ASTM D5337-11

(Practice)Standard Practice for Flow Rate for Calibration of Personal Sampling Pumps

Standard Practice for Flow Rate for Calibration of Personal Sampling Pumps

SIGNIFICANCE AND USE

Most occupational exposure assessment methods require the use of personal sampling pumps to collect air samples at typical workplace sampling rates, with sampling volumes specified by (a) particular procedure(s). The precision and bias of these methods are directly affected by the precision and bias of the pumps used to measure the air volume(s) sampled.

SCOPE

1.1 This practice describes the calibration of sampling pumps commonly used for monitoring personal airborne exposures in the work-place.

1.2 This practice includes procedures for describing primary and secondary calibration techniques.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5337 − 11

StandardPractice for

1

Flow Rate Adjustment of Personal Sampling Pumps

This standard is issued under the fixed designation D5337; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope primary standard, unless the apparatus used in the calibration

(burets, stop-watches, etc.) has been demonstrated to be

1.1 This practice describes the calibration of sampling

traceable to national or international standards, and that this

pumps commonly used for monitoring personal airborne ex-

traceability is established on a routine (generally annual) basis.

posures in the work-place.

Traceability of calibration is strongly recommended.

1.2 Thispracticeincludesproceduresfordescribingprimary

and secondary calibration techniques.

4. Summary of Practice

1.3 This standard does not purport to address all of the

4.1 Abubbletubemeterorelectronicnear-frictionlesspump

safety concerns, if any, associated with its use. It is the

is used for primary calibration of personal sampling pumps.

responsibility of the user of this standard to establish appro-

The practice is applicable to systems using air sampling

priate safety and health practices and determine the applica-

devices. Provisions are made for both manual and automated

bility of regulatory limitations prior to use.

bubble meters.

4.2 Secondary calibration procedures for field applications

2. Referenced Documents

2 are also included in the practice (see 7.3).

2.1 ASTM Standards:

D1356 Terminology Relating to Sampling and Analysis of

5. Significance and Use

Atmospheres

5.1 Most occupational exposure assessment methods re-

2.2 NIOSH and OSHA Documents:

quiretheuseofpersonalsamplingpumpstocollectairsamples

HSM-99-71-31 Personal Sampling Pump for Charcoal

3

at typical workplace sampling rates, with sampling volumes

Tubes; Final Report

th 4

specified by (a) particular procedure(s). The precision and bias

NIOSH— Manual of Analytical Methods, 4 ed.

5

of these methods are directly affected by the precision and bias

OSHA— Analytical Methods Manual

of the pumps used to measure the air volume(s) sampled.

3. Terminology

6. Apparatus

3.1 For definitions of terms used in this practice, refer to

Terminology D1356.

6.1 Burets, 1-L (for high flow) and 100-mL or 10 mL (for

low flow).

3.2 The term primary flow-rate calibration, as used in this

practice, does not imply the calibration is traceable to a

6.2 Manometer.

6.3 Rotameter.

1

This practice is under the jurisdiction ofASTM Committee D22 on Air Quality

6.4 Stop Watch.

and is the direct responsibility of Subcommittee D22.04 on WorkplaceAir Quality.

Current edition approved Nov. 15, 2011. Published December 2011. Originally

6.5 Electronic Bubble Meter or Near-frictionless Piston

approved in 1992. Last previous edition approved in 2004 as D5337 – 04. DOI:

Flowmeter (alternates), should have traceable calibration (see

10.1520/D5337-11.

3.2).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

7. Procedure

the ASTM website.

3

7.1 Calibrate the personal sampling pumps before and

Available from the U.S. Department of Commerce, National Technical Infor-

mation Service, Port Royal Road, Springfield, VA 22161.

measure after each day’s sampling.

4

Centers for Disease Control and Prevention (CDC), National Institute for

7.2 Primary Flow-rate Calibration Device(s), (as noted in

Occupational Safety and Health (NIOSH), Cincinnati, Ohio (1994);Available from

NIOSH Publications, 4676 Columbia Parkway, Cincinnati, Ohio 45226;

3.2, these are not primary standards unless the apparatus used

www.cdc.gov/niosh/nmam.

in the calibration has been demonstrated to be traceable to

5

Occupational Safety and Health Administration, Salt Lake Technical Center,

national and international standards):

Salt Lake City, Utah (1985); Available from OSHAAnalytical Laboratory, 8660 S.

Sandy Parkway, Sandy, UT 84070; www.osha.gov/dts/sltc/methods. 7.2.1 Bubble Meter Method:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5337 − 11

7.2.1.1 Allow the pump to run five minutes prior to calibra-

tion to stabilize pump.

