ASTM D696-98

(Test Method)Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C With a Vitreous Silica Dilatometer

Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C With a Vitreous Silica Dilatometer

SCOPE

1.1 This test method covers determination of the coefficient of linear thermal expansion for plastic materials having coefficients of expansion greater than 1 X 10 -6 1°C by use of a vitreous silica dilatometer. At the test temperatures and under the stresses imposed, the plastic materials shall have a negligible creep or elastic strain rate or both, insofar as these properties would significantly affect the accuracy of the measurements. Note 1-There is no similar or equivalent ISO standard.

1.1.1 Test Method E228 shall be used for temperatures other than -30°C to 30°C.

1.1.2 This test method shall not be used for measurements on materials having a very low coefficient of expansion (less than 1 X 10 -6 1°C). For materials having very low coefficient of expansion, interferometer or capacitance techniques are recommended.

1.2 The thermal expansion of a plastic is composed of a reversible component on which are superimposed changes in length due to changes in moisture content, curing, loss of plasticizer or solvents, release of stresses, phase changes and other factors. This test method is intended for determining the coefficient of linear thermal expansion under the exclusion of these factors as far as possible. In general, it will not be possible to exclude the effect of these factors completely. For this reason, the test method can be expected to give only an approximation to the true thermal expansion.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 696 – 98

Standard Test Method for

Coefficient of Linear Thermal Expansion of Plastics

Between −30°C and 30°C With a Vitreous Silica Dilatometer

This standard is issued under the fixed designation D 696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

1.1 This test method covers determination of the coefficient

D 883 Terminology Relating to Plastics

of linear thermal expansion for plastic materials having coef-

−6

D 1898 Practice for Sampling of Plastics

ficients of expansion greater than 1 3 10 1°C by use of a

D 4065 Practice for Determining and Reporting Dynamic

vitreous silica dilatometer. At the test temperatures and under

Mechanical Properties of Plastics

the stresses imposed, the plastic materials shall have a negli-

E 228 Test Method for Linear Thermal Expansion of Solid

gible creep or elastic strain rate or both, insofar as these

Materials with a Vitreous Silica Dilatometer

properties would significantly affect the accuracy of the mea-

E 691 Practice for Conducting an Interlaboratory Study to

surements.

Determine the Precision of a Test Method

NOTE 1—There is no similar or equivalent ISO standard.

E 831 Test Method for Linear Thermal Expansion of Solid

1.1.1 Test Method E 228 shall be used for temperatures Materials by Thermomechanical Analysis

other than −30°C to 30°C.

3. Terminology

1.1.2 This test method shall not be used for measurements

on materials having a very low coefficient of expansion (less 3.1 Definitions—Definitions are in accordance with Termi-

−6

nology D 883 unless otherwise specified.

than 1 3 10 1°C). For materials having very low coefficient

of expansion, interferometer or capacitance techniques are

4. Summary of Test Method

recommended.

4.1 This test method is intended to provide a means of

1.2 The thermal expansion of a plastic is composed of a

determining the coefficient of linear thermal expansion of

reversible component on which are superimposed changes in

plastics which are not distorted or indented by the thrust of the

length due to changes in moisture content, curing, loss of

dilatometer on the specimen. For materials that may indent, see

plasticizer or solvents, release of stresses, phase changes and

8.4. The specimen is placed at the bottom of the outer

other factors. This test method is intended for determining the

dilatometer tube with the inner one resting on it. The measuring

coefficient of linear thermal expansion under the exclusion of

device which is firmly attached to the outer tube is in contact

these factors as far as possible. In general, it will not be

with the top of the inner tube and indicates variations in the

possible to exclude the effect of these factors completely. For

length of the specimen with changes in temperature. Tempera-

this reason, the test method can be expected to give only an

ture changes are brought about by immersing the outer tube in

approximation to the true thermal expansion.

a liquid bath or other controlled temperature environment

1.3 The values stated in SI units are to be regarded as the

maintained at the desired temperature.

standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 The coefficient of linear thermal expansion, a, between

responsibility of the user of this standard to establish appro-

temperatures T and T for a specimen whose length is L at

priate safety and health practices and determine the applica-

1 2 0

the reference temperature, is given by the following equation:

bility of regulatory limitations prior to use.

a5 ~L 2 L !/@L ~T 2T !#5DL/L DT

2 1 0 2 1 0

2. Referenced Documents

where L and L are the specimen lengths at temperatures T

1 2 1

2.1 ASTM Standards:

and T , respectively. a is, therefore, obtained by dividing the

linear expansion per unit length by the change in temperature.

