ASTM D909-00

(Test Method)Standard Test Method for Knock Characteristics of Aviation Gasolines by the Supercharge Method

Standard Test Method for Knock Characteristics of Aviation Gasolines by the Supercharge Method

SCOPE

1.1 This test method covers the determination of the knock-limited power, under supercharge rich-mixture conditions, of fuels for use in spark-ignition reciprocating aircraft engines, in terms of ASTM supercharge octane or performance number. By operational considerations, this test method is restricted to testing fuels of 85 ASTM supercharge octane number and over.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Annex 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 909 – 00 An American National Standard

Method 6012.6—Federal Test

Method Standard No. 791b

Designation: 119/96

Standard Test Method for

Knock Characteristics of Aviation Gasolines by the

Supercharge Method

This standard is issued under the fixed designation D 909; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Monochloride Method

D 4057 Practice for Manual Sampling of Petroleum and

1.1 This test method covers the determination of the knock-

Petroleum Products

limited power, under supercharge rich-mixture conditions, of

E 1 Specifications for ASTM Thermometers

fuels for use in spark-ignition reciprocating aircraft engines, in

terms of ASTM supercharge octane or performance number.

3. Terminology

By operational considerations, this test method is restricted to

3.1 Definitions:

testing fuels of 85 ASTM supercharge octane number and over.

3.1.1 ASTM supercharge octane number of a fuel below

1.2 The values stated in inch-pound units are to be regarded

100—the whole number nearest the percentage by volume of

as the standard. The values in parentheses are for information

isooctane (equals 100) in a blend with n-heptane (equals 0) that

only.

matches the knock characteristics of the fuel when compared

1.3 This standard does not purport to address all of the

by this test method.

safety concerns, if any, associated with its use. It is the

3.1.2 ASTM supercharge rating of a fuel above 100—the

responsibility of the user of this standard to establish appro-

amount of tetraethyllead (TEL) in isooctane, expressed in

priate safety and health practices and determine the applica-

millilitres per U.S. gallon.

bility of regulatory limitations prior to use. Specific precau-

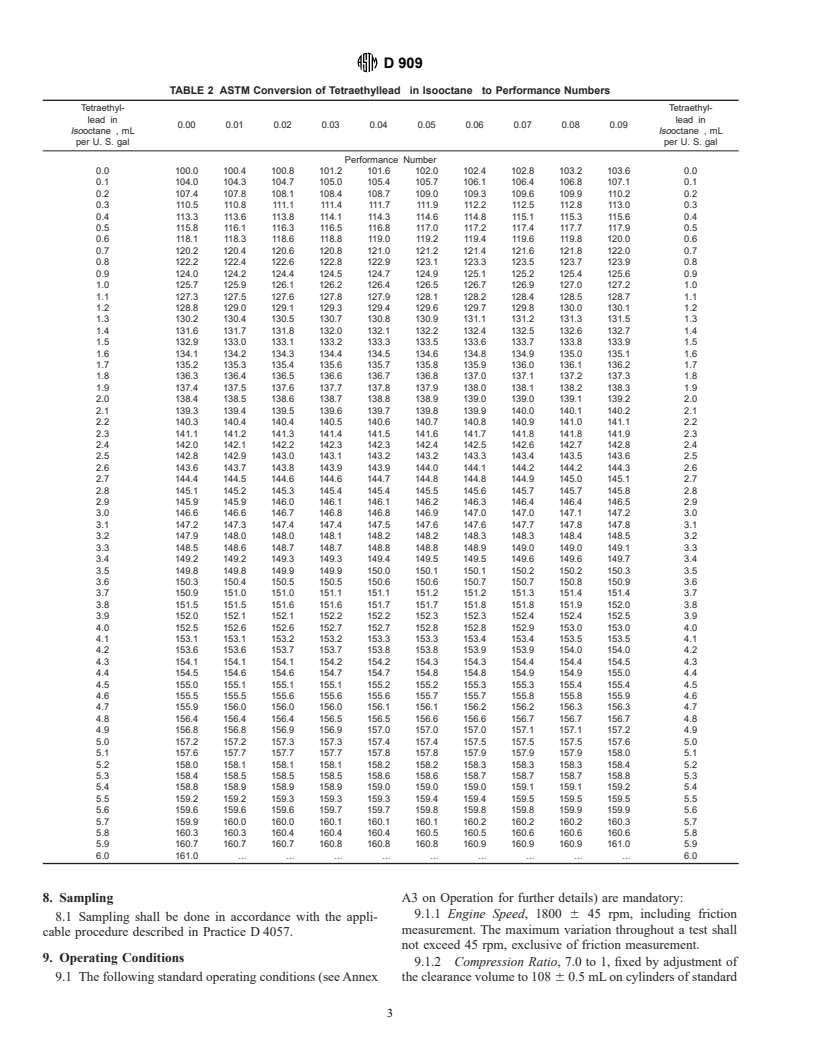

3.2 ASTM supercharge ratings are normally expressed as

tionary statements are given in Annex A7.

