ASTM D2394-05(2011)

(Test Method)Standard Test Methods for Simulated Service Testing of Wood and Wood-Base Finish Flooring

Standard Test Methods for Simulated Service Testing of Wood and Wood-Base Finish Flooring

SIGNIFICANCE AND USE

The test methods presented herein are intended to provide both a factual and comparative means of appraising the suitability of finish flooring. The procedures developed simulate some conditions of use that may require either maintenance beyond that considered normal or replacement of the floor surface material.

It is important for some of the evaluations that the substrate to be used beneath the finish flooring be duplicated because the type and degree of support will have a direct influence on the value obtained from test. For example, in some present-day construction, low-density materials are used for sound-deadening immediately below the finish flooring. The way this substrate distributes loading and absorbs energy will have an influence on evaluations such as those in rolling and concentrated loads.

The test methods presented herein may be used to compare different finish floorings as to their resistance to severe and ordinary service loads and also may serve as the means to set specification limits. The properties obtained by these test methods are needed in addition to such basic material properties as stiffness, strength, hardness, and dimensional stability.

Not all test may be required for any specific investigation. There may be an interrelation between two tests, and when it has been demonstrated what the interrelation is, a complete evaluation will only be required as a final stage of a study. In each instance, therefore, it will be necessary to determine which evaluations should be made to fulfill the objectives.

SCOPE

1.1 These test methods cover procedures for measuring the performance of finish flooring under the following service loadings and conditions:

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2394 − 05 (Reapproved 2011)

Standard Test Methods for

Simulated Service Testing of Wood and Wood-Base Finish

Flooring

This standard is issued under the fixed designation D2394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope sound-deadening immediately below the finish flooring. The

way this substrate distributes loading and absorbs energy will

1.1 These test methods cover procedures for measuring the

have an influence on evaluations such as those in rolling and

performance of finish flooring under the following service

concentrated loads.

loadings and conditions:

3.3 The test methods presented herein may be used to

Section

Loading Tests

compare different finish floorings as to their resistance to

Concentrated Loading 7

severe and ordinary service loads and also may serve as the

Floor Surface Indentation from Small Area Loads 12

means to set specification limits. The properties obtained by

Falling-Ball Indentation 18

Rolling Load 23

thesetestmethodsareneededinadditiontosuchbasicmaterial

Mechanical Tests

properties as stiffness, strength, hardness, and dimensional

Abrasion Resistance 28

stability.

Coefficient of Friction 33

Moisture Tests

3.4 Not all test may be required for any specific investiga-

Surface Wetting 38

tion. There may be an interrelation between two tests, and

2. Referenced Documents

when it has been demonstrated what the interrelation is, a

complete evaluation will only be required as a final stage of a

2.1 ASTM Standards:

study. In each instance, therefore, it will be necessary to

D1037 Test Methods for Evaluating Properties of Wood-

determine which evaluations should be made to fulfill the

Base Fiber and Particle Panel Materials

objectives.

E72 Test Methods of Conducting Strength Tests of Panels

for Building Construction

4. Test Specimens

3. Significance and Use

4.1 The number of specimens to be chosen for test and the

method of their selection depend on the variability of the finish

3.1 The test methods presented herein are intended to

flooring material and on the purpose of the particular tests

providebothafactualandcomparativemeansofappraisingthe

under consideration, so no general rule can be given to cover

suitability of finish flooring. The procedures developed simu-

all instances. It is recommended that, whenever possible,

late some conditions of use that may require either mainte-

sufficient replications be made to establish reliable mean

nance beyond that considered normal or replacement of the

values. Even for the most simple evaluation, a replication of

floor surface material.

three tests for each property is recommended.

