ASTM G106-89(1999)

(Practice)Standard Practice for Verification of Algorithm and Equipment for Electrochemical Impedance Measurements

Standard Practice for Verification of Algorithm and Equipment for Electrochemical Impedance Measurements

SCOPE

1.1 This practice describes an experimental procedure which can be used to check one's instrumentation and technique for collecting and presenting electrochemical impedance data. If followed, this practice provides a standard material, electrolyte, and procedure for collecting electrochemical impedance data at the open circuit or corrosion potential that should reproduce data determined by others at different times and in different laboratories. This practice may not be appropriate for collecting impedance information for all materials or in all environments.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 106 – 89 (Reapproved 1999)

Standard Practice for

Verification of Algorithm and Equipment for Electrochemical

Impedance Measurements

This standard is issued under the fixed designation G 106; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

E8 = real component of voltage (volts)

E9 = imaginary component of voltage (volts)

1.1 This practice describes an experimental procedure

E = complex voltage (volts)

which can be used to check one’s instrumentation and tech-

−1

f = frequency (s )

nique for collecting and presenting electrochemical impedance

−2

I8 = real component of current (amp-cm )

data. If followed, this practice provides a standard material,

−2

I9 = imaginary component of current (amp-cm )

electrolyte, and procedure for collecting electrochemical im-

−2

I = complex current (amp-cm )

pedance data at the open circuit or corrosion potential that

j = 21

=

should reproduce data determined by others at different times

L = inductance (henry − cm )

and in different laboratories. This practice may not be appro-

R = solution resistance (ohm-cm )

s

priate for collecting impedance information for all materials or

R = polarization resistance (ohm-cm )

p

in all environments.

R = charge transfer resistance (ohm-cm )

t

1.2 This standard does not purport to address all of the

Z8 = real component of impedance (ohm-cm )

safety concerns, if any, associated with its use. It is the Z9 = imaginary component of impedance (ohm-cm )

responsibility of the user of this standard to establish appro- Z = complex impedance (ohm-cm )

a = phenomenological coefficients caused by depression

priate safety and health practices and determine the applica-

of the Nyquist plot below the real axis, a is the

bility of regulatory limitations prior to use.

exponent and t is the time constant(s).

2. Referenced Documents

u = phase angle (deg)

−1

v = frequency (radians-s )

2.1 ASTM Standards:

D 1193 Specification for Reagent Water

Subscripts:

G 3 Practice for Conventions Applicable to Electrochemical

x = in-phase component

Measurements in Corrosion Testing

y = out-of-phase component

G 5 Reference Test Method for Making Potentiostatic and

Potentiodynamic Anodic Polarization Measurements

4. Summary of Practice

G 15 Terminology Relating to Corrosion and Corrosion

4.1 Reference impedance plots in both Nyquist and Bode

Testing

format are included. These reference plots are derived from the

G 59 Practice for Conducting Potentiodynamic Polarization

results from nine different laboratories that used a standard

Resistance Measurements

dummy cell and followed the standard procedure using a

specific ferritic type alloy UNS-S43000 in 0.005 M H SO

2 4

3. Terminology

and 0.495 M Na SO . The plots for the reference material are

2 4

3.1 Definitions—For definitions of corrosion related terms,

presented as an envelope that surrounds all of the data with and

see Terminology G 15.

without inclusion of the uncompensated resistance. Plots for

3.2 Symbols:

one data set from one laboratory are presented as well. Since

the results from the dummy cell are independent of laboratory,

−2

only one set of results is presented.

C = capacitance (farad-cm )

4.2 A discussion of the electrochemical impedance tech-

nique, the physics that underlies it, and some methods of

1 interpreting the data are given in the Appendix X1-Appendix

This practice is under the jurisdiction of ASTM Committee G-1 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemi-

cal Measurements in Corrosion Testing.