octane numbers below 100 and as performance numbers above

2. Referenced Documents 100. At 100, a rating may be expressed either as 100 octane

number or as 100 performance number. Sometimes it is

2.1 ASTM Standards:

desirable to convert the ASTM supercharge octane number to

D 1368 Test Method for Trace Concentrations of Lead in

performance number. This can be done by using Table 1. Table

Primary Reference Fuels

2 lists the corresponding performance numbers for various

D 2268 Test Method for Analysis of High Purity

concentrations of tetraethyllead in isooctane.

D 2599 Test Method for Lead in Gasoline by X-Ray Spec-

trometry

4. Summary of Test Method

D 2699 Test Method for Research Octane Number of

5 4.1 ASTM supercharge octane or performance number of a

Spark-Ignition Engine Fuel

fuel is determined by comparing its knock-limited power with

D 2700 Test Method for Knock Characteristics of Motor

5 those for bracketing blends of reference fuels under standard

and Aviation Fuels by the Motor Method

operating conditions. This is done at constant compression

D 3237 Test Method for Lead in Gasoline by Atomic

6 ratio by varying the manifold pressure and fuel flow rate, the

Absorption Spectrometry

independent variables of the test, and measuring indicated

D 3341 Test Method for Lead in Gasoline by the Iodine

mean effective pressure (imep) at enough points to define the

mixture response curves for the sample and the reference fuels.

This test method is under the jurisdiction of ASTM Committee D02 on

When the knock-limited power for the sample is bracketed

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

between those for two adjacent reference fuels suitably chosen

D02.01 on Combustion Characteristics.

from the prescribed list (see 12.1.2), the rating of the sample is

Current edition approved April 10, 2000. Published June 2000. Originally

published as D 909 – 58. Last previous edition D 909 – 95.

calculated by interpolation at the fuel-air ratio for maximum

Discontinued, see 1994 Annual Book of ASTM Standards, Vol 05.01.

power for the lower bracketing reference fuel.

Annual Book of ASTM Standards, Vol 05.01.

Discontinued, Replaced by Test Method D 5059, see 1992 Annual Book of

ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 05.04.

6 7

Annual Book of ASTM Standards, Vol 05.02. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 909

