ASTM F3110-14(2024)

(Practice)Standard Practice for Proper Use of Mechanical Trenchless Point Repair Sleeve with Locking Gear Mechanism for Pipes of Varying Inner Diameter and Offset Joints

Standard Practice for Proper Use of Mechanical Trenchless Point Repair Sleeve with Locking Gear Mechanism for Pipes of Varying Inner Diameter and Offset Joints

SIGNIFICANCE AND USE

4.1 This practice is for use by design engineers, specifiers, regulatory agencies, owners, installers, and inspection organizations who are involved in the rehabilitation of pipes through the use of a Mechanical Trenchless Point Repair Sleeve with a Locking Gear Mechanism for Pipes of Varying Inner Diameter and Offset Joints within a damaged existing pipe.

4.2 This practice applies to the following types of defects in pipe that can be repaired: longitudinal, radial and circumferential cracks, fragmentation, leaking joints, displacement or joint misalignment, closing or sealing unused laterals, corrosion, spalling, wear, leaks in the barrel of the pipe, deformation in the pipe and root penetration. There are no limitations on the diameters of the laterals that can be sealed. The degree of deformation that can be repaired is dependent on the minimum and maximum diameters for which the sleeve is applicable as listed in the tables of dimensions shown in Appendix X1 but shall never exceed 5 %.

4.3 This practice applies to pipes made of vitrified clay, concrete, reinforced concrete, plastics, glass reinforced plastics, cast iron, ductile iron and steel for both pressure and non-pressure applications.

4.4 In this practice, no issues of snagging waste or build-up of sludge or sediment have been recorded to date; the performance of this sleeve, however, depends on many factors; therefore, past operational records may not include all possible future conditions under which the user may install these sleeves.

4.5 The suitability of the technology covered in this practice for a particular application shall be jointly decided by the authority, the engineer and the installer.

SCOPE

1.1 This practice establishes minimum requirements for good practices for the materials and installation of mechanical trenchless repair sleeve with a locking gear mechanism for pipes of varying inner diameter and offset joints in the range of 6 in. to 72 in. (150 mm to 1800 mm).

1.2 This practice applies to storm, potable water, wastewater and industrial pipes, conduits and drainage culverts.

1.3 When the specified materials are used in manufacturing the sleeve and installed in accordance with this practice, the sleeve shall extend over a predetermined length of the host pipe as a continuous, tight fitting, corrosion resistant and verifiable non-leaking pipe repaired using one or more pieces of the repair sleeve mechanism. The maximum internal pressure this sleeve can carry depends on the diameter and the wall thickness, ranging from 10 to 15 bars; the external pressure shall not exceed 1.5 bars.

1.4 All materials in contact with potable water shall be certified to meet NSF/ANSI 61/372.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3110 − 14 (Reapproved 2024)

Standard Practice for

Proper Use of Mechanical Trenchless Point Repair Sleeve

with Locking Gear Mechanism for Pipes of Varying Inner

1

Diameter and Offset Joints

This standard is issued under the fixed designation F3110; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This practice establishes minimum requirements for

mendations issued by the World Trade Organization Technical

good practices for the materials and installation of mechanical

Barriers to Trade (TBT) Committee.

trenchless repair sleeve with a locking gear mechanism for

pipes of varying inner diameter and offset joints in the range of

2. Referenced Documents

6 in. to 72 in. (150 mm to 1800 mm).

2

2.1 ASTM Standards:

1.2 This practice applies to storm, potable water, wastewater

A240/A240M Specification for Chromium and Chromium-

and industrial pipes, conduits and drainage culverts.

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

Vessels and for General Applications

1.3 When the specified materials are used in manufacturing

A666 Specification for Annealed or Cold-Worked Austenitic

the sleeve and installed in accordance with this practice, the

Stainless Steel Sheet, Strip, Plate, and Flat Bar

sleeve shall extend over a predetermined length of the host pipe

3

2.2 NASSCO Guidelines:

as a continuous, tight fitting, corrosion resistant and verifiable

Specifications for Sewer Collection System Rehabilitation

non-leaking pipe repaired using one or more pieces of the

4

2.3 European Standard:

repair sleeve mechanism. The maximum internal pressure this

EN 681-1 Elastomeric seals—Materials requirement for pipe

sleeve can carry depends on the diameter and the wall

joint seals used in water and drainage applications—Part

thickness, ranging from 10 to 15 bars; the external pressure

1: Vulcanized rubber

shall not exceed 1.5 bars.

