ASTM F673-02

(Test Method)Standard Test Methods for Measuring Resistivity of Semiconductor Slices or Sheet Resistance of Semiconductor Films with a Noncontact Eddy-Current Gage (Withdrawn 2003)

Standard Test Methods for Measuring Resistivity of Semiconductor Slices or Sheet Resistance of Semiconductor Films with a Noncontact Eddy-Current Gage (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 These test methods cover the nondestructive measurement of bulk resistivity of silicon and certain gallium-arsenide slices and of the sheet resistance of thin films of silicon or gallium-arsenide fabricated on a limited range of substrates at the slice center point using a noncontact eddy-current gage.

1.1.1 The measurements are made at room temperature between 18 and 28°C.

1.2 These test methods are presently limited to single-crystal and polycrystalline silicon and extrinsically conducting gallium-arsenide bulk specimens or to thin films of silicon or gallium-arsenide fabricated on relatively high resistivity substrates but in principle can be extended to cover other semiconductor materials.

1.2.1 The bulk silicon or gallium-arsenide specimens may be single crystal or poly crystal and of either conductivity type (p or n) in the form of slices (round or other shape) that are free of diffusions or other conducting layers that are fabricated thereon, that are free of cracks, voids or other structural discontinuities, and that have (1) an edge-to-edge dimension, measured through the slice centerpoint, not less than 25 mm (1.00 in.); (2) thickness in the range 0.1 to 1.0 mm (0.004 to 0.030 in.), inclusive, and (3) resistivity in the range 0.001 to 200 [omega][dot]cm, inclusive. Not all combinations of thickness and resistivity may be measurable. The instrument will fundamentally be limited to a fixed sheet resistance range such as given in 1.2.2; see also 9.3.

1.2.2 The thin films of silicon or gallium-arsenide may be fabricated by diffusion, epitaxial or ion implant processes. The sheet resistance of the layer should be in the nominal range from 2 to 3000 [omega] per square. The substrate on which the thin film is fabricated should have a minimum edge to edge dimension of 25 mm, measured through the centerpoint and an effective sheet resistance at least 1000 X that of the thin film. The effective sheet resistance of a bulk substrate is its bulk resistivity (in [omega][dot]cm) divided by its thickness in cm.

1.2.3 Measurements are not affected by specimen surface finish.

1.3 These test methods require the use of resistivity standards to calibrate the apparatus (see 7.1), and a set of reference specimens for qualifying the apparatus (see 7.2).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 673 – 02

Standard Test Methods for

Measuring Resistivity of Semiconductor Slices or Sheet

Resistance of Semiconductor Films with a Noncontact

1

Eddy-Current Gage

This standard is issued under the fixed designation F 673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is intended to outline the principles of eddy-current measurements as they relate

to semiconductor substrates and certain thin films fabricated on such substrates as well as requirements

for setting up and calibrating such instruments for use particularly at a buyer-seller interface. Because

such eddy-current measurements for semiconductor materials are made almost exclusively with

commercial instrumentation from one of several suppliers, some details included here such as specific

range limits and manner of entering slice/wafer thickness values to obtain resistivity values may not

apply strictly to all instruments. In all such cases, the owner’s manual for the particular instrument

shall be considered to contain the correct information for that instrument. It is to be noted that an

eddy-current instrument directly measures conductance of a specimen. Values of sheet resistance and

resistivity are calculated from the measured conductance, with the resistivity values also requiring a

measurement of specimen thickness.

1. Scope (1.00 in.); (2) thickness in the range 0.1 to 1.0 mm (0.004 to

0.030 in.), inclusive, and ( 3) resistivity in the range 0.001 to

1.1 These test methods cover the nondestructive measure-

200 V·cm, inclusive. Not all combinations of thickness and

ment of bulk resistivity of silicon and certain gallium-arsenide

resistivity may be measurable. The instrument will fundamen-

slices and of the sheet resistance of thin films of silicon or

tally be limited to a fixed sheet resistance range such as given

gallium-arsenide fabricated on a limited range of substrates at

in 1.2.2; see also 9.3.

the slice center point using a noncontact eddy-current gage.

