ASTM D2809-04

(Test Method)Standard Test Method for Cavitation Corrosion and Erosion-Corrosion Characteristics of Aluminum Pumps With Engine Coolants

Standard Test Method for Cavitation Corrosion and Erosion-Corrosion Characteristics of Aluminum Pumps With Engine Coolants

SCOPE

1.1 This test method covers the evaluation of the cavitation corrosion and erosion-corrosion characteristics of aluminum automotive water pumps with coolants.

Note 1—During the development of this test method, it was found that results obtained when testing two-phase coolants did not correlate with results from field tests. Therefore, the test method cannot be recommended as being a significant test for determining cavitation effects of two-phase coolants.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 5.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2809–04

Standard Test Method for

Cavitation Corrosion and Erosion-Corrosion Characteristics

1

of Aluminum Pumps With Engine Coolants

This standard is issued under the fixed designation D 2809; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

A,B

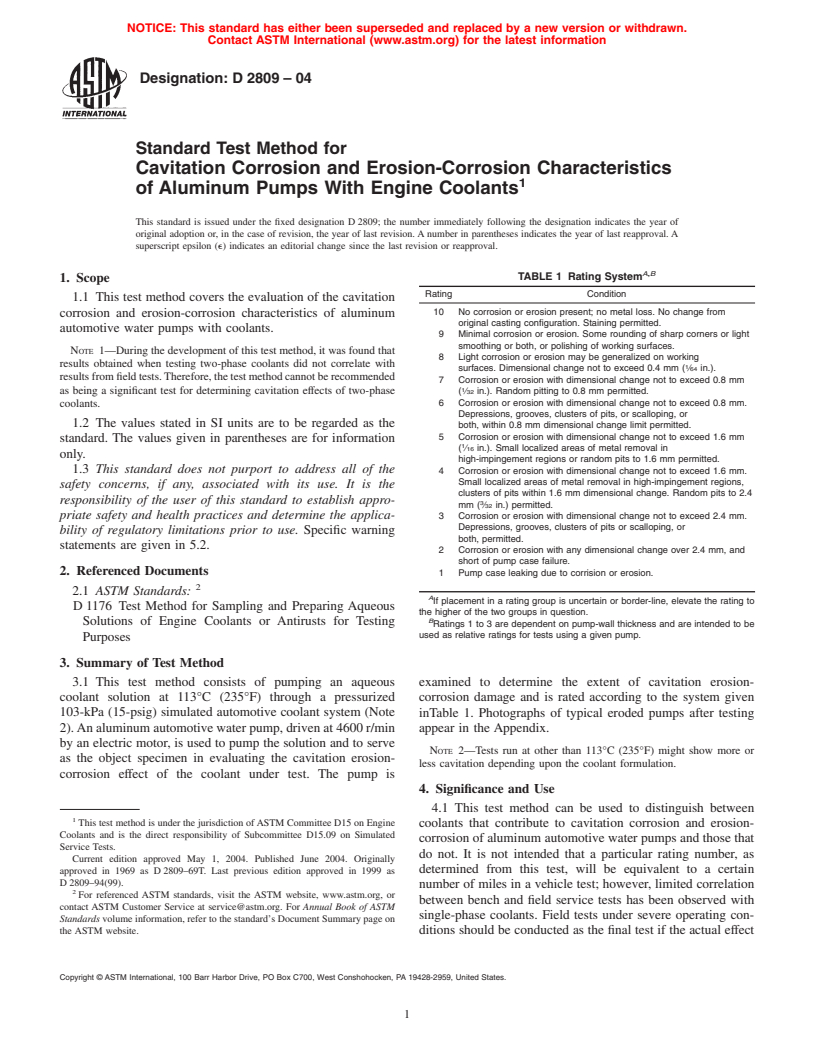

TABLE 1 Rating System

1. Scope

Rating Condition

1.1 This test method covers the evaluation of the cavitation

10 No corrosion or erosion present; no metal loss. No change from

corrosion and erosion-corrosion characteristics of aluminum

original casting configuration. Staining permitted.

automotive water pumps with coolants.

