ASTM D5213-04

(Specification)Standard Specification for Polymeric Resin Film for Electrical Insulation and Dielectric Applications

Standard Specification for Polymeric Resin Film for Electrical Insulation and Dielectric Applications

SCOPE

1.1 This specification covers requirements for the material, dimensions and tolerances, and property values of film, in sheet or strip form, with or without heat-sealable coatings.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1—This document is similar to IEC 60674, Part 3, Sheets 2, 4, 5, 6, and 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 5213 – 04

Standard Specification for

Polymeric Resin Film for Electrical Insulation and Dielectric

1

Applications

This standard is issued under the fixed designation D 5213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers requirements for the material, 3.1 Definitions—Definitions are in accordance with Termi-

dimensionsandtolerances,andpropertyvaluesoffilm,insheet nologies D 1711 and D 883 unless otherwise specified.

or strip form, with or without heat-sealable coatings. 3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as the 3.2.1 sheet, n—material greater than 75 mm in width.

standard. The values given in parentheses are for information 3.2.2 strip, n—material 75 mm or less in width.

only.

4. Classification

NOTE 1—This document is similar to IEC 60674, Part 3, Sheets 2, 4, 5,

4.1 This specification covers the following:

6, and 7.

4.1.1 Type I—General purpose,

2. Referenced Documents 4.1.2 Type II—Heat sealable,

2

4.1.2.1 Grade 1—One side coated, and

2.1 ASTM Standards:

4.1.2.2 Grade 2—Two sides coated.

D 149 Test Method for Dielectric Breakdown Voltage and

4.2 Materials:

Dielectric Strength of Solid Electrical Insulating Materials

4.2.1 Item A—Poly(N,N8-p,p8-oxydiphenylene pyromelliti-

at Commercial Power Frequencies

mide),

D 883 Terminology Relating to Plastics

4.2.2 Item B—Poly(N,N8-p,p8-oxydiphenylene biphenyltet-

D 1711 Terminology Relating to Electrical Insulation

racarboxylimide,

D 2305 Test Methods for Polymeric Films Used for Elec-

4.2.3 Item C—Poly(N,N8-p-phenylene biphenyltetracar-

trical Insulation

boxylimide),

D 3636 Practice for Sampling and Judging Quality of Solid

4.2.4 Item D—FEP-fluorocarbon, and

Electrical Insulating Materials

4.2.5 Item E—Polyethylene terephthalate.

D 4088 Practice for Preparation for Shipment of Solid

3

4.2.6 Item F—Polyethylene naphthalate.

Electrical Insulating Materials

2.2 IEC Standards:

5. Ordering Information

Publication 60674-3 Specification for Electrical Films for

4 5.1 Order the film covered by this specification stating the

Electrical Purposes

type, grade, class, thickness, width, and roll dimensions.

6. Materials

1

This specification is under the jurisdiction of ASTM Committee D09 on

6.1 Type I material is flexible, unsupported film.

Electrical and Electronic Insulating Materials and is the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

6.2 Type II material is film meeting all of the requirements

CurrenteditionapprovedMay1,2004.PublishedJune2004.Orginallyapproved

of Type I, and having a heat-sealable coating on one or both

in 1991. Last previous edition approved in 1999 as D 5213 – 99.