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

(Section D20.30.07). Annual Book of ASTM Standards, Vol 08.01.

Current edition approved Feb. 10, 1998. Published January 1999. Originally Annual Book of ASTM Standards, Vol 08.02.

e1 4

published as D 696 – 42. Last previous edition D 696 – 91 . Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 696

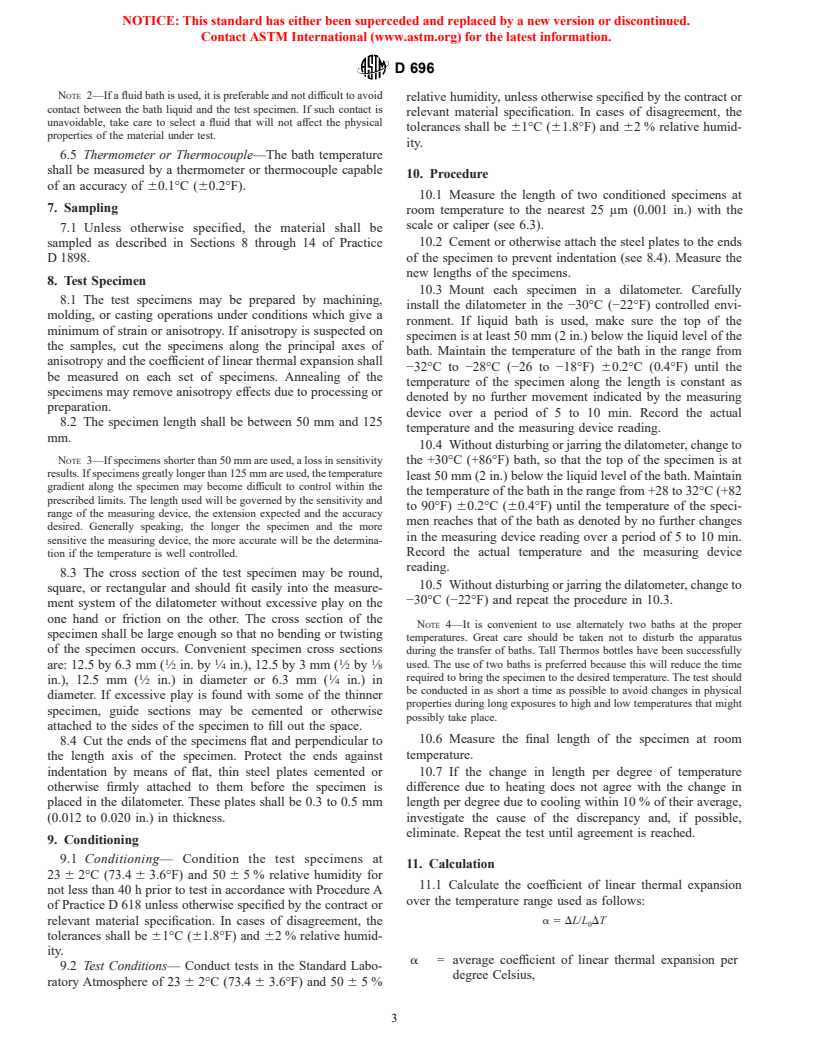

5.2 The nature of most plastics and the construction of the 6. Apparatus

dilatometer make −30 to +30°C (−22°F to +54°F) a convenient

6.1 Fused-Quartz-Tube Dilatometer suitable for this test

temperature range for linear thermal expansion measurements

method is illustrated in Fig. 1. A clearance of approximately 1

of plastics. This range covers the temperatures in which

mm is allowed between the inner and outer tubes.