Current edition approved Sept. 29, 1989. Published November 1989.Originally

e1 4

published as G 106-89. Last previous edition G 106 - 89 (1994) . These standard samples are available from ASTM Headquarters. Generally, one

Annual Book of ASTM Standards, Vol 11.01. sample can be repolished and reused for many runs. This procedure is suggested to

Annual Book of ASTM Standards, Vol 03.02. conserve the available material. Order PCN 12–700050–00.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G 106 – 89 (1999)

X6. These sections are included to aid the individual in electrode. The minimum distance should be no less than two

understanding the electrochemical impedance technique and capillary diameters from the working electrode.

some of its capabilities. The information is not intended to be

6.3 Electrode Holder—The auxillary and working elec-

all inclusive.

trodes can be mounted in the manner shown in Reference Test

Method G 5. Precautions described in Reference Test Method

5. Significance and Use

G 5 about assembly should be followed.

5.1 The availability of a standard procedure, standard ma-

6.4 Potentiostat—The potentiostat must be of the kind that

terial, and standard plots should allow the investigator to check

allows for the application of a potential sweep as described in

his laboratory technique. This practice should lead to electro-

Reference Test Method G 5 and Reference Practice G 59. The

chemical impedance curves in the literature which can be

potentiostat must have outputs in the form of voltage versus

compared easily and with confidence.

ground for both potential and current. The potentiostat must

5.2 Samples of a standard ferritic type 430 stainless steel

have sufficient bandwidth for minimal phase shift up to at least

(UNS 430000) used to obtain the reference plots are available

1000 Hz and preferably to 10 000 Hz. The potentiostat must be

for those who wish to check their equipment. Suitable resistors

capable of accepting an external excitation signal. Many

and capacitors can be obtained from electronics supply houses.

commercial potentiostats meet the specification requirements

5.3 This test method may not be appropriate for electro-

for these types of measurements.

chemical impedance measurements of all materials or in all

6.5 Collection and Analysis of Current-Voltage Response—

environments.

The potential and current measuring circuits must have the

characteristics described in Reference Test Method G 5 along

6. Apparatus

with sufficient band-width as described above. The impedance

6.1 Dummy Cell—The dummy cell used to check the

can be calculated in several ways, for example, by means of a

equipment and method for generating electrochemical imped-

transfer function analyzer, Lissajous figures on an oscilloscope,

ance data is composed of a 10 V precision resistor placed in

or transient analysis of a white noise input using a Fast Fourier

series with a circuit element composed of a 100 V precision

Transform algorithm. Other methods of analysis exist.

resistor in parallel with a 100 μF capacitor. The resistors should

6.6 Electrodes:

have a stated precision of 60.1 %. The capacitor can have a

6.6.1 Working electrode preparation should follow Refer-

precision of 620 %. The cell can be constructed from readily

ence Test Method G 5, which involves drilling and tapping the

available circuit elements by following the circuit diagram

specimen and mounting it on the electrode holder.

shown in Fig. 1.

6.6.2 Auxillary electrode preparation should follow Refer-

6.2 Test Cell—The test cell should be constructed to allow

ence Test Method G 5. The auxillary electrode arrangement

the following items to be inserted into the solution chamber:

should be symmetrical around the working electrode.

the test electrode, two counter electrodes or a symmetrically

6.6.3 Reference electrode type and usage should follow

arranged counter electrode around the working electrode, a

Reference Test Method G 5. The reference electrode is to be a

Luggin-Haber capillary with salt bridge connection to the

saturated calomel electrode.

reference electrode, an inlet and an outlet for an inert gas, and

a thermometer or thermocouple holder. The test cell must be

7. Experimental Procedure

constructed of materials that will not corrode, deteriorate, or

7.1 Test of Algorithm and Electronic Equipment (Dummy

otherwise contaminate the solution.

