ASTM D4975-04(2011)

(Test Method)Standard Test Methods for Single-Filament Tire Bead Wire Made from Steel

Standard Test Methods for Single-Filament Tire Bead Wire Made from Steel

SIGNIFICANCE AND USE

The procedures for the determination of properties of single-filament bead wire made from steel are considered satisfactory for acceptance testing of commercial shipments of this product because the procedures are the best available and have been used extensively in the trade.

In case of a dispute arising from differences in reported test results when using these test methods for acceptance testing of commercial shipments, the purchaser and supplier should conduct comparative test to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens which are as homogeneous as possible and which are from a lot of material of the type in question. The test specimens then should be randomly assigned in equal number to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be determined and corrected or the purchaser and the supplier must agree to interpret future test results with consideration to the known bias.

SCOPE

1.1 These test methods cover testing of single-filament steel wires that are components of tire beads used in the manufacture of pneumatic tires. By agreement, these test methods may be applied to similar filaments used for reinforcing other rubber products.

1.2 These test methods describe test procedures only and do not establish specifications and tolerances.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4975 − 04(Reapproved 2011)

Standard Test Methods for

Single-Filament Tire Bead Wire Made from Steel

This standard is issued under the fixed designation D4975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 Thesetestmethodscovertestingofsingle-filamentsteel

3.1 Definitions:

wiresthatarecomponentsoftirebeadsusedinthemanufacture

3.1.1 Fordefinitionsoftermsrelatingtotirecord,beadwire,

of pneumatic tires. By agreement, these test methods may be

hose wire, and tire cord fabrics, refer to Terminology D6477.

applied to similar filaments used for reinforcing other rubber

3.1.1.1 The following terms are relevant to this standard:

products.

percent elongation, tire bead, tire bead wire, torsion resistance,

1.2 Thesetestmethodsdescribetestproceduresonlyanddo in tire bead wire, yield strength.

not establish specifications and tolerances.

3.1.2 For definitions of terms related to force and deforma-

tion in textiles, refer to Terminology D4848

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 3.1.2.1 The following terms are relevant to this standard:

breaking force.

standard.

3.1.3 For definitions of other textile terms, refer to Termi-

1.4 These test methods cover the determination of the

nology D123.

mechanical properties listed below:

Property Section

4. Summary of Test Methods

Breaking Force (Strength) 7–13

4.1 A summary of the procedures prescribed for the deter-

Yield Strength 7–13

Elongation 7–13

mination of specific properties of tire bead wire is stated in the

Torsion Resistance 14–20

appropriate sections of the specific test methods that follow.

Diameter (Gage) 21–27

1.5 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5.1 The procedures for the determination of properties of

priate safety and health practices and determine the applica- single-filament bead wire made from steel are considered

bility of regulatory limitations prior to use.

satisfactory for acceptance testing of commercial shipments of

this product because the procedures are the best available and

2. Referenced Documents

have been used extensively in the trade.

2.1 ASTM Standards: 5.1.1 In case of a dispute arising from differences in

reported test results when using these test methods for accep-

D76Specification for Tensile Testing Machines for Textiles

tance testing of commercial shipments, the purchaser and

D123Terminology Relating to Textiles

supplier should conduct comparative test to determine if there

D4848Terminology Related to Force, Deformation and

is a statistical bias between their laboratories. Competent

Related Properties of Textiles

statistical assistance is recommended for the investigation of

D6477TerminologyRelatingtoTireCord,BeadWire,Hose

bias.Asaminimum,thetwopartiesshouldtakeagroupoftest

Reinforcing Wire, and Fabrics

specimens which are as homogeneous as possible and which

are from a lot of material of the type in question. The test

These test methods are under the jurisdiction of ASTM Committee D13 on

specimens then should be randomly assigned in equal number

Textiles and are the direct responsibility of Subcommittee D13.19 on Industrial

toeachlaboratoryfortesting.Theaverageresultsfromthetwo

Fibers and Metallic Reinforcements.

laboratories should be compared using Student’s t-test for

Current edition approved Jan. 1, 2011. Published March 2011. Originally

unpaireddataandanacceptableprobabilitylevelchosenbythe

approved in 1989. Last previous edition approved in 2010 as D4975–04(2010).

