ASTM D97-17b(2022)

(Test Method)Standard Test Method for Pour Point of Petroleum Products

Standard Test Method for Pour Point of Petroleum Products

SIGNIFICANCE AND USE

5.1 The pour point of a petroleum specimen is an index of the lowest temperature of its utility for certain applications.

SCOPE

1.1 This test method covers and is intended for use on any petroleum product.3 A procedure suitable for black specimens, cylinder stock, and nondistillate fuel oil is described in 8.8. The cloud point procedure formerly part of this test method now appears as Test Method D2500.

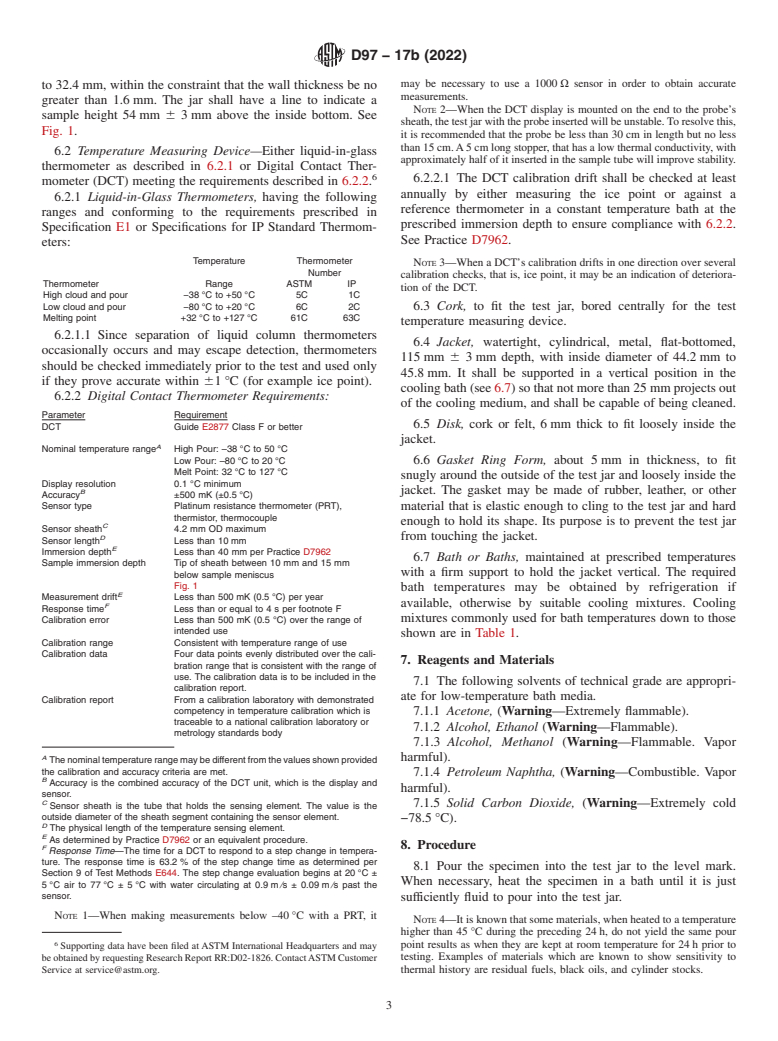

1.2 Currently there is no ASTM test method for automated Test Method D97 pour point measurements.

1.3 Several ASTM test methods offering alternative procedures for determining pour points using automatic apparatus are available. None of them share the same designation number as Test Method D97. When an automatic instrument is used, the ASTM test method designation number specific to the technique shall be reported with the results. A procedure for testing the pour point of crude oils is described in Test Method D5853.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D97 − 17b (Reapproved 2022)

Designation: 15/22

Standard Test Method for

1,2

Pour Point of Petroleum Products

ThisstandardisissuedunderthefixeddesignationD97;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope mercuryormercury-containingproducts,orboth,isprohibited

bylocalornationallaw.Usersmustdeterminelegalityofsales

1.1 This test method covers and is intended for use on any

3 in their location.

petroleum product. Aprocedure suitable for black specimens,

1.6 This standard does not purport to address all of the

cylinderstock,andnondistillatefueloilisdescribedin8.8.The

safety concerns, if any, associated with its use. It is the

cloud point procedure formerly part of this test method now

responsibility of the user of this standard to establish appro-

appears as Test Method D2500.

priate safety, health, and environmental practices and deter-

1.2 Currently there is no ASTM test method for automated

mine the applicability of regulatory limitations prior to use.

Test Method D97 pour point measurements.

1.7 This international standard was developed in accor-

1.3 Several ASTM test methods offering alternative proce-

dance with internationally recognized principles on standard-

dures for determining pour points using automatic apparatus

ization established in the Decision on Principles for the

areavailable.Noneofthemsharethesamedesignationnumber

Development of International Standards, Guides and Recom-

as Test Method D97. When an automatic instrument is used,

mendations issued by the World Trade Organization Technical

the ASTM test method designation number specific to the

Barriers to Trade (TBT) Committee.

technique shall be reported with the results. A procedure for

testing the pour point of crude oils is described inTest Method

2. Referenced Documents

D5853.

4

2.1 ASTM Standards:

1.4 The values stated in SI units are to be regarded as

D117Guide for Sampling, Test Methods, and Specifications

standard. No other units of measurement are included in this

for Electrical Insulating Liquids

standard.

D396Specification for Fuel Oils

D2500Test Method for Cloud Point of Petroleum Products

1.5 WARNING—Mercury has been designated by many

and Liquid Fuels

regulatory agencies as a hazardous substance that can cause

D5853Test Method for Pour Point of Crude Oils

serious medical issues. Mercury, or its vapor, has been dem-

D6300Practice for Determination of Precision and Bias

onstrated to be hazardous to health and corrosive to materials.

Data for Use in Test Methods for Petroleum Products,

Use caution when handling mercury and mercury-containing

Liquid Fuels, and Lubricants

products. See the applicable product Safety Data Sheet (SDS)

D7962Practice for Determination of Minimum Immersion

for additional information. The potential exists that selling

Depth and Assessment of Temperature Sensor Measure-

ment Drift

1

This test method is under the jurisdiction of ASTM International Committee

E1Specification for ASTM Liquid-in-Glass Thermometers

D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct

E644Test Methods for Testing Industrial Resistance Ther-

responsibility ofASTM Subcommittee D02.07 on Flow Properties. The technically

equivalent standard as referenced is under the jurisdiction of the Energy Institute mometers

Subcommittee SC-C-4.

E1137SpecificationforIndustrialPlatinumResistanceTher-

Current edition approved Nov. 1, 2022. Published November 2022. Originally

mometers

approved in 1927, replacing D47. Last previous edition approved in 2017 as

E2877Guide for Digital Contact Thermometers

D97–17b. DOI: 10.1520/D0097-17BR22.

This test method was adopted as a joint ASTM-IP Standard in 1965.

2

This test method has been developed through the cooperative effort between

ASTMandtheEnergyInstitute,London.ASTMandIPstandardswereapprovedby

4

ASTMandEItechnicalcommitteesasbeingtechnicallyequivalentbutthatdoesnot For referenced ASTM standards, visit the ASTM website, www.astm.org, or

imply both standards are identical. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Statements defining this test and its significance when applied to electrical Standards volume information, refer to the standard’s Document Summary page on

insulating oils of mineral origin will be found in Guide D117. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, We

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.