5

2.4 NSF/ANSI Standards:

1.4 All materials in contact with potable water shall be

NSF/ANSI 61 Drinking water system components

certified to meet NSF/ANSI 61/372.

NSF/ANSI 372 Drinking water system components

1.5 The values stated in inch-pound units are to be regarded

3. Terminology

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3.1 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.1.1 access point, n—upstream or downstream locations

that serve as the point of entry or exit for the point repair of the

1.6 This standard does not purport to address all of the

existing pipe.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.2 bladder, n—an apparatus, when pressurized, inflates a

priate safety, health, and environmental practices and deter-

tube that presses against the inner pipe walls.

mine the applicability of regulatory limitations prior to use.

3.1.3 EPDM rubber, n—ethylene propylene diene monomer

Particular attention is drawn to those safety regulations and

rubber formed to yield wide ranging engineering properties

requirements involving entering into and working in confined

using a synthetic process.

spaces.

1.7 This international standard was developed in accor-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

dance with internationally recognized principles on standard-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This practice is under the jurisdiction of ASTM Committee F36 on Technology Available from National Association of Sewer Service Companies (NASSCO),

and Underground Utilities and is the direct responsibility of Subcommittee F36.20 2470 Longstone Lane, Suite M, Marriottsville, MD 21104, http://www.nassco.org.

4

on Inspection and Renewal of Water and Wastewater Infrastructure. Available from European Committee for Standardization (CEN), Avenue

Current edition approved Feb. 1, 2024. Published February 2024. Originally Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

5

approved in 2014. Last previous edition approved in 2018 as F3110 – 14 (2018). Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/F3110-14R24.

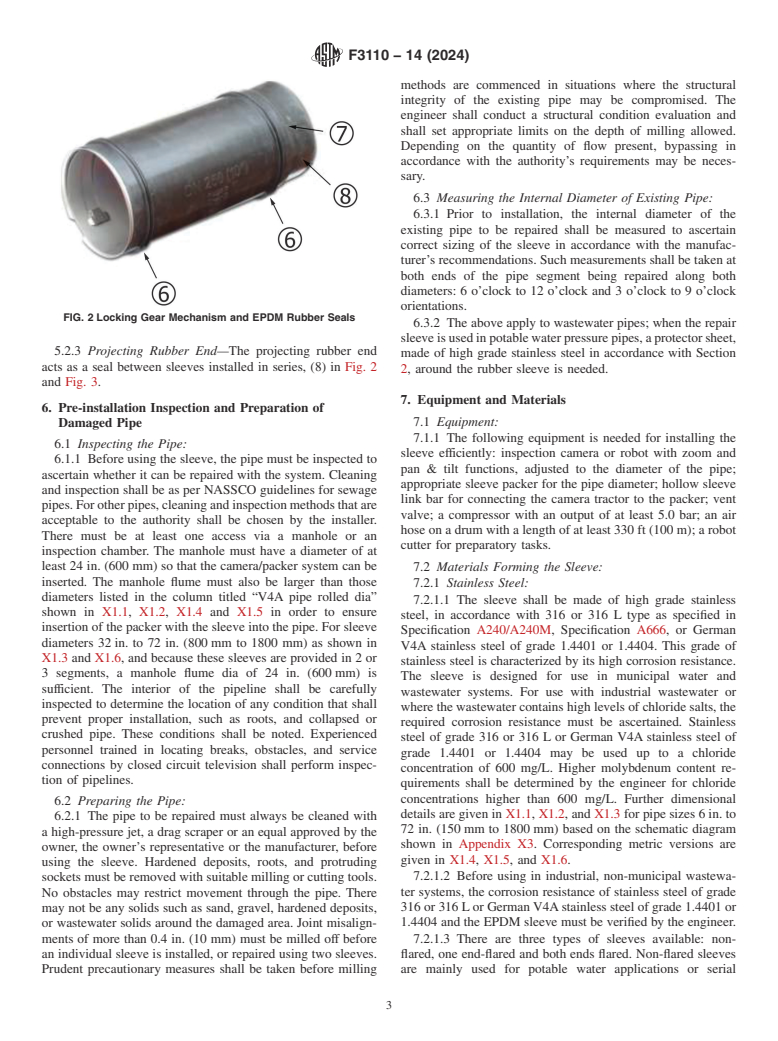

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.