ASTM E1209-99

(Test Method)Standard Test Method for Fluorescent Liquid Penetrant Examination Using the Water-Washable Process

Standard Test Method for Fluorescent Liquid Penetrant Examination Using the Water-Washable Process

SCOPE

1.1 This test method covers procedures for water-washable fluorescent penetrant examination of materials. It is a nondestructive testing method for detecting discontinuities that are open to the surface such as cracks, seams, laps, cold shuts, laminations, isolated porosity, through leaks, or lack of porosity and is applicable to in-process, final, and maintenance examination. It can be effectively used in the examination of nonporous, metallic materials, both ferrous and nonferrous, and of nonmetallic materials such as glazed or fully densified ceramics and certain nonporous plastics and glass.

1.2 This test method also provides a reference:

1.2.1 By which a fluorescent penetrant examination method using the water-washable process recommended or required by individual organizations can be reviewed to ascertain its applicability and completeness.

1.2.2 For use in the preparation of process specifications dealing with the water-washable fluorescent penetrant examination of materials and parts. Agreement by the purchaser and the manufacturer regarding specific techniques is strongly recommended.

1.2.3 For use in the organization of the facilities and personnel concerned with the liquid penetrant examination.

1.3 This test method does not indicate or suggest standards for evaluation of the indications obtained. It should be pointed out, however, that after indications have been produced, they must be interpreted or classified and then evaluated. For this purpose there must be a separate code or specification or a specific agreement to define the type, size, location, and direction of indications considered acceptable, and those considered unacceptable.

1.4 The values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Notes 6, 14, and 20.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1209–99

Standard Test Method for

Fluorescent Liquid Penetrant Examination Using the Water-

Washable Process

This standard is issued under the fixed designation E 1209; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers procedures for water-washable

responsibility of the user of this standard to establish appro-

fluorescent penetrant examination of materials. It is a nonde-

priate safety and health practices and determine the applica-

structive testing method for detecting discontinuities that are

bility of regulatory limitations prior to use. For specific hazard

open to the surface such as cracks, seams, laps, cold shuts,

statements, see Notes 13 and 18.

laminations, isolated porosity, through leaks, or lack of poros-

ity and is applicable to in-process, final, and maintenance

2. Referenced Documents

examination. It can be effectively used in the examination of

2.1 ASTM Standards:

nonporous, metallic materials, both ferrous and nonferrous,

D 129 Test Method for Sulfur in Petroleum Products (Gen-

and of nonmetallic materials such as glazed or fully densified

eral Bomb Method)

ceramics and certain nonporous plastics and glass.

D 516 Test Methods for Sulfate Ion in Water

1.2 This test method also provides a reference:

D 808 Test Method for Chlorine in New and Used Petro-

1.2.1 By which a fluorescent penetrant examination method

leum Products (Bomb Method)

using the water-washable process recommended or required by

D 1552 Test Method for Sulfur in Petroleum Products

individual organizations can be reviewed to ascertain its

(High-Temperature Method)

applicability and completeness.

E 165 Test Method for Liquid Penetrant Examination

1.2.2 For use in the preparation of process specifications

E 433 Reference Photographs for Liquid Penetrant Inspec-

dealing with the water-washable fluorescent penetrant exami-

tion

nation of materials and parts.Agreement by the purchaser and

E 543 Practice for Evaluating Agencies that Perform Non-

the manufacturer regarding specific techniques is strongly

destructive Testing

recommended.

E 1316 Terminology for Nondestructive Examinations

1.2.3 For use in the organization of the facilities and

2.2 ASNT Documents:

personnel concerned with the liquid penetrant examination.

Recommended Practice SNT-TC-1A Personnel Qualifica-

1.3 This test method does not indicate or suggest standards

tion and Certification in Nondestructive Testing

for evaluation of the indications obtained. It should be pointed

ANSI/ASNT-CP-189 Qualification and Certification of

out, however, that indications must be interpreted or classified

NDT Personnel

and then evaluated. For this purpose there must be a separate

2.3 Military Standard:

code or specification or a specific agreement to define the type,

MIL-STD-410 Nondestructive Testing Personnel Qualifica-

size, location, and direction of indications considered accept-

tion and Certification

able, and those considered unacceptable.

2.4 AIA Standard:

1.4 The values stated in inch-pound units are to be regarded

NAS 410 Certification and Qualification of Nondestructive

as the standard. SI units are provided for information only.

