ASTM B275-02

(Practice)Standard Practice for Codification of Certain Nonferrous Metals and Alloys, Cast and Wrought

Standard Practice for Codification of Certain Nonferrous Metals and Alloys, Cast and Wrought

SCOPE

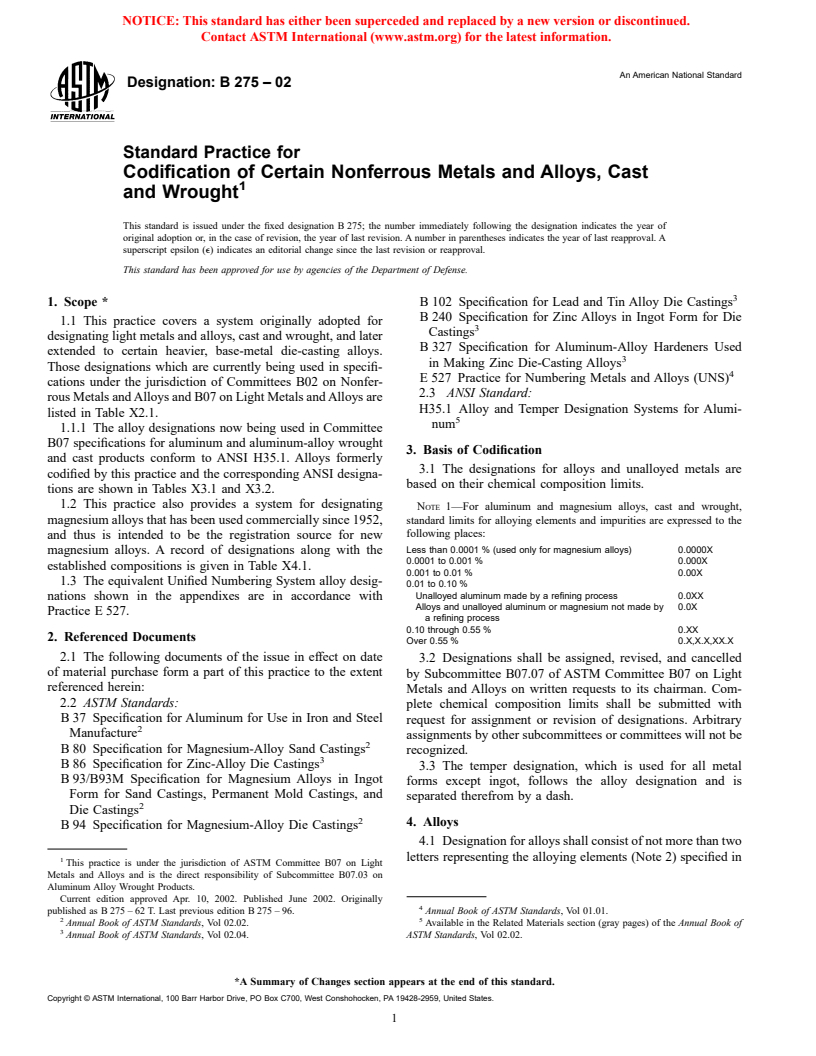

1.1 This practice covers a system originally adopted for designating light metals and alloys, cast and wrought, and later extended to certain heavier, base-metal die-casting alloys. Those designations which are currently being used in specifications under the jurisdiction of Committees B02 on Nonferrous Metals and Alloys and B07 on Light Metals and Alloys are listed in Table X2.1.

