ASTM D1676-03(2011)

(Test Method)Standard Test Methods for Film-Insulated Magnet Wire

Standard Test Methods for Film-Insulated Magnet Wire

SIGNIFICANCE AND USE

Bond strength values obtained by flexural tests can provide information with regard to the bond strength of a particular self-bonding outer coating in combination with a particular round film-insulated magnet wire when measured under conditions described in this test method.

SCOPE

1.1 These test methods cover procedures for testing film-insulated magnet wire that is used in electrical apparatus. These test methods are intended primarily for the evaluation of the electrical insulating materials used. The intent is that these test methods be used, except where modified, by individual specifications for particular applications.

1.2 These test methods present different procedures for evaluating given properties of round, rectangular or square, copper or aluminum film-insulated magnet wire.

1.3 The values stated in inch-pound units are the standard. The SI units in parentheses are provided for information only.

1.4 The test methods appear in the following sections:

Sections Bond Strength 4-12 Burnout (AC Overload Resistance)13-21 Chemical Resistance22-28 Coefficient of Friction29-37 Continuity, DC High Voltage38-45 Continuity, DC Low Voltage46-53 Completeness of Cure54-60 Cut-Through Temperature (Thermoplastic Flow)61-68 Dielectric Breakdown AC Voltage69-75 Dielectric Breakdown AC Voltage after Bending76-82 Dielectric Breakdown AC Voltage at Elevated Temperatures83-89 Dielectric Breakdown AC Voltage after Conditioning in Refrigerant Atmosphere90-99 Dimensional Measurement100-106 Dissipation Factor Measurement107-114 Electrical Resistance115-121 Elongation122-129 Extractables, Refrigerant130-140 Film Adherence and Flexibility141-148 Formability: a) Elastic Ratio152 b) Low Stress Elongation153 c) Spring Back154-155 Heat Shock156-162 Oiliness163-169 Scrape Resistance, Unidirectional170-177 Solderability178-185 Resistance to Insulating Liquids and Hydrolytic Stability186-195

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 9.5, 19.1, 19.3, 19.8, 52.1, 58, 59.1, 74.1, 112.1, 135.4, and 182.3.

Note 1—This test method is related to IEC 60851. Since both methods contain multiple test procedures, many procedures are technically equivalent while others differ significantly.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1676 − 03 (Reapproved 2011)

Standard Test Methods for

Film-Insulated Magnet Wire

This standard is issued under the fixed designation D1676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 These test methods cover procedures for testing film-

responsibility of the user of this standard to establish appro-

insulatedmagnetwirethatisusedinelectricalapparatus.These

priate safety and health practices and determine the applica-

test methods are intended primarily for the evaluation of the

bility of regulatory limitations prior to use. Specific hazard

electrical insulating materials used.The intent is that these test

statements are given in 9.5, 19.1, 19.3, 19.8, 52.1, 58, 59.1,

methods be used, except where modified, by individual speci-

74.1, 112.1, 135.4, and 182.3.

fications for particular applications.

NOTE 1—This test method is related to IEC 60851. Since both methods

1.2 These test methods present different procedures for

contain multiple test procedures, many procedures are technically equiva-

evaluating given properties of round, rectangular or square,

lent while others differ significantly.

copper or aluminum film-insulated magnet wire.

2. Referenced Documents

1.3 The values stated in inch-pound units are the standard.

2.1 ASTM Standards:

The SI units in parentheses are provided for information only.

