ASTM C673-97(2003)

(Classification)Standard Classification of Fireclay and High-Alumina Plastic Refractories and Ramming Mixes

Standard Classification of Fireclay and High-Alumina Plastic Refractories and Ramming Mixes

SCOPE

1.1 This classification covers fireclay and high-alumina plastic refractories and ramming mixes that can be pounded or rammed into place to form a monolithic structure. The terms "plastic" and" ramming mix" are generally intended to describe the workability of the material. In this regard, plastics are considered to be materials having a workability index of more than 15 % in accordance with Test Method C 181, while ramming mixes generally have less than 15 % workability by the same procedure.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 673 – 97 (Reapproved 2003)

Standard Classification of

Fireclay and High-Alumina Plastic Refractories and

1

Ramming Mixes

This standard is issued under the fixed designation C 673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

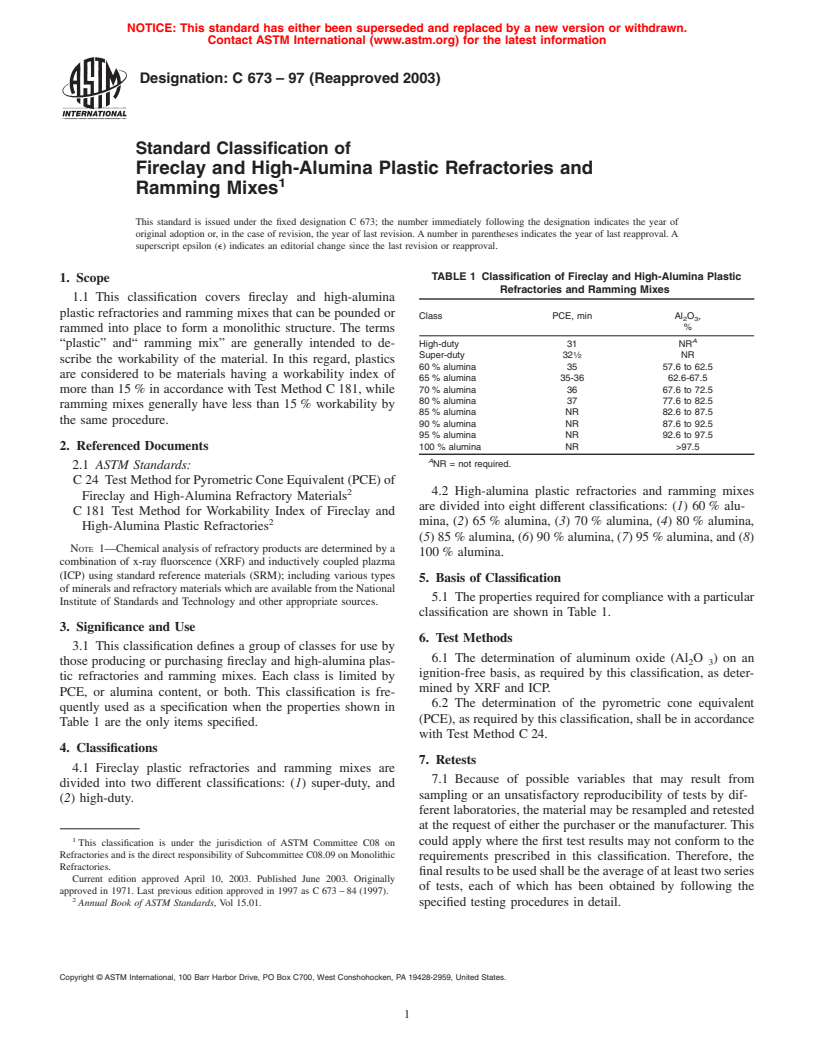

TABLE 1 Classification of Fireclay and High-Alumina Plastic

1. Scope

Refractories and Ramming Mixes

1.1 This classification covers fireclay and high-alumina

plastic refractories and ramming mixes that can be pounded or

Class PCE, min Al O ,

2 3

%

rammed into place to form a monolithic structure. The terms

A

“plastic” and“ ramming mix” are generally intended to de- High-duty 31 NR

1

Super-duty 32 ⁄2 NR

scribe the workability of the material. In this regard, plastics

60 % alumina 35 57.6 to 62.5

are considered to be materials having a workability index of

65 % alumina 35-36 62.6-67.5

more than 15 % in accordance with Test Method C 181, while 70 % alumina 36 67.6 to 72.5

80 % alumina 37 77.6 to 82.5

ramming mixes generally have less than 15 % workability by

85 % alumina NR 82.6 to 87.5

the same procedure.

90 % alumina NR 87.6 to 92.5

95 % alumina NR 92.6 to 97.5

2. Referenced Documents 100 % alumina NR >97.5

A

NR = not required.

2.1 ASTM Standards:

C 24 TestMethodforPyrometricConeEquivalent(PCE)of

2 4.2 High-alumina plastic refractories and ramming mixes

Fireclay and High-Alumina Refractory Materials

are divided into eight different classifications: (1) 60 % alu-

C 181 Test Method for Workability Index of Fireclay and

2 mina, (2) 65 % alumina, (3) 70 % alumina, (4) 80 % alumina,

High-Alumina Plastic Refractories

(5) 85 % alumina, (6) 90 % alumina, (7) 95 % alumina, and (8)

NOTE 1—Chemical analysis of refractory products are determined by a

100 % alumina.

combination of x-ray fluorscence (XRF) and inductively coupled plazma

(ICP) using standard reference materials (SRM); including various types

5. Basis of Classification

of minerals and refractory materials which are available from the National

5.1 The properties required for compliance with a particular

Institute of Standards and Technology and other appropriate sources.

classification are shown in Table 1.

3. Significance and Use

6. Test Methods

3.1 This classification defines a group of classes for use by

6.1 The determination of aluminum oxide (Al O )onan

those producing or purchasing fireclay and high-alumina plas- 2 3

ignition-free basis, as required by this classification, as deter-

tic refractories and ramming mixes. Each class is limited by

mined by XRF and ICP.

PCE, or alumina content, or both. This classification is fre-

6.2 The determination of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.