3.2 It is important for some of the evaluations that the

substrate to be used beneath the finish flooring be duplicated

5. Control of Moisture Content and Temperature

because the type and degree of support will have a direct

5.1 Wood and wood-base materials are hygroscopic. The

influenceonthevalueobtainedfromtest.Forexample,insome

moisture content at time of test will influence values obtained

present-day construction, low-density materials are used for

from tests. Therefore, material for test shall be conditioned to

essentially constant weight at a condition of 65 6 1 % relative

These test methods are under the jurisdiction of ASTM Committee D07 on humidity and a temperature of 68 6 6°F (20 6 3°C) (Note 1

Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental

and Note 2). If there is any departure from this recommended

Test Methods and Properties.

condition, it shall be so stated in the report. No tests shall be

Current edition approved March 1, 2011. Published March 2011. Originally

made on any material when it is not essentially stable in

approved in 1965. Last previous edition approved in 2005 as D2394 – 05. DOI:

10.1520/D2394-05R11.

moisture content.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—In following the recommendation that the temperature be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on controlled to 68 6 6°F (20 6 3°C) it should be understood that it is

the ASTM website. desirable to maintain the temperature as nearly constant as possible at

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2394 − 05 (2011)

some temperature within this range.

9.1.1 Steel Disk Loading Tool—The steel disk loading tool

NOTE 2—Requirements for temperature and relative humidity vary for

shall be 1 in. (25 mm) in diameter with the circumference of

different materials and different conditions of use. The condition above

the end rounded to a radius of 0.05 in. (1.3 mm). The loading

meets the standard condition for wood and wood-base materials, and for

tool shall be provided with a collar to engage the movable tip

finish flooring represents the near-maximum seasonal condition for most

of the micrometer dial for measuring deformation under load,

locations. The amount of damage from the various loadings is usually

greater at higher moisture contents than at lower ones.

andshallbefabricatedwithameansoffasteningittotheplaten

of the testing machine or loading device.

6. Report

9.1.2 Deformation Gage—The deformation gage shall con-

6.1 The data recorded shall include, in addition to the actual

sist of a dial micrometer mounted on the three-point supported

test results and data required specifically from each test, a

bridge. The dial micrometer shall be of the kind with divisions

complete description of the material, sampling procedure, and

of0.001in.(0.025mm).Thebridgeshallbeofsufficientlength

record of any special treatment or conditioning of the flooring

so that the distance between the single-point support and a line

material.Any special details concerning the material under test

between the pair of point supports is at least 12 in. (305 mm).

that may have a bearing on the results shall also be recorded.

The bridge support shall have a slot in the center of its span of

sufficientopeningtocleartheloadingtooltopermitplacingthe

CONCENTRATED LOADING

micrometer directly adjacent to the disk loading tool with the

stem end in contact with the collar.

7. Scope

9.1.3 Loading Device—Atesting machine with a platen area

7.1 Specimens shall be subjected to the concentrated load-

sufficiently large to accommodate the 18-in. (457-mm) square

ing test to obtain a measure of the resistance of the finish

or other suitable loading device convenient for loading and

flooring to heavy loads produced by such articles of furniture

measuring the amount of loading to 1000 lb (or 4.45 kN) at the

as chests and pianos. This test procedure uses the same

prescribed rate shall be provided.

equipment and is essentially the same as the one described in

9.1.4 An indentation measuring tool, as required for the

Test Methods E72.

falling-ball indentation test (see 20.1.4) shall be provided for

determining the residual indentation from the loading to 1000

8. Test Specimen

lb (4.45 kN) 1 h after removal of load.