Test Personnel

1.5 All areas of this document may be open to agreement

2.5 Department of Defense (DoD) Contracts—Unless oth-

between the cognizant engineering organization and the sup-

erwise specified, the issue of the documents that are DoD

plier, or specific direction from the cognizant engineering

organization.

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 11.01.

1 5

This test method is under the jurisdiction of ASTM Committee E-7 on Annual Book of ASTM Standards, Vol 03.03.

Nondestructive Testing and is the direct responsibility of Subcommittee E07.03 on Available from the American Society for Nondestructive Testing, 1711 Arlin-

Liquid Penetrant and Magnetic Particle Methods. gate Plaza, Columbus, OH 43228-0518.

Current edition approved Feb. 10, 1999. Published April 1999. Originally AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

published as E 1209 – 87. Last previous edition E 1209 – 94. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

2 8

For ASME Boiler and Pressure Vessel Code applications see related Test Available from the Aerospace Industries Association of America, Inc., 1250

Method SE-1209 in Section II of that Code. Eye Street, N.W., Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1209–99

adopted are those listed in the issue of the DoDISS (Depart- a family of fluorescent water-washable penetrants and appro-

ment of Defense Index of Specifications and Standards) cited priate developers and are classified as Type I Fluorescent,

in the solicitation. Method A—Water-Washable. Intermixing of materials from

various manufacturers is not recommended.

2.6 Order of Precedence—In the event of conflict between

NOTE 4—Refer to 8.1 for special requirements for sulfur, halogen, and

the text of this test method and the references cited herein, the

alkali metal content.

text of this test method takes precedence.

NOTE 5—Caution: While approved penetrant materials will not ad-

verselyaffectcommonmetallicmaterials,someplasticsorrubbersmaybe

swollen or stained by certain penetrants.

3. Terminology

6.2 Water-Washable Penetrants are designed to be directly

3.1 Definitions—definitions relating to liquid penetrant ex-

water-washable from the surface of the test part after a suitable

amination, which appear inTerminology E 1316, shall apply to

penetrant dwell time. Because the emulsifier is “built-in’’ to

the terms used in this test method.

the water-washable penetrant, it is extremely important to

4. Summary of Test Method exercise proper process control in removal of excess surface

penetrant to assure against overwashing. Water-washable pen-

4.1 A liquid penetrant is applied evenly over the surface

etrants can be washed out of discontinuities if the rinsing step

being tested and allowed to enter open discontinuities. After a

is too long or too vigorous. Some penetrants are less resistant

suitable dwell time, the excess surface penetrant is removed

to overwashing than others.

with water and the surface is dried prior to the application of a

6.3 Developers—Development of penetrant indications is

dry or nonaqueous developer. A developer is then applied,

the process of bringing the penetrant out of open discontinui-

drawing the entrapped penetrant out of the discontinuity and

ties through blotting action of the applied developer, thus

staining the developer. If an aqueous developer is to be

increasing the visibility of the penetrant indications. Several

employed,thedeveloperisappliedpriortothedryingstep.The

types of developers are suitable for use and the fluorescent

test surface is then examined visually under black light in a

penetrant water-washable process.

darkened area to determine the presence or absence of indica-

tions.

NOTE 6—Caution: Aqueous developers may cause stripping of indica-

tions if not properly applied and controlled. The procedure shall be

NOTE 1—The developer may be omitted by agreement between pur-

qualified in accordance with 9.2.

chaser and supplier.

NOTE 2—Caution: Fluorescent penetrant examination shall not follow

6.3.1 Dry Powder Developers are used as supplied (that is,

a visible penetrant examination unless the procedure has been qualified in

free-flowing,noncakingpowder)inaccordancewith7.1.7.1(a).

accordance with 9.2, because visible dyes may cause deterioration or

Care should be taken not to contaminate the developer with

quenching of fluorescent dyes.

fluorescent penetrant, as the specks can appear as indications.

4.2 The selection of particular water-washable penetrant

6.3.2 Aqueous Developers are normally supplied as dry

process parameters depends upon the nature of the application,

powder particles to be either suspended or dissolved (soluble)

condition under which the examination is to be performed,

in water. The concentration, use, and maintenance shall be in

availability of processing equipment, and type of materials to

accordance with the manufacturer’s recommendations (see

perform the examination.

7.1.7.1(b)).

