ASTM C131-03

(Specification)Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine

Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine

SCOPE

1.1 This test method covers a procedure for testing sizes of coarse aggregate smaller than 37.5 mm (1½ in.) for resistance to degradation using the Los Angeles testing machine (Note 1).

Note 1—A procedure for testing coarse aggregate larger than 19.0 mm (3/4 in.) is covered in Test Method C 535.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C131–03

Standard Test Method for

Resistance to Degradation of Small-Size Coarse Aggregate

1

by Abrasion and Impact in the Los Angeles Machine

This standard is issued under the fixed designation C 131; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E11 Specification for Wire Cloth and Sieves for Testing

5

Purposes

1.1 This test method covers a procedure for testing sizes of

1

coarse aggregate smaller than 37.5 mm (1 ⁄2 in.) for resistance

3. Terminology

to degradation using the LosAngeles testing machine (Note 1).

3.1 Definitions—For definitions of terms used in this test

NOTE 1—Aprocedure for testing coarse aggregate larger than 19.0 mm

method, refer to Terminology C 125.

3

( ⁄4 in.) is covered in Test Method C 535.

4. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

standard. The inch-pound values given in parentheses are for

4.1 This test is a measure of degradation of mineral aggre-

information only. gates of standard gradings resulting from a combination of

1.3 This standard does not purport to address all of the

actions including abrasion or attrition, impact, and grinding in

safety concerns, if any, associated with its use. It is the a rotating steel drum containing a specified number of steel

responsibility of the user of this standard to establish appro-

spheres, the number depending upon the grading of the test

priate safety and health practices and determine the applica- sample. As the drum rotates, a shelf plate picks up the sample

bility of regulatory limitations prior to use.

and the steel spheres, carrying them around until they are

dropped to the opposite side of the drum, creating an impact-

2. Referenced Documents

crushing effect. The contents then roll within the drum with an

2.1 ASTM Standards:

abrading and grinding action until the shelf plate picks up the

A 6/A 6M Specification for General Requirements for sample and the steel spheres, and the cycle is repeated. After

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

the prescribed number of revolutions, the contents are removed

2

Piling

from the drum and the aggregate portion is sieved to measure

C 125 Terminology Relating to Concrete and Concrete

the degradation as percent loss.

3

Aggregates

5. Significance and Use

C 136 Test Method for Sieve Analysis of Fine and Coarse

3

Aggregates

5.1 This test has been widely used as an indicator of the

C 535 Test Method for Resistance to Degradation of Large- relative quality or competence of various sources of aggregate

Size CoarseAggregate byAbrasion and Impact in the Los

having similar mineral compositions. The results do not

3

Angeles Machine automatically permit valid comparisons to be made between

C 670 Practice for Preparing Precision and Bias Statements

sources distinctly different in origin, composition, or structure.

3

for Test Methods for Construction Materials Assign specification limits with extreme care in consideration

C 702 Practice for Reducing Samples of Aggregate to

of available aggregate types and their performance history in

3

Testing Size specific end uses.

4

D75 Practice for Sampling Aggregates

6. Apparatus

6.1 Los Angeles Machine—A Los Angeles machine, con-

1

This test method is under the jurisdiction of ASTM Committee C09 on

forming in all essential characteristics to the design shown in

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

Fig. 1, shall be used. The machine shall consist of a hollow

C09.20 on Normal Weight Aggregates.

Current edition approved March 10, 2003. Published April 2003. Originally steel cylinder, with a wall thickness of not less than 12.4 mm

approved in 1937. Last previous edition approved in 2001 as C 131-01.

2

Annual Book of ASTM Standards, Vol 01.04.

3

Annual Book of ASTM Standards, Vol 04.02.

4 5

Annual Book of ASTM Standards, Vol 04.03. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

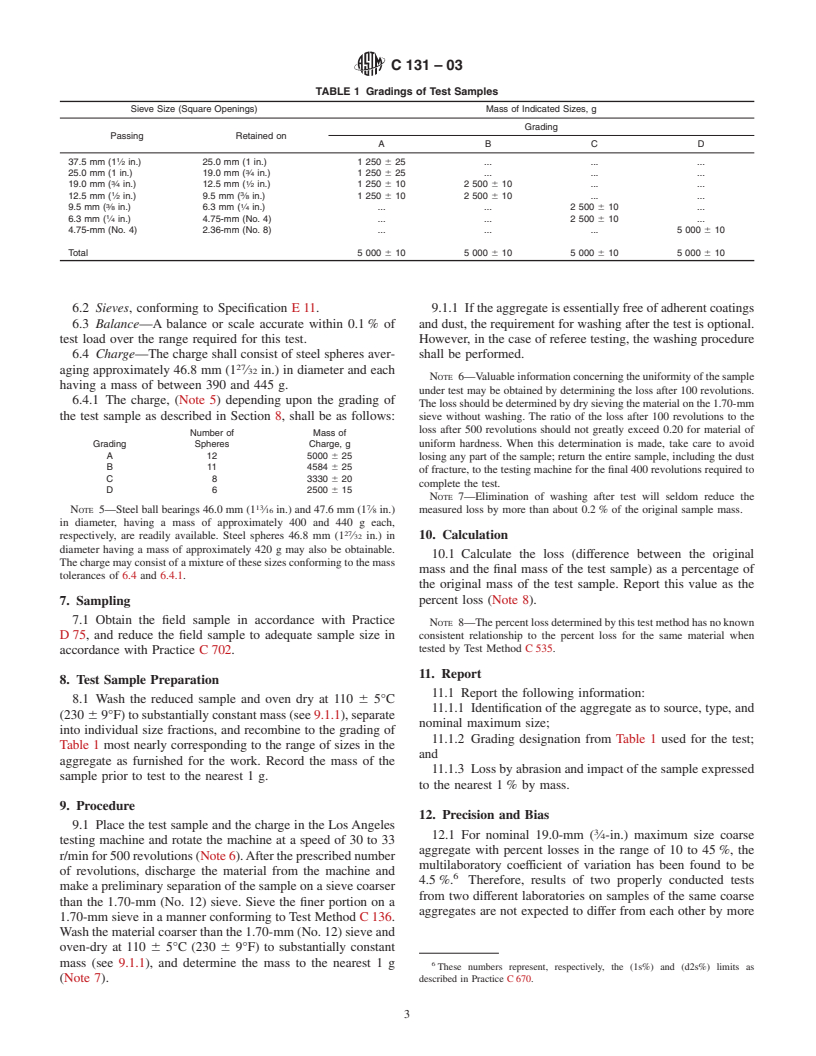

C131–03

Inch Equivalents

mm 6.4 12.7 25.4 89 102 152 190 508 711 1270

1 1 1 1

in. ⁄4 ⁄2 1 3 ⁄2 4 6 7 ⁄2 20 28 50

FIG. 1 Los Angeles Testing Machine

(Note 2) closed at both ends, conforming to the dimensions shelf to the opening, measured along the outside circumference

shown in Fig. 1, having an inside diameter of 711 65mm(28 ofthecylinderinthedirectionofro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.