ASTM G31-72(2004)

(Practice)Standard Practice for Laboratory Immersion Corrosion Testing of Metals

Standard Practice for Laboratory Immersion Corrosion Testing of Metals

SIGNIFICANCE AND USE

Corrosion testing by its very nature precludes complete standardization. This practice, rather than a standardized procedure, is presented as a guide so that some of the pitfalls of such testing may be avoided.

Experience has shown that all metals and alloys do not respond alike to the many factors that affect corrosion and that “accelerated” corrosion tests give indicative results only, or may even be entirely misleading. It is impractical to propose an inflexible standard laboratory corrosion testing procedure for general use, except for material qualification tests where standardization is obviously required.

In designing any corrosion test, consideration must be given to the various factors discussed in this practice, because these factors have been found to affect greatly the results obtained.

SCOPE

1.1 This practice describes accepted procedures for and factors that influence laboratory immersion corrosion tests, particularly mass loss tests. These factors include specimen preparation, apparatus, test conditions, methods of cleaning specimens, evaluation of results, and calculation and reporting of corrosion rates. This practice also emphasizes the importance of recording all pertinent data and provides a checklist for reporting test data. Other ASTM procedures for laboratory corrosion tests are tabulated in the Appendix. (Warning-In many cases the corrosion product on the reactive metals titanium and zirconium is a hard and tightly bonded oxide that defies removal by chemical or ordinary mechanical means. In many such cases, corrosion rates are established by mass gain rather than mass loss.)

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G31–72 (Reapproved 2004)

Standard Practice for

Laboratory Immersion Corrosion Testing of Metals

ThisstandardisissuedunderthefixeddesignationG31;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope G16 Guide forApplying Statistics toAnalysis of Corrosion

Data

1.1 This practice describes accepted procedures for and

G46 Guide for Examination and Evaluation of Pitting

factors that influence laboratory immersion corrosion tests,

Corrosion

particularly mass loss tests. These factors include specimen

preparation, apparatus, test conditions, methods of cleaning

3. Significance and Use

specimens, evaluation of results, and calculation and reporting

3.1 Corrosion testing by its very nature precludes complete

of corrosion rates. This practice also emphasizes the impor-

standardization. This practice, rather than a standardized pro-

tance of recording all pertinent data and provides a checklist

cedure, is presented as a guide so that some of the pitfalls of

for reporting test data. Other ASTM procedures for laboratory

such testing may be avoided.

corrosion tests are tabulated in the Appendix. (Warning—In

3.2 Experience has shown that all metals and alloys do not

many cases the corrosion product on the reactive metals

respond alike to the many factors that affect corrosion and that

titanium and zirconium is a hard and tightly bonded oxide that

“accelerated” corrosion tests give indicative results only, or

defies removal by chemical or ordinary mechanical means. In

mayevenbeentirelymisleading.Itisimpracticaltoproposean

many such cases, corrosion rates are established by mass gain

inflexible standard laboratory corrosion testing procedure for

rather than mass loss.)

general use, except for material qualification tests where

1.2 The values stated in SI units are to be regarded as the

standardization is obviously required.

standard. The values given in parentheses are for information

3.3 In designing any corrosion test, consideration must be

only.

given to the various factors discussed in this practice, because

1.3 This standard does not purport to address all of the

these factors have been found to affect greatly the results

safety concerns, if any, associated with its use. It is the

obtained.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Interferences

bility of regulatory limitations prior to use.

4.1 The methods and procedures described herein represent

the best current practices for conducting laboratory corrosion

2. Referenced Documents

3 tests as developed by corrosion specialists in the process

2.1 ASTM Standards:

industries. For proper interpretation of the results obtained, the

A262 Practices for Detecting Susceptibility to Intergranular

specific influence of certain variables must be considered.

Attack in Austenitic Stainless Steels

These include:

E8 Test Methods for Tension Testing of Metallic Materials

4.1.1 Metal specimens immersed in a specific hot liquid

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

may not corrode at the same rate or in the same manner as in

sion Test Specimens

equipment where the metal acts as a heat transfer medium in

G4 Guide for Conducting Corrosion Tests in FieldApplica-

heating or cooling the liquid. If the influence of heat transfer

tions

effects is specifically of interest, specialized procedures (in

which the corrosion specimen serves as a heat transfer agent)

This practice is under the jurisdiction of ASTM Committee J01 on Corrosion 4

must be employed (1).

and is the direct responsibility of Subcommittee J01.01 on Working Group on

4.1.2 In laboratory tests, the velocity of the environment

Laboratory Immersion Tests.