TABLE 1 ASTM Conversion of Octane Numbers to Performance Numbers

Octane Octane

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Number Number

Performance Number

70 48.3 48.4 48.4 48.5 48.6 48.7 48.8 48.9 49.0 49.0 70

71 49.1 49.2 49.3 49.4 49.5 49.6 49.6 49.7 49.8 49.9 71

72 50.0 50.1 50.2 50.3 50.4 50.5 50.5 50.6 50.7 50.8 72

73 50.9 51.0 51.1 51.2 51.3 51.4 51.5 51.6 51.7 51.8 73

74 51.9 51.9 52.0 52.1 52.2 52.3 52.4 52.5 52.6 52.7 74

75 52.8 52.9 53.0 53.1 53.2 53.3 53.4 53.5 53.6 53.7 75

76 53.8 53.9 54.1 54.2 54.3 54.4 54.5 54.6 54.7 54.8 76

77 54.9 55.0 55.1 55.2 55.3 55.4 55.6 55.7 55.8 55.9 77

78 56.0 56.1 56.2 56.3 56.5 56.6 56.7 56.8 56.9 57.0 78

79 57.1 57.3 57.4 57.5 57.6 57.7 57.9 58.0 58.1 58.2 79

80 58.3 58.5 58.6 58.7 58.8 58.9 59.1 59.2 59.3 59.4 80

81 59.6 59.7 59.8 60.0 60.1 60.2 60.3 60.5 60.6 60.7 81

82 60.9 61.0 61.1 61.3 61.4 61.5 61.7 61.8 61.9 62.1 82

83 62.2 62.4 62.5 62.6 62.8 62.9 63.1 63.2 63.3 63.5 83

84 63.6 63.8 63.9 64.1 64.2 64.4 64.5 64.7 64.8 65.0 84

85 65.1 65.3 65.4 65.6 65.7 65.9 66.0 66.2 66.4 66.5 85

86 66.7 66.8 67.0 67.2 67.3 67.5 67.6 67.8 68.0 68.1 86

87 68.3 68.5 68.6 68.8 69.0 69.1 69.3 69.5 69.7 69.8 87

88 70.0 70.2 70.4 70.5 70.7 70.9 71.1 71.2 71.4 71.6 88

89 71.8 72.0 72.2 72.4 72.5 72.7 72.9 73.1 73.3 73.5 89

90 73.7 73.9 74.1 74.3 74.5 74.7 74.9 75.1 75.3 75.5 90

91 75.7 75.9 76.1 76.3 76.5 76.7 76.9 77.1 77.3 77.6 91

92 77.8 78.0 78.2 78.4 78.7 78.9 79.1 79.3 79.5 79.8 92

93 80.0 80.2 80.5 80.7 80.9 81.2 81.4 81.6 81.9 82.1 93

94 82.4 82.6 82.8 83.1 83.3 83.6 83.8 84.1 84.3 84.6 94

95 84.8 85.1 85.4 85.6 85.9 86.2 86.4 86.7 87.0 87.2 95

96 87.5 87.8 88.1 88.3 88.6 88.9 89.2 89.5 89.7 90.0 96

97 90.3 90.6 90.9 91.2 91.5 91.8 92.1 92.4 92.7 93.0 97

98 93.3 93.6 94.0 94.3 94.6 94.9 95.2 95.6 95.9 96.2 98

99 96.6 96.9 97.2 97.6 97.9 98.2 98.6 98.9 99.3 99.6 99

100 100.0 . . . . . . . . . 100

Conversion Equation for Performance Number (PN):

PN = 2800/(128 − Octane number)

5. Significance and Use 6. Apparatus

6.1 The knock testing unit illustrated in Fig. 1 consists of a

5.1 The supercharge test method provides a means of

single-cylinder engine with accessories mounted on a station-

determining the rich-mixture antiknock performance of avia-

ary base. It is equipped with controls for varying manifold

tion gasoline. The test method utilizes a single-cylinder engine

pressure and fuel flow. The engine and equipment specified in

and requires critical adjustment of the fuel/air ratio and

inlet-manifold pressure to establish the knock-limited power Annex A1 on Apparatus shall be used without modification,

and installed as directed in Annex A5 on Installation and

characteristic of the gasoline. The knock-limited power rating

of the gasoline sample is determined by comparing its knock- Assembly. It is necessary to keep the apparatus in good

mechanical condition as described in Annex A4 on Mainte-

limited power level with that of the knock-limited power level

of primary reference fuels whose volumetric composition nance.

establishes the rating scale. The rating is expressed as an octane

7. Reference Materials

number at and below 100 and as a performance number above

100.

7.1 ASTM Knock Test Reference Fuels, conforming to the

5.2 It is customary to express grades of aviation fuel in specifications in A2.9.1 of Annex A2 on Reference Materials

terms of double numbers. The first number expresses the

and Blending Accessories, are the following:

antiknock quality by its lean-mixture or aviation rating, and the 7.1.1 ASTM isooctane (2,2,4-trimethylpentane),

second by its rich-mixture or supercharge rating. See Test

7.1.2 ASTM n-heptane,

Method D 2700. 7.1.3 ASTM 80 octane number blend of 7.1.1 and 7.1.2.

5.3 This test is used by engine manufacturers, by petroleum 7.2 Tetraethyllead, conforming to the specifications and

refiners and marketers, and in commerce as a primary specifi- requirements in A2.9.4 of Annex A2 on Reference Materials

cation measurement to ensure proper matching of fuel anti- and Blending Accessories, blended with ASTM isooctane is

knock quality and engine requirement. required for making ratings above 100 octane number.

