOI: 10.1520/F0710-08. – 08. DOI: 10.1520/F0710-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Concrete Institute, 19150 Redford Station, Detroit, MI 48219.

4

Resilient Floor Covering Institute, 966 Hungerford Drive, Rockville, MD 20850.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F710–11

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.