7.2.1.2 Connect pump to an appropriate sampling train.

Sampling trains identical to that used in sampling for sorbent

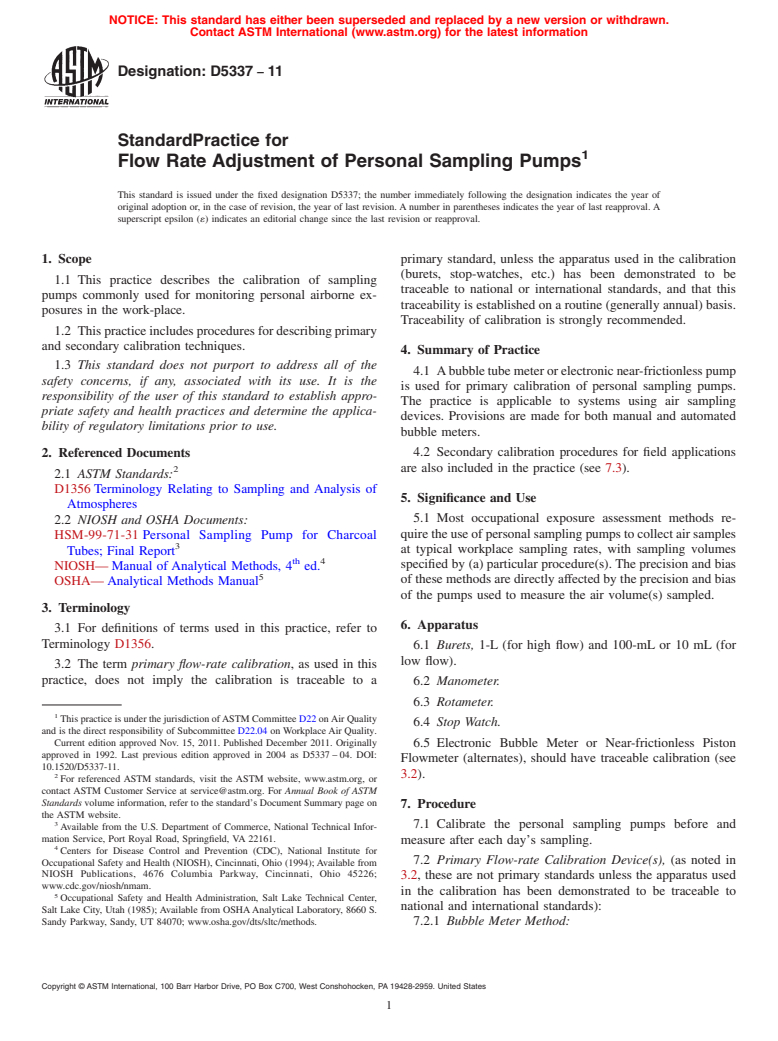

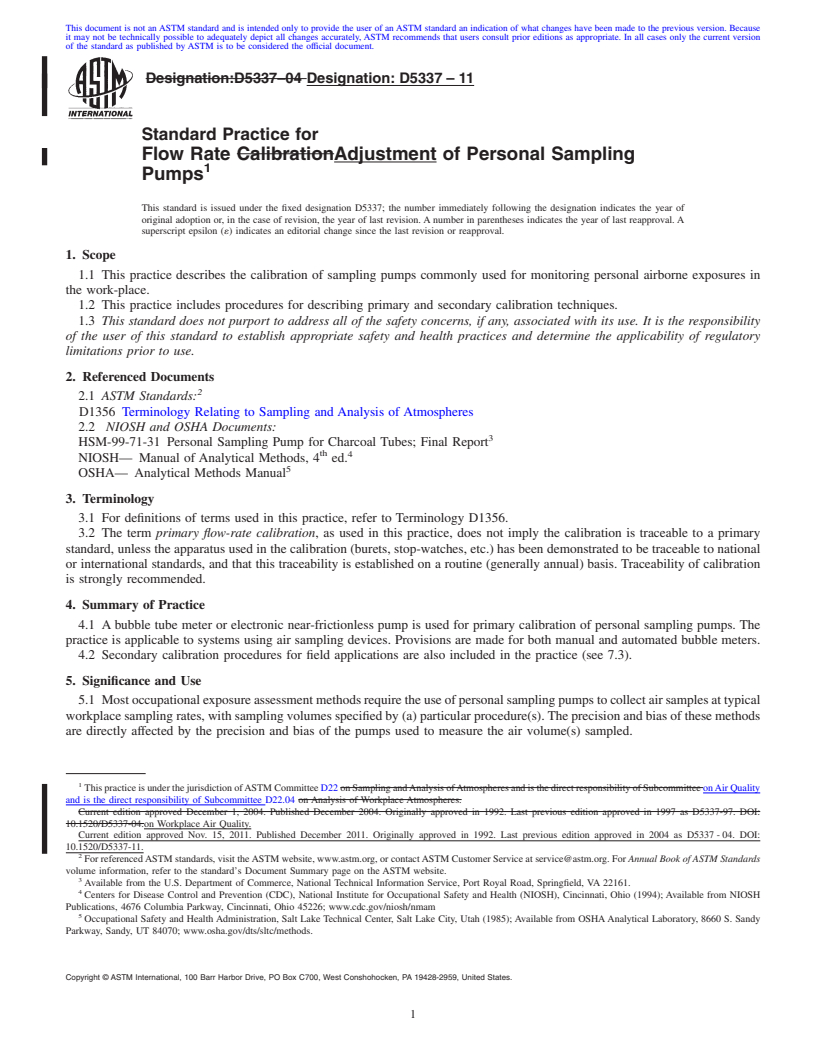

tubes, filter cassettes, and cyclones are shown in Figs. 1-3.

7.2.1.3 Check all connections to insure their integrity.

7.2.1.4 Wet th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5337–04 Designation:D5337–11

Standard Practice for

Flow Rate CalibrationAdjustment of Personal Sampling

1

Pumps

This standard is issued under the fixed designation D5337; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the calibration of sampling pumps commonly used for monitoring personal airborne exposures in

the work-place.

1.2 This practice includes procedures for describing primary and secondary calibration techniques.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1356 Terminology Relating to Sampling and Analysis of Atmospheres

2.2 NIOSH and OSHA Documents:

3

HSM-99-71-31 Personal Sampling Pump for Charcoal Tubes; Final Report

th

4

NIOSH— Manual of Analytical Methods, 4 ed.

5

OSHA— Analytical Methods Manual

3. Terminology

3.1 For definitions of terms used in this practice, refer to Terminology D1356.

3.2 The term primary flow-rate calibration, as used in this practice, does not imply the calibration is traceable to a primary

standard, unless the apparatus used in the calibration (burets, stop-watches, etc.) has been demonstrated to be traceable to national

or international standards, and that this traceability is established on a routine (generally annual) basis. Traceability of calibration

is strongly recommended.

4. Summary of Practice

4.1 A bubble tube meter or electronic near-frictionless pump is used for primary calibration of personal sampling pumps. The

practice is applicable to systems using air sampling devices. Provisions are made for both manual and automated bubble meters.

4.2 Secondary calibration procedures for field applications are also included in the practice (see 7.3).

5. Significance and Use

