ASTM A684/A684M-08

(Specification)Standard Specification for Steel, Strip, High-Carbon, Cold-Rolled

Standard Specification for Steel, Strip, High-Carbon, Cold-Rolled

ABSTRACT

This specification covers cold-rolled, high-carbon strip. The strip shall be furnished cold rolled spheroidized annealed, soft annealed, intermediate hardness, or full hard, as specified. The heat or cast analysis shall conform to that specified requirement. Hardness test and bend test shall be made to conform to the requirements specified.

SCOPE

1.1 This specification covers cold-rolled, high-carbon strip in coils or cut lengths. Strip is classified as product that is 0.3000 in. [7.6 mm] or less in thickness and over ½ to 2315/16 in. [12.5 to 600 mm] in width, inclusive. Strip tolerance products may be available in widths wider than 2315/16 in. (600 mm) by agreement between purchaser and supplier; however, such products are technically classified as cold-rolled sheet. The maximum of the specified carbon range is over 0.25 to 1.35 %, inclusive. It is furnished in the following types as specified:

1.1.1 Soft spheroidized annealed high-carbon steel is intended for applications requiring maximum cold forming. It is normally produced to give the lowest maximum Rockwell hardness for each grade.

1.1.2 Soft annealed high-carbon steel is intended for applications requiring moderate cold forming. It is produced to a maximum Rockwell hardness.

