ASTM F1076-87(2015)e1

(Practice)Standard Practice for Expanded Welded and Silver Brazed Socket Joints for Pipe and Tube

Standard Practice for Expanded Welded and Silver Brazed Socket Joints for Pipe and Tube

SIGNIFICANCE AND USE

3.1 Expanded welded socket joints may be used with the following pipe and tube:

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.1.4 Seamless Stainless Steel Pipe—2 NPS through 6 NPS, Schedules 5 and 10.

3.2 Expanded silver brazed socket joints may be used with the following tube:

3.2.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.3 Expanded welded and silver brazed socket joints may be used where experience or test has demonstrated that the joint is safe and suitable for design and operating conditions, and where adequate provision is made to prevent separation of the joint.

SCOPE

1.1 This practice covers expanded welded and silver brazed socket joints for use on shipboard piping systems.

1.2 Expanded welded and silver brazed socket joints are to be used to join two pipes or tubes having the same NPS (see Note 1) without using a fitting or butt weld.

1.3 Brazed socket type joints are not intended for use on systems containing flammable or combustible fluids in areas where fire hazards exist or where the service temperature exceeds 425°F (205°C).

1.4 Brazed joints depending solely upon a fillet weld rather than primarily upon brazing material between pipe/tube and socket are not covered by this practice.

Note 1: The dimensionless designator nominal pipe size (NPS) has been substituted in this practice for such traditional terms as “nominal diameter,” “size,” “nominal size,” and “iron pipe size.”

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1076 − 87 (Reapproved 2015) An American National Standard

Standard Practice for

Expanded Welded and Silver Brazed Socket Joints for Pipe

and Tube

This standard is issued under the fixed designation F1076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Keywords section was editorially added in May 2015.

1. Scope Heavily Cold Worked Austenitic Stainless Steel Pipes

B75Specification for Seamless Copper Tube

1.1 This practice covers expanded welded and silver brazed

B88Specification for Seamless Copper Water Tube

socket joints for use on shipboard piping systems.

B466/B466M Specification for Seamless Copper-Nickel

1.2 Expanded welded and silver brazed socket joints are to

Pipe and Tube

be used to join two pipes or tubes having the same NPS (see 3

2.2 Military Standards:

Note 1) without using a fitting or butt weld.

MIL-P-1144 Pipe, Corrosion-Resistant, Stainless Steel,

1.3 Brazed socket type joints are not intended for use on Seamless and Welded

systems containing flammable or combustible fluids in areas

MIL-T-16420Tube, Copper-Nickel Alloy, Seamless and

where fire hazards exist or where the service temperature Welded

exceeds 425°F (205°C).

MIL-T-24107Tube, Copper (Seamless)

2.3 ASME Standard:

1.4 Brazed joints depending solely upon a fillet weld rather

ASME Boiler Code

than primarily upon brazing material between pipe/tube and

2.4 Federal Standard:

socket are not covered by this practice.

Title 46Code of Federal Regulations

NOTE 1—The dimensionless designator nominal pipe size (NPS) has

2.5 NAVSEA Document:

been substituted in this practice for such traditional terms as “nominal

0900-LP-001-7000Fabrication and Inspection of Brazed

diameter,” “size,” “nominal size,” and “iron pipe size.”

Piping Systems

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

as standard. The values given in parentheses are mathematical

3. Significance and Use

conversions to SI units that are provided for information only

3.1 Expanded welded socket joints may be used with the

and are not considered standard.

following pipe and tube:

1.6 This standard does not purport to address all of the

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside

safety concerns, if any, associated with its use. It is the

diameter through 6.625-in. (170-mm) outside diameter.

responsibility of the user of this standard to establish appro-

3.1.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm)

priate safety and health practices and determine the applica-

outsidediameterthrough6.625-in.(170-mm)outsidediameter.

bility of regulatory limitations prior to use.

3.1.3 SeamlessCopperWaterTube—2.125-in.(55-mm)out-

side diameter through 4.125-in. (105-mm) outside diameter.

2. Referenced Documents

3.1.4 Seamless Stainless Steel Pipe—2 NPS through 6 NPS,

2.1 ASTM Standards:

Schedules 5 and 10.

