ASTM D6082-00

(Test Method)Standard Test Method for High Temperature Foaming Characteristics of Lubricating Oils

Standard Test Method for High Temperature Foaming Characteristics of Lubricating Oils

SCOPE

1.1 This test method describes the procedure for determining the foaming characteristics of lubricating oils (specifically transmission fluid and motor oil) at 150°C.

1.2 Foaming characteristics of lubricating oils at temperatures up to 93.5°C are determined by Test Method D 892 or IP 146 .

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6082 – 00 An American National Standard

Standard Test Method for

High Temperature Foaming Characteristics of Lubricating

1

Oils

This standard is issued under the fixed designation D 6082; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

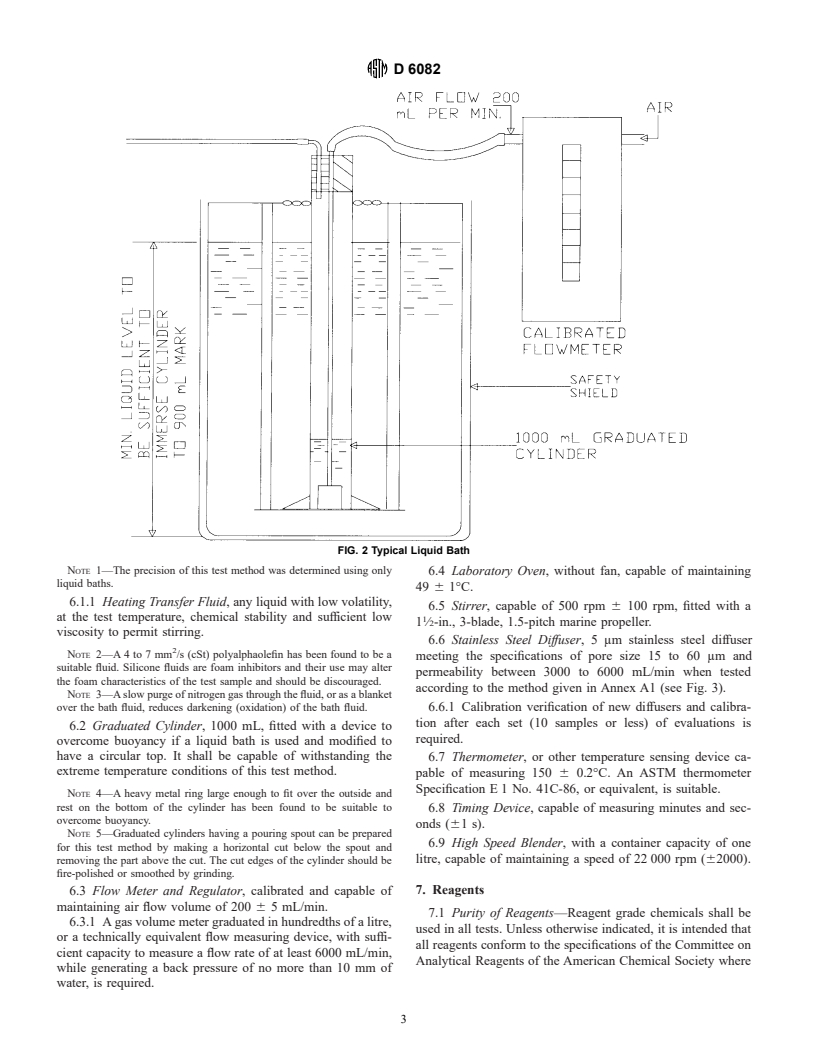

1. Scope mixture of air (or gas) dispersed in a liquid in which the liquid

is the major component on a volumetric basis.

1.1 This test method describes the procedure for determin-

3.1.2.1 Discussion—The air (or gas) is in the form of

ing the foaming characteristics of lubricating oils (specifically

discrete bubbles of about 10 to 1000 μm in diameter. The

transmission fluid and motor oil) at 150°C.

bubbles are not uniformly dispersed. In time, they rise to the

1.2 Foaming characteristics of lubricating oils at tempera-

surface to coalesce to form larger bubbles which break or form

tures up to 93.5°C are determined by Test Method D 892 or IP

foam. Subsurface coalescence can also occur, in which case,

146 .

the bubbles will rise more rapidly.

1.3 The values stated in SI units are to be regarded as the

3.1.3 foam, n—in liquids, a collection of bubbles formed in

standard.

or on the surface of a liquid in which the air or gas is the major

1.4 This standard does not purport to address all of the

component on a volumetric basis.

safety concerns, if any, associated with its use. It is the

3.1.4 gas, n—a fluid (such as air) that has neither indepen-

responsibility of the user of this standard to establish appro-

dent shape nor volume but tends to expand indefinitely.

priate safety and health practices and determine the applica-

3.1.5 lubricant, n—any material interposed between two

bility of regulatory limitations prior to use. For specific hazard

surfaces that reduces friction or wear between them.

statements, see Section 8.

3.1.5.1 Discussion—In this test method, the lubricant is an

2. Referenced Documents oil which may or may not contain additives such as foam

inhibitors.

2.1 ASTM Standards:

3.1.6 maximum pore diameter, n—in gas diffusion, the

D 892 Test Method for Foaming Characteristics of Lubri-

2

diameter of a capillary of circular cross-section which is

cating Oils

3

equivalent (with respect to surface tension effects) to the

E 1 Specification for ASTM Thermometers

largest pore of the diffuser under consideration. The pore

E 128 Test Method for Maximum Pore Diameter and Per-

4

dimension is expressed in micrometers (μm).

meability of Rigid Porous Filters for Laboratory Use

5

3.1.7 permeability, n—in gas diffusion, the rate of a sub-

2.2 Institute of Petroleum Standards:

stance that passes through a material (diffuser) under given

IP146 Standard Method of Test for Foaming Characteristics

conditions.

of Lubricating Oils

3.2 Definitions of Terms Specific to This Standard:

3. Terminology

3.2.1 collapse time, n—in foam testing, the time in seconds,

for zero foam to appear after the air is disconnected at the end

3.1 Definitions:

of the five minute air blowing time.

3.1.1 diffuser, n—for gas, a device for dispersing gas into a

3.2.2 dynamic bubble, n—the first bubble to pass through

liquid (Test Method D 892).

and escape from the diffuser followed by a continuous succes-

3.1.1.1 Discussion—Although diffusers can be made of

sion of bubbles when testing for the pore diameter in Annex

either metallic or non-metallic materials, in this test method the

A1.

diffuser is sintered stainless steel.

3.2.2.1 Discussion—When a diffuser is immersed in a liquid

3.1.2 entrained air (or gas), n—in liquids, a two-phase

such as propan-2-ol, air can be trapped in the pores. It can

escape eventually or as soon as a pressure is applied to the

1

This test method is under the jurisdiction of ASTM Committee D02 on

diffuser. When testing for pore diameter (Annex A1), the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

escape of such bubbles is to be ignored.

D02.06on Analysis of Lubricants.

Current edition approved Dec. 10, 2000. Published February 2001. Originally

3.2.3 foam stability, n—in foam testing, the amount of static

published as D 6082 – 97. Last previous edition D 6082 – 97.

foam remaining at specified times following the disconnecting

2

Annual Book of ASTM Standards, Vol 05.01.

3 of the air supply.

Annual Book of ASTM Standards, Vol 14.03.

4

Annual Book of ASTM Standards, Vol 14.02. 3.2.3.1 five-second foam stability—the amount of static

5

Available from Institute of Petroleum, 61 New Cavendish St., London, W.I.,

foam present 5 s after disconnecting the air supply.

England.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, U

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.