ASTM C457-08c

(Test Method)Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete

Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete

SIGNIFICANCE AND USE

The parameters of the air-void system of hardened concrete determined by the procedures described in this test method are related to the susceptibility of the cement paste portion of the concrete to damage by freezing and thawing. Hence, this test method can be used to develop data to estimate the likelihood of damage due to cyclic freezing and thawing or to explain why it has occurred. The test method can also be used as an adjunct to the development of products or procedures intended to enhance the resistance of concrete to cyclic freezing and thawing (1).

Values for parameters of the air-void system can be obtained by either of the procedures described in this test method.

No provision is made for distinguishing among entrapped air voids, entrained air voids, and water voids. Any such distinction is arbitrary, because the various types of voids intergrade in size, shape, and other characteristics. Reports that do make such a distinction typically define entrapped air voids as being larger than 1 mm in at least one dimension being irregular in shape, or both. The honey-combing that is a consequence of the failure to compact the concrete properly is one type of entrapped air void (9, 10).

Water voids are cavities that were filled with water at the time of setting of the concrete. They are significant only in mixtures that contained excessive mixing water or in which pronounced bleeding and settlement occurred. They are most common beneath horizontal reinforcing bars, pieces of coarse aggregate and as channelways along their sides. They occur also immediately below surfaces that were compacted by finishing operations before the completion of bleeding.

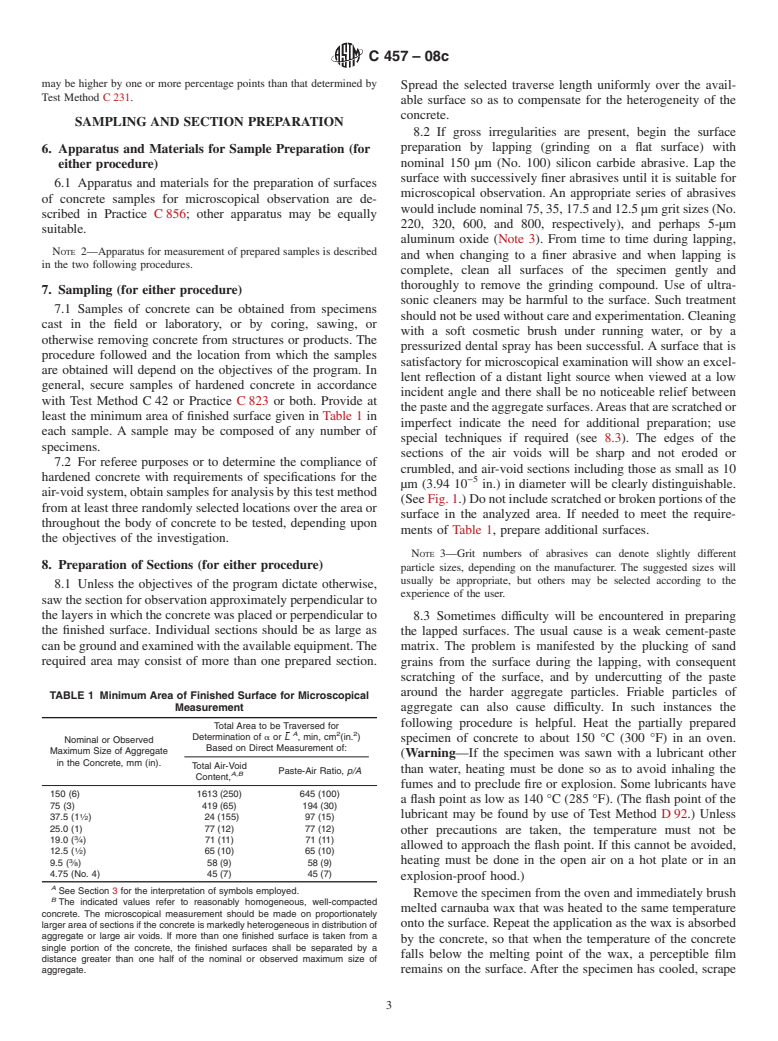

Application of the paste-air ratio procedure is necessary when the concrete includes large nominal maximum size aggregate, such as 50 mm (2 in.) or more. Prepared sections of such concrete should include a maximum of the mortar fraction, so as to increase the number of counts on air voids or traverse across...

SCOPE

1.1 This test method describes procedures for microscopical determinations of the air content of hardened concrete and of the specific surface, void frequency, spacing factor, and paste-air ratio of the air-void system in hardened concrete (1). Two procedures are described:

1.1.1 Procedure A,

the linear-traverse method (2, 3).

1.1.2 Procedure B,

the modified point-count method (3, 4, 5, 6).

1.2 This test method is based on prescribed procedures that are applied to sawed and lapped sections of specimens of concrete from the field or laboratory.

1.3 It is intended to outline the principles of this test method and to establish standards for its adequate performance but not to describe in detail all the possible variations that might be used to accomplish the objectives of this test method.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see 8.3 and 10.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 457 – 08c

Standard Test Method for

Microscopical Determination of Parameters of the Air-Void

1

System in Hardened Concrete

This standard is issued under the fixed designation C 457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* C173/C173M Test Method for Air Content of Freshly

Mixed Concrete by the Volumetric Method

1.1 Thistestmethoddescribesproceduresformicroscopical

C231 Test Method for Air Content of Freshly Mixed

determinations of the air content of hardened concrete and of

Concrete by the Pressure Method

the specific surface, void frequency, spacing factor, and paste-

2

C666/C666M Test Method for Resistance of Concrete to

air ratio of the air-void system in hardened concrete (1). Two

Rapid Freezing and Thawing

procedures are described:

C670 Practice for Preparing Precision and Bias Statements

1.1.1 Procedure A, the linear-traverse method (2, 3).

for Test Methods for Construction Materials

1.1.2 ProcedureB,themodifiedpoint-countmethod(3,4,5,

C672/C672M Test Method for Scaling Resistance of Con-

6).

crete Surfaces Exposed to Deicing Chemicals

1.2 This test method is based on prescribed procedures that

C823 Practice for Examination and Sampling of Hardened

are applied to sawed and lapped sections of specimens of

Concrete in Constructions

concrete from the field or laboratory.