A312/A312M Specification for Seamless, Welded, and

3.2 Expanded silver brazed socket joints may be used with

the following tube:

3.2.1 Seamless Copper Tube—2.375-in. (60-mm) outside

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

diameter through 6.625-in. (170-mm) outside diameter.

Marine Technology and is the direct responsibility of Subcommittee F25.11 on

Machinery and Piping Systems.

Current edition approved May 1, 2015. Published June 2015. Originally

approved in 1987. Last previous edition approved in 2010 as F1076–87 (2010). AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

DOI: 10.1520/F1076-87R15. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.access.gpo.gov.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1076 − 87 (2015)

3.2.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) 4.2.3 Seamless Copper-Nickel Tube (70-30)—Specification

outsidediameterthrough6.625-in.(170-mm)outsidediameter. B466/B466M, UNS Number C71500 and MIL-T-16420, UNS

3.2.3 SeamlessCopperWaterTube—2.125-in.(55-mm)out- Number C71500, Class 200, annealed.

side diameter through 4.125-in. (105-mm) outside diameter. 4.2.4 Seamless Copper Water Tube—Specification B88,

Type K, UNS Number C12200, drawn (see 5.3).

3.3 Expandedweldedandsilverbrazedsocketjointsmaybe

usedwhereexperienceortesthasdemonstratedthatthejointis

5. Procedure

safe and suitable for design and operating conditions, and

5.1 Install no more than two expanded joints in any 36-in.

where adequate provision is made to prevent separation of the

(915-mm) long section of pipe/tube and in no case allow a

joint.

pipe/tube expanded at both ends in lengths of less than 36 in.

4. Materials and Manufacture

5.2 Fabricate expanded joints on the ends of the pipe/tube

by use of an expanding machine.

4.1 Welded Socket Joint:

4.1.1 Seamless Copper Tube—Specification B75, UNS

5.3 Expanded joints shall not be used on Class I piping

Number C12200 and MIL-T-24107, UNS Number C12200,

systems as defined in 46CFR56.04 for United States Coast

light drawn (see 5.3).

Guard inspected and certified vessels.

4.1.2 Seamless Copper-Nickel Tube (90-10)—Specification

5.4 Perform a minimum of three expansions to ensure the

B466/B466M, UNS Number C70600 and MIL-T-16420, UNS

degree of expansion.

Number C70600, Class 200, annealed.

4.1.3 Seamless Copper-Nickel Tube (70-30)—Specification 5.5 Bevel the unexpanded end of pipe/tube 30 to 40° for

copper-nickel alloy and 10 to 20° for stainless steel.

B466/B466M, UNS Number C71500 and MIL-T-16420, UNS

Number C71500, Class 200, annealed.

5.6 Clean the pipe/tube ends to be inserted into the silver-

4.1.4 Seamless Copper Water Tube—Specification B88,

brazedexpandedpipe/tubesocketandtheinteriorofthesocket

Type K, UNS Number C71500, drawn (see 5.3).

itself to a bright metal before insertion.

4.1.5 Seamless Stainless Steel Pipe—Specification A312/

5.7 Align pipe/tube ends concentrically as accurately as

A312M, UNS Number S30400 and S31600. MIL-P-1144,

possible, and preserve this alignment during the welding

UNS Number S30400 and S31600, Schedules 5 and 10.

process.

