ASTM F1685-00(2019)

(Specification)Standard Specification for Pressure-Reducing Manifolds for Air or Nitrogen Systems

Standard Specification for Pressure-Reducing Manifolds for Air or Nitrogen Systems

ABSTRACT

This specification covers the design, construction, testing and operating requirements for pressure-reducing manifolds for air or nitrogen systems, which constitute the combination of all components and piping between, and including, the inlet and outlet ports. The manufactured manifolds shall perform satisfactorily to the following procedures: visual examination; hydrostatic shell test; relief-valve lift test; seat tightness test; and external leakage test.

SCOPE

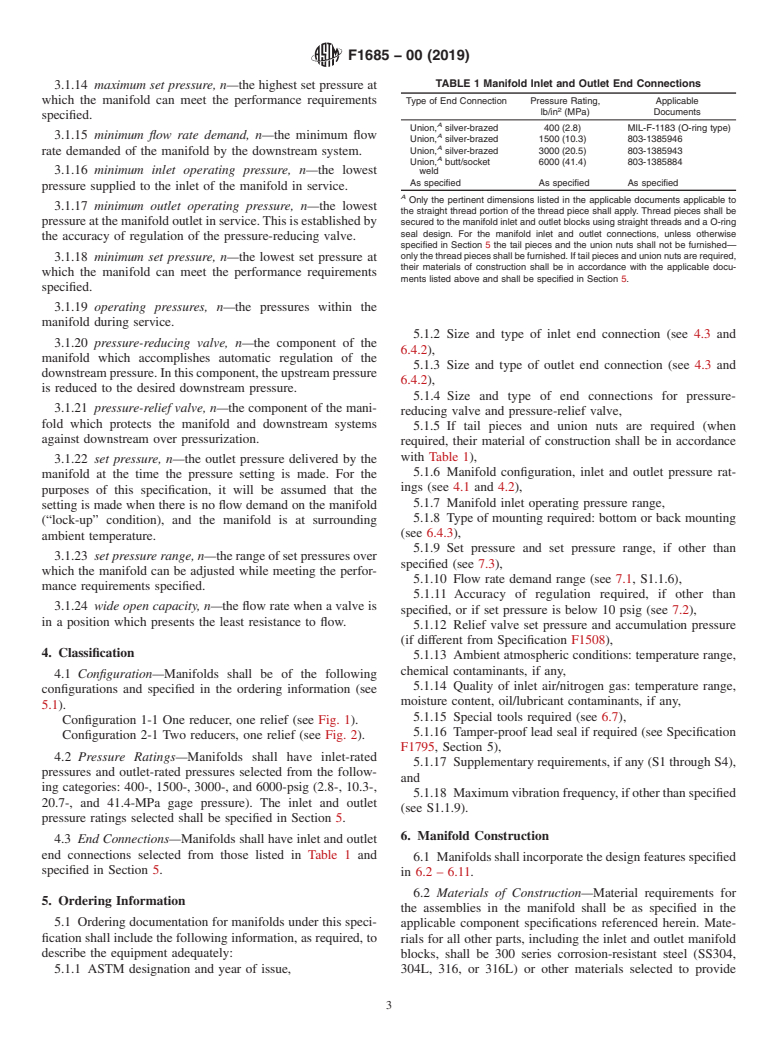

1.1 This specification covers the design, construction, testing and operating requirements for pressure-reducing manifolds for air or nitrogen systems, referred to herein also as manifolds. The term manifold constitutes the combination of all components and piping between, and including, the inlet and outlet ports (see Fig. 1 and Fig. 2).

FIG. 1 Manifold Configuration

FIG. 2 Manifold Configuration

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1685 −00 (Reapproved 2019) An American National Standard

Standard Specification for

1

Pressure-Reducing Manifolds for Air or Nitrogen Systems

This standard is issued under the fixed designation F1685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 Military Standards and Specifications:

MIL-STD-167-1 Mechanical Vibrations of Shipboard

1.1 This specification covers the design, construction, test-

Equipment (Type I—Environmental and Type II— Inter-

ing and operating requirements for pressure-reducing mani-

nally Excited)

folds for air or nitrogen systems, referred to herein also as

MIL-STD-740AirborneandStructureborneNoiseMeasure-

manifolds. The term manifold constitutes the combination of

ments and Acceptance Criteria of Shipboard Equipment

all components and piping between, and including, the inlet

MS16142Boss, Gasket Seal Straight Thread Tube Fitting,

and outlet ports (see Fig. 1 and Fig. 2).

Standard Dimensions for

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

MIL-S-901Shock Tests, H.I. (High-Impact); Shipboard

as standard. The values given in parentheses are mathematical

Machinery, Equipment and Systems, Requirements for

conversions to SI units that are provided for information only

MIL-F-1183Fittings, Pipe, Cast Bronze, Silver-Brazing,

and are not considered standard.

General Specification for

4

1.3 This international standard was developed in accor-

2.4 Government Drawings:

dance with internationally recognized principles on standard-

Naval Sea Systems Command (NAVSEA):

ization established in the Decision on Principles for the

NAVSEA803-1385884Unions, Fittings and Adapters Butt

Development of International Standards, Guides and Recom-

and Socket Welding 6000 PSI, WOG and OXY (IPS)

mendations issued by the World Trade Organization Technical

NAVSEA803-1385943Unions, Silver Brazing 3000 PSI,

Barriers to Trade (TBT) Committee.

WOG, IPS, for UT Inspection

NAVSEA 803-1385946 Unions, Bronze, Silver Brazing,

2. Referenced Documents

WOG for UT Inspection, 1500 PSI, WOG

2

2.1 ASTM Standards:

F992Specification for Valve Label Plates 3. Terminology

F1508Specification forAngle Style, Pressure Relief Valves

3.1 Definitions:

for Steam, Gas, and Liquid Services

3.1.1 accuracy of regulation, n—the amount by which the

F1795Specification for Pressure-ReducingValves forAir or

downstreampressuremayvarywhenthemanifoldissetatany

Nitrogen Systems

pressurewithintherequiredsetpressurerangeandissubjected

3

2.2 ASME Standard:

to any combination of inlet pressure, flow demand, and

B1.1Unified Inch Screw Threads

ambient temperature variations within the specified limits.

3.1.2 bubble-tight, n—no visible leakage over a 5-min

1

This specification is under the jurisdiction ofASTM Committee F25 on Ships

period using either water submersion or the application of

and Marine Technology and is under the direct responsibility of Subcommittee

bubble fluid for detection.

F25.11 on Machinery and Piping Systems.

Current edition approved May 1, 2019. Published June 2019. Originally

3.1.3 external leakage, n—leakagefromthemanifoldwhich

approved in 1996. Last previous edition approved in 2013 as F1685–00 (2013).

escapes to atmosphere.

DOI: 10.1520/F1685-00R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.4 flow rate demand, n—theamountofflowdemandedat

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

any given time by the system downstream of the manifold.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME

4

International Headquarters, Two Park Ave., New York, NY 10016-5990, http:// Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

www.asme.org. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1685 − 00 (2019)

FIG. 1 Manifold Configuration

FIG. 2 Manifold Configuration

3.1.5 flow rate demand range, n—the range over which the including the seats of the outlet stop valve and bypass throttle

flow demand can vary. valve. The outlet pressure rating is applicable from the outlet

side of the seats of the outlet stop valve to the manifold outlet

3.1.6 hydrostatic shell test pressures, n—thehydrostatictest

a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.