6.3.3 Nonaqueous, Wet Developers are supplied as suspen-

NOTE 3—Caution: Acontrolled method for applying water and dispos-

sions of developer particles in nonaqueous, solvent carriers

ing of the water is essential.

ready for use as supplied. Nonaqueous, wet developers form a

4.3 Processing parameters, such as precleaning, penetration

coating on the surface of the part when dried, which serves as

time and wash times, are determined by the specific materials

the developing medium for fluorescent penetrants (see

used, the nature of the part under examination, (that is, size,

7.1.7.1(c)).

shape, surface condition, alloy) and type of discontinuities

expected. NOTE 7—Caution: This type of developer is intended for application

by spray only.

5. Significance and Use

6.3.4 Liquid Film Developers are solutions or colloidal

5.1 Liquidpenetrantexaminationmethodsindicatethepres-

suspensions of resins/polymer in a suitable carrier. These

ence, location, and, to a limited extent, the nature and magni-

developerswillformatransparentortranslucentcoatingonthe

tude of the detected discontinuities. This method is normally

surface of the part. Certain types of film developer will fix

used for production inspection of large volumes of parts or

indications and may be stripped from the part and retained for

structures, where emphasis is on productivity. The method

record purposes (see 7.1.7.1(d)).

enjoys a wide latitude in applicability when extensive and

controlled conditions are available. Multiple levels of sensitiv-

7. Procedure

ity can be achieved by proper selection of materials and

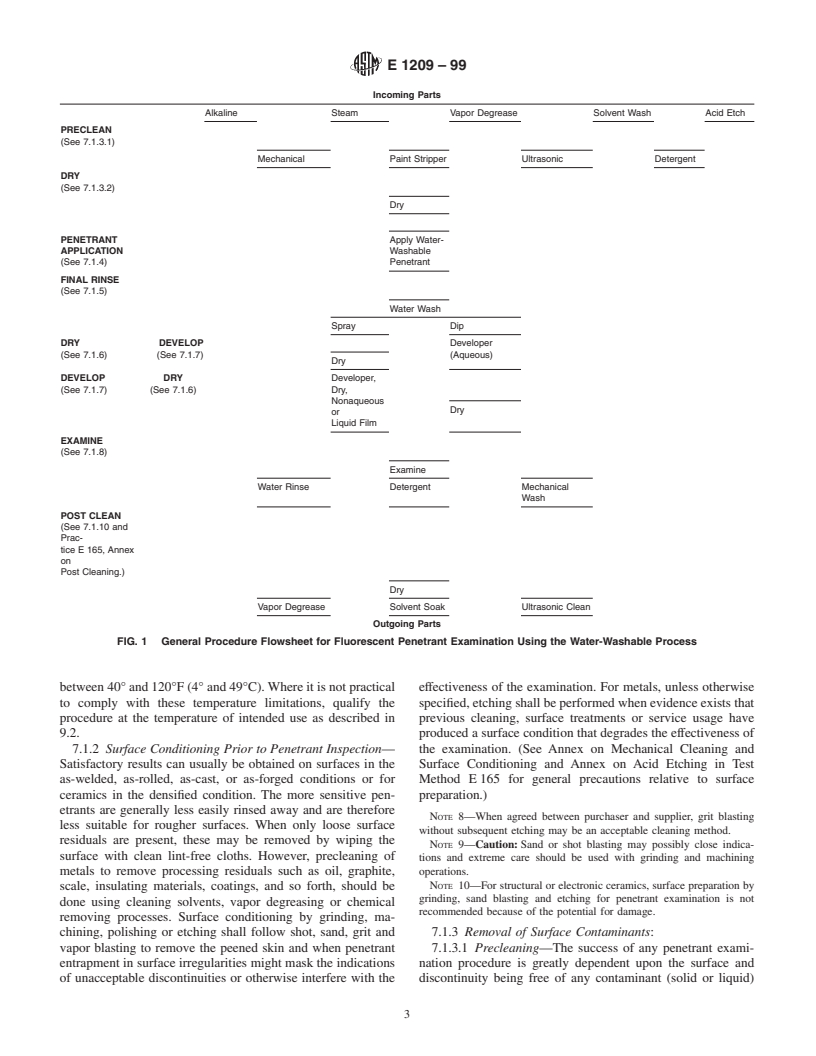

7.1 The following general procedure applies to the fluores-

variations in process.

cent penetrant examination water-washable method (see Fig.