Cell):

6.2.1 One type of suitable cell is described in Reference Test

7.1.1 Measure the impedance of a dummy cell consisting of

Method G 5. Cells are not limited to that design. For example,

a10 V resistor in series with a parallel combination of a 100

a 1-L round-bottom flask can be modified for the addition of

V resistor and a 100 μF capacitor. The circuit diagram is shown

various necks to permit the introduction of electrodes, gas inlet

and outlet tubes, and the thermometer holder. A Luggin-Haber in Fig. 1.

capillary probe could be used to separate the bulk solution from 7.1.2 Typical connections from the potentiostat are shown in

the saturated calomel electrode. The capillary tip can be easily Fig. 1. Connect the auxillary electrode and reference electrode

adjusted to bring it into close proximity to the working leads to the series resistor side of the circuit. Connect the

FIG. 1 Circuit Diagram for Dummy Cell Showing Positions for Hook-Up to Potentiostat

G 106 – 89 (1999)

working electrode lead to the opposite side of the circuit

beyond the resistor-capacitor parallel combination.

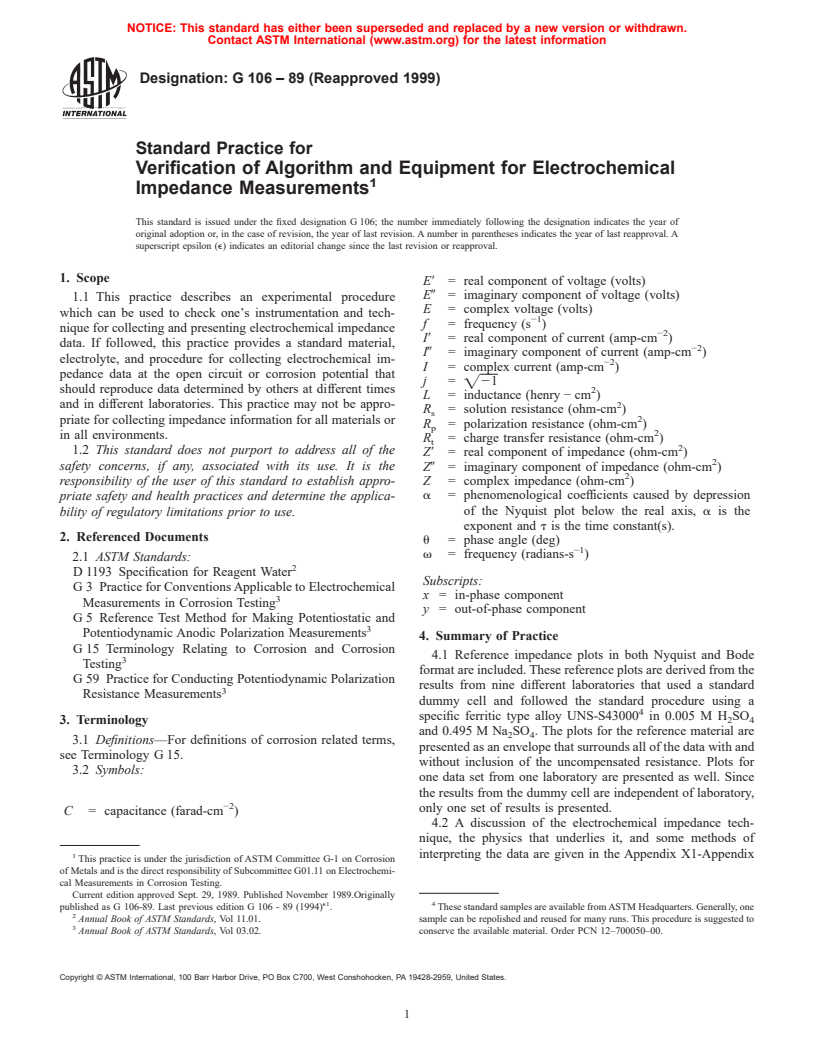

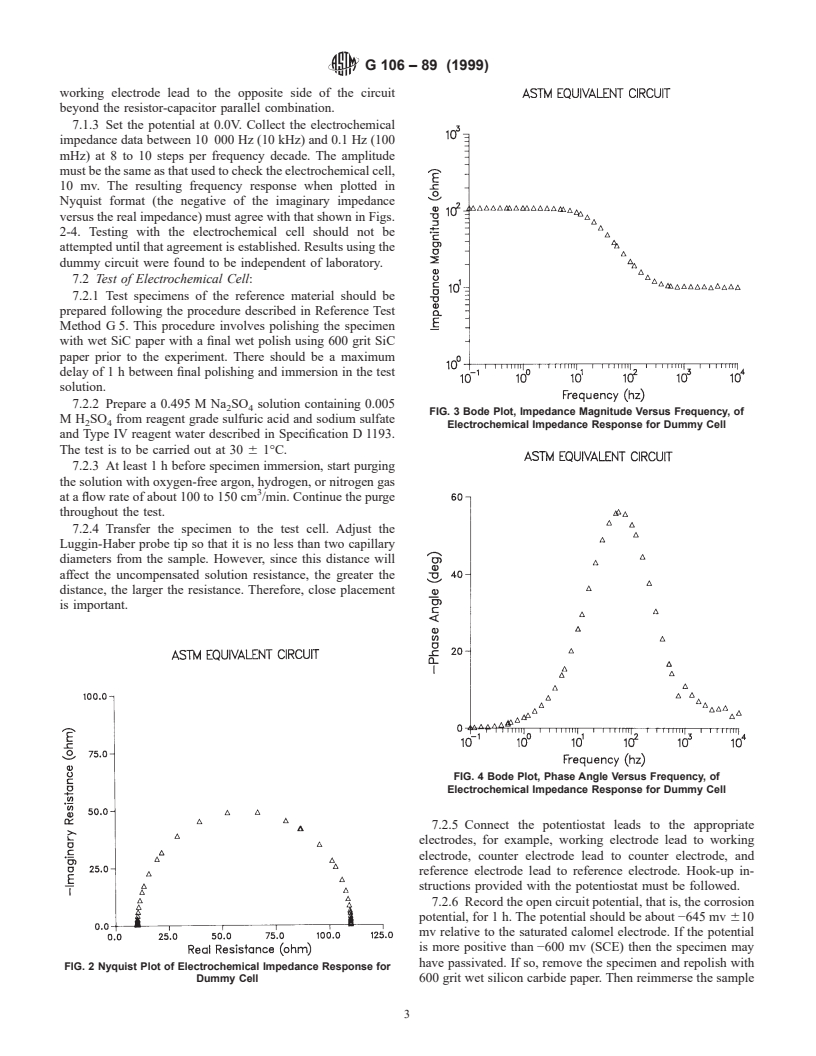

7.1.3 Set the potential at 0.0V. Collect the electrochemical

impedance data between 10 000 Hz (10 kHz) and 0.1 Hz (100

mHz) at 8 to 10 steps per frequency decade. The amplitude

must be the same as that used to check the electrochemical cell,

10 mv. The resulting frequency response when plotted in

Nyquist format (the negative of the imaginary impedance

versus the real impedance) must agree with that shown in Figs.

2-4. Testing with the electrochemical cell should not be

attempted until that agreement is established. Results using the

dummy circuit were found to be independent of laboratory.

7.2 Test of Electrochemical Cell:

7.2.1 Test specimens of the reference material should be

prepared following the procedure described in Reference Test

Method G 5. This procedure involves polishing the specimen

with wet SiC paper with a final wet polish using 600 grit SiC

paper prior to the experiment. There should be a maximum

delay of 1 h between final polishing and immersion in the test

solution.

7.2.2 Prepare a 0.495 M Na SO solution containing 0.005

2 4

FIG. 3 Bode Plot, Impedance Magnitude Versus Frequency, of

MH SO from reagent grade sulfuric acid and sodium sulfate

2 4

Electrochemical Impedance Response for Dummy Cell

and Type IV reagent water described in Specification D 1193.

