ASTM E967-03

(Practice)Standard Practice for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

Standard Practice for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

SIGNIFICANCE AND USE

Differential scanning calorimeters and differential thermal analyzers are used to determine the transition temperatures of materials. For this information to be meaningful in an absolute sense, temperature calibration of the apparatus or comparison of the resulting data to that of known standard materials is required.

This test method is useful in calibrating the temperature axis of differential scanning calorimeters and differential thermal analyzers.

SCOPE

1.1 This test method describes the temperature calibration of differential thermal analyzers and differential scanning calorimeters over the temperature range from -40 to +2500°C.

1.2 Computer or electronic based instruments, techniques, or data manipulation equivalent to this test method may also be used.

1.3 SI units are the standard.

1.4 This test method is similar to ISO standard 11357-1.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E967–03

Standard Test Method for

Temperature Calibration of Differential Scanning

1

Calorimeters and Differential Thermal Analyzers

This standard is issued under the fixed designation E967; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

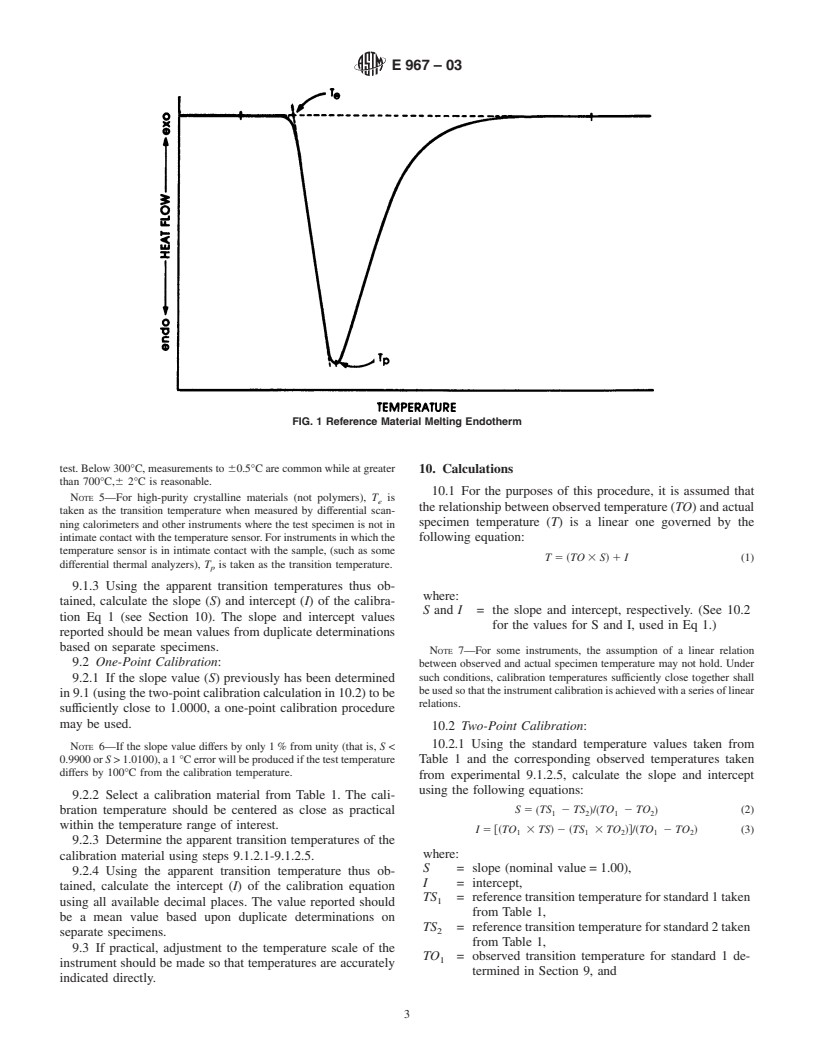

1.1 This test method describes the temperature calibration 4.1 This test method consists of heating the calibration

of differential thermal analyzers and differential scanning materials at a controlled rate in a controlled atmosphere

calorimeters over the temperature range from−40 to+2500°C. through a region of known thermal transition. The heat flow

1.2 Computer or electronic based instruments, techniques, into the calibration material or the difference of temperature

ordatamanipulationequivalenttothistestmethodmayalsobe between the calibration material and a reference sample and a

used. reference material is monitored and continuously recorded. A

1.3 SI units are the standard. transition is marked by the absorption of energy by the

1.4 This test method is similar to ISO standard 11357–1. specimenresultinginacorrespondingendothermicpeakinthe

1.5 This standard does not purport to address all of the heating curve.

safety concerns, if any, associated with its use. It is the

NOTE 1—Heat flow calibrations are sometimes determined in conjunc-

responsibility of the user of this standard to establish appro-

tion with temperature calibration. Some differential scanning calorimeters

priate safety and health practices and determine the applica-

permitbothheatflowandtemperaturecalibrationstobeobtainedfromthe

bility of regulatory limitations prior to use. Specific precau-

same experimental procedure.

tionary statements are given in Section 7.

5. Significance and Use

2. Referenced Documents

5.1 Differential scanning calorimeters and differential ther-

2.1 ASTM Standards: malanalyzersareusedtodeterminethetransitiontemperatures

2

E473 Terminology Relating to Thermal Analysis of materials. For this information to be meaningful in an

E968 Practice for Heat Flow Calibration of Differential absolute sense, temperature calibration of the apparatus or

2

Scanning Calorimeters comparison of the resulting data to that of known standard

E1142 Terminology Relating to Thermophysical Proper- materials is required.

2

ties 5.2 This test method is useful in calibrating the temperature

E1953 Practice for Description of ThermalAnalysisAppa- axis of differential scanning calorimeters and differential ther-

3

ratus mal analyzers.

2.2 ISO Standard:

6. Apparatus

11357–1 Plastics-Differential Scanning Calorimetry (DSC)-

Part 1: General Principles 6.1 Apparatus shall be of either type listed below:

6.1.1 Differential Scanning Calorimeter (DSC), capable of

3. Terminology

heatingatestspecimenandareferencematerialatacontrolled

3.1 Specific technical terms used in this test method are rate and of automatically recording the differential heat flow

defined in Terminologies E473 and E1142. between the sample and the reference material to the required

sensitivity and precision.

6.1.1.1 A Furnace(s), to provide uniform controlled heating

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

or cooling of a specimen and reference to a constant tempera-

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

ture or at a constant rate within the applicable temperature

Methods and Practices.

Current edition approved March 10, 2003. PublishedApril 20038. Originallyap-

range of this test method.

proved in 1983. Last previous edition approved in 1997 as E967–97.

6.1.1.2 A Temperature Sensor, to provide an indication of

2

Annual Book of ASTM Standards, Vol 14.02.

3 the specimen temperature.

Available form American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E967–03

TABLE 1 Melting Temperature of Calibration Material

6.1.1.3 Differential sensors, to detect a heat flow (power)

difference between the specimen and reference.

NOTE 1—The values in Table 1 were determined under special, highly

6.1.1.4 Test Chamber Environment—a means of sustaining

accurate steady state conditions that are not attainable or applicable to

atestchamberenvironmentofnitrogenorotherinertpurgegas thermal analysis techniques. The actual precision of this test method is

given in Section 12 of this test method.

at a purge rate of 10 to 50 mL/min.

A

6.1.1.5 A Temperature Control

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.