ASTM F2016-00

(Practice)Standard Practice for Establishing Shipbuilding Quality Requirements for Hull Structure, Outfitting, and Coatings

Standard Practice for Establishing Shipbuilding Quality Requirements for Hull Structure, Outfitting, and Coatings

SCOPE

1.1 This practice consists of three annexes: hull structure, outfitting, and coating. The subject of these annexes was selected for several reasons. Other commercial shipbuilding nations already have in place widely recognized standards of expectations in these areas. These constitute the most significant areas where workmanship is a critical factor in customer satisfaction. The cost associated with the labor involved in these three areas is a significant factor in construction man-hours and overall schedules.

1.2 The standard criteria provided in this practice are intended to apply to conventional, commercial ship construction. In many cases, specialized, nonconventional vessels using nonstandard materials or built-to-serve sole requirements may require unique acceptance criteria that are beyond those provided in this practice.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 2016 – 00

Standard Practice for

Establishing Shipbuilding Quality Requirements for Hull

Structure, Outfitting, and Coatings

This standard is issued under the fixed designation F 2016; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Other Hard Materials by High-and Ultrahigh-Pressure

Water Jetting Prior to Re-coating (SSPC-SP 12)

1.1 This practice consists of three annexes: hull structure,

NACE No. 7 Interim Guide and Visual Reference Photo-

outfitting, and coating. The subject of these annexes was

graphs for Steel Cleaned by Water Jetting (SSPC-VIS

selected for several reasons. Other commercial shipbuilding

4(1))

nations already have in place widely recognized standards of

2.4 SSPC Standards:

expectations in these areas. These constitute the most signifi-

SSPC-AB 1 Mineral and Slag Abrasives

cant areas where workmanship is a critical factor in customer

SSPC-AB 2 Specification for Cleanliness of Recycled Fer-

satisfaction. The cost associated with the labor involved in

rous Metallic Abrasives

these three areas is a significant factor in construction man-

SSPC-PA 2 Measurement of Dry Coating Thickness With

hours and overall schedules.

Magnetic Gages

1.2 The standard criteria provided in this practice are

SSPC-SP 1 Solvent Cleaning

intended to apply to conventional, commercial ship construc-

SSPC-SP 2 Hand Tool Cleaning

tion.Inmanycases,specialized,nonconventionalvesselsusing

SSPC-SP 3 Power Tool Cleaning

nonstandard materials or built-to-serve sole requirements may

SSPC-SP 7 Brush-Off Blast Cleaning

require unique acceptance criteria that are beyond those

SSPC-SP 10 Near-White Blast Cleaning

provided in this practice.

SSPC-SP 11 Power Toll Cleaning to Bare Metal

2. Referenced Documents SSPC-SP 12 Surface Preparation and Cleaning of Steel and

Other Hard Materials by High-and Ultrahigh-Pressure

2.1 ASTM Standards:

Water Jetting Prior to Re-coating (NACE No. 5)

D 4417 Test Methods for Field Measurement of Surface

SSPC-VIS 1-89 Visual Standard forAbrasive Blast Cleaned

Profile of Blast-Cleaned Steel

Steel

E 337 Test Method for Measuring Humidity with a Psy-

SSPC-VIS 3 Visual Standard for Power- and Hand-Tool

chrometer (the Measurement of Wet-Bulb and Dry-Bulb

Cleaned Steel

Temperatures

SSPC-VIS 4(1) Interim Guide and Visual Reference Photo-

2.2 ISO Standards:

graphs for Steel Cleaned by Water Jetting (NACE No. 7)

ISO 8502–3 Assessment of Dust on Steel Surfaces Prepared

2.5 NSRP Documents:

for Painting (Pressure-Sensitive Tape Method)

National Shipbuilding Research Project 6–97–1 “American

ISO 8502–6 Extraction of Soluble Contaminants for

Shipbuilding Quality Standards,” dated May 28, 1999

Analysis—The Bresle Method

2.3 NACE Standards:

3. Summary of Practice

NACE No. 5 Surface Preparation and Cleaning of Steel and

3.1 This practice provides workmanship criteria to be ap-

plied to commercial shipbuilding or ship repair, or both. The

This practice is under the jurisdiction ofASTM Committee F–25 on Ships and criteria covers three primary phases of ship construction, that

Marine Technologyand is the direct responsibility of Subcommittee F25.07on

is, hull structure, outfitting, and coatings. Specific criteria to be

General Requirements.

Current edition approved May 10, 2000. Published October 2000.

Annual Book of ASTM Standards, Vol 06.02.

3 6

Annual Book of ASTM Standards, Vol 11.03. Available from Society for Protective Coatings, 40 24th St., 6th Floor,

Available from American National Standards Institute, 11 W. 42nd St., 13th Pittsburgh, PA 15222–4656.