6. Reagents and Materials

1).

6.1 Liquid Fluorescent Penetrant Examination Materials 7.1.1 Temperature Limits—Thetemperatureofthepenetrant

(see Note 4) for use in the water-washable process consist of materials and the surface of the part to be processed should be

E1209–99

Incoming Parts

Alkaline Steam Vapor Degrease Solvent Wash Acid Etch

PRECLEAN

(See 7.1.3.1)

Mechanical Paint Stripper Ultrasonic Detergent

DRY

(See 7.1.3.2)

Dry

PENETRANT Apply Water-

APPLICATION Washable

(See 7.1.4) Penetrant

FINAL RINSE

(See 7.1.5)

Water Wash

Spray Dip

DRY DEVELOP Developer

(See 7.1.6) (See 7.1.7) (Aqueous)

Dry

DEVELOP DRY Developer,

(See 7.1.7) (See 7.1.6) Dry,

Nonaqueous

Dry

or

Liquid Film

EXAMINE

(See 7.1.8)

Examine

Water Rinse Detergent Mechanical

Wash

POST CLEAN

(See 7.1.10 and

Prac-

tice E 165, Annex

on

Post Cleaning.)

Dry

Vapor Degrease Solvent Soak Ultrasonic Clean

Outgoing Parts

FIG. 1 General Procedure Flowsheet for Fluorescent Penetrant Examination Using the Water-Washable Process

between 40° and 120°F (4° and 49°C).Where it is not practical effectiveness of the examination. For metals, unless otherwise

to comply with these temperature limitations, qualify the specified, etching shall be performed when evidence exists that

procedure at the temperature of intended use as described in previous cleaning, surface treatments or service usage have

9.2. produced a surface condition that degrades the effectiveness of

7.1.2 Surface Conditioning Prior to Penetrant Inspection— the examination. (See Annex on Mechanical Cleaning and

Satisfactory results can usually be obtained on surfaces in the Surface Conditioning and Annex on Acid Etching in Test

as-welded, as-rolled, as-cast, or as-forged conditions or for Method E 165 for general precautions relative to surface

ceramics in the densified condition. The more sensitive pen- preparation.)

etrants are generally less easily rinsed away and are therefore

NOTE 8—When agreed between purchaser and supplier, grit blasting

less suitable for rougher surfaces. When only loose surface

without subsequent etching may be an acceptable cleaning method.

residuals are present, these may be removed by wiping the

NOTE 9—Caution: Sand or shot blasting may possibly close indica-

surface with clean lint-free cloths. However, precleaning of

tions and extreme care should be used with grinding and machining

operations.

metals to remove processing residuals such as oil, graphite,

NOTE 10—For structural or electronic ceramics, surface preparation by

scale, insulating materials, coatings, and so forth, should be

grinding, sand blasting and etching for penetrant examination is not

done using cleaning solvents, vapor degreasing or chemical

recommended because of the potential for damage.

removing processes. Surface conditioning by grinding, ma-

chining, polishing or etching shall follow shot, sand, grit and 7.1.3 Removal of Surface Contaminants:

vapor blasting to remove the peened skin and when penetrant 7.1.3.1 Precleaning—The success of any penetrant exami-

entrapment in surface irregularities might mask the indications nation procedure is greatly dependent upon the surface and

of unacceptable discontinuities or otherwise interfere with the discontinuity being free of any contaminant (solid or liquid)

E1209–99

TABLE 1 Recommended Minimum Dwell Times

that might interfere with the penetrant process. All parts or

A

areas of parts to be examined must be clean and dry before the Dwell Times

(minutes)

penetrant is applied. If only a section of a part, such as weld Type of

Material Form

Discontinuity

Pene- Devel-

including the heat-affected zone, is to be examined, all con-

B C

trant oper

taminants shall be removed from the area being examined as

Aluminum, castings and cold shuts, 510

defined by the contracting parties. “Clean” is intended to mean

magnesium, steel, welds porosity,

that the surface must be free of any rust, scale, welding flux,

brass and bronze, lack of fusion,

titanium and cracks (all forms)

spatter, grease, paint, oily films, dirt, etc., that might interfere

high-temperature

with penetration. All of these contaminants can prevent the

alloys

penetrant from entering discontinuities. (See Annex on Clean-

wrought- laps, cracks (all 10 10

materials— forms)

ing of Parts and Materials in Test Method E 165 for more

extrus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.