C856 Practice for Petrographic Examination of Hardened

1.3 Itisintendedtooutlinetheprinciplesofthistestmethod

Concrete

and to establish standards for its adequate performance but not

D92 Test Method for Flash and Fire Points by Cleveland

to describe in detail all the possible variations that might be

Open Cup Tester

used to accomplish the objectives of this test method.

2.2 American Concrete Institute Standards:

1.4 The values stated in SI units are to be regarded as

4

201.2R Guide to Durable Concrete

standard. The values given in parentheses are mathematical

211.1 Recommended Practice for Selecting Proportions for

conversions to inch-pound units that are provided for informa-

4

Normal, Heavyweight, and Mass Concrete

tion only and are not considered standard.

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns associated with its use. It is the responsibility

3.1 Definitions:

of the user of this standard to establish appropriate safety and

3.1.1 air content (A)—Theproportionofthetotalvolumeof

health practices and determine the applicability of regulatory

the concrete that is air voids; expressed as percentage by

limitations prior to use. For specific hazard statements see 8.3

volume.

and 10.1.

3.1.2 air void—A space enclosed by the cement paste and

2. Referenced Documents that was filled with air or other gas prior to the setting of the

3

paste.

2.1 ASTM Standards:

3.1.2.1 Discussion—This term does not refer to voids of

C42/C42M Test Method for Obtaining andTesting Drilled

submicroscopical dimensions, such as the porosity inherent to

Cores and Sawed Beams of Concrete

the hardened-cement paste.Air voids are usually larger than a

C138/C138M Test Method for Density (Unit Weight),

fewmicrometersindiameter.Thetermincludesbothentrapped

Yield, and Air Content (Gravimetric) of Concrete

and entrained voids.

3.1.3 average chord length( l)—Theaveragelengthofthe

1

This test method is under the jurisdiction of ASTM Committee C09 on

chords formed by the transection of the voids by the line of

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

traverse; the unit is a length.

C09.65 on Petrography.

3.1.4 paste-air ratio (p/A)—The ratio of the volume of

Current edition approved Oct. 1, 2008. Published November 2008. Originally

approved in 1960. Last previous edition approved in 2008 as C457–08b.

hardened cement paste to the volume of the air voids in the

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

concrete.

this test method.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromAmericanConcreteInstitute(ACI),P.O.Box9094,Farmington

the ASTM website. Hills, MI 48333-9094, http://www.aci-int.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 457 – 08c

3.1.5 paste content (p)—Theproportionofthetotalvolume and S lose their significance and cannot be used as

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 457–08b Designation: C 457 – 08c

Standard Test Method for

Microscopical Determination of Parameters of the Air-Void

1

System in Hardened Concrete

This standard is issued under the fixed designation C 457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes procedures for microscopical determinations of the air content of hardened concrete and of the

2

specificsurface,voidfrequency,spacingfactor,andpaste-airratiooftheair-voidsysteminhardenedconcrete(1). Twoprocedures

are described:

1.1.1 Procedure A, the linear-traverse method (2, 3).

1.1.2 Procedure B, the modified point-count method (3, 4, 5, 6).

1.2 This test method is based on prescribed procedures that are applied to sawed and lapped sections of specimens of concrete

from the field or laboratory.

1.3 It is intended to outline the principles of this test method and to establish standards for its adequate performance but not

to describe in detail all the possible variations that might be used to accomplish the objectives of this test method.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use. For specific hazard statements see 8.3 and 10.1.

2. Referenced Documents

3

2.1 ASTM Standards:

C42/C42M Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

C138/C138M Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete

C173/C173M Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method

C231 Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method

C666/C666M Test Method for Resistance of Concrete to Rapid Freezing and Thawing

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

C672/C672M Test Method for Scaling Resistance of Concrete Surfaces Exposed to Deicing Chemicals

C823 Practice for Examination and Sampling of Hardened Concrete in Constructions

C856 Practice for Petrographic Examination of Hardened Concrete

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

2.2 American Concrete Institute Standards:

4

201.2R Guide to Durable Concrete

4

211.1 Recommended Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete

3. Terminology

3.1 Definitions:

3.1.1 air content (A)—The proportion of the total volume of the concrete that is air voids; expressed as percentage by volume.

3.1.2 air void—Aspace enclosed by the cement paste and that was filled with air or other gas prior to the setting of the paste.

3.1.2.1 Discussion—This term does not refer to voids of submicroscopical dimensions, such as the porosity inherent to the

1

This test method is under the jurisdiction ofASTM Committee C09 on Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee C09.65 on

Petrography.

Current edition approved JulyOct. 1, 2008. Published AugustNovember 2008. Originally approved in 1960. Last previous edition approved in 2008 as C457–08ab.

2

The boldface numbers in parentheses refer to the list of references at the end of this test method.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333-9094, http://www.aci-int.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 457 – 08c

hardened-cement paste. Air voids are usually larger than a few micrometers in diameter. The term includes both entrapped and

entrained voids.

3.1.3 averagechordlength(l)—Theaverageleng

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.