ASTM D942-02

(Test Method)Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Bomb Method

Standard Test Method for Oxidation Stability of Lubricating Greases by the Oxygen Bomb Method

SCOPE

1.1 This test method determines resistance of lubricating greases to oxidation when stored statically in an oxygen atmosphere in a sealed system at an elevated temperature under conditions of test.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Sections 6 and 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D942–02

Designation: 142/85 (92)

Standard Test Method for

Oxidation Stability of Lubricating Greases by the Oxygen

1

Pressure Vessel Method

This standard is issued under the fixed designation D 942; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committee and accepted by the cooperating societies in accordance with the

established procedures.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * 3. Summary of Test Method

1.1 This test method determines resistance of lubricating 3.1 The sample of grease is oxidized in a pressure vessel

greases to oxidation when stored statically in an oxygen heated to 99°C (210°F) and filled with oxygen at 110 psi (758

atmosphereinasealedsystematanelevatedtemperatureunder kPa). Pressure is observed and recorded at stated intervals.The

conditions of test. degree of oxidation after a given period of time is determined

1.2 This standard does not purport to address all of the by the corresponding decrease in oxygen pressure.

safety concerns, if any, associated with its use. It is the

NOTE 1—The pressure vessel has been referred to as “a bomb” in

responsibility of the user of this standard to establish appro-

previous issues of this test method.

priate safety and health practices and determine the applica-

NOTE 2—The accepted unit of pressure is the pascal (Pa) for ASTM

bility of regulatory limitations prior to use. For specific hazard

methods and will be parenthetically included after the conventional

pound-force per square inch (psi) value. The Institute of Petroleum uses

statements see Sections 6 and 7.

the bar as a pressure measurement. Conversion of units may be obtained

2. Referenced Documents as follows:

To convert from pound-force per square inch (psi) to pascal (Pa)

2.1 ASTM Standards:

3

multiply by 6.894757 3 10 .

A 240 Specification for Heat-Resisting Chromium and

To convert from pound-force per square inch (psi) to bar multiply by

Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

0.06894757.

2

5

for Pressure Vessels To convert from bar to pascal (Pa) multiply by 10 .

D 525 Test Method for Oxidation Stability of Gasoline

3 4. Significance and Use

(Induction Period Method)

4

E 1 Specification for ASTM Thermometers 4.1 This test method measures the net change in pressure

resultingfromconsumptionofoxygenbyoxidationandgainin

2.2 Other Standards:

5

IP Specification for Standard IP Thermometers pressure due to formation of volatile oxidation by-products.

6

This test method may be used for quality control to indicate

BS 970:1983 Part I, Section S

batch-to-batch uniformity. It predicts neither the stability of

greases under dynamic service conditions, nor the stability of

1

This test method is under the jurisdiction of ASTM Committee D02 on

greases stored in containers for long periods, nor the stability

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

of films of greases on bearings and motor-parts. It should not

D02.09 on Oxidation.

be used to estimate the relative oxidation resistance of different

In the IP, this test method is under the jurisdiction of the Standardization

Committee.

grease types.

Current edition approved June 10, 2002. Published September 2002. Originally

e1

published as D 942–47. Last previous edition D 942–90(1995) .

5. Apparatus

2

Annual Book of ASTM Standards, Vol 01.03.

3

5.1 Oxidation Pressure Vessel, Sample Dish, Dish Holder,

Annual Book of ASTM Standards, Vol 05.01.

4

Annual Book of ASTM Standards, Vol 14.03.

Pressure Gage and Oil Bath as described in detail in the

5

Available from The Institute of Petroleum, 61 New Cavendish St., London

Annex.

W1M, 8AR, England.

6

Available from British Standards Institute, 2 Park St., London, England

WIA2B5.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

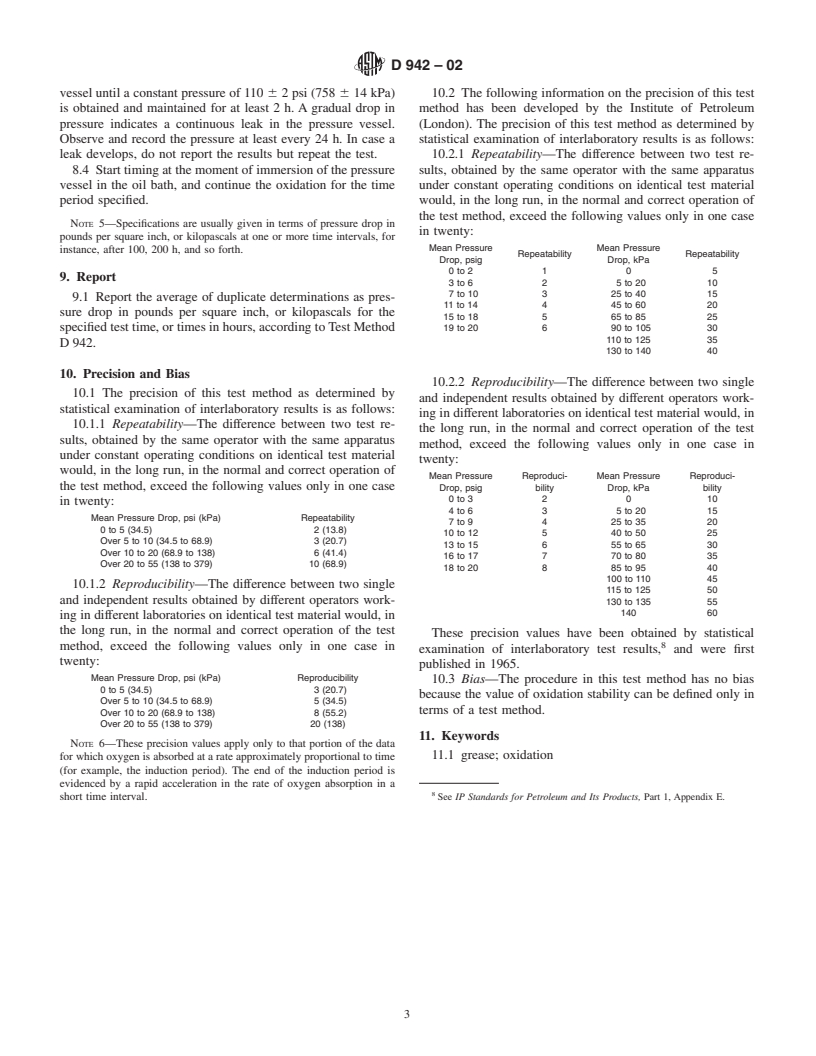

D942–02

NOTE 3—Other constant-temperature baths may be used if they are

function as an alternate to the preferred procedure, cleaning

equivalent in heat capacity and thermal gradient characteristics to the oil

with detergent solutions.

bath described in the Annex and can be shown to maintain the pressure

vessel at the prescribed test temperature.

7. Preparation of Apparatus

5.2 Thermometer, having a range as shown below and

7.1 Clean the sample dishes from all contamination from

conforming to the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.