9 Minimal corrosion or erosion. Some rounding of sharp corners or light

smoothing or both, or polishing of working surfaces.

NOTE 1—During the development of this test method, it was found that

8 Light corrosion or erosion may be generalized on working

results obtained when testing two-phase coolants did not correlate with

1

surfaces. Dimensional change not to exceed 0.4 mm ( ⁄64 in.).

resultsfromfieldtests.Therefore,thetestmethodcannotberecommended

7 Corrosion or erosion with dimensional change not to exceed 0.8 mm

1

as being a significant test for determining cavitation effects of two-phase ( ⁄32 in.). Random pitting to 0.8 mm permitted.

6 Corrosion or erosion with dimensional change not to exceed 0.8 mm.

coolants.

Depressions, grooves, clusters of pits, or scalloping, or

1.2 The values stated in SI units are to be regarded as the

both, within 0.8 mm dimensional change limit permitted.

5 Corrosion or erosion with dimensional change not to exceed 1.6 mm

standard. The values given in parentheses are for information

1

( ⁄16 in.). Small localized areas of metal removal in

only.

high-impingement regions or random pits to 1.6 mm permitted.

1.3 This standard does not purport to address all of the

4 Corrosion or erosion with dimensional change not to exceed 1.6 mm.

Small localized areas of metal removal in high-impingement regions,

safety concerns, if any, associated with its use. It is the

clusters of pits within 1.6 mm dimensional change. Random pits to 2.4

responsibility of the user of this standard to establish appro-

3

mm ( ⁄32 in.) permitted.

priate safety and health practices and determine the applica- 3 Corrosion or erosion with dimensional change not to exceed 2.4 mm.

Depressions, grooves, clusters of pits or scalloping, or

bility of regulatory limitations prior to use. Specific warning

both, permitted.

statements are given in 5.2.

2 Corrosion or erosion with any dimensional change over 2.4 mm, and

short of pump case failure.

2. Referenced Documents 1 Pump case leaking due to corrision or erosion.

2

2.1 ASTM Standards:

A

If placement in a rating group is uncertain or border-line, elevate the rating to

D 1176 Test Method for Sampling and Preparing Aqueous

the higher of the two groups in question.

B

Solutions of Engine Coolants or Antirusts for Testing

Ratings 1 to 3 are dependent on pump-wall thickness and are intended to be

used as relative ratings for tests using a given pump.

Purposes

3. Summary of Test Method

3.1 This test method consists of pumping an aqueous examined to determine the extent of cavitation erosion-

coolant solution at 113°C (235°F) through a pressurized

corrosion damage and is rated according to the system given

103-kPa (15-psig) simulated automotive coolant system (Note inTable 1. Photographs of typical eroded pumps after testing

2).An aluminum automotive water pump, driven at 4600 r/min

appear in the Appendix.

by an electric motor, is used to pump the solution and to serve

NOTE 2—Tests run at other than 113°C (235°F) might show more or

as the object specimen in evaluating the cavitation erosion-

less cavitation depending upon the coolant formulation.

corrosion effect of the coolant under test. The pump is

4. Significance and Use

4.1 This test method can be used to distinguish between

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

coolants that contribute to cavitation corrosion and erosion-

Coolants and is the direct responsibility of Subcommittee D15.09 on Simulated

corrosion of aluminum automotive water pumps and those that

Service Tests.

do not. It is not intended that a particular rating number, as

Current edition approved May 1, 2004. Published June 2004. Originally

determined from this test, will be equivalent to a certain

approved in 1969 as D 2809–69T. Last previous edition approved in 1999 as

D 2809–94(99).

number of miles in a vehicle test; however, limited correlation

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

between bench and field serv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.