A228/A228MSpecification for Steel Wire, Music Spring

1.4 The test methods appear in the following sections:

Quality

Sections

B3Specification for Soft or Annealed Copper Wire

Bond Strength 4–12

B43Specification for Seamless Red Brass Pipe, Standard

Burnout (AC Overload Resistance) 13–21

Chemical Resistance 22–28 Sizes

Coefficient of Friction 29–37

B193Test Method for Resistivity of Electrical Conductor

Continuity, DC High Voltage 38–45

Materials

Continuity, DC Low Voltage 46–53

B279Test Method for Stiffness of Bare Soft Square and

Completeness of Cure 54–60

Cut-Through Temperature (Thermoplastic Flow) 61–68

RectangularCopperandAluminumWireforMagnetWire

Dielectric Breakdown AC Voltage 69–75

Fabrication

Dielectric Breakdown AC Voltage after Bending 76–82

Dielectric Breakdown AC Voltage at Elevated Temperatures 83–89 B324Specification for Aluminum Rectangular and Square

Dielectric Breakdown AC Voltage after Conditioning in Refriger-

Wire for Electrical Purposes

ant Atmosphere 90–99

B609/B609M Specification for Aluminum 1350 Round

Dimensional Measurement 100 – 106

Dissipation Factor Measurement 107 – 114 Wire, Annealed and Intermediate Tempers, for Electrical

Electrical Resistance 115 – 121

Purposes

Elongation 122 – 129

D149Test Method for Dielectric Breakdown Voltage and

Extractables, Refrigerant 130 – 140

Film Adherence and Flexibility 141 – 148

DielectricStrengthofSolidElectricalInsulatingMaterials

Formability:

at Commercial Power Frequencies

a) Elastic Ratio 152

D150Test Methods forAC Loss Characteristics and Permit-

b) Low Stress Elongation 153

c) Spring Back 154-155 tivity (Dielectric Constant) of Solid Electrical Insulation

Heat Shock 156 – 162

D374Test Methods for Thickness of Solid Electrical Insu-

Oiliness 163 – 169

lation (Withdrawn 2013)

Scrape Resistance, Unidirectional 170 – 177

Solderability 178 – 185

D877Test Method for Dielectric Breakdown Voltage of

Resistance to Insulating Liquids and Hydrolytic Stability 186 – 195

Insulating Liquids Using Disk Electrodes

D1533Test Method for Water in Insulating Liquids by

Coulometric Karl Fischer Titration

D1711Terminology Relating to Electrical Insulation

These test methods are under the jurisdiction of ASTM Committee D09 on

D2475Specification for Felt

Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.12 on Electrical Tests.

Current edition approved Aug. 1, 2011. Published August 2011. Originally

approved in 1959. Last previous edition approved in 2003 as D1676-03. DOI: The last approved version of this historical standard is referenced on

10.1520/D1676-03R11. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1676 − 03 (2011)

D2519Test Method for Bond Strength of Electrical Insulat- 7. Significance and Use

ing Varnishes by the Helical Coil Test

7.1 Bond strength values obtained by flexural tests can

D5423Specification for Forced-Convection Laboratory Ov-

provide information with regard to the bond strength of a

ens for Evaluation of Electrical Insulation

particular self-bonding outer coating in combination with a

E4Practices for Force Verification of Testing Machines

particular round film-insulated magnet wire when measured

E6Terminology Relating to Methods of Mechanical Testing

under conditions described in this test method.

E8Test Methods for Tension Testing of Metallic Materials

E220Test Method for Calibration of Thermocouples By

8. Apparatus

Comparison Techniques

8.1 Testing Machine—Tensile testing machines used for

E1356Test Method for Assignment of the Glass Transition

bond strength test shall conform to the requirements of

Temperatures by Differential Scanning Calorimetry

Practices E4.

E1545Test Method for Assignment of the Glass Transition

Temperature by Thermomechanical Analysis

8.2 Test Fixture—The test fixture shall conform to the test

2.2 Other Documents: fixture for bond strength tests required byTest Method D2519.

Federal Specification CCCM-911for Bleached Muslin

8.3 Mandrel Holder—The mandrel holder shall be a metal

IEC 60851Methods of Test for Winding Wire

block of sufficient size and thickness with a hole capable of

supporting the winding mandrel in a vertical position during

3. Terminology

the bonding cycle of the helical coil.

