ASTM D1676-03

(Test Method)Standard Test Methods for Film-Insulated Magnet Wire

Standard Test Methods for Film-Insulated Magnet Wire

SIGNIFICANCE AND USE

Bond strength values obtained by flexural tests can provide information with regard to the bond strength of a particular self-bonding outer coating in combination with a particular round film-insulated magnet wire when measured under conditions described in this test method.

SCOPE

1.1 These test methods cover procedures for testing film-insulated magnet wire that is used in electrical apparatus. These test methods are intended primarily for the evaluation of the electrical insulating materials used. The intent is that these test methods be used, except where modified, by individual specifications for particular applications.

1.2 These test methods present different procedures for evaluating given properties of round, rectangular or square, copper or aluminum film-insulated magnet wire.

1.3 The values stated in inch-pound units are the standard. The SI units in parentheses are provided for information only.

1.4 The test methods appear in the following sections: SectionsBond Strength4-12Burnout (AC Overload Resistance)13-21Chemical Resistance22-28Coefficient of Friction29-37Continuity, DC High Voltage38-45Continuity, DC Low Voltage46-53Completeness of Cure54-60Cut-Through Temperature (Thermoplastic Flow)61-68Dielectric Breakdown AC Voltage69-75Dielectric Breakdown AC Voltage after Bending76-82Dielectric Breakdown AC Voltage at Elevated Temperatures83-89Dielectric Breakdown AC Voltage after Conditioning in Refrigerant Atmosphere90-99Dimensional Measurement100-106Dissipation Factor Measurement107-114Electrical Resistance115-121Elongation122-129Extractables, Refrigerant130-140Film Adherence and Flexibility141-148Formability:a) Elastic Ratio152b) Low Stress Elongation153c) Spring Back154-155Heat Shock156-162Oiliness163-169Scrape Resistance, Unidirectional170-177Solderability178-185Resistance to Insulating Liquids and Hydrolytic Stability186-195

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 9.5, 19.1, 19.3, 19.8, 52.1, 58, 59.1, 74.1, 112.1, 135.4, and 182.3 . Note 1—This test method is related to IEC 60851. Since both methods contain multiple test procedures, many procedures are technically equivalent while others differ significantly.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D1676 – 03

Standard Test Methods for

1

Film-Insulated Magnet Wire

This standard is issued under the fixed designation D1676; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 These test methods cover procedures for testing film-

bility of regulatory limitations prior to use. Specific hazard

insulatedmagnetwirethatisusedinelectricalapparatus.These

statements are given in 9.5, 19.1, 19.3, 19.8, 52.1, 58, 59.1,

test methods are intended primarily for the evaluation of the

74.1, 112.1, 135.4, and 182.3.

electrical insulating materials used.The intent is that these test

methods be used, except where modified, by individual speci-

NOTE 1—This test method is related to IEC60851. Since both methods

fications for particular applications. contain multiple test procedures, many procedures are technically equiva-

lent while others differ significantly.

1.2 These test methods present different procedures for

evaluating given properties of round, rectangular or square,

2. Referenced Documents

copper or aluminum film-insulated magnet wire.

2

2.1 ASTM Standards:

1.3 The values stated in inch-pound units are the standard.

A228/A228M Specification for Steel Wire, Music Spring

The SI units in parentheses are provided for information only.

3

Quality

1.4 The test methods appear in the following sections:

4

B3 Specification for Soft or Annealed Copper Wire

Sections

Bond Strength 4-12 B43 Specification for Seamless Red Brass Pipe, Standard

3

Burnout (AC Overload Resistance) 13-21

Sizes

Chemical Resistance 22-28

B193 Test Method for Resistivity of Electrical Conductor

Coefficient of Friction 29-37

3

Continuity, DC High Voltage 38-45 Materials

Continuity, DC Low Voltage 46-53

B279 Test Method for Stiffness of Bare Soft Square and

Completeness of Cure 54-60

Rectangular Copper andAluminum Wire for Magnet Wire

Cut-Through Temperature (Thermoplastic Flow) 61-68

3

Dielectric Breakdown AC Voltage 69-75

Fabrication

Dielectric Breakdown AC Voltage after Bending 76-82

B324 Specification for Aluminum Rectangular and Square

Dielectric Breakdown AC Voltage at Elevated Temperatures 83-89

3

Wire for Electrical Purposes

Dielectric Breakdown AC Voltage after Conditioning in Refriger-

ant Atmosphere 90-99

B609/B609M Specification for Aluminum 1350 Round

Dimensional Measurement 100-106

Wire, Annealed and Intermediate Tempers, for Electrical

Dissipation Factor Measurement 107-114

5

Purposes

Electrical Resistance 115-121

Elongation 122-129 D149 Test Method for Dielectric Breakdown Voltage and

Extractables, Refrigerant 130-140

Dielectric Strength of Solid Electrical Insulating Materials

Film Adherence and Flexibility 141-148

5

at Commercial Power Frequencies

Formability:

a) Elastic Ratio 152

D150 Test Methods for AC Loss Characteristics and Per-

b) Low Stress Elongation 153

mittivity (Dielectric Constant) of Solid Electrical Insula-

c) Spring Back 154-155

5

tion

Heat Shock 156-162

Oiliness 163-169

D374 Test Methods for Thickness of Solid Electrical Insu-

Scrape Resistance, Unidirectional 170-177 6

lation

Solderability 178-185

D877 Test Method for Dielectric Breakdown Voltage of

Resistance to Insulating Liquids and Hydrolytic Stability 186-195

6

Insulating Liquids Using Disk Electrodes

1.5 This standard does not purport to address all of the

D1533 Test Method for Water in Insulating Liquids by

safety concerns, if any, associated with its use. It is the

5

Coulometric Karl Fischer Titration

1

These test methods are under the jurisdiction of ASTM Committee D09 on

2

Electrical and Electronic Insulating Materials and are the direct responsibility of Annual Book of ASTM Standards, Vol 01.03.

3

Subcommittee D09.10 on Magnet Wire Insulation. Annual Book of ASTM Standards, Vol 02.03.

4

Current edition approved Apr. 10, 2003. Published June 2003. Originally Annual Book of ASTM Standards, Vol 02.01.

5

approved in 1959. Last previous edition approved in 2002 as D1676-02. DOI: Annual Book of ASTM Standards, Vol 10.01.

6

10.1520/D1676-03. Annual Book of ASTM Standards, Vol 10.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

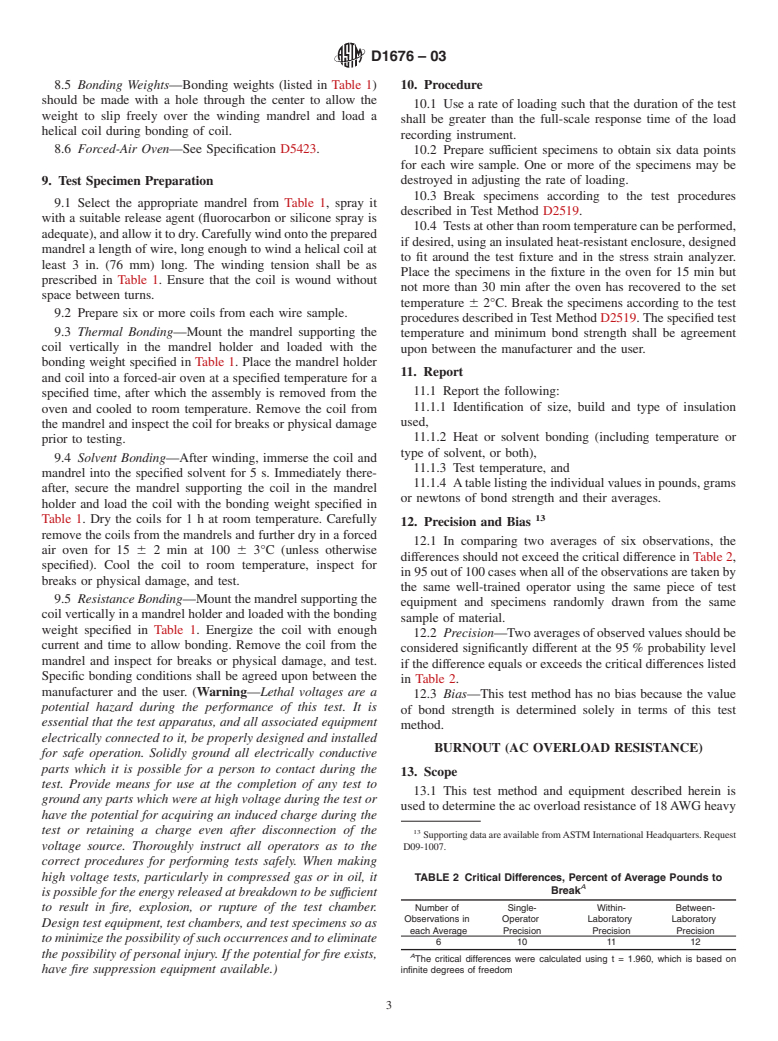

D1676 – 03

7

D1711 Terminology Relating to Electrical Insulation 5.1.1.1 Discussion—For magnet wire which has been self

8

D2475 Specification for Felt bonded or varnish treated, the bond strength is reported as the

D2519 Test Method for Bond Stren

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.