ASTM A666-00

(Specification)Standard Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar

Standard Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar

SCOPE

1.1 This specification covers austenitic stainless steels in the annealed and normally required cold-worked conditions for various structural, architectural, pressure vessel, magnetic, cryogenic, and heat-resisting applications. (This revision of Specification A 666 replaces prior Specifications A 412 and A 177.)

1.2 The application of this specification, or the use of material covered by this specification does not automatically allow usage in pressure vessel applications. Only annealed conditions of grades specifically approved by the ASME code are permitted for pressure vessel use.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 666 – 00

Standard Specification for

Annealed or Cold-Worked Austenitic Stainless Steel Sheet,

Strip, Plate, and Flat Bar

This standard is issued under the fixed designation A 666; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Chemical Composition

1.1 This specification covers austenitic stainless steels in the 4.1 The steel shall conform to the requirements as to

annealed and normally required cold-worked conditions for chemical composition specified in Table 1, and shall conform

various structural, architectural, pressure vessel, magnetic, to applicable requirements specified in the current edition of

cryogenic, and heat-resisting applications. (This revision of Specification A 480/A 480M.

Specification A 666 replaces prior Specifications A 412 and

5. Mechanical Properties

A 177.)

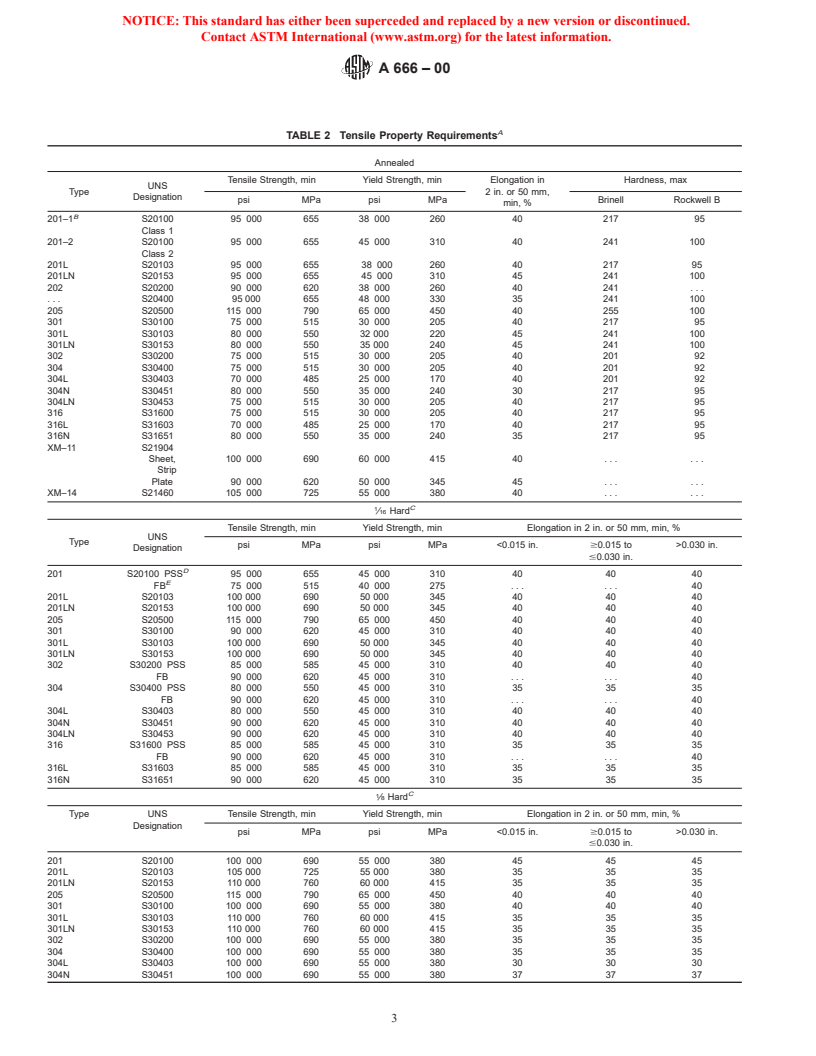

5.1 The material shall conform to the mechanical properties

1.2 The application of this specification, or the use of

material covered by this specification does not automatically specified in Table 2 and Table 3, or Table 2 and Table 4.

allow usage in pressure vessel applications. Only annealed

6. General Requirements

conditions of grades specifically approved by the ASME code

6.1 The following requirements for orders for material

are permitted for pressure vessel use.

furnished under this specification shall conform to the appli-

1.3 The values stated in inch-pound units are to be regarded

cable requirements of the current edition of Specification

as the standard. The values given in parentheses are for

A 480/A 480M or A484/A 484M:

information only.

