ASTM D562-01(2005)

(Test Method)Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer

Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer

SIGNIFICANCE AND USE

This test method provides values that are useful in specifying and controlling the consistency of paints, such as consumer or trade sales products.

SCOPE

1.1 This test method covers the measurement of Krebs Unit (KU) viscosity to evaluate the consistency of paints and related coatings using the Stormer-type viscometer.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D562–01(Reapproved2005)

Standard Test Method for

Consistency of Paints Measuring Krebs Unit (KU) Viscosity

1

Using a Stormer-Type Viscometer

This standard is issued under the fixed designation D562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 5. Significance and Use

1.1 This test method covers the measurement of Krebs Unit 5.1 This test method provides values that are useful in

(KU)viscositytoevaluatetheconsistencyofpaintsandrelated specifying and controlling the consistency of paints, such as

coatings using the Stormer-type viscometer. consumer or trade sales products.

1.2 The values stated in SI units are to be regarded as the

METHOD A

standard. The values given in parentheses are for information

only. 6. Apparatus

1.3 This standard does not purport to address all of the

6.1 Viscometer, Stormer, with the paddle-type rotor as

safety concerns, if any, associated with its use. It is the

illustrated in Fig. 1 and Fig. 2. The stroboscopic timer

responsibility of the user of this standard to establish appro-

attachment in Fig. 1 can be removed and the instrument used

priate safety and health practices and determine the applica-

without it but with a sacrifice of speed and accuracy. The

bility of regulatory limitations prior to use.

stroboscopic timer gives the 200 r/min reading directly.

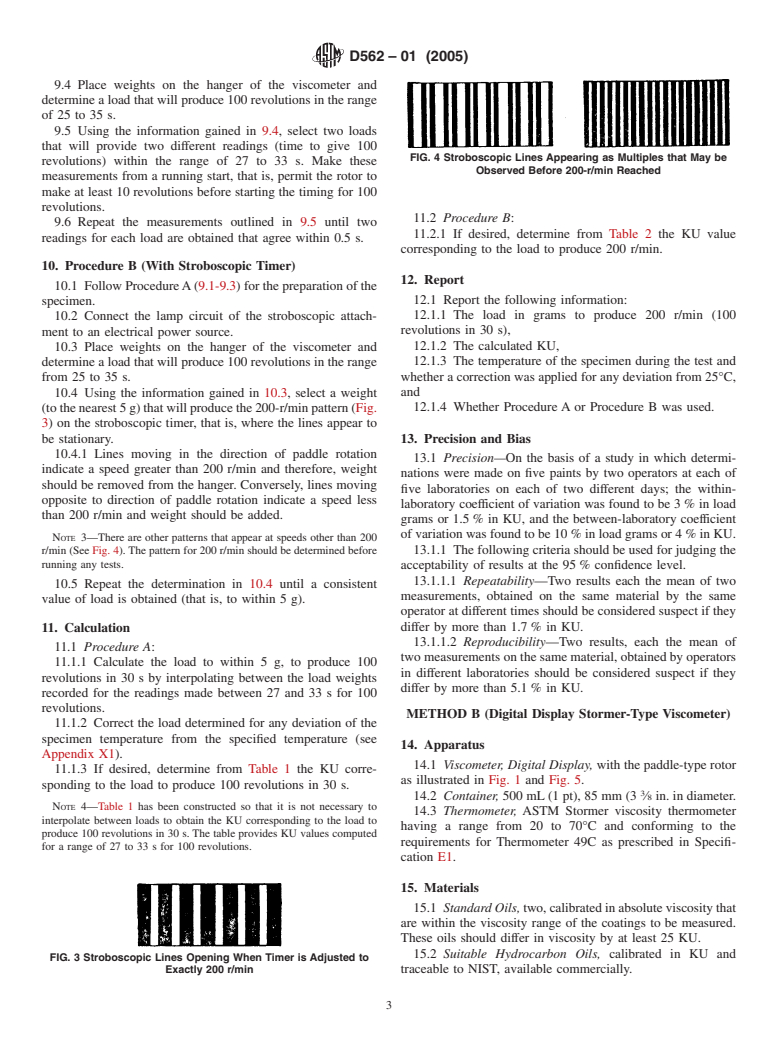

3

6.2 Container, 500-mL (1-pt), 85 mm (3 ⁄8 in.) in diameter.

2. Referenced Documents

6.3 Thermometer—An ASTM Stormer Viscosity thermom-

2

2.1 ASTM Standards:

eter having a range from 20 to 70°C and conforming to the

E1 Specification for ASTM Liquid-in-Glass Thermometers

requirements for Thermometer 49C, as prescribed in Specifi-

cation E1.

3. Terminology

6.4 Stopwatch, or suitable timer measuring to 0.2 s.

3.1 Definitions of Terms Specific to This Standard:

6.5 Weights, a set covering the range from 5 to 1000 g.

3.1.1 consistency, n—load in grams to produce a rotational

frequency of 200 r/min (Stormer Viscometer)

7. Materials

3.1.2 Krebs units (KU), n—values of a scale commonly

7.1 Two standard oils, calibrated in absolute viscosity

used to express the consistency of paints generally applied by

(poise), that are within the viscosity range of the coatings to be

brush or roller.

measured. These oils should differ in viscosity by at least 5 P.

3.1.2.1 Discussion—This scale is a function of the “load to

NOTE 1—The normal range of the Stormer is covered by oils having

produce 200-r/min” scale.

viscosities of 4 P (70 KU), 10 P (85 KU), and 14 P (95 KU).

4. Summary of Test Method

7.1.1 Suitable standards are silicone, hydrocarbon, linseed,

4.1 The load required to produce a rotational frequency of and castor oils. Silicone and hydrocarbon oils calibrated in

200 r/min for an offset paddle rotor immersed in a paint is poises are commercially available. Uncalibrated linseed and

determined. castor oils may be calibrated with any apparatus that provides

measurements of absolute viscosity.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints & Paint Materials.

Current edition approved Dec. 1, 2005. Published December 2005. Originally

approved in 1947. Last previous edition approved in 2001 as D562 – 01. DOI:

10.1520/D0562-01R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D562–01 (2005)

L 5 ~610O 1 906.6 D!/30

where:

O = viscosity of oil in poises and

D = density of oil.

4

8. Calibration

8.1 Remove the rotor and weight carrier from the viscom-

eter. Make sure the string is wound evenly on the drum and

does not overlap itself.

8.2 Attach a 5-g weight onto the string and then release the

brake. If the viscometer starts to run from this dead start and

continuestorunthroughseveralrevolutionsofthestringdrum,

it is satisfactory for use. If it does not start unaided when the

5-g weight is applied, the instrument should be reconditioned.

8.3 Check the dimensions of the paddle-type rotor. They

shouldbewithin0.1mm(60.004in.)ofthedimensionsshown

in Fig. 2.

8.4 Select two standard oils having assigned value

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.