ASTM F1076-19

(Practice)Standard Practice for Expanded Welded and Silver Brazed Socket Joints for Pipe and Tube

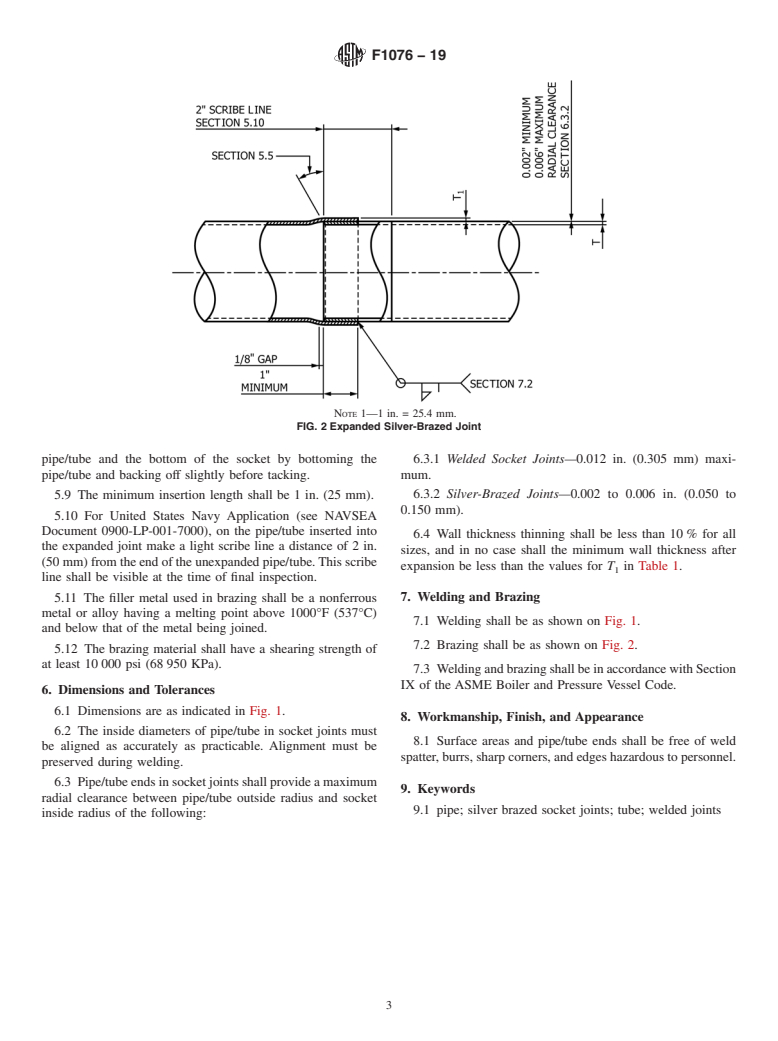

Standard Practice for Expanded Welded and Silver Brazed Socket Joints for Pipe and Tube

SIGNIFICANCE AND USE

3.1 Expanded welded socket joints may be used with the following pipe and tube:

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.1.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.1.4 Seamless Stainless Steel Pipe—2 NPS through 6 NPS, Schedules 5 and 10.

3.2 Expanded silver brazed socket joints may be used with the following tube:

3.2.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (170-mm) outside diameter.

3.2.3 Seamless Copper Water Tube—2.125-in. (55-mm) outside diameter through 4.125-in. (105-mm) outside diameter.

3.3 Expanded welded and silver brazed socket joints may be used where experience or test has demonstrated that the joint is safe and suitable for design and operating conditions, and where adequate provision is made to prevent separation of the joint.

SCOPE

1.1 This practice covers expanded welded and silver brazed socket joints for use on shipboard piping systems.

1.2 Expanded welded and silver brazed socket joints are to be used to join two pipes or tubes having the same NPS (see Note 1) without using a fitting or butt weld.

1.3 Brazed socket type joints are not intended for use on systems containing flammable or combustible fluids in areas where fire hazards exist or where the service temperature exceeds 425°F (205°C).

1.4 Brazed joints depending solely upon a fillet weld rather than primarily upon brazing material between pipe/tube and socket are not covered by this practice.

Note 1: The dimensionless designator nominal pipe size (NPS) has been substituted in this practice for such traditional terms as “nominal diameter,” “size,” “nominal size,” and “iron pipe size.”

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1076 − 19 An American National Standard

Standard Practice for

Expanded Welded and Silver Brazed Socket Joints for Pipe

1

and Tube

This standard is issued under the fixed designation F1076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice covers expanded welded and silver brazed

A312/A312M Specification for Seamless, Welded, and

socket joints for use on shipboard piping systems.

Heavily Cold Worked Austenitic Stainless Steel Pipes

1.2 Expanded welded and silver brazed socket joints are to

B75/B75MSpecification for Seamless Copper Tube

be used to join two pipes or tubes having the same NPS (see

B88Specification for Seamless Copper Water Tube

Note 1) without using a fitting or butt weld.