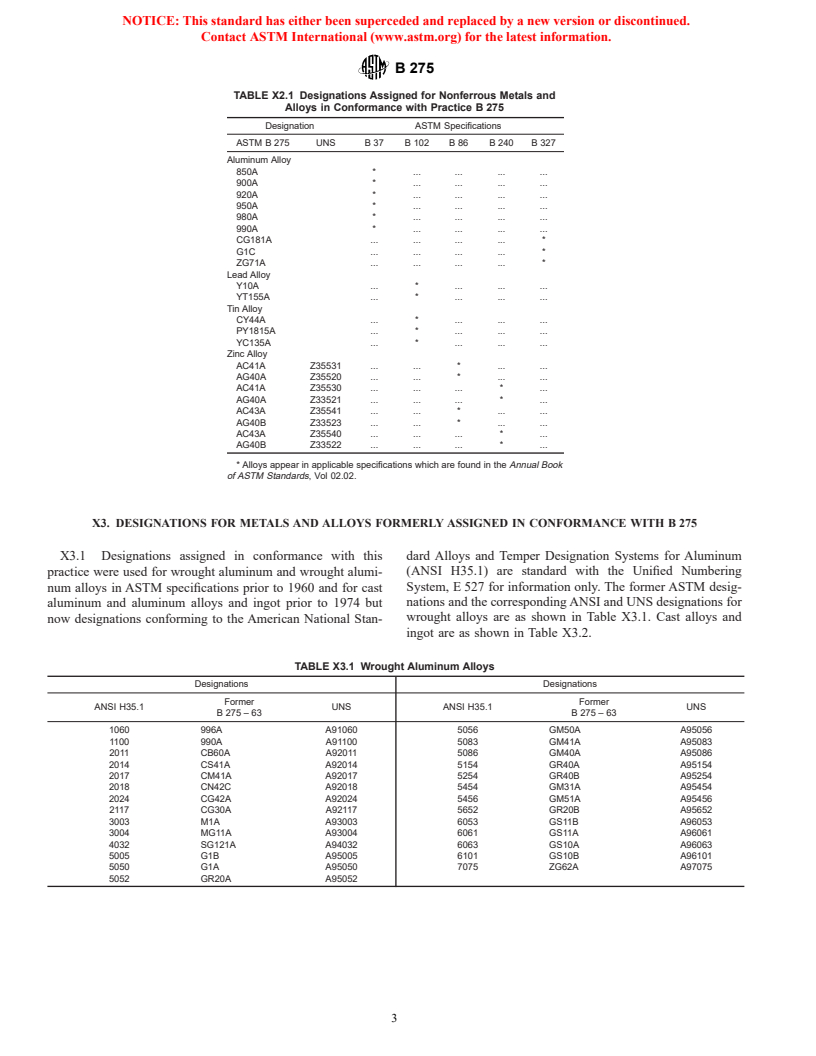

1.1.1 The alloy designations now being used in Committee B07 specifications for aluminum and aluminum-alloy wrought and cast products conform to ANSI H35.1. Alloys formerly codified by this practice and the corresponding ANSI designations are shown in Tables X3.1 and X3.2.

1.2 This practice also provides a system for designating magnesium alloys that has been used commercially since 1952, and thus is intended to be the registration source for new magnesium alloys. A record of designations along with the established compositions is given in Table X4.1.

1.3 The equivalent Unified Numbering System alloy designations shown in the appendixes are in accordance with Practice E 527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: B 275 – 02

Standard Practice for

Codification of Certain Nonferrous Metals and Alloys, Cast

1

and Wrought

This standard is issued under the fixed designation B 275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope * B 102 Specification for Lead and Tin Alloy Die Castings

B 240 Specification for Zinc Alloys in Ingot Form for Die

1.1 This practice covers a system originally adopted for

3

Castings

designating light metals and alloys, cast and wrought, and later

B 327 Specification for Aluminum-Alloy Hardeners Used

extended to certain heavier, base-metal die-casting alloys.

3

in Making Zinc Die-Casting Alloys

Those designations which are currently being used in specifi-

4

E 527 Practice for Numbering Metals and Alloys (UNS)

cations under the jurisdiction of Committees B02 on Nonfer-

2.3 ANSI Standard:

rous Metals and Alloys and B07 on Light Metals and Alloys are

H35.1 Alloy and Temper Designation Systems for Alumi-

listed in Table X2.1.

5

num

1.1.1 The alloy designations now being used in Committee

B07 specifications for aluminum and aluminum-alloy wrought

3. Basis of Codification

and cast products conform to ANSI H35.1. Alloys formerly

3.1 The designations for alloys and unalloyed metals are

codified by this practice and the corresponding ANSI designa-

based on their chemical composition limits.

tions are shown in Tables X3.1 and X3.2.

1.2 This practice also provides a system for designating

NOTE 1—For aluminum and magnesium alloys, cast and wrought,

magnesium alloys that has been used commercially since 1952, standard limits for alloying elements and impurities are expressed to the

following places:

and thus is intended to be the registration source for new

Less than 0.0001 % (used only for magnesium alloys) 0.0000X

magnesium alloys. A record of designations along with the

0.0001 to 0.001 % 0.000X

established compositions is given in Table X4.1.

0.001 to 0.01 % 0.00X

1.3 The equivalent Unified Numbering System alloy desig-

0.01 to 0.10 %

Unalloyed aluminum made by a refining process 0.0XX

nations shown in the appendixes are in accordance with

Alloys and unalloyed aluminum or magnesium not made by 0.0X

Practice E 527.

a refining process

0.10 through 0.55 % 0.XX

2. Referenced Documents

Over 0.55 % 0.X,X.X,XX.X

2.1 The following documents of the issue in effect on date

3.2 Designations shall be assigned, revised, and cancelled

of material purchase form a part of this practice to the extent

by Subcommittee B07.07 of ASTM Committee B07 on Light

referenced herein:

Metals and Alloys on written requests to its chairman. Com-

2.2 ASTM Standards:

plete chemical composition limits shall be submitted with

B 37 Specification for Aluminum for Use in Iron and Steel

request for assignment or revision of designations. Arbitrary

2

Manufacture

assignments by other subcommittees or committees will not be

2

B 80 Specification for Magnesium-Alloy Sand Castings

recognized.

3

B 86 Specification for Zinc-Alloy Die Castings

3.3 The temper designation, which is used for all metal

B 93/B93M Specification for Magnesium Alloys in Ingot

forms except ingot, follows the alloy designation and is

Form for Sand Castings, Permanent Mold Castings, and

separated therefrom by a dash.

2

Die Castings

2

4. Alloys

B 94 Specification for Magnesium-Alloy Die Castings

4.1 Designation for alloys shall consist of not more than two

letters representing the alloying elements (Note 2) specified in

1

This practice is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

Current edition approved Apr. 10, 2002. Published June 2002. Originally

4

published as B 275 – 62 T. Last previous edition B 275 – 96. Annual Book of ASTM Standards, Vol 01.01.

2 5

Annual Book of ASTM Standards, Vol 02.02. Available in the Related Materials section (gray pages) of the Annual Book of

3

Annual Book of ASTM Standards, Vol 02.04. ASTM Standards, Vol 02.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 275

TABLE 1 Letters Representing Alloying Elements

the greatest amount, arranged in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.