DOI: 10.1520/D4975-04R11.

two parties before testing is begun. If a bias is found, either its

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cause must be determined and corrected or the purchaser and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the supplier must agree to interpret future test results with

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. consideration to the known bias.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D4975 − 04 (2011)

6. Sampling the various possibilities for recording test data, use of this type

of equipment is not covered in this test method.

6.1 Lot Sample—Asalotsampleforacceptancetesting,take

at random the number of reels, coils, spools, or other shipping 9.3 Grips, of such design that failure of the specimen does

units of wire directed in an applicable material specification or not occur at the gripping point, and slippage of the specimen

other agreement between the purchaser and the supplier. within the jaws (grips) is prevented.

Consider reels, coils, spools, or other shipping units of wire to

be the primary sampling units. 10. Procedure

10.1 Thermally age the specimen by placing it in an oven

NOTE 1—A realistic specification or other agreement between the

purchaser and the supplier requires taking into account the variability

for 60 6 1 min, at 150 6 3°C. Allow specimens to cool to

between and within primary sampling units so as to provide a sampling

room temperature before testing.

plan which at the specified level of the property of interest has a

10.2 Select the proper force scale range on the tensile

meaningfulproducer’srisk,consumer’srisk,acceptablequalitylevel,and

desired limiting quality level.

testing machine based on the estimated breaking force of the

specimen being tested.

6.2 Laboratory Sample—Use the primary sampling units in

the lot sample as a laboratory sample.

10.3 Adjust the distance between the grips of the testing

machine, nip to nip, to a gage length of 250 mm.

6.3 Test Specimens—For each test procedure, take the num-

ber of lengths of tire bead wire of the specified lengths from

10.4 Secure the specimen in the top clamp, exerting enough

each laboratory sample as directed in the test procedure.

pressure to prevent the specimen from slipping when loaded.

Place the other end of the specimen between the jaws of the

BREAKING FORCE, YIELD STRENGTH, AND

bottom clamp.

ELONGATION

10.5 Apply a pretension of 1% of full scale to keep the

specimen taut.

7. Summary of Test Method

10.6 After setting the cross head speed at 25 mm/min and

7.1 The two ends of a specimen are clamped in a tensile

recorder chart speed at 250 mm/min, start the testing machine

testing machine; an increasing force is applied until the

and record the force-extension curve generated.

specimen breaks. The change in force is measured versus the

10.6.1 Ifthespecimenfractureswithin5mmofthegripping

increase in separation of the specimen clamps to form a

point, discard the result and test another specimen. If such jaw

force-extension curve. Breaking force is read directly from the

breaks continue to occur, insert a jaw liner such as an abrasive

curve and is expressed in newtons. Percent elongation at break

cloth between the gripping surface and the specimen in a

is the extension at break divided by the original specimen

manner so that the liner extends beyond the grip edge where it

length,×100. The yield strength, the intersection of the force-

comes in contact with the specimen.

extension curve with a line at 0.2% elongation offset, is read

from the force-extension curve and is expressed in newtons.

10.7 Conduct this test procedure on two specimens from

each laboratory sampling unit.

8. Significance and Use

10.8 Elongation, the increase in gage length of a tensile

8.1 The load-bearing ability of a reinforced rubber product

specimen, is usually expressed as a percentage of the original

such as a tire bead is related to the strength of the single-

gage length and can be determined from the force-extension

filament wire used as the reinforcing material. The breaking

curve.

forceandyieldstrengthoftirebeadwireisusedinengineering

10.8.1 When a greater degree of accuracy is required in the

calculations when designing this type of reinforced product.

determination of elongation, an extensometer can be attached

to the specimen.

8.2 Elongation of tire bead wire is taken into consideration

inthedesignandengineeringoftirebeadsbecauseofitseffect

10.9 Yield strength is the stress at which a material exhibits

on uniformity and dimensional stability during service.

a specified limiting deviation from the proportionality of stress

to strain. Determine the yield strength by the 0.2% offset

9. Apparatus

elongation method.