B466/B466M Specification for Seamless Copper-Nickel

Pipe and Tube

1.3 Brazed socket type joints are not intended for use on

3

2.2 Military Standards:

systems containing flammable or combustible fluids in areas

MIL-P-24691/3Pipe and Tube, Corrosion-Resistant, Stain-

where fire hazards exist or where the service temperature

less Steel, Seamless or Welded

exceeds 425°F (205°C).

MIL-T-16420Tube, Copper-Nickel Alloy, Seamless and

Welded

1.4 Brazed joints depending solely upon a fillet weld rather

MIL-T-24107Tube, Copper (Seamless)

than primarily upon brazing material between pipe/tube and

4

2.3 ASME Standard:

socket are not covered by this practice.

ASME Boiler and Pressure Vessel Code,Section IX

3

NOTE 1—The dimensionless designator nominal pipe size (NPS) has

2.4 Federal Standard:

been substituted in this practice for such traditional terms as “nominal

Code of Federal Regulations,Title 46

diameter,” “size,” “nominal size,” and “iron pipe size.”

3

2.5 NAVSEA Document:

0900-LP-001-7000Fabrication and Inspection of Brazed

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

Piping Systems

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Significance and Use

and are not considered standard.

3.1 Expanded welded socket joints may be used with the

1.6 This standard does not purport to address all of the

following pipe and tube:

safety concerns, if any, associated with its use. It is the

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside

responsibility of the user of this standard to establish appro-

diameter through 6.625-in. (170-mm) outside diameter.

priate safety, health, and environmental practices and deter-

3.1.2 Seamless Copper-Nickel Tube—2.375-in. (60-mm)

mine the applicability of regulatory limitations prior to use.

outsidediameterthrough6.625-in.(170-mm)outsidediameter.

1.7 This international standard was developed in accor- 3.1.3 SeamlessCopperWaterTube—2.125-in.(55-mm)out-

dance with internationally recognized principles on standard- side diameter through 4.125-in. (105-mm) outside diameter.

ization established in the Decision on Principles for the 3.1.4 Seamless Stainless Steel Pipe—2 NPS through 6 NPS,

Schedules 5 and 10.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Available from U.S. Government Printing Office, Superintendent of

Marine Technology and is the direct responsibility of Subcommittee F25.11 on Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://

Machinery and Piping Systems. www.access.gpo.gov.

4

Current edition approved Dec. 1, 2019. Published December 2019. Originally Available from American Society of Mechanical Engineers (ASME), ASME

ɛ1

approved in 1987. Last previous edition approved in 2015 as F1076–87 (2015) . International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

DOI: 10.1520/F1076-19. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1076 − 19

3.2 Expanded silver brazed socket joints may be used with 4.2.2 Seamless Copper

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1076 − 87 (Reapproved 2015) F1076 − 19 An American National Standard

Standard Practice for

Expanded Welded and Silver Brazed Socket Joints for Pipe

1

and Tube

This standard is issued under the fixed designation F1076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Keywords section was editorially added in May 2015.

1. Scope Scope*

1.1 This practice covers expanded welded and silver brazed socket joints for use on shipboard piping systems.

1.2 Expanded welded and silver brazed socket joints are to be used to join two pipes or tubes having the same NPS (see Note

1) without using a fitting or butt weld.

1.3 Brazed socket type joints are not intended for use on systems containing flammable or combustible fluids in areas where

fire hazards exist or where the service temperature exceeds 425°F (205°C).

1.4 Brazed joints depending solely upon a fillet weld rather than primarily upon brazing material between pipe/tube and socket

are not covered by this practice.

NOTE 1—The dimensionless designator nominal pipe size (NPS) has been substituted in this practice for such traditional terms as “nominal diameter,”

“size,” “nominal size,” and “iron pipe size.”

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A312/A312M Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

B75B75/B75M Specification for Seamless Copper Tube (Metric) B0075_B0075M

B88 Specification for Seamless Copper Water Tube

B466/B466M Specification for Seamless Copper-Nickel Pipe and Tube

3

2.2 Military Standards:

MIL-P-1144MIL-P-24691/3 Pipe, Pipe and Tube, Corrosion-Resistant, Stainless Steel, Seamless andor Welded

MIL-T-16420 Tube, Copper-Nickel Alloy, Seamless and Welded

MIL-T-24107 Tube, Copper (Seamless)

4

2.3 ASME Standard:

ASME Boiler Codeand Pressure Vessel Code, Section IX

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved May 1, 2015Dec. 1, 2019. Published June 2015December 2019. Originally approved in 1987. Last previous edition approved in 20102015 as

ɛ1

F1076 – 87 (2010).(2015) . DOI: 10.1520/F1076-87R15.10.1520/F1076-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from U.S. Government Printing Office, Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401,20401-0001,

http://www.access.gpo.gov.

4

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1076 − 19

3

2.4 Federal Standard:

Title 46Code of Federal Regulations, Code of Federal RegulationsTitle 46

3

2.5 NAVSEA Document:

0900-LP-001-7000 Fabrication and Inspection of Brazed Piping Systems

3. Significance and Use

3.1 Expanded welded socket joints may be used with the following pipe and tube:

3.1.1 Seamless Copper Tube—2.375-in. (60-mm) outside diameter through 6.625-in. (1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.