8.1 The size of the test specimen will depend on the size of

10. Procedure

components making up the finish flooring, but should be at

least 18 in. (457 mm) square. When the finish flooring is

10.1 Loading Points—Load points 1 and 2, for both square

prefabricated in parquet or tile form, the specimen shall consist

or rectangular parquet or tile form finish flooring, are illus-

of at least four such tiles attached to an underlayment, subfloor,

tratedinFig.1.Loadpoint1forthetileformofflooringisnear

or other substrate, using the same construction and technique

the corner, so that deformation under load at a corner can be

as will be used in the finished construction. When the flooring

determined. Load point 2 is provided to obtain an index of

is manufactured in strip form, the flooring shall be laid in

resistance to concentrated load at a point where the finish

courses over the subfloor and substrate so that end joints occur

flooring can distribute the load because of its inherent stiffness.

in the same manner as in actual construction.At least two such

Load point 2 should be at the approximate center of the tile

end joints shall occur near midwidth in the center one-half of

area, and when using a 12-in. (305-mm) deformation bridge,

the specimen. Fig. 1 shows the orientation for typical speci-

the bridge can be placed along the diagonal. Load point 1 for

mens using square and strip configurations of flooring.

stripflooringistosimulatetheloadingconditionpossiblewhen

the concentrated load comes at or near an end joint. Load point

9. Apparatus

2 simulates the condition that exists when loading is on a

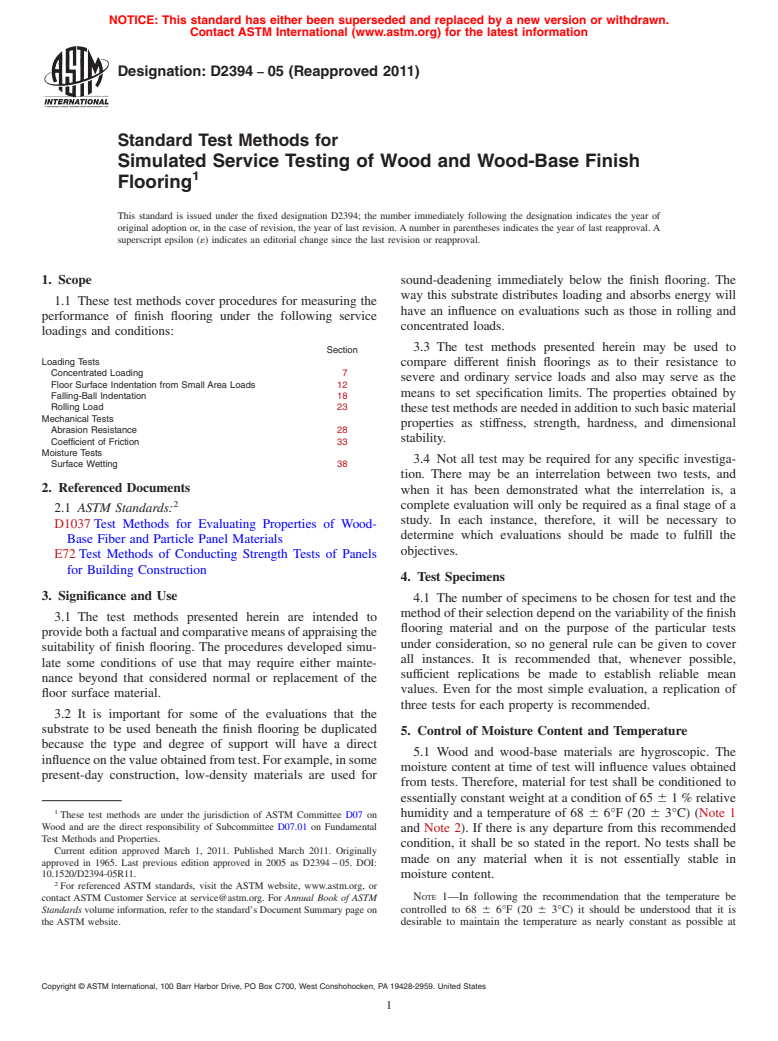

9.1 The apparatus shall be assembled as shown in Fig. 2 and continuous strip of flooring but there is a joint in the adjacent

shall conform in the requirements for component parts as course of flooring. When strip flooring is less than 2 in. (51

described in 9.1.1 – 9.1.4. mm)wide,thepointofload2shallbecenteredonthestrip.For

other configurations of finish flooring, load point 1 should

correspond to the one producing maximum deformation under

load and point 2 the more average condition. In each instance,

the 1-in. (25-mm) diameter loading disk shall be centered over

the dimensioned point.