4.2 Silver-Brazed Socket Joint:

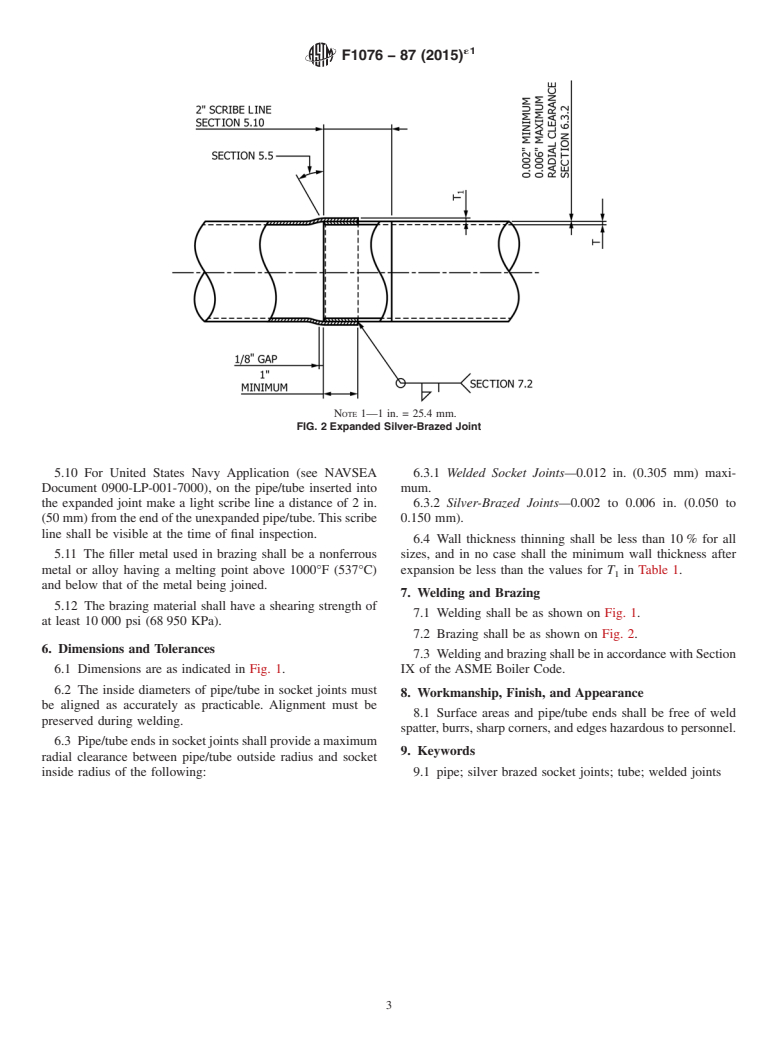

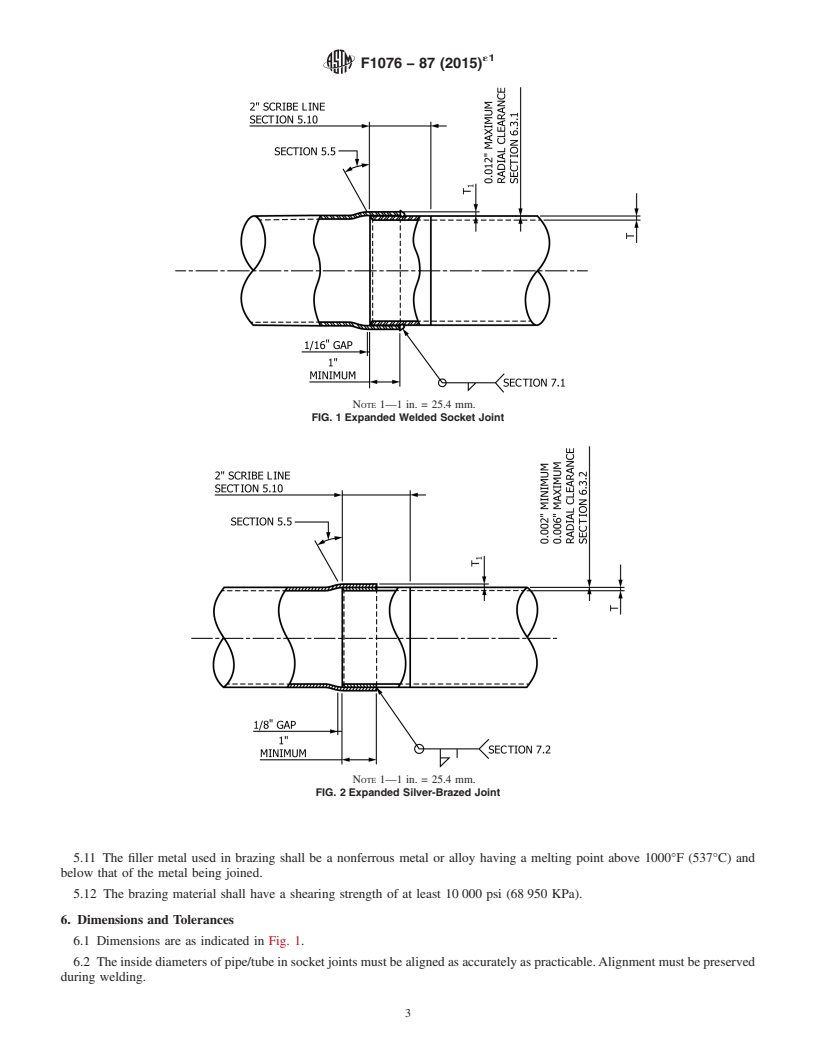

5.8 Provide a gap of approximately ⁄16 in. (1.5 mm)

4.2.1 Seamless Copper Tube—Specification B75, UNS

(expanded welded socket joint, Fig. 1) and ⁄8 in. (3

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1076 − 87 (Reapproved 2010) F1076 − 87 (Reapproved 2015)An American National Standard

Standard Practice for

Expanded Welded and Silver Brazed Socket Joints for Pipe

and Tube

This standard is issued under the fixed designation F1076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Keywords section was editorially added in May 2015.