D 909

TABLE 2 ASTM Conversion of Tetraethyllead in Isooctane to Performance Numbers

Tetraethyl- Tetraethyl-

lead in lead in

0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09

Isooctane , mL Isooctane , mL

per U. S. gal per U. S. gal

Performance Number

0.0 100.0 100.4 100.8 101.2 101.6 102.0 102.4 102.8 103.2 103.6 0.0

0.1 104.0 104.3 104.7 105.0 105.4 105.7 106.1 106.4 106.8 107.1 0.1

0.2 107.4 107.8 108.1 108.4 108.7 109.0 109.3 109.6 109.9 110.2 0.2

0.3 110.5 110.8 111.1 111.4 111.7 111.9 112.2 112.5 112.8 113.0 0.3

0.4 113.3 113.6 113.8 114.1 114.3 114.6 114.8 115.1 115.3 115.6 0.4

0.5 115.8 116.1 116.3 116.5 116.8 117.0 117.2 117.4 117.7 117.9 0.5

0.6 118.1 118.3 118.6 118.8 119.0 119.2 119.4 119.6 119.8 120.0 0.6

0.7 120.2 120.4 120.6 120.8 121.0 121.2 121.4 121.6 121.8 122.0 0.7

0.8 122.2 122.4 122.6 122.8 122.9 123.1 123.3 123.5 123.7 123.9 0.8

0.9 124.0 124.2 124.4 124.5 124.7 124.9 125.1 125.2 125.4 125.6 0.9

1.0 125.7 125.9 126.1 126.2 126.4 126.5 126.7 126.9 127.0 127.2 1.0

1.1 127.3 127.5 127.6 127.8 127.9 128.1 128.2 128.4 128.5 128.7 1.1

1.2 128.8 129.0 129.1 129.3 129.4 129.6 129.7 129.8 130.0 130.1 1.2

1.3 130.2 130.4 130.5 130.7 130.8 130.9 131.1 131.2 131.3 131.5 1.3

1.4 131.6 131.7 131.8 132.0 132.1 132.2 132.4 132.5 132.6 132.7 1.4

1.5 132.9 133.0 133.1 133.2 133.3 133.5 133.6 133.7 133.8 133.9 1.5

1.6 134.1 134.2 134.3 134.4 134.5 134.6 134.8 134.9 135.0 135.1 1.6

1.7 135.2 135.3 135.4 135.6 135.7 135.8 135.9 136.0 136.1 136.2 1.7

1.8 136.3 136.4 136.5 136.6 136.7 136.8 137.0 137.1 137.2 137.3 1.8

1.9 137.4 137.5 137.6 137.7 137.8 137.9 138.0 138.1 138.2 138.3 1.9

2.0 138.4 138.5 138.6 138.7 138.8 138.9 139.0 139.0 139.1 139.2 2.0

2.1 139.3 139.4 139.5 139.6 139.7 139.8 139.9 140.0 140.1 140.2 2.1

2.2 140.3 140.4 140.4 140.5 140.6 140.7 140.8 140.9 141.0 141.1 2.2

2.3 141.1 141.2 141.3 141.4 141.5 141.6 141.7 141.8 141.8 141.9 2.3

2.4 142.0 142.1 142.2 142.3 142.3 142.4 142.5 142.6 142.7 142.8 2.4

2.5 142.8 142.9 143.0 143.1 143.2 143.2 143.3 143.4 143.5 143.6 2.5

2.6 143.6 143.7 143.8 143.9 143.9 144.0 144.1 144.2 144.2 144.3 2.6

2.7 144.4 144.5 144.6 144.6 144.7 144.8 144.8 144.9 145.0 145.1 2.7

2.8 145.1 145.2 145.3 145.4 145.4 145.5 145.6 145.7 145.7 145.8 2.8

2.9 145.9 145.9 146.0 146.1 146.1 146.2 146.3 146.4 146.4 146.5 2.9

3.0 146.6 146.6 146.7 146.8 146.8 146.9 147.0 147.0 147.1 147.2 3.0

3.1 147.2 147.3 147.4 147.4 147.5 147.6 147.6 147.7 147.8 147.8 3.1

3.2 147.9 148.0 148.0 148.1 148.2 148.2 148.3 148.3 148.4 148.5 3.2

3.3 148.5 148.6 148.7 148.7 148.8 148.8 148.9 149.0 149.0 149.1 3.3

3.4 149.2 149.2 149.3 149.3 149.4 149.5 149.5 149.6 149.6 149.7 3.4

3.5 149.8 149.8 149.9 149.9 150.0 150.1 150.1 150.2 150.2 150.3 3.5

3.6 150.3 150.4 150.5 150.5 150.6 150.6 150.7 150.7 150.8 150.9 3.6

3.7 150.9 151.0 151.0 151.1 151.1 151.2 151.2 151.3 151.4 151.4 3.7

3.8 151.5 151.5 151.6 151.6 151.7 151.7 151.8 151.8 151.9 152.0 3.8

3.9 152.0 152.1 152.1 152.2 152.2 152.3 152.3 152.4 152.4 152.5 3.9