The test is to be carried out at 30 6 1°C.

7.2.3 At least 1 h before specimen immersion, start purging

the solution with oxygen-free argon, hydrogen, or nitrogen gas

at a flow rate of about 100 to 150 cm /min. Continue the purge

throughout the test.

7.2.4 Transfer the specimen to the test cell. Adjust the

Luggin-Haber probe tip so that it is no less than two capillary

diameters from the sample. However, since this distance will

affect the uncompensated solution resistance, the greater the

distance, the larger the resistance. Therefore, close placement

is important.

FIG. 4 Bode Plot, Phase Angle Versus Frequency, of

Electrochemical Impedance Response for Dummy Cell

7.2.5 Connect the potentiostat leads to the appropriate

electrodes, for example, working electrode lead to working

electrode, counter electrode lead to counter electrode, and

reference electrode lead to reference electrode. Hook-up in-

structions provided with the potentiostat must be followed.

7.2.6 Record the open circuit potential, that is, the corrosion

potential, for 1 h. The potential should be about −645 mv 610

mv relative to the saturated calomel electrode. If the potential

is more positive than −600 mv (SCE) then the specimen may

have passivated. If so, remove the specimen and repolish with

FIG. 2 Nyquist Plot of Electrochemical Impedance Response for

Dummy Cell 600 grit wet silicon carbide paper. Then reimmerse the sample

G 106 – 89 (1999)

and monitor the corrosion potential for 1 h. If the potential

again becomes more positive than −600 mv (SCE) check for

oxygen contamination of the solution.

7.2.7 Record the frequency response between 10 000 Hz

(10 kHz) and 0.1 Hz (100 mHz) at the corrosion potential

recorded after1hof exposure using 8 to 10 steps per frequency

decade. The amplitude must be the same as that used in 6.1.3,

10 mv.

7.2.8 Plot the frequency response in both Nyquist format

(real response versus the negative of the imaginary response)

and Bode format (impedance modulus and phase angle versus

frequency). Frequency can be reported in units of radians/

second or hertz (cycles/s).

7.2.9 There was no attempt to estimate circuit analogues for

the electrochemical impedance curves since there is no univer-

sally recognized, standard method for making such estimates.

8. Standard Reference Results and Plots

8.1 Dummy Cell:

FIG. 6 Bode Plot, Impedance Magnitude Versus Frequency, for

8.1.1 The results from nine different laboratories were

UNS-S43000 From One Laboratory

virtually identical and overlayed each other almost perfectly.

Typical plots of the raw data are shown in Figs. 2-4. No attempt

has been made to estimate the variance and standard deviation

of the results from the nine laboratories. The measured values

of R,R , and the frequency at which the phase angle is a

s p

maximum must agree with these curves within the specifica-

tions of the instrumentation, resistors, and capacitors before

testing of the electrochemical cell commences. See 9.1.1.

8.2 Electrochemical Cell:

8.2.1 Standard electrochemical impedance plots in both

Nyquist format and Bode format are shown in Figs. 5-7. These

are actual results from one laboratory. Figs. 8-10 show plots in

both Nyquist and Bode formats which envelop all of the results

from the nine laboratories. The solution resistance from each

laboratory was not subtracted out prior to making this plot.

8.2.2 The average solution resistance from the nine labora-

2 2

tories in 3.3 V-cm 6 1.8 V-cm (one standard deviation). The

solution resistance of the user’s test cell as measured by the

FIG. 7 Bode Plot, Phase Angle Versus Frequency, for UNS-

S43000 From One Laboratory

high frequency intercept on the Nyquist plot must lie in this

range to use agreement with Figs. 8-10 for verification of the

electrochemical test cell. If the uncompensated resistance lies

outside of this range, it should be subtracted from the results

(see 7.2.4). Then, results from the electrochemical test cell can

be compared with the results in Figs.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.