1.2.2 The thin films of silicon or gallium-arsenide may be

1.1.1 The measurements are made at room temperature

fabricated by diffusion, epitaxial or ion implant processes. The

between 18 and 28°C.

sheet resistance of the layer should be in the nominal range

1.2 These test methods are presently limited to single-

from 2 to 3000 V per square. The substrate on which the thin

crystal and polycrystalline silicon and extrinsically conducting

film is fabricated should have a minimum edge to edge

gallium-arsenide bulk specimens or to thin films of silicon or

dimension of 25 mm, measured through the centerpoint and an

gallium-arsenide fabricated on relatively high resistivity sub-

effective sheet resistance at least 1000 3 that of the thin film.

strates but in principle can be extended to cover other semi-

The effective sheet resistance of a bulk substrate is its bulk

conductor materials.

resistivity (in V·cm) divided by its thickness in cm.

1.2.1 The bulk silicon or gallium-arsenide specimens may

1.2.3 Measurements are not affected by specimen surface

be single crystal or poly crystal and of either conductivity type

finish.

(p or n) in the form of slices (round or other shape) that are free

1.3 These test methods require the use of resistivity stan-

of diffusions or other conducting layers that are fabricated

dards to calibrate the apparatus (see 7.1), and a set of reference

thereon, that are free of cracks, voids or other structural

specimens for qualifying the apparatus (see 7.1.2).

discontinuities, and that have (1) an edge-to-edge dimension,

1.4 The values stated in SI units are to be regarded as the

measured through the slice centerpoint, not less than 25 mm

standard. The values given in parentheses are for information

only.

1

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon

Materials and Process Control.

Current edition approved Dec. 10, 2002. Published February 2003. Originally

e1

approved in 1980. Last previous edition approved in 1990 as F 673 – 90 (1996) .

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F673–02

1.5 This standard does not purport to address all of the by the apparatus and converted to a resistivity value that is

safety concerns, if

...

Questions, Comments and Discussion

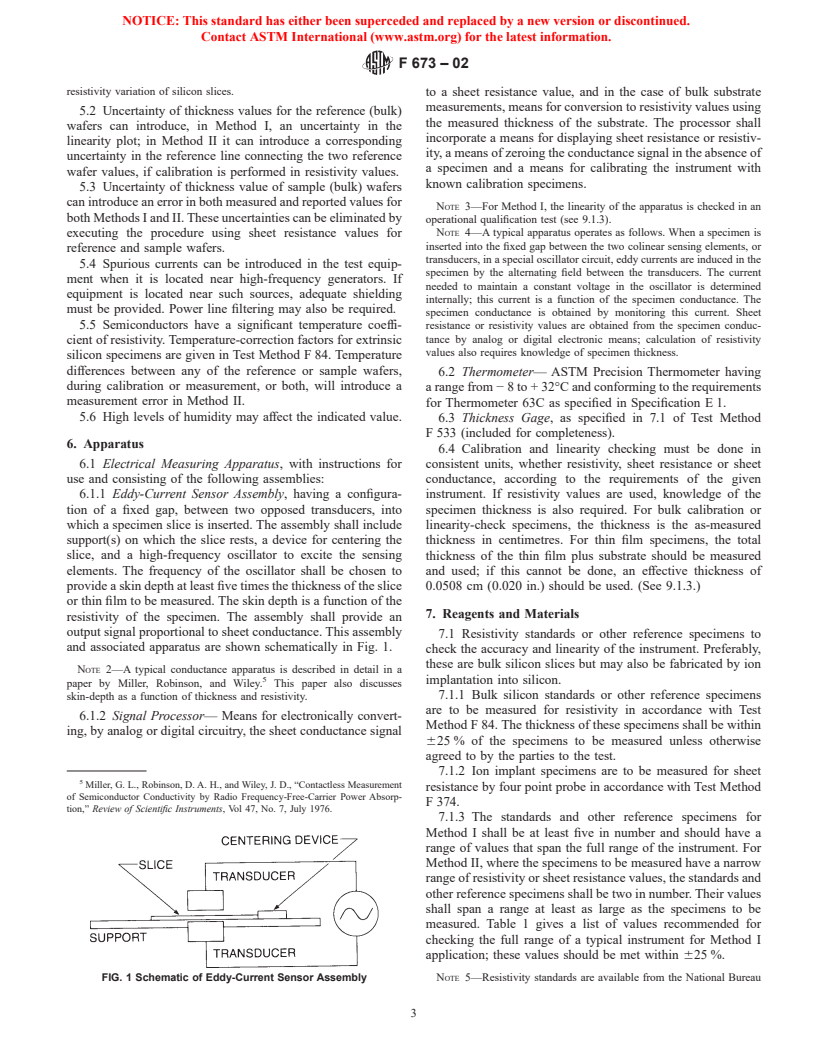

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.