4.0 152.5 152.6 152.6 152.7 152.7 152.8 152.8 152.9 153.0 153.0 4.0

4.1 153.1 153.1 153.2 153.2 153.3 153.3 153.4 153.4 153.5 153.5 4.1

4.2 153.6 153.6 153.7 153.7 153.8 153.8 153.9 153.9 154.0 154.0 4.2

4.3 154.1 154.1 154.1 154.2 154.2 154.3 154.3 154.4 154.4 154.5 4.3

4.4 154.5 154.6 154.6 154.7 154.7 154.8 154.8 154.9 154.9 155.0 4.4

4.5 155.0 155.1 155.1 155.1 155.2 155.2 155.3 155.3 155.4 155.4 4.5

4.6 155.5 155.5 155.6 155.6 155.6 155.7 155.7 155.8 155.8 155.9 4.6

4.7 155.9 156.0 156.0 156.0 156.1 156.1 156.2 156.2 156.3 156.3 4.7

4.8 156.4 156.4 156.4 156.5 156.5 156.6 156.6 156.7 156.7 156.7 4.8

4.9 156.8 156.8 156.9 156.9 157.0 157.0 157.0 157.1 157.1 157.2 4.9

5.0 157.2 157.2 157.3 157.3 157.4 157.4 157.5 157.5 157.5 157.6 5.0

5.1 157.6 157.7 157.7 157.7 157.8 157.8 157.9 157.9 157.9 158.0 5.1

5.2 158.0 158.1 158.1 158.1 158.2 158.2 158.3 158.3 158.3 158.4 5.2

5.3 158.4 158.5 158.5 158.5 158.6 158.6 158.7 158.7 158.7 158.8 5.3

5.4 158.8 158.9 158.9 158.9 159.0 159.0 159.0 159.1 159.1 159.2 5.4

5.5 159.2 159.2 159.3 159.3 159.3 159.4 159.4 159.5 159.5 159.5 5.5

5.6 159.6 159.6 159.6 159.7 159.7 159.8 159.8 159.8 159.9 159.9 5.6

5.7 159.9 160.0 160.0 160.1 160.1 160.1 160.2 160.2 160.2 160.3 5.7

5.8 160.3 160.3 160.4 160.4 160.4 160.5 160.5 160.6 160.6 160.6 5.8

5.9 160.7 160.7 160.7 160.8 160.8 160.8 160.9 160.9 160.9 161.0 5.9

6.0 161.0 . . . . . . . . . 6.0

8. Sampling A3 on Operation for further details) are mandatory:

9.1.1 Engine Speed, 1800 6 45 rpm, including friction

8.1 Sampling shall be done in accordance with the appli-

measurement. The maximum variation throughout a test shall

cable procedure described in Practice D 4057.

not exceed 45 rpm, exclusive of friction measurement.

9. Operating Conditions

9.1.2 Compression Ratio, 7.0 to 1, fixed by adjustment of

9.1 The following standard operating conditions (see Annex the clearance volume to 108 6 0.5 mL on cylinders of standard

D 909

FIG. 1 Supercharge Unit

bore by the bench tilt procedure, Section A3.2 of Annex A3. viscosity index improvers or multi-graded oils shall not be

Clearance volumes for oversize cylinders are shown in this used.

section. If the Type D-1 detonation meter pickup is used, the 9.1.8 Oil Pressure,60 6 5 psi (0.41 6 0.03 MPa) gage in

clearance volumes are 2 mL less than for the Waukesha plug. the oil gallery leading to the crankshaft bearings.

9.1.3 Spark Advance, constant, 45°. 9.1.9 Oil Temperature, 165 6 5°F (74 6 3°C) at the

9.1.4 Spark-Plug Gap, 0.020 6 0.003 in. (0.51 6 0.13 mm). entrance to the oil gallery.

9.1.5 Ignition Settings: 9.1.10 Coolant Temperature, 375 6 5°F (191 6 3°C) in the

9.1.5.1 Breaker-Point Gap, 0.020 in. (0.51 mm). top of the coolant return line from the condenser to the

9.1.5.2 Breakerless ignition system basic setting for trans- cylinder.

ducer to rotor (vane) gap is 0.003 to 0.005 in. (0.08 to 0.13 9.1.11 Fuel-Pump Pressure,15 6 2 psi (0.10 6 0.01 MPa)

mm). in the gallery.

9.1.6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.