ASTM F951-96

(Test Method)Standard Test Method for Determination of Radial Interstitial Oxygen Variation in Silicon Wafers

Standard Test Method for Determination of Radial Interstitial Oxygen Variation in Silicon Wafers

SCOPE

1.1 This test method covers test site selection and data reduction procedures for radial variation of the interstitial oxygen concentration in silicon slices typically used in the manufacture of microelectronic semiconductor devices.

1.2 This test method is intended as both a referee and production test through selection of an appropriate test position plan.

1.3 The interstitial oxygen content may be measured in accordance with Test Methods F 1188 or F 1619, DIN 50438/1, JEIDA 61, or any other procedure agreed upon by the parties to the test.

Note 1—Test Method F 1366 is not based on infrared absorption measurement and it measures total oxygen content, not interstitial oxygen content. It is also a destructive technique. However, it can be used to determine the radial variation of the oxygen content if suitable modifications of the test procedure are made.

1.4 Acceptable thickness and surface finish for the test specimens are specified in the applicable test methods. This test method is suitable for use on chemically etched, single-side polished and double-side polished silicon wafers or slices with no surface defects that could adversely change infrared radiation transmission through the test specimen (subsequently called slice), provided that appropriate test methods for oxygen content are selected.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 951 – 96

Standard Test Method for Variation of

Determination of Radial Interstitial Oxygen Variation in

Silicon Wafers

This standard is issued under the fixed designation F 951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 533 Test Method for Thickness and Thickness Variation

of Silicon Wafers

1.1 This test method covers test sight selection and data

F 1188 Test Method for Interstitial Atomic Oxygen Content

reduction procedures for radial variation of the interstitial

of Silicon by Infrared Absorption

oxygen concentration in silicon slices typically used in the

F 1366 Test Method for Measuring Oxygen Concentration

manufacture of microelectronic semiconductor devices.

in Heavily Doped Silicon Substrates by Secondary Ion

1.2 This test method is intended as both a referee and

Mass Spectrometry

production test through selection of an appropriate test position

2.2 DIN Standard:

plan.

DIN 50438/1 Test of Materials for Semiconductor Technol-

1.3 The interstitial oxygen content may be measured in

ogy; Determination of Impurity Content in Silicon by

accordance with Test Methods F 1188 or F 1366, DIN 50438/1,

Infrared Absorption; Oxygen

or any other procedure agreed upon by the parties to the test.

2.3 ANSI Standard:

NOTE 1—Test Method F 1188 covers only double-side polished test 4

ANSI/ASQC 21.4

specimens and cites the IOC-88 Conversion Factor. Test Method F 1188

requires the use on an “oxygen-free” reference specimen of approximately

3. Summary of Test Method

the same thickness as the test specimen that can have a thickness from 0.4

3.1 Instruments are selected and qualified according to the

to 4 mm; either a dispersive or a Fourier transform infrared spectropho-

test procedure chosen.

tometer may be used and computer control is allowed, but not required.

NOTE 2—DIN 50438/1 covers double-side polished specimens with

3.2 Measurements are made at the specified test locations

thicknesses at least 1 mm, and single-side polished wafers with etched

and a relative oxygen variation is calculated by one of four

back surfaces and a thickness at least 0.3 mm. Either dispersive or Fourier

available plans.

transform instruments may be used. This standard contains two methods.

Method A requires double-side polished test and reference specimens and

4. Significance and Use

it is essentially equivalent to Test Method F 1188 except that multiple

4.1 The presence of oxygen can be beneficial to certain

spectra must be taken, therefore requiring computer control of the

manufacturing operations by preventing the formation of

spectrophotometer. Method B can be applied to single-side polished test

wafers, but it requires a double-side polished reference specimen.

process-induced defects. To the extent that this is true, it

becomes important that the oxygen be uniformly distributed

1.4 Sample surface finishes can include chemically etched,

over the entire slice.

single-side polished, and double-side polished silicon slices

4.2 Multiple test plans are included to satisfy a variety of

with no surface defects that could adversely change infrared

requirements. The characteristic shape and magnitude of oxy-

radiation transmission through the slice.

gen concentration distributions in crystals are functions of the

1.5 This standard does not purport to address all of the

crystal growth process. Although the specified test plans are

safety concerns, if any, associated with its use. It is the

intended to cover oxygen concentration distributions which are

responsibility of the user of this standard to establish appro-

typically found, other distributions may occur. In such cases, it

priate safety and health practices and determine the applica-

may be necessary to use test positions other than those

bility of regulatory limitations prior to use.

specified in order to adequately describe the distribution

2. Referenced Documents

pattern.

4.3 This test method may be used for process control,

2.1 ASTM Standards:

research and development, and materials acceptance purposes.

1 Annual Book of ASTM Standards, Vol 10.05.

This test method is under the jurisdiction of ASTM Committee F-1 on

DIN 50438/1 is the responsibility of DIN Committee NMP 221, with which

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon

ASTM F-1 maintains close liason. DIN 50438/1 is available from Beuth Verlag

Materials and Process Control.