6.1.1 Definitions,

2. Referenced Documents

6.1.2 General requirements for delivery,

2.1 ASTM Standards: 6.1.3 Ordering information,

6.1.4 Process,

A 240/A 240M Specification for Heat-Resisting Chromium

and Chromium-Nickel Stainless Steel Plate, Sheet, and 6.1.5 Special tests,

6.1.6 Heat treatment,

Strip for Pressure Vessels

A 370 Test Methods and Definitions for Mechanical Testing 6.1.7 Dimensions and permissible variations,

6.1.8 Workmanship, finish and appearance,

of Steel Products

6.1.9 Number of tests/test methods,

A 480/A 480M Specification for General Requirements for

Flat-Rolled Stainless and Heat-Resisting Steel Plate, 6.1.10 Specimen preparation,

6.1.11 Retreatment,

Sheet, and Strip

A 484/A 484M Specification for General Requirements for 6.1.12 Inspection,

6.1.13 Rejection and rehearing,

Stainless and Heat-Resisting Steel Bars, Billets, and Forg-

ings 6.1.14 Material test report,

6.1.15 Certification, and

3. Material Test Report and Certification

6.1.16 Packaging, marking, and loading.

3.1 In addition to the requirements of Specification A 480/

7. Sampling

1 1

A 480M, the cold-worked condition (annealed, ⁄4H, ⁄2H, and

so forth) shall be noted. 7.1 Tension and bend-test specimens of sheet, strip, and

plate products shall be selected from finished material and shall

be selected in the transverse direction, except in the case of

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

strip under 9 in. (229 mm) in width, in which case tension test

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

specimens shall be selected in the longitudinal direction.

A01.17 on Flat Stainless Steel Products.

Current edition approved March 10, 2000. Published May 2000. Originally

published as A 666 – 72. Last previous edition A 666 – 99.

Annual Book of ASTM Standards, Vol 01.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 666–00

7.2 Flat bar tension and bend-test specimens shall be se-

75 000 0.0098

110 000 0.0125

lected from the finished material and shall be in the longitudi-

135 000 0.0144

nal direction.

140 000 0.0148

7.3 Corrosion samples, if required, shall be taken from

9.1.2 The requirement of this specification for yield strength

material after final annealing and descaling and prior to cold

will be considered as having been fulfilled if the extension

working.

under load for the specified yield strength does not exceed the

8. Number of Tests specified values. The values obtained in this manner should

not, however, be taken as the actual yield strength for 0.2 %. In

8.1 For cold-worked product produced in coil form, one

case of dispute, the offset method of determining yield strength

tension test shall be made from each end of each coil. One bend

shall be used.

test shall be made from one end of each coil.

9.2 Bend Test:

8.2 For cold-worked flat bar and plate products, two tension

9.2.1 Bend-test specimens shall withstand cold bending

test and one bend test shall be made on each size of flat bar and

without cracking when subjected to either the free-bend

each thickness of plate from each heat in a lot annealed in a

method or the controlled-bend (V-block) method at the condi-

single charge or under the same conditions in a continuous

tion specified by Table 3 or Table 4, respectively. Specimens

furnace.

shall be bent around a diameter equal to the product of the bend

8.3 Annealed material produced to Table 2 requirements

factor times the specified thickness of the test specimen. The

shall be tested in accordance with Specification A 480/

choice of test method for materials in conditions other than

A 480M.

annealed shall be at the option of the seller.

9. Test Methods

9.2.2 Free-bend test specimens shall be bent cold, either by

pressure or by blows. However, in the case of dispute, tests

9.1 Tension Test:

shall be made by pressure.

9.1.1 The yield strength shall be determined by the offset

9.2.3 Controlled-bend (V-block) test specimens shall be

method as described in Test Methods and Definitions A 370.

bent cold by means of V-blocks or a mating punch and die

An alternative method of determining field strength may be

having an included angle of 45° and with proper curvature of

used based on the following total extension under load:

surface at the bend areas to impart the desired shape and

Yield Strength, min. psi Total Extension under Load in 2 in.

Gage Length, incl. diameter of bend to the specimen.