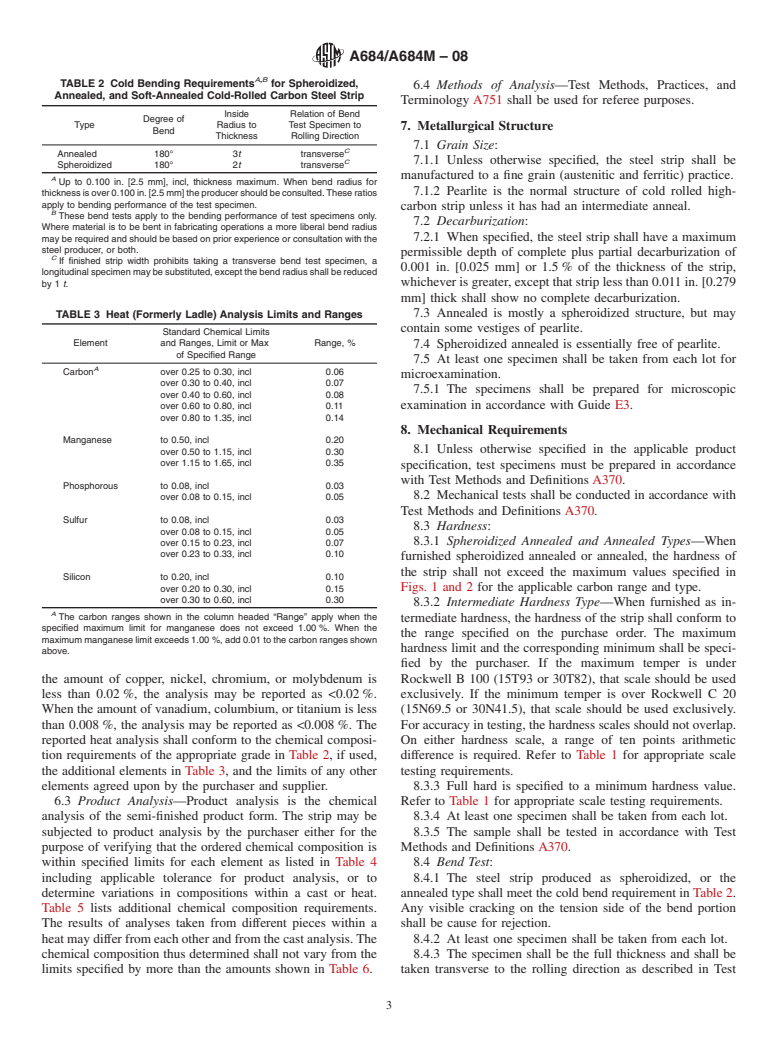

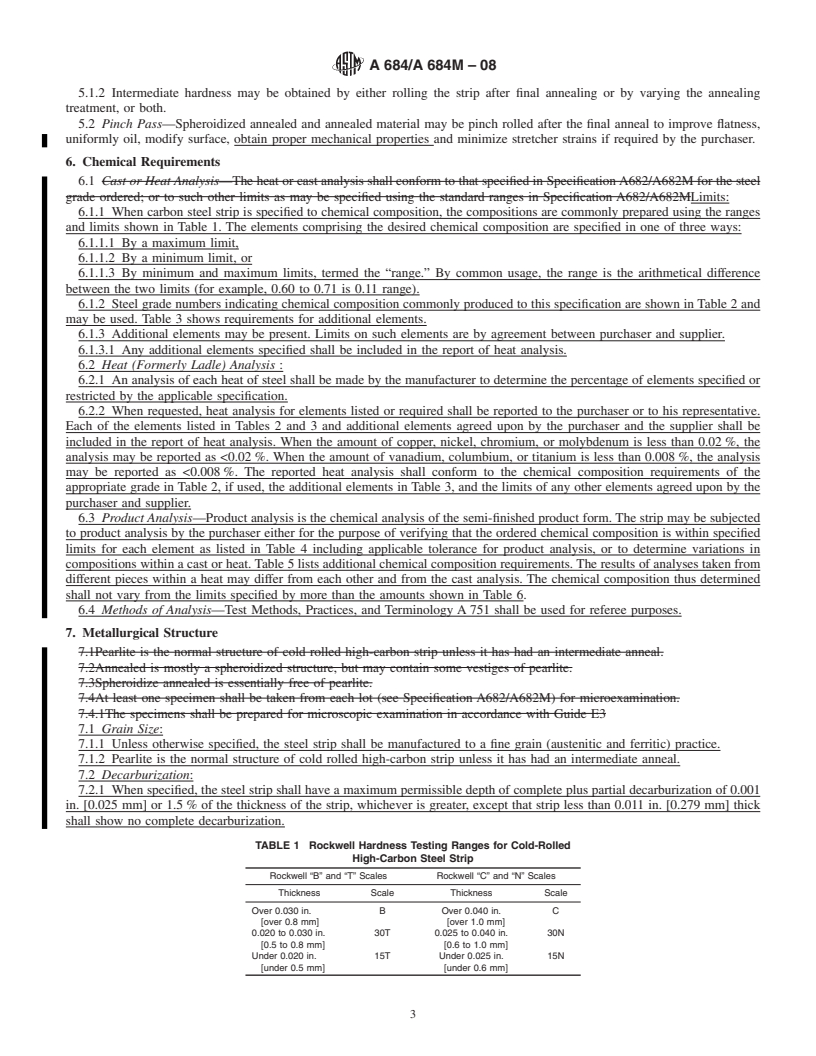

1.1.3 Intermediate hardness high-carbon steel is intended for applications where cold forming is slight or a stiff, springy product is needed, or both. It is produced to specified Rockwell hardness ranges, the maximum being higher than obtained for the annealed type.

1.1.4 Full hard high-carbon steel is intended for flat applications. It is produced to minimum Rockwell hardness requirements, which vary with grade, microstructure and gauge. Full hard can be produced with either a pearlitic or spheroidized microstructure or a mixture of both. The minimum hardness should be established between the consumer and the producer.

1.2 This specification is applicable for orders in either inch-pound units or SI units.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 The tolerances in this specification are different than those in Specification A 568/A 568M and Specification A 109/A 109M.

1.5 For the purpose of determining conformance with this specification, values shall be rounded to the nearest unit in the right hand place of figures used in expressing the limiting values in accordance with the rounding method of Practice E 29.

1.6 This specification is expressed in both inch-pound units and SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units. The metric portions of the tables herein list permissible variations in dimensions and mass (see Note 1) in SI (metric) units. The values listed are not exact conversions of the values listed in the inch-pound tables but instead are rounded or rationalized values. Conformance to SI tolerances is mandatory when the “M” specification is used.

Note 1—The term weight is used when inch-pound units are the standard. However, under SI the preferred term is mass. ^REFERENCE:

ASTM Standards:

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A684/A684M – 08

Standard Specification for

1

Steel, Strip, High-Carbon, Cold-Rolled

This standard is issued under the fixed designationA684/A684M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.4 The tolerances in this specification are different than

those in Specification A568/A568M and Specification A109/

1.1 This specification covers cold-rolled, high-carbon strip

A109M.

in coils or cut lengths. Strip is classified as product that is

1.5 For the purpose of determining conformance with this

1 15

0.3000 in. [7.6 mm] or less in thickness and over ⁄2 to 23 ⁄16

specification, values shall be rounded to the nearest unit in the

in. [12.5 to 600 mm] in width, inclusive. Strip tolerance

right hand place of figures used in expressing the limiting

15

products may be available in widths wider than 23 ⁄16 in. (600

values in accordance with the rounding method of Practice

mm) by agreement between purchaser and supplier; however,

E29.

such products are technically classified as cold-rolled sheet.

1.6 This specification is expressed in both inch-pound units

The maximum of the specified carbon range is over 0.25 to

and SI units. However, unless the order specifies the applicable

1.35 %, inclusive. It is furnished in the following types as

“M” specification designation (SI units), the material shall be

specified:

furnished to inch-pound units.The metric portions of the tables

1.1.1 Soft spheroidized annealed high-carbon steel is in-

herein list permissible variations in dimensions and mass (see

tended for applications requiring maximum cold forming. It is

Note 1) in SI (metric) units. The values listed are not exact

normally produced to give the lowest maximum Rockwell

conversions of the values listed in the inch-pound tables but

hardness for each grade.

instead are rounded or rationalized values. Conformance to SI

1.1.2 Soft annealed high-carbon steel is intended for appli-

tolerances is mandatory when the “M” specification is used.

cations requiring moderate cold forming. It is produced to a

maximum Rockwell hardness.