1. Scope

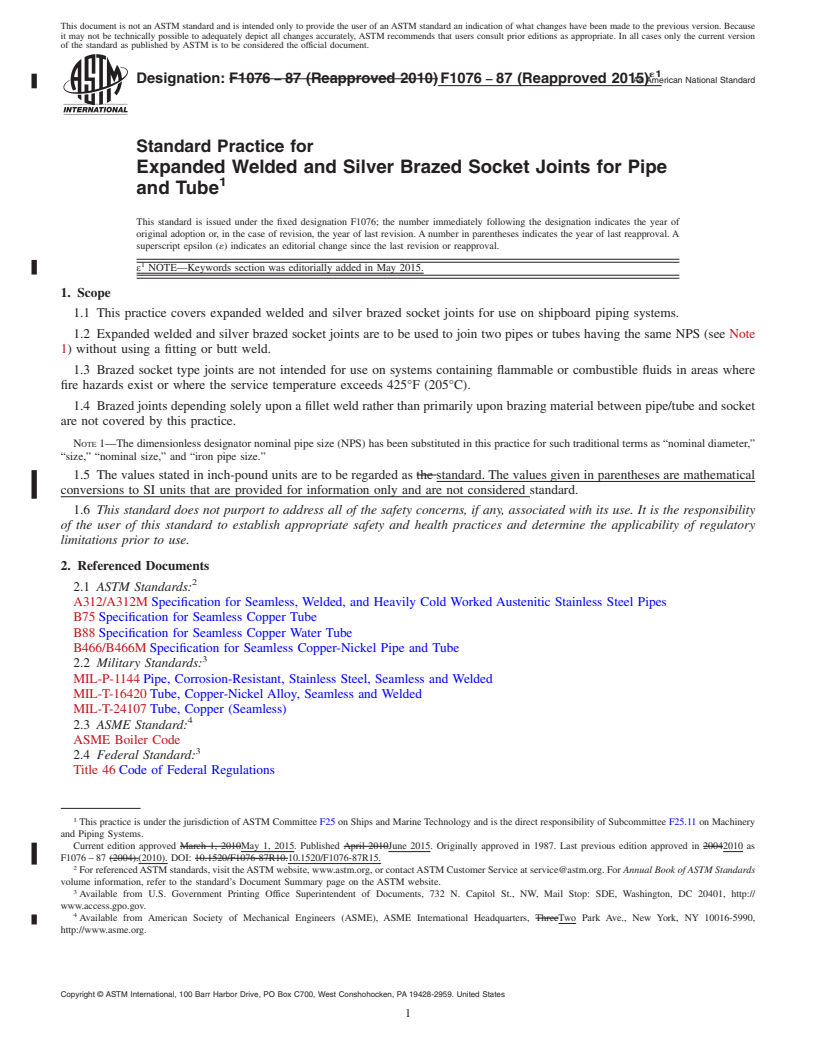

1.1 This practice covers expanded welded and silver brazed socket joints for use on shipboard piping systems.

1.2 Expanded welded and silver brazed socket joints are to be used to join two pipes or tubes having the same NPS (see Note

1) without using a fitting or butt weld.

1.3 Brazed socket type joints are not intended for use on systems containing flammable or combustible fluids in areas where

fire hazards exist or where the service temperature exceeds 425°F (205°C).