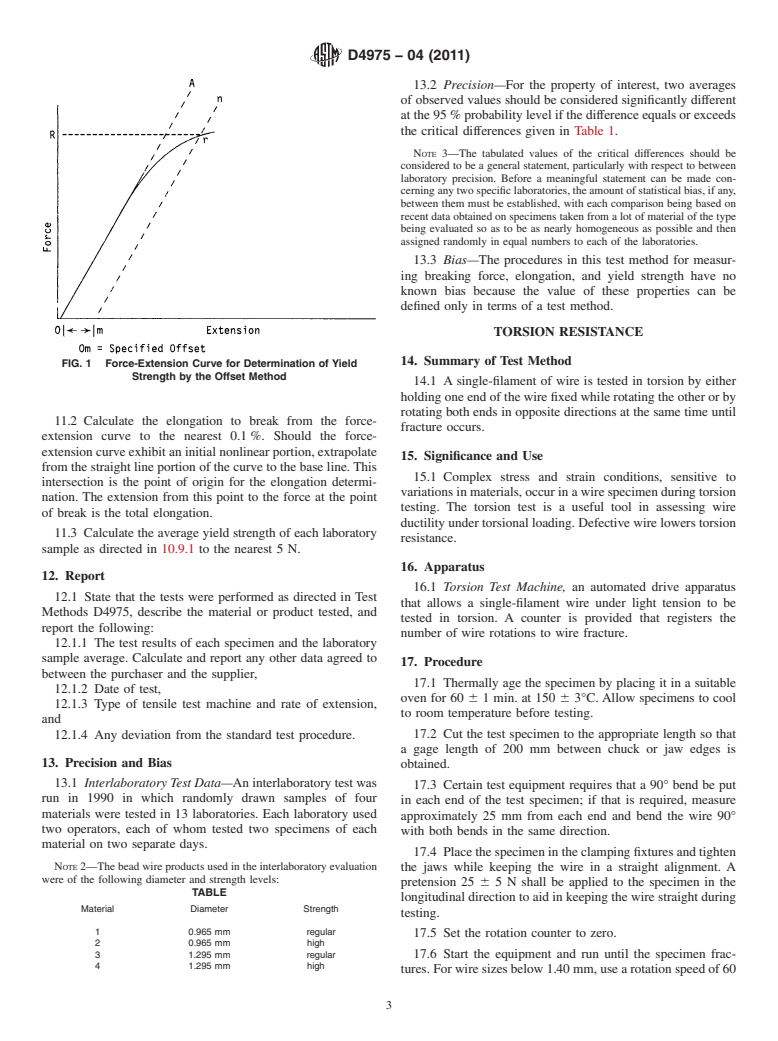

9.1 Tensile Testing Machine, CRE (Constant-Rate-of- 10.9.1 On the force-extension curve (Fig. 1) that has been

Extension) tensile testing machine of such capacity that the generated (see 10.6) mark off Om equal to the specified value

maximum force required to fracture the wire shall not exceed of the offset (0.2% elongation); draw mn parallel to OA and

90% nor be of less than 10% of the selected force measure- locate r.Thisintersectionof mnwiththeforce-extensioncurve

ment range. The specifications and methods of calibration and corresponds to force R which is the yield strength. Should the

verification for tensile testing machines shall conform to force-extension curve exhibit an initial nonlinear portion,

Specification D76. extrapolate from the straight line portion to the base line. The

intersection is point O used in this section.

9.2 In some laboratories, the output of CRE type of tensile

testing machine is connected with electronic recording and

11. Calculation

computing equipment which may be programmed to calculate

and print the results for each of these desired properties. 11.1 Calculate the average breaking force of the laboratory

Because of the variety of electronic equipment available and sample to the nearest 5 N.

D4975 − 04 (2011)

13.2 Precision—For the property of interest, two averages

of observed values should be considered significantly different

atthe95%probabilitylevelifthedifferenceequalsorexceeds

the critical differences given in Table 1.