45 000 0.0071

A

TABLE 1 Chemical Composition Requirements

B

Type UNS Composition, %

Designation

Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Other

Elements

201 S20100 0.15 5.5–7.5 0.060 0.030 0.75 16.0–18.0 3.5–5.5 N 0.25

201L S20103 0.03 5.5–7.5 0.045 0.030 0.75 16.0–18.0 3.5–5.5 N 0.25

201LN S20153 0.03 6.4–7.5 0.045 0.015 0.75 16.0–17.5 4.0–5.0 N 0.10–0.25

Cu 1.00

202 S20200 0.15 7.5–10.0 0.060 0.030 0.75 17.0–19.0 4.0–6.0 N 0.25

. . . S20400 0.030 7.0–9.0 0.040 0.030 1.00 15.0–17.0 1.50–3.00 N 0.15–0.30

205 S20500 0.12–0.25 14.0–15.0 0.060 0.030 0.75 16.5–18.0 1.00–1.75 N 0.32–0.40

301 S30100 0.15 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 N 0.10

301L S30103 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 N 0.20

301LN S30153 0.03 2.00 0.045 0.030 1.00 16.0–18.0 6.0–8.0 N 0.07–0.20

302 S30200 0.15 2.00 0.045 0.030 0.75 17.0–19.0 8.0–10.0

304 S30400 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 N 0.10

304L S30403 0.030 2.00 0.045 0.030 0.75 18.0–20.0 8.0–12.0 N 0.10

304N S30451 0.08 2.00 0.045 0.030 0.75 18.0–20.0 8.0–10.5 N 0.10–0.16

304LN S30453 0.030 2.00 0.045 0.030 0.75 18.0–20.0 8.0–12.0 N 0.10–0.16

316 S31600 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 Mo 2.00–3.00

316L S31603 0.030 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 Mo 2.00–3.00

316N S31651 0.08 2.00 0.045 0.030 0.75 16.0–18.0 10.0–14.0 Mo 2.00–3.00

N 0.10–0.16

XM–11 S21904 0.04 8.0–10.0 0.060 0.030 0.75 19.0–21.5 5.5–7.5 N 0.15–0.40

XM–14 S21460 0.12 14.0–16.0 0.060 0.030 0.75 17.0–19.0 5.0–6.0 N 0.35–0.50

A

Types XM–10 and XM–19, which appeared in Specification A 412, do not appear as XM–10 is no longer produced and XM–19 is covered in Specification A 240/A

240M.

B

Maximum unless otherwise indicated.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 666–00

A

TABLE 2 Tensile Property Requirements

Annealed

Tensile Strength, min Yield Strength, min Elongation in Hardness, max

UNS

Type 2 in. or 50 mm,

Designation

psi MPa psi MPa Brinell Rockwell B

min, %

B

201–1 S20100 95 000 655 38 000 260 40 217 95

Class 1

201–2 S20100 95 000 655 45 000 310 40 241 100

Class 2

201L S20103 95 000 655 38 000 260 40 217 95

201LN S20153 95 000 655 45 000 310 45 241 100

202 S20200 90 000 620 38 000 260 40 241 . . .

. . . S20400 95 000 655 48 000 330 35 241 100

205 S20500 115 000 790 65 000 450 40 255 100

301 S30100 75 000 515 30 000 205 40 217 95

301L S30103 80 000 550 32 000 220 45 241 100

301LN S30153 80 000 550 35 000 240 45 241 100

302 S30200 75 000 515 30 000 205 40 201 92

304 S30400 75 000 515 30 000 205 40 201 92

304L S30403 70 000 485 25 000 170 40 201 92

304N S30451 80 000 550 35 000 240 30 217 95

304LN S30453 75 000 515 30 000 205 40 217 95

316 S31600 75 000 515 30 000 205 40 217 95

316L S31603 70 000 485 25 000 170 40 217 95

316N S31651 80 000 550 35 000 240 35 217 95

XM–11 S21904

Sheet, 100 000 690 60 000 415 40 . . . . . .

Strip

Plate 90 000 620 50 000 345 45 . . . . . .

XM–14 S21460 105 000 725 55 000 380 40 . . . . . .

C

⁄16 Hard

Tensile Strength, min Yield Strength, min Elongation in 2 in. or 50 mm, min, %

UNS

Type

psi MPa psi MPa <0.015 in. $0.015 to >0.030 in.

Designation

#0.030 in.

D

201 S20100 PSS 95 000 655 45 000 310 40 40 40

E

FB 75 000 515 40 000 275 . . . . . . 40

201L S20103 100 000 690 50 000 345 40 40 40

201LN S20153 100 000 690 50 000 345 40 40 40

205 S20500 115 000 790 65 000 450 40 40 40

301 S30100 90 000 620 45 000 310 40 40 40

301L S30103 100 000 690 50 000 345 40 40 40

301LN S30153 100 000 690 50 000 345 40 40 40

302 S30200 PSS 85 000 585 45 000 310 40 40 40

FB 90 000 620 45 000 310 . . . . . . 40

304 S30400 PSS 80 000 550 45 000 310 35 35 35

FB 90 000 620 45 000 310 . . . . . . 40

304L S30403 80 000 550 45 000 310 40 40 40

304N S30451 90 000 620 45 000 310 40 40 40

304LN S30453 90 000 620 45 000 310 40 40 40

316 S31600 PSS 85 000 585 45 000 310 35 35 35

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.