NOTE 1—The term weight is used when inch-pound units are the

1.1.3 Intermediate hardness high-carbon steel is intended

standard. However, under SI the preferred term is mass.

for applications where cold forming is slight or a stiff, springy

2. Referenced Documents

product is needed, or both. It is produced to specified Rockwell

2

2.1 ASTM Standards:

hardness ranges, the maximum being higher than obtained for

the annealed type. A109/A109M Specification for Steel, Strip, Carbon (0.25

Maximum Percent), Cold-Rolled

1.1.4 Full hard high-carbon steel is intended for flat appli-

cations. It is produced to minimum Rockwell hardness require- A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

ments, which vary with grade, microstructure and gauge. Full

hard can be produced with either a pearlitic or spheroidized A568/A568M Specification for Steel, Sheet, Carbon, Struc-

tural, and High-Strength, Low-Alloy, Hot-Rolled and

microstructure or a mixture of both. The minimum hardness

should be established between the consumer and the producer. Cold-Rolled, General Requirements for

A700 PracticesforPackaging,Marking,andLoadingMeth-

1.2 This specification is applicable for orders in either

inch-pound units or SI units. ods for Steel Products for Shipment

A751 Test Methods, Practices, andTerminology for Chemi-

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in cal Analysis of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Re-

each system may not be exact equivalents; therefore, each

lated Alloys, and Ferroalloys

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance E3 Guide for Preparation of Metallographic Specimens

E29 Practice for Using Significant Digits in Test Data to

with the standard.

Determine Conformance with Specifications

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

2

A01.19 on Steel Sheet and Strip.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2008. Published October 2008. Originally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1973. Last previous edition approved in 2006 as A684/A684M – 06.

Standards volume information, refe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A684/A684M–06 Designation: A 684/A 684M – 08

Standard Specification for

1

Steel, Strip, High-Carbon, Cold-Rolled

This standard is issued under the fixed designationA 684/A 684M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1This specification covers cold-rolled, high-carbon strip. It is furnished in the following types as specified: *

1.1 This specification covers cold-rolled, high-carbon strip in coils or cut lengths. Strip is classified as product that is 0.3000

1 15

in. [7.6 mm] or less in thickness and over ⁄2 to 23 ⁄16 in. [12.5 to 600 mm] in width, inclusive. Strip tolerance products may be

15

available in widths wider than 23 ⁄16 in. (600 mm) by agreement between purchaser and supplier; however, such products are

technically classified as cold-rolled sheet. The maximum of the specified carbon range is over 0.25 to 1.35 %, inclusive. It is

furnished in the following types as specified:

1.1.1 Soft spheroidized annealed high-carbon steel is intended for applications requiring maximum cold forming. It is normally

produced to give the lowest maximum Rockwell hardness for each grade.

1.1.2 Softannealedhigh-carbonsteelisintendedforapplicationsrequiringmoderatecoldforming.Itisproducedtoamaximum

Rockwell hardness.

1.1.3 Intermediate hardness high-carbon steel is intended for applications where cold forming is slight or a stiff, springy product

is needed, or both. It is produced to specified Rockwell hardness ranges, the maximum being higher than obtained for the annealed

type.

1.1.4 Full hard high-carbon steel is intended for flat applications. It is produced to minimum Rockwell hardness requirements,

which vary with grade, microstructure and gauge. Full hard can be produced with either a pearlitic or spheroidized microstructure

or a mixture of both. The minimum hardness should be established between the consumer and the producer.

1.2 This specification is applicable for orders in either inch-pound units or SI units.

1.3

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 ThetolerancesinthisspecificationaredifferentthanthoseinSpecificationA 568/A 568MandSpecificationA 109/A 109M.

1.5 For the purpose of determining conformance with this specification, values shall be rounded to the nearest unit in the right

hand place of figures used in expressing the limiting values in accordance with the rounding method of Practice E 29.

1.6 Thisspecificationisexpressedinbothinch-poundunitsandSIunits.However,unlesstheorderspecifiestheapplicable“M”

specification designation (SI units), the material shall be furnished to inch-pound units. The metric portions of the tables herein

list permissible variations in dimensions and mass (see Note 1) in SI (metric) units. The values listed are not exact conversions

of the values listed in the inch-pound tables but instead are rounded or rationalized values. Conformance to SI tolerances is

mandatory when the “M” specification is used.

NOTE 1—The term weight is used when inch-pound units are the standard. However, under SI the preferred term is mass.

2. Referenced Documents

2

2.1 ASTM Standards:

A 109/A 109M Specification for Steel, Strip, Carbon (0.25 Maximum Percent), Cold-Rolled

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A682/A682MSpecification for Steel, Strip, High-Carbon, Cold-Rolled, General Requirements For 568/A 568M Specification

for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements for

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys,Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip.

Current edition approved Oct. 1, 2006.2008. Published October 2006.2008. Originally approved in 1973. Last previous edition approved in 20022006 asA684/A684M–86

(2002). A 684/A 684M – 06.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Cust

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.