NOTE 3—The tabulated values of the critical differences should be

considered to be a general statement, particularly with respect to between

laboratory precision. Before a meaningful statement can be made con-

cerninganytwospecificlaboratories,theamountofstatisticalbias,ifany,

between them must be established, with each comparison being based on

recent data obtained on specimens taken from a lot of material of the type

being evaluated so as to be as nearly homogeneous as possible and then

assigned randomly in equal numbers to each of the laboratories.

13.3 Bias—The procedures in this test method for measur-

ing breaking force, elongation, and yield strength have no

known bias because the value of these properties can be

defined only in terms of a test method.

TORSION RESISTANCE

14. Summary of Test Method

FIG. 1 Force-Extension Curve for Determination of Yield

Strength by the Offset Method

14.1 A single-filament of wire is tested in torsion by either

holdingoneendofthewirefixedwhilerotatingtheotherorby

rotating both ends in opposite directions at the same time until

11.2 Calculate the elongation to break from the force-

fracture occurs.

extension curve to the nearest 0.1%. Should the force-

extensioncurveexhibitaninitialnonlinearportion,extrapolate

15. Significance and Use

fromthestraightlineportionofthecurvetothebaseline.This

15.1 Complex stress and strain conditions, sensitive to

intersection is the point of origin for the elongation determi-

variationsinmaterials,occurinawirespecimenduringtorsion

nation. The extension from this point to the force at the point

testing. The torsion test is a useful tool in assessing wire

of break is the total elongation.

ductilityundertorsionalloading.Defectivewirelowerstorsion

11.3 Calculate the average yield strength of each laboratory

resistance.

sample as directed in 10.9.1 to the nearest 5 N.

16. Apparatus

12. Report

16.1 Torsion Test Machine, an automated drive apparatus

12.1 State that the tests were performed as directed in Test

that allows a single-filament wire under light tension to be

Methods D4975, describe the material or product tested, and

tested in torsion. A counter is provided that registers the

report the following:

number of wire rotations to wire fracture.

12.1.1 The test results of each specimen and the laboratory

sample average. Calculate and report any other data agreed to

17. Procedure

between the purchaser and the supplier,

17.1 Thermally age the specimen by placing it in a suitable

12.1.2 Date of test,

oven for 60 6 1 min. at 150 6 3°C.Allow specimens to cool

12.1.3 Type of tensile test machine and rate of extension,

to room temperature before testing.

and

12.1.4 Any deviation from the standard test procedure. 17.2 Cut the test specimen to the appropriate length so that

a gage length of 200 mm between chuck or jaw edges is

13. Precision and Bias

obtained.

13.1 Interlaboratory Test Data—Aninterlaboratorytestwas

17.3 Certain test equipment requires that a 90° bend be put

run in 1990 in which randomly drawn samples of four

in each end of the test specimen; if that is required, measure

materials were tested in 13 laboratories. Each laboratory used

approximately 25 mm from each end and bend the wire 90°

two operators, each of whom tested two specimens of each

with both bends in the same direction.

material on two separate days.

17.4 Placethespecimenintheclampingfixturesandtighten

NOTE 2—The bead wire products used in the interlaboratory evaluation the jaws while keeping the wire in a straight alignment. A

were of the following diameter and strength levels:

pretension 25 6 5 N shall be applied to the specimen in the

TABLE

longitudinaldirectiontoaidinkeepingthewirestraightduring

Material Diameter Strength

testing.

1 0.965 mm regular

17.5 Set the rotation counter to zero.

2 0.965 mm high

3 1.295 mm regular 17.6 Start the equipment and run until the specimen frac-

4 1.295 mm high

tures.Forwiresizesbelow1.40mm,usearotationspeedof60

D4975 − 04 (2011)

TABLE 1 Critical Differences for Conditions Noted

Number of Within-Laboratory

Name of Property Single Operator Precision Between-Laboratory Precision

Observations Precision

Single-Material Comparisons

Breaking force, N 1 17 17 27

21212 25

499 23

866 22

1644 22

Multi-Material Comparisons

11717 31

21212 28

499 27

866 26

1655 26

Single-Material Comparisons

A B

Yield strength, N Group 1 Group 2 Group 1 Gro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.