Floor, New York, NY 10036. Available from The Librarian, Documentation Center, Marine Systems Divi-

Available from NationalAssociation of Corrosion Engineers, PO Box 218340, sion, University of Michigan Transportation Research Institute, 2901 Baxter Rd.,

Houston, TX 77218. Ann Arbor, MI 48109–2150.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2016–00

selected from this standard should be as contractually agreed 4.2.2 Toprovideabaselinefromwhichindividualshipyards

between the ship owner and shipbuilder. can begin to develop their own product and process standards

in accordance with generally accepted practice in the commer-

4. Significance and Use cial marine industry.

4.2.3 To provide a foundation for negotiations between the

4.1 To achieve success in ship construction, it is necessary

shipbuilder and the ship owner in reaching a common expec-

for the ship owner and the ship builder to agree on the level of

tation of construction quality.

quality in the final product. Classification rules, regulatory

4.3 The acceptance criteria herein are based on currently

requirements, and ship specifications all help to define an

practiced levels of quality generally achieved by leading

acceptable level of construction quality; however, this guid-

international commercial shipbuilders. These criteria are not

ancealoneisnotsufficient.Itisuptotheshipbuilder,therefore,

intended to be a hard standard with which all U.S. shipyards

to describe the level of workmanship sufficiently that will be

must comply. Rather, they are intended to provide guidance

reflected in the delivered ship, and for the ship owner to

and recommendations in the key areas that play a major role in

communicate his expectations effectively for the final product.

customer satisfaction and cost-effective ship construction.

4.2 It is the intent of this document to contribute to these

5. Keywords

objectives in the following ways:

4.2.1 Todescribeareasonableacceptablelevelofworkman- 5.1 coatings; hull structure; outfitting; quality; shipbuilding;

ship for commercial vessels built in the United States. workmanship

ANNEXES

(Mandatory Information)

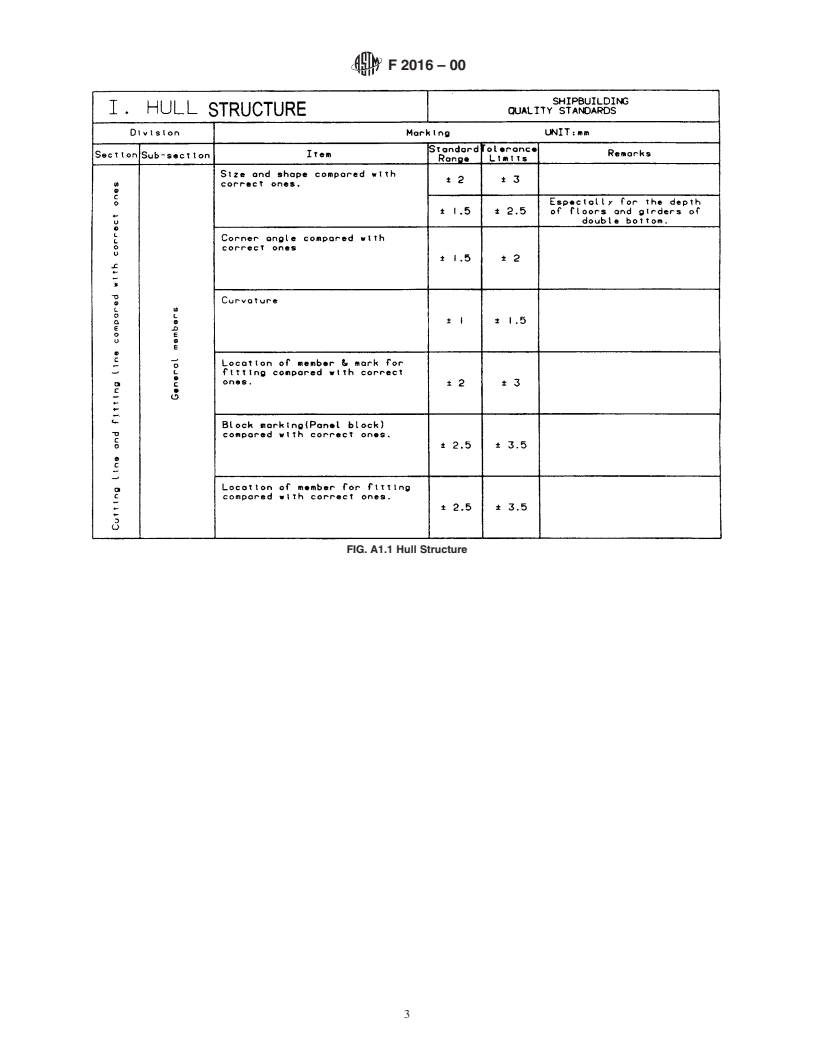

A1. HULL STRUCTURE

F2016–00

FIG. A1.1 Hull Structure

F2016–00

FIG. A1.2 Hull Structure

F2016–00

FIG. A1.3 Hull Structure

F2016–00

FIG. A1.4 Hull Structure

F2016–00

FIG. A1.5 Hull Structure

F2016–00

FIG. A1.6 Hull Structure

F2016–00

FIG. A1.7 Hull Structure

F2016–00

FIG. A1.8 Hull Structure

F2016–00

FIG. A1.9 Hull Structure

F2016–00

FIG. A1.10 Hull Structure

F2016–00

FIG. A1.11 Hull Structure

F2016–00

FIG. A1.12 Hull Structure

F2016–00

FIG. A1.13 Hull Structure

F2016–00

FIG. A1.14 Hull Structure

F2016–00

FIG. A1.15 Hull Structure

F2016–00

FIG. A1.16 Hull Structure

F2016–00

FIG. A1.17 Hull Structure

F2016–00

FIG. A1.18 Hull Structure

F2016–00

FIG. A1.19 Hull Structure

F2016–00

FIG. A1.20 Hull Structure

F2016–00

FIG. A1.21 Hull Structure

F2016–00

FIG. A1.22 Hull Structure

F2016–00

FIG. A1.23 Hull Structure

F2016–00

FIG. A1.24 Hull Structure

F2016–00

A2. OUTFITTING

F2016–00

FIG. A2.1 Piping

F2016–00

FIG. A2.2 Piping

F2016–00

FIG.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.