5.1 Mostoccupationalexposureassessmentmethodsrequiretheuseofpersonalsamplingpumpstocollectairsamplesattypical

workplace sampling rates, with sampling volumes specified by (a) particular procedure(s).The precision and bias of these methods

are directly affected by the precision and bias of the pumps used to measure the air volume(s) sampled.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD22onSamplingandAnalysisofAtmospheresandisthedirectresponsibilityofSubcommitteeonAirQuality

and is the direct responsibility of Subcommittee D22.04 on Analysis of Workplace Atmospheres.

Current edition approved December 1, 2004. Published December 2004. Originally approved in 1992. Last previous edition approved in 1997 as D5337-97. DOI:

10.1520/D5337-04.on Workplace Air Quality.

Current edition approved Nov. 15, 2011. Published December 2011. Originally approved in 1992. Last previous edition approved in 2004 as D5337 - 04. DOI:

10.1520/D5337-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the U.S. Department of Commerce, National Technical Information Service, Port Royal Road, Springfield, VA 22161.

4

Centers for Disease Control and Prevention (CDC), National Institute for Occupational Safety and Health (NIOSH), Cincinnati, Ohio (1994); Available from NIOSH

Publications, 4676 Columbia Parkway, Cincinnati, Ohio 45226; www.cdc.gov/niosh/nmam

5

Occupational Safety and Health Administration, Salt Lake Technical Center, Salt Lake City, Utah (1985); Available from OSHAAnalytical Laboratory, 8660 S. Sandy

Parkway, Sandy, UT 84070; www.osha.gov/dts/sltc/methods.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5337–11

6. Apparatus

6.1 Burets, 1-L (for high flow) and 100-mL or 10 mL (for low flow).

6.2 Manometer.

6.3 Rotameter.

6.4 Stop Watch.

6.5 Electronic Bubble Meter or Near-frictionless Piston Flowmeter (alternates), should have traceable calibration (see 3.2).

7. Procedure

7.1 Calibrate the personal sampling pumps before and measure after each day’s sampling.

7.2 Pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.