Current edition approved May 1, 2004. Published May 2004. Originally

relative to the specimens will normally be determined by

approved in 1972. Last previous edition approved in 1998 as G31 – 72 (1998). DOI:

convection currents or the effects induced by aeration or

10.1520/G0031-72R04.

2 boiling or both. If the specific effects of high velocity are to be

This practice is based upon NACE Standard TM-01-69, “Test Method-

studied, special techniques must be employed to transfer the

Laboratory Corrosion Testing of Metals for the Process Industries,” with modifica-

tions to relate more directly to Practices G1 and G1 and Guide G4.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G31–72 (2004)

environment through tubular specimens or to move it rapidly 4.1.7.4 Dealloying or “parting” corrosion is a condition in

past the plane face of a corrosion coupon (2).Alternatively, the which one constituent is selectively removed from an alloy, as

coupon may be rotated through the environment, although it is in the dezincification of brass or the graphitization of cast iron.

then difficult to evaluate the velocity quantitatively because of Close attention and a more sophisticated evaluation than a

the stirring effects incurred. simple mass loss measurement are required to detect this

phenomenon.

4.1.3 The behavior of certain metals and alloys may be

4.1.7.5 Certain metals and alloys are subject to a highly

profoundly influenced by the presence of dissolved oxygen. If

localized type of attack called pitting corrosion.This cannot be

this is a factor to be considered in a specific test, the solution

evaluated by mass loss alone. The reporting of nonuniform

should be completely aerated or deaerated in accordance with

corrosion is discussed below. It should be appreciated that

8.7.

pitting is a statistical phenomenon and that the incidence of

4.1.4 In some cases, the rate of corrosion may be governed

pittingmaybedirectlyrelatedtotheareaofmetalexposed.For

by other minor constituents in the solution, in which case they

example, a small coupon is not as prone to exhibit pitting as a

will have to be continually or intermittently replenished by

large one and it is possible to miss the phenomenon altogether

changing the solution in the test.

in the corrosion testing of certain alloys, such as theAISIType

4.1.5 Corrosion products may have undesirable effects on a

300 series stainless steels in chloride contaminated environ-

chemical product. The amount of possible contamination can

ments.

beestimatedfromthelossinmassofthespecimen,withproper

4.1.7.6 All metals and alloys are subject to stress-corrosion

application of the expected relationships among (1) the area of

cracking under some circumstances. This cracking occurs

corroding surface, (2) the mass of the chemical product

under conditions of applied or residual tensile stress, and it

handled, and (3) the duration of contact of a unit of mass of the

may or may not be visible to the unaided eye or upon casual

chemical product with the corroding surface.

inspection. A metallographic examination may confirm the

4.1.6 Corrosionproductsfromthecouponmayinfluencethe

presence of stress-corrosion cracking. It is imperative to note

corrosion rate of the metal itself or of different metals exposed

that this usually occurs with no significant loss in mass of the

at the same time. For example, the accumulation of cupric ions

testcoupon,althoughcertainrefractorymetalsareanexception

in the testing of copper alloys in intermediate strengths of

to these observations. Generally, if cracking is observed on the

sulfuric acid will accelerate the corrosion of copper alloys, as

coupon, it can be taken as positive indication of susceptibility,

compared to the rates that would be obtained if the corrosion

whereas failure to effect this phenomenon simply means that it

products were continually removed. Cupric ions may also

did not occur under the duration and specific conditions of the

exhibit a passivating effect upon stainless steel coupons ex-

test. Separate and special techniques are employed for the

posed at the same time. In practice, only alloys of the same

specific evaluation of the susceptibility of metals and alloys to

general type should be exposed in the testing apparatus.

stress corrosion cracking (see Ref. (3)).