3.1 Definitions:

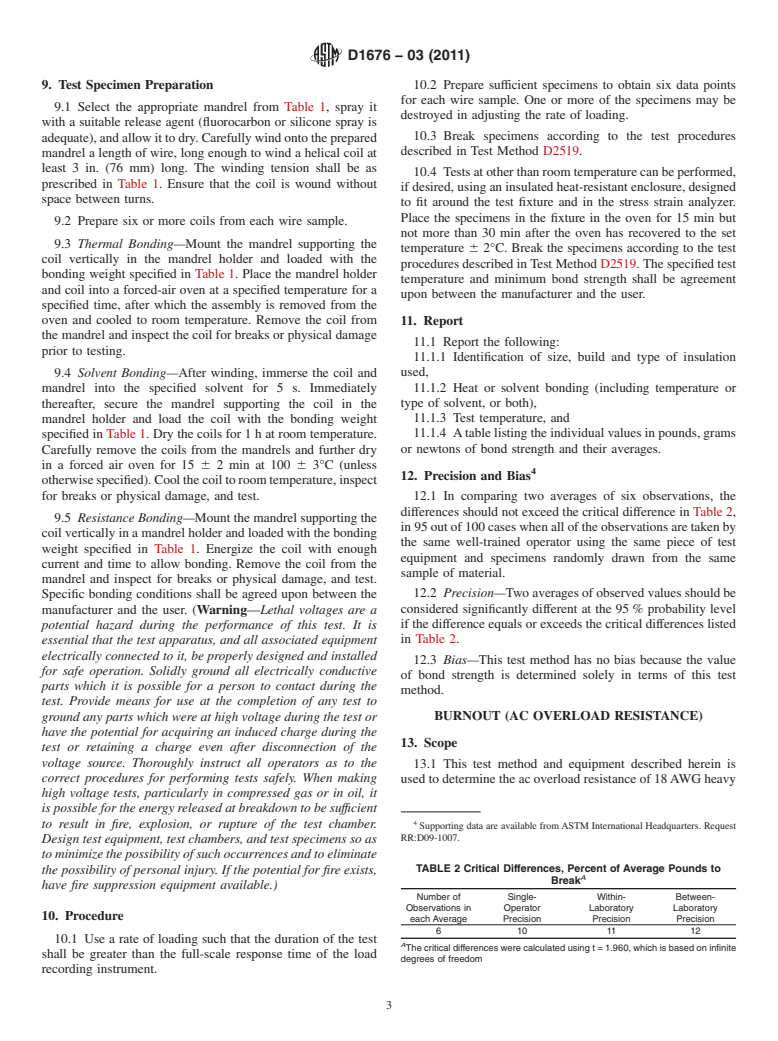

8.4 Winding Tensions—The winding tensions are listed in

3.1.1 conductor, n—a wire or combination of wires not

Table 1.

insulatedfromeachother,suitableforcarryingelectriccurrent.

8.5 Bonding Weights—Bonding weights (listed in Table 1)

3.1.2 magnet wire, n—a metal electrical conductor, covered

should be made with a hole through the center to allow the

with electrical insulation, for use in the assembly of electrical

weight to slip freely over the winding mandrel and load a

inductive apparatus such as coils for motors, transformers,

helical coil during bonding of coil.

generators, relays, magnets, etc.

8.6 Forced-Air Oven—See Specification D5423.

3.1.3 For definition of other terms used in this test method

refer to Terminology D1711.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 film coating, n—cured enamel coating.

TABLE 1 Helical Coil Bond Parameters

3.2.2 film insulated wire, n—a conductor insulated with a

Recommended

A A

film coating.