10.2 Loading—Apply the load continuously at a uniform

rate of movement of the loading tool of 0.10 in. (2.5 mm)/min.

Make at least ten simultaneous measurements of load and

deformationbetweenzeroloadand1000lb(4.45kN)(Note4).

After the load of 1000 lb (4.45 kN) has been applied, it shall be

removed immediately so that residual deformation can be

determined. Record any observed behavior of either the finish

flooring or the substrate during test.

NOTE 1—One in. equals 25.4 mm.

FIG. 1 Layout of Specimens for Concentrated Load Test NOTE 3—The testing machine speed used shall not vary by more than

D2394 − 05 (2011)

FIG. 2 Assembly for Concentrated Loading Test of Finish Flooring

650 % from that specified for a given test. The testing machine speed

floorings to determine which may have better service possi-

shall mean the free-running, or no load, crosshead speed for testing

bilities. Results obtained are qualitative rather than quantita-

machines of the mechanical-drive type and the loaded crosshead speed for

tive.

testing machines of the hydraulic-loading type.

NOTE 4—For some evaluations of finish flooring where possible use is

in commercial buildings, concentrated load evaluations may be desirable 13. Test Specimen

forloadsgreaterthan1000lb(4.45kN).Whenthisisso,thematerialshall

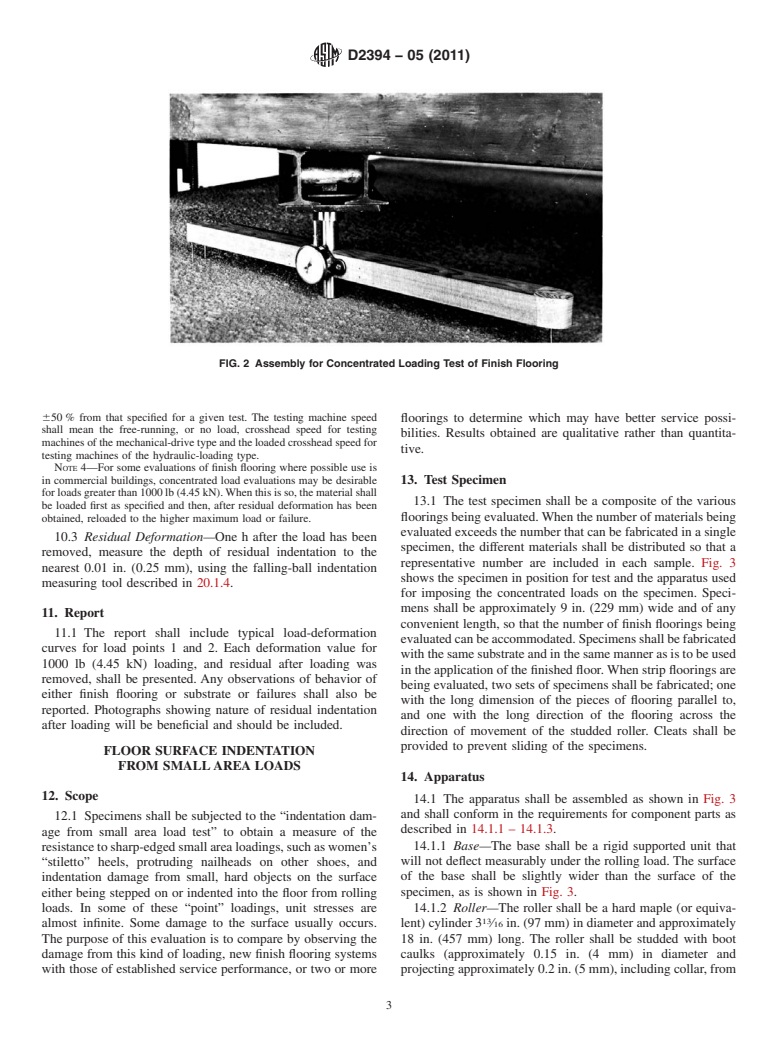

13.1 The test specimen shall be a composite of the various

be loaded first as specified and then, after residual deformation has been

floorings being evaluated.When the number of materials being

obtained, reloaded to the higher maximum load or failure.