1.4 Brazed joints depending solely upon a fillet weld rather than primarily upon brazing material between pipe/tube and socket

are not covered by this practice.

NOTE 1—The dimensionless designator nominal pipe size (NPS) has been substituted in this practice for such traditional terms as “nominal diameter,”

“size,” “nominal size,” and “iron pipe size.”

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A312/A312M Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

B75 Specification for Seamless Copper Tube

B88 Specification for Seamless Copper Water Tube

B466/B466M Specification for Seamless Copper-Nickel Pipe and Tube

2.2 Military Standards:

MIL-P-1144 Pipe, Corrosion-Resistant, Stainless Steel, Seamless and Welded

MIL-T-16420 Tube, Copper-Nickel Alloy, Seamless and Welded

MIL-T-24107 Tube, Copper (Seamless)

2.3 ASME Standard:

ASME Boiler Code

2.4 Federal Standard:

Title 46 Code of Federal Regulations

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved March 1, 2010May 1, 2015. Published April 2010June 2015. Originally approved in 1987. Last previous edition approved in 20042010 as

F1076 – 87 (2004).(2010). DOI: 10.1520/F1076-87R10.10.1520/F1076-87R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, ThreeTwo Park Ave., New York, NY 10016-5990,

http://www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1076 − 87 (2015)

2.5 NAVSEA Document:

0900-LP-001-7000 Fabrication and Inspection of Brazed Piping Systems

3. Significance and Use

3.1 Expanded welded socket joints may be used with the following pipe and tube:

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.1.4 Seamless Stainless Steel Pipe—2 NPS through 6 NPS, Schedules 5 and 10.

3.2 Expanded silver brazed socket joints may be used with the following tube:

3.2.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.3 Expanded welded and silver brazed socket joints may be used where experience or test has demonstrated that the joint is

safe and suitable for design and operating conditions, and where adequate provision is made to prevent separation of the joint.

4. Materials and Manufacture

4.1 Welded Socket Joint:

4.1.1 Seamless Copper Tube—Specification B75, UNS Number C12200 and MIL-T-24107, UNS Number C12200, light drawn

(see 5.3).

4.1.2 Seamless Copper-Nickel Tube (90-10)—Specification B466/B466M, UNS Number C70600 and MIL-T-16420, UNS

Number C70600, Class 200, annealed.

4.1.3 Seamless Copper-Nickel Tube (70-30)—Specification B466/B466M, UNS Number C71500 and MIL-T-16420, UNS

Number C71500, Class 200, annealed.

4.1.4 Seamless Copper Water Tube—Specification B88, Type K, UNS Number C71500, drawn (see 5.3).

4.1.5 Seamless Stainless Steel Pipe—Specification A312/A312M, UNS Number S30400 and S31600. MIL-P-1144, UNS

Number S30400 and S31600, Schedules 5 and 10.

4.2 Silver-Brazed Socket Joint:

4.2.1 Seamless Copper Tube—Specification B75, UNS Number C12200 and MIL-T-24107, UNS Number C12200, light drawn

(see 5.3).

4.2.2 Seamless Copper-Nickel Tube (90-10)—Specification B466/B466M, UNS Number C70600 and MIL-T-16420, UNS

Number C70600, Class 200, annealed.

4.2.3 Seamless Copper-Nickel Tube (70-30)—Specification B466/B466M, UNS Number C71500 and MIL-T-16420, UNS

Number C71500, Class 200, annealed.

4.2.4 Seamless Copper Water Tube—Specification B88, Type K, UNS Number C12200, drawn (see 5.3).

5. Procedure

5.1 Install no more than two expanded joints in any 36-in. (915-mm) long section of pipe/tube and in no case allow a pipe/tube

expanded at both ends in lengths of less than 36 in.

5.2 Fabricate expanded joints on the ends of the pipe/tube by use of an expanding machine.

5.3 Expanded joints shall not be used on Class I piping systems as defined in 46CFR56.04 for United States Coast Guard

inspected and certified vessels.

5.4 Perform a minimum of three expansions to ensure the degree of expansion.

5.5 Bevel the unexpanded end of pipe/tube 30 to 40° for copper-nickel alloy and 10 to 20° for stainless steel.

5.6 Clean the pipe/tube ends to be inserted into the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.