Mandrel Diameter Bond Weights

Wire Size,

Winding Tension

AWG

in. mm g N g N

BOND STRENGTH OF ROUND FILM-INSULATED

44 0.011 0.28 2.5 0.025 0.80 0.008

SELF-BONDING MAGNET WIRE BY THE HELICAL

43 0.011 0.28 2.5 0.025 0.80 0.008

COIL TEST

42 0.016 0.41 5.0 0.50 1.60 0.016

41 0.016 0.41 5.0 0.50 1.60 0.016

40 0.022 0.56 10.0 0.098 3.15 0.031

4. Scope

39 0.022 0.56 10.0 0.098 3.15 0.031

4.1 This test method covers the determination of the bond 38 0.022 0.56 10.0 0.098 3.15 0.031

37 0.032 0.81 20.0 0.196 6.30 0.062

strengthofaself-bondingoutercoatingonroundfilm-insulated

36 0.032 0.81 20.0 0.196 6.30 0.062

magnet wires (AWG 14 through 44). Both thermal and solvent

35 0.032 0.81 20.0 0.196 6.30 0.062

bonding methods are defined.

34 0.044 1.12 40.0 0.392 12.5 0.123

33 0.044 1.12 40.0 0.392 12.5 0.123

32 0.044 1.12 40.0 0.392 12.5 0.123

5. Terminology

31 0.063 1.60 80.0 0.785 25.0 0.245

30 0.063 1.60 80.0 0.785 25.0 0.245

5.1 Definitions of Terms Specific to This Standard:

29 0.063 1.60 80.0 0.785 25.0 0.245

5.1.1 bond strength, n—a measure of the force required to

28 0.088 2.24 160.0 1.569 50.0 0.490

separate surfaces which have been bonded together.

27 0.088 2.24 160.0 1.569 50.0 0.490

26 0.088 2.24 160.0 1.569 50.0 0.490

5.1.1.1 Discussion—For magnet wire which has been self

25 0.124 3.15 315.0 3.089 100.0 0.981

bonded or varnish treated, the bond strength is reported as the

24 0.124 3.15 315.0 3.089 100.0 0.981

force required to break a test specimen in flexure.

23 0.124 3.15 315.0 3.089 100.0 0.981

22 0.177 4.50 630.0 6.178 200.0 1.961

21 0.177 4.50 630.0 6.178 200.0 1.961

6. Summary of Test Method

20 0.177 4.50 630.0 6.178 200.0 1.961

19 0.248 6.30 1250.0 12.258 400.0 3.923

6.1 Flexural strength tests are made on bonded helical coils

18 0.248 6.30 1250.0 12.258 400.0 3.923

todeterminetheforcerequiredtobreakthecoilunderspecified

17 0.248 6.30 1250.0 12.258 400.0 3.923

conditions.

16 0.354 8.99 2500.0 24.517 800.0 7.845

15 0.354 8.99 2500.0 24.517 800.0 7.845

14 0.354 8.99 2500.0 24.517 800.0 7.845

A

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

± 2 % on all mandrels and bond weights.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

D1676 − 03 (2011)

9. Test Specimen Preparation 10.2 Prepare sufficient specimens to obtain six data points

for each wire sample. One or more of the specimens may be

9.1 Select the appropriate mandrel from Table 1, spray it

destroyed in adjusting the rate of loading.

with a suitable release agent (fluorocarbon or silicone spray is

10.3 Break specimens according to the test procedures

adequate),andallowittodry.Carefullywindontotheprepared

described in Test Method D2519.

mandrel a length of wire, long enough to wind a helical coil at

least 3 in. (76 mm) long. The winding tension shall be as

10.4 Testsatotherthanroomtemperaturecanbeperformed,

prescribed in Table 1. Ensure that the coil is wound without

ifdesired,usinganinsulatedheat-resistantenclosure,designed

space between turns.

to fit around the test fixture and in the stress strain analyzer.