evaluated exceeds the number that can be fabricated in a single

10.3 Residual Deformation—One h after the load has been

specimen, the different materials shall be distributed so that a

removed, measure the depth of residual indentation to the

representative number are included in each sample. Fig. 3

nearest 0.01 in. (0.25 mm), using the falling-ball indentation

shows the specimen in position for test and the apparatus used

measuring tool described in 20.1.4.

for imposing the concentrated loads on the specimen. Speci-

mens shall be approximately 9 in. (229 mm) wide and of any

11. Report

convenient length, so that the number of finish floorings being

11.1 The report shall include typical load-deformation

evaluatedcanbeaccommodated.Specimensshallbefabricated

curves for load points 1 and 2. Each deformation value for

with the same substrate and in the same manner as is to be used

1000 lb (4.45 kN) loading, and residual after loading was

in the application of the finished floor. When strip floorings are

removed, shall be presented. Any observations of behavior of

being evaluated, two sets of specimens shall be fabricated; one

either finish flooring or substrate or failures shall also be

with the long dimension of the pieces of flooring parallel to,

reported. Photographs showing nature of residual indentation

and one with the long direction of the flooring across the

after loading will be beneficial and should be included.

direction of movement of the studded roller. Cleats shall be

provided to prevent sliding of the specimens.

FLOOR SURFACE INDENTATION

FROM SMALL AREA LOADS

14. Apparatus

12. Scope

14.1 The apparatus shall be assembled as shown in Fig. 3

and shall conform in the requirements for component parts as

12.1 Specimens shall be subjected to the “indentation dam-

described in 14.1.1 – 14.1.3.

age from small area load test” to obtain a measure of the

14.1.1 Base—The base shall be a rigid supported unit that

resistancetosharp-edgedsmallarealoadings,suchaswomen’s

will not deflect measurably under the rolling load. The surface

“stiletto” heels, protruding nailheads on other shoes, and

of the base shall be slightly wider than the surface of the

indentation damage from small, hard objects on the surface

specimen, as is shown in Fig. 3.

either being stepped on or indented into the floor from rolling

loads. In some of these “point” loadings, unit stresses are 14.1.2 Roller—The roller shall be a hard maple (or equiva-

almost infinite. Some damage to the surface usually occurs. lent) cylinder 3 ⁄16 in. (97 mm) in diameter and approximately

The purpose of this evaluation is to compare by observing the 18 in. (457 mm) long. The roller shall be studded with boot

damage from this kind of loading, new finish flooring systems caulks (approximately 0.15 in. (4 mm) in diameter and

with those of established service performance, or two or more projecting approximately 0.2 in. (5 mm), including collar, from

D2394 − 05 (2011)

FIG. 3 Assembly for Tests of Floor-Surface Indentation from Small-Area Loads, Showing Loaded Maple Roller Studded with Boot

Caulks and Specimens Firmly Supported on Heavy Beam

surface of roller) 1 in. (25 mm) on center around the circum- of actual tested specimens (Fig. 4) are desirable and shall be

ference for an 8-in. (203-mm) width. Alternate rows of studs considered in reporting. In Fig. 4, material G can be considered

shallbestaggered.Theendsoftherollershallbeprovidedwith typical of a specimen showing none to minor damage; J is

arms for rolling it along the specimen and, either through moderate, H severe, and material I probably would be cons

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.