4.1.7 Coupon corrosion testing is predominantly designed

to investigate general corrosion. There are a number of other

5. Apparatus

special types of phenomena of which one must be aware in the

5.1 A versatile and convenient apparatus should be used,

design and interpretation of corrosion tests.

consisting of a kettle or flask of suitable size (usually 500 to

4.1.7.1 Galvanic corrosion may be investigated by special

5000 mL), a reflux condenser with atmospheric seal, a sparger

devices which couple one coupon to another in electrical

for controlling atmosphere or aeration, a thermowell and

contact. The behavior of the specimens in this galvanic couple

temperature-regulating device, a heating device (mantle, hot

are compared with that of insulated specimens exposed on the

plate, or bath), and a specimen support system. If agitation is

same holder and the galvanic effects noted. It should be

required, the apparatus can be modified to accept a suitable

observed, however, that galvanic corrosion can be greatly

stirring mechanism, such as a magnetic stirrer. A typical resin

affected by the area ratios of the respective metals, the distance

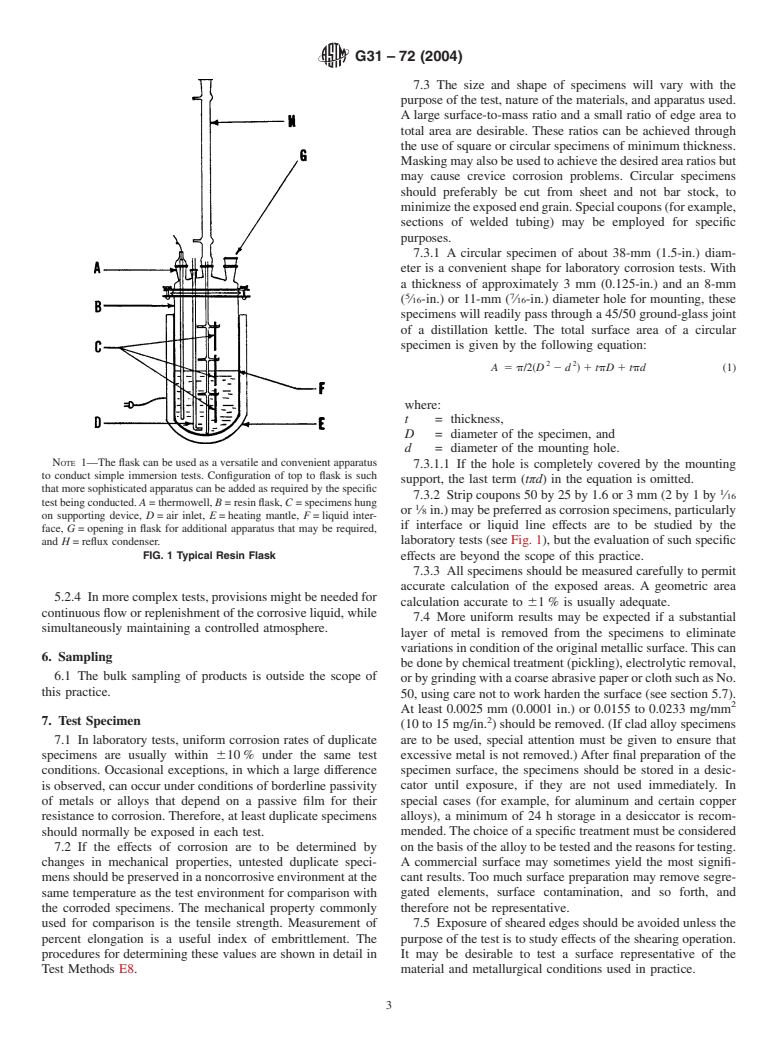

flask setup for this type test is shown in Fig. 1.

between the metals and the resistivity of the electrolyte. The

5.2 The suggested components can be modified, simplified,

coupling of corrosion coupons then yields only qualitative

or made more sophisticated to fit the needs of a particular

results, as a particular coupon reflects only the relationship

investigation. The suggested apparatus is basic and the appa-

between these two metals at the particular area ratio involved.

ratus is limited only by the judgment and ingenuity of the

4.1.7.2 Crevice corrosion or concentration cell corrosion

investigator.

may occur where the metal surface is partially blocked from

5.2.1 Aglass reaction kettle can be used where the configu-

the corroding liquid as under a spacer or supporting hook. It is

ration and size of the specimen will permit entry through the

necessary to evaluate this localized corrosion separately from

narrowkettleneck(forexample,45/50ground-glassjoint).For

the overall mass loss. solutions corrosive to glass, suitable metallic or plastic kettles

may be employed.