Place the specimens in the fixture in the oven for 15 min but

9.2 Prepare six or more coils from each wire sample.

not more than 30 min after the oven has recovered to the set

9.3 Thermal Bonding—Mount the mandrel supporting the

temperature 6 2°C. Break the specimens according to the test

coil vertically in the mandrel holder and loaded with the

proceduresdescribedinTestMethodD2519.Thespecifiedtest

bonding weight specified in Table 1. Place the mandrel holder

temperature and minimum bond strength shall be agreement

and coil into a forced-air oven at a specified temperature for a

upon between the manufacturer and the user.

specified time, after which the assembly is removed from the

oven and cooled to room temperature. Remove the coil from

11. Report

the mandrel and inspect the coil for breaks or physical damage

11.1 Report the following:

prior to testing.

11.1.1 Identification of size, build and type of insulation

used,

9.4 Solvent Bonding—After winding, immerse the coil and

mandrel into the specified solvent for 5 s. Immediately 11.1.2 Heat or solvent bonding (including temperature or

type of solvent, or both),

thereafter, secure the mandrel supporting the coil in the

mandrel holder and load the coil with the bonding weight 11.1.3 Test temperature, and

11.1.4 Atablelistingtheindividualvaluesinpounds,grams

specified in Table 1. Dry the coils for1hat room temperature.

Carefully remove the coils from the mandrels and further dry or newtons of bond strength and their averages.

in a forced air oven for 15 6 2 min at 100 6 3°C (unless

12. Precision and Bias

otherwisespecified).Coolthecoiltoroomtemperature,inspect

for breaks or physical damage, and test. 12.1 In comparing two averages of six observations, the

differences should not exceed the critical difference in Table 2,

9.5 Resistance Bonding—Mountthemandrelsupportingthe

in95outof100caseswhenalloftheobservationsaretakenby

coilverticallyinamandrelholderandloadedwiththebonding

the same well-trained operator using the same piece of test

weight specified in Table 1. Energize the coil with enough

equipment and specimens randomly drawn from the same

current and time to allow bonding. Remove the coil from the

sample of material.

mandrel and inspect for breaks or physical damage, and test.

12.2 Precision—Twoaveragesofobservedvaluesshouldbe

Specific bonding conditions shall be agreed upon between the

manufacturer and the user. (Warning—Lethal voltages are a considered significantly different at the 95% probability level

ifthedifferenceequalsorexceedsthecriticaldifferenceslisted

potential hazard during the performance of this test. It is

essential that the test apparatus, and all associated equipment in Table 2.

electrically connected to it, be properly designed and installed

12.3 Bias—This test method has no bias because the value

for safe operation. Solidly ground all electrically conductive

of bond strength is determined solely in terms of this test

parts which it is possible for a person to contact during the

method.

test. Provide means for use at the completion of any test to

BURNOUT (AC OVERLOAD RESISTANCE)

ground any parts which were at high voltage during the test or

have the potential for acquiring an induced charge during the

13. Scope

test or retaining a charge even after disconnection of the

voltage source. Thoroughly instruct all operators as to the

13.1 This test method and equipment described herein is

correct procedures for performing tests safely. When making

usedtodeterminetheacoverloadresistanceof18AWGheavy

high voltage tests, particularly in compressed gas or in oil, it

is possible for the energy released at breakdown to be suffıcient

to result in fire, explosion, or rupture of the test chamber.

Supporting data are available fromASTM International Headquarters. Request

RR:D09-1007.

Design test equipment, test chambers, and test specimens so as

tominimizethepossibilityofsuchoccurrencesandtoeliminate

TABLE 2 Critical Differences, Percent of Average Pounds to

the possibility of personal injury. If the potential for fire exists,

A

Break

have fire suppression equipment available.)

Number of Single- Within- Between-

Observations in Operator Laboratory Laboratory

10. Procedure

each Average Precision Precision Precision

610 11 12

10.1 Use a rate of loading such that the duration of the test

A

The critical differences were calculated usingt=1.960, which is based on infinite

shall be greater than the full-scale response time of the load

degrees of freedom

recording instrument.

D1676 − 03 (2011)

build film-insulated round copper magnet wire by measuring 16.3 Test condition #1 was developed for faster and more

the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.