GmbH, Burggrafenstrasse 4-10, D-1000, Berlin 30, Germany (see also Vol 10.05).

Current edition approved Dec. 10, 1996. Published February 1997. Originally

Available from American Society for Quality Control (ASQC), P.O. Box 3005

published as F 951 – 85. Last previous edition F 951 – 92.

Milwaukee, WI 53201-9404.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 951

In the absence of an interlaboratory evaluation of the precision ~Avg of Edge Values! 2 Center

ROV 5 3 100 (2)

Center

of this test method, its use for materials acceptance is not

recommended unless the parties involved establish the degree

9.1.3 Plan B-1—Five Positions (Fig. A2.1): ROV is the

of correlation which can be expected (see Section 11).

larger of the values found from the equation in 9.1.2 and the

following:

5. Interferences

~Avg of R/2 Values! 2 Center

5.1 Variations of optical thickness can be caused by thick-

ROV 5 3 100 (3)

Center

ness or surface finish variations, or both.

9.1.4 Plan C—Five Positions (Fig. A3.1):

5.2 Beam size differences from instrument to instrument can

cause errors when the beam area is smaller than the aperture

~Avg of Edge Values! 2 Center

ROV 5 3 100 (4)

used in this test method.

Center

9.1.5 Plan D—Multiple Positions (Fig. A4.1):

6. Apparatus

Individual High2Individual Low

~ !

6.1 Infrared Spectrophotometer, as required by the test

ROV 5 3 100 (5)

Center

method for interstitial oxygen measurement.

6.2 Thickness Measurement Equipment, as required by the

NOTE 3—All edge positions are located from the center of the IR beam

test method.

to the slice edge. All other non-center positions are located such that the

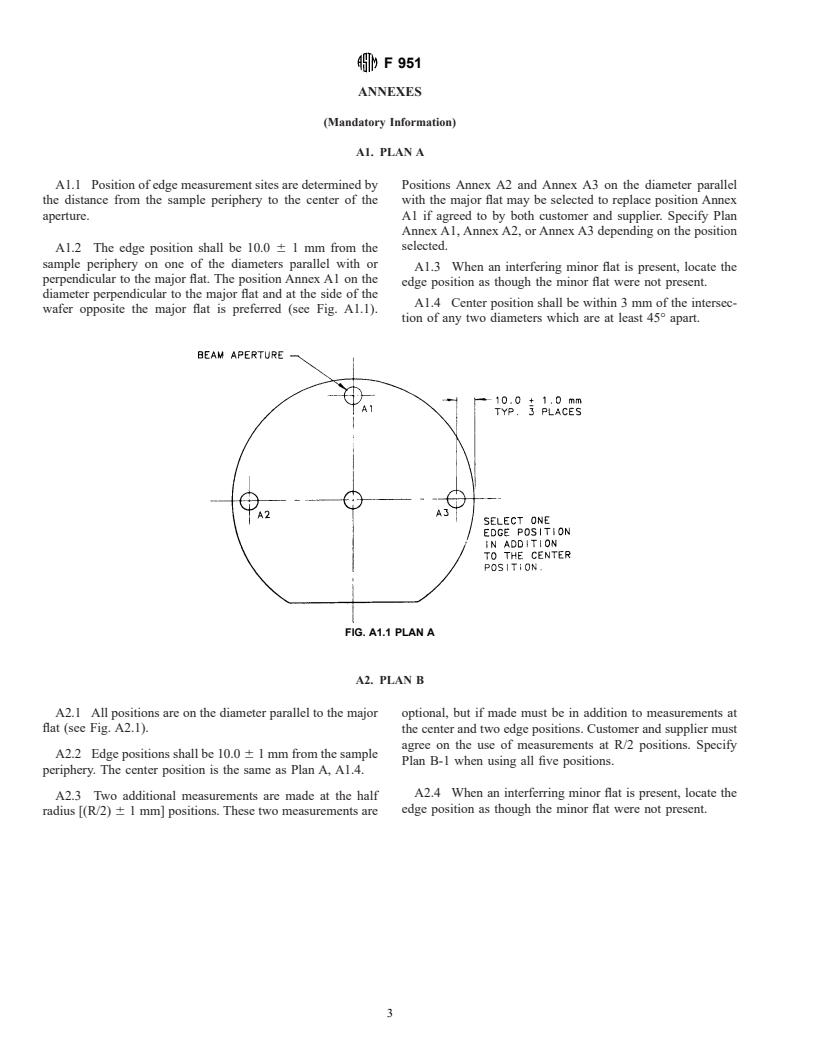

center of the IR beam is located as given by the dimensions in Fig. A1.1,

6.3 Fixturing, capable of positioning test slices to the

Fig. A2.1, Fig. A3.1, and Fig. A4.1.

tolerances required in each plan, includin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.