4.1.7.3 Selective corrosion at the grain boundaries (for

5.2.2 Insomecasesawide-mouthjarwithasuitableclosure

example, intergranular corrosion of sensitized austenitic stain-

less steels) will not be readily observable in mass loss is sufficient when simple immersion tests at ambient tempera-

tures are to be investigated.

measurementsunlesstheattackissevereenoughtocausegrain

dropping, and often requires microscopic examination of the

5.2.3 Open-beaker tests should not be used because of

coupons after exposure. evaporation and contamination.

G31–72 (2004)

7.3 The size and shape of specimens will vary with the

purpose of the test, nature of the materials, and apparatus used.

A large surface-to-mass ratio and a small ratio of edge area to

total area are desirable. These ratios can be achieved through

the use of square or circular specimens of minimum thickness.

Maskingmayalsobeusedtoachievethedesiredarearatiosbut

may cause crevice corrosion problems. Circular specimens

should preferably be cut from sheet and not bar stock, to

minimizetheexposedendgrain.Specialcoupons(forexample,

sections of welded tubing) may be employed for specific

purposes.

7.3.1 A circular specimen of about 38-mm (1.5-in.) diam-

eter is a convenient shape for laboratory corrosion tests. With

a thickness of approximately 3 mm (0.125-in.) and an 8-mm

5 7

( ⁄16-in.) or 11-mm ( ⁄16-in.) diameter hole for mounting, these

specimens will readily pass through a 45/50 ground-glass joint

of a distillation kettle. The total surface area of a circular

specimen is given by the following equation:

2 2

A 5p/2~D 2 d ! 1 tpD 1 tpd (1)

where:

t = thickness,

D = diameter of the specimen, and

d = diameter of the mounting hole.

NOTE 1—The flask can be used as a versatile and convenient apparatus

7.3.1.1 If the hole is completely covered by the mounting

to conduct simple immersion tests. Configuration of top to flask is such

support, the last term (tπd) in the equation is omitted.

that more sophisticated apparatus can be added as required by the specific

7.3.2 Strip coupons 50 by 25 by 1.6 or 3 mm (2 by 1 by ⁄16

testbeingconducted.A = thermowell,B = resinflask,C = specimenshung

or ⁄8 in.) may be preferred as corrosion specimens, particularly

on supporting device, D = air inlet, E = heating mantle, F = liquid inter-

if interface or liquid line effects are to be studied by the

face, G = opening in flask for additional apparatus that may be required,

laboratory tests (see Fig. 1), but the evaluation of such specific

and H = reflux condenser.

FIG. 1 Typical Resin Flask

effects are beyond the scope of this practice.

7.3.3 All specimens should be measured carefully to permit

accurate calculation of the exposed areas. A geometric area

5.2.4 In more complex tests, provisions might be needed for

calculation accurate to 61 % is usually adequate.

continuous flow or replenishment of the corrosive liquid, while

7.4 More uniform results may be expected if a substantial

simultaneously maintaining a controlled atmosphere.

layer of metal is removed from the specimens to eliminate

variationsinconditionoftheoriginalmetallicsurface.Thiscan

6. Sampling

be done by chemical treatment (pickling), electrolytic removal,

6.1 The bulk sampling of products is outside the scope of

orbygrindingwithacoarseabrasivepaperorclothsuchasNo.

this practice.

50, using care not to work harden the surface (see section 5.7).

At least 0.0025 mm (0.0001 in.) or 0.0155 to 0.0233 mg/mm

7. Test Specimen

(10 to 15 mg/in. ) should be removed. (If clad alloy specimens

7.1 In laboratory tests, uniform corrosion rates of duplicate are to be used, special attention must be given to ensure that

specimens are usually within 610 % under the same test excessive metal is not removed.) After final preparation of the

conditions. Occasional exceptions, in which a large differenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.