plastics are most commonly used. Where testing outside of this

6.2 Device for measuring the changes in length (dial gage,

temperature range or when linear thermal expansion character-

LVDT, or the equivalent) is fixed on the mounting fixture so

istics of a particular plastic are not known through this

that its position may be adjusted to accommodate specimens of

temperature range, particular attention shall be paid to the

varying length (see 8.2). The accuracy shall be such that the

factors mentioned in 1.2 and special preliminary investigations

−5

error of indication will not exceed 61.0 μm (4 3 10 in.) for

by thermo-mechanical analysis, such as that prescribed in

any length change. The weight of the inner silica tube plus the

Practice D 4065 for the location of transition temperatures,

measuring device reaction shall not exert a stress of more than

may be required to avoid excessive error. Other ways of

70 kPa (10 psi) on the specimen so that the specimen is not

locating phase changes or transition temperatures using the

distorted or appreciably indented.

dilatometer itself may be employed to cover the range of

6.3 Scale or Caliper capable of measuring the initial length

temperatures in question by using smaller steps than 30°C

of the specimen with an accuracy of 60.5 %.

(54°F) or by observing the rate of expansion during a steady

rise in temperature of the specimen. Once such a transition 6.4 Controlled Temperature Environment to control the

point has been located, a separate coefficient of expansion for temperature of the specimen. Arrange the bath so a uniform

a temperature range below and above the transition point shall temperature is assured over the length of the specimen. Means

be determined. For specification and comparison purposes, the shall be provided for stirring the bath and for controlling its

range from −30°C to +30°C (−22°F to +86°F) (provided it is

temperature within 60.2°C (60.4°F) at the time of the

known that no transition exists in this range) shall be used. temperature and measuring device readings.

FIG. 1 Quartz-Tube Dilatometer

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 696

NOTE 2—If a fluid bath is used, it is preferable and not difficult to avoid

relative humidity, unless otherwise specified by the contract or

contact between the bath liquid and the test specimen. If such contact is

relevant material specification. In cases of disagreement, the

unavoidable, take care to select a fluid that will not affect the physical

tolerances shall be 61°C (61.8°F) and 62 % relative humid-

properties of the material under test.

ity.

6.5 Thermometer or Thermocouple—The bath temperature

shall be measured by a thermometer or thermocouple capable

10. Procedure

of an accuracy of 60.1°C (60.2°F).

10.1 Measure the length of two conditioned specimens at

7. Sampling

room temperature to the nearest 25 μm (0.001 in.) with the

scale or caliper (see 6.3).

7.1 Unless otherwise specified, the material shall be

10.2 Cement or otherwise attach the steel plates to the ends

sampled as described in Sections 8 through 14 of Practice

D 1898. of the specimen to prevent indentation (see 8.4). Measure the

new lengths of the specimens.

8. Test Specimen

10.3 Mount each specimen in a dilatometer. Carefully

8.1 The test specimens may be prepared by machining,

install the dilatometer in the −30°C (−22°F) controlled envi-

molding, or casting operations under conditions which give a

ronment. If liquid bath is used, make sure the top of the

minimum of strain or anisotropy. If anisotropy is suspected on

specimen is at least 50 mm (2 in.) below the liquid level of the

the samples, cut the specimens along the principal axes of

bath. Maintain the temperature of the bath in the range from

anisotropy and the coefficient of linear thermal expansion shall

−32°C to −28°C (−26 to −18°F) 60.2°C (0.4°F) until the

be measured on each set of specimens. Annealing of the

temperature of the specimen along the length is constant as

specimens may remove anisotropy effects due to processing or

denoted by no further movement indicated by the measuring

preparation.

device over a period of 5 to 10 min. Record the actual

8.2 The specimen length shall be between 50 mm and 125

temperature and the measuring device reading.

mm.

10.4 Without disturbing or jarring the dilatometer, change to

NOTE 3—If specimens shorter than 50 mm are used, a loss in sensitivity

the +30°C (+86°F) bath, so that the top of the specimen is at

results. If specimens greatly longer than 125 mm are used, the temperature

least 50 mm (2 in.) below the liquid level of the bath. Maintain

gradient along the specimen may become difficult to control within the

the temperature of the bath in the range from +28 to 32°C (+82

prescribed limits. T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.