2 sides.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7. Requirements

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

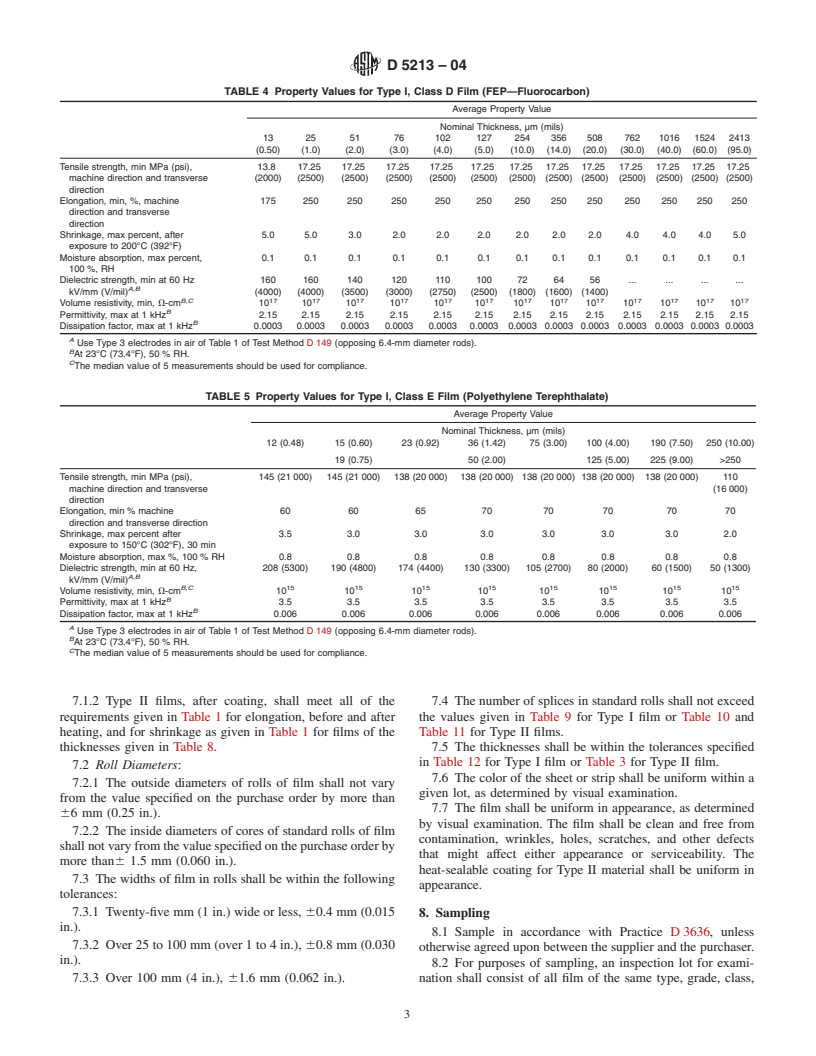

7.1 The film covered by this specification shall meet the

3

Withdrawn.

4 nd property requirements given in Tables 1-6 and Table 7 when

AvailablefromAmericanNationalStandardsInstitute,4W.42 St.,NewYork,

NY 10036. tested by the methods given in Test Methods D 2305.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5213–04

TABLE 1 Property Values for Type I, Class A Film poly(N,N*-p-p*-oxydiphenylene pyromellitimide)

Average Property Value

Nominal Thickness, µm (mils)

7.5 (0.3) 13 (0.5) 20 (0.8) 25 (1.0) 50 (2.0) 75 (3.0) 100 (4.0) 130 (5.0)

Tensile strength, min MPa (psi), 69 97 138 138 138 138 138 138

machine direction and transverse (10 000) (14 000) (20 000) (20 000) (20 000) (20 000) (20 000) (20 000)

direction

Elongation, min percent, machine 10 20 35 35 40 45 45 45

and transverse direction

Shrinkage, max percent, after . . 0.30 0.30 0.35 0.35 0.35 0.35

exposure to 200°C (392°F),

machine and transverse direction

Moisture absorption, max percent, 100 % RH 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

Dielectric strength, min kV/mm 120 120 180 180 150 140 100 100

A,B

(V/mil), 60 Hz (3000) (3000) (4500) (4500) (3800) (3600) (2500) (2500)

B,C 15 15 15 15 15 15 15 15

Volume resistivity, min V-cm, 10 10 10 10 10 10 10 10

B

Permittivity, max at 1 kHz 4.0 4.0 4.0 4.0 4.0 4.0 4.0 4.0

B

Dissipation factor, max at 1 kHz 0.007 0.005 0.005 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.