ASTM D2275-95

(Test Method)Standard Test Method for Voltage Endurance of Solid Electrical Insulating Materials Subjected to Partial Discharges (Corona) on the Surface

Standard Test Method for Voltage Endurance of Solid Electrical Insulating Materials Subjected to Partial Discharges (Corona) on the Surface

SCOPE

1.1 This test method differentiates among solid electrical insulating materials for use at commercial power frequencies with respect to their voltage endurance under the action of corona (see Note 1). In general, this test method is more meaningful for rating materials with respect to their resistance to prolonged a-c stress under corona conditions than is dielectric strength.

Note 1--The term "corona" is used almost exclusively in this test method instead of "partial discharge", because it is a visible glow at the edge of the smaller electrode. This is a difference in location, not in kind. Partial discharges also occur at the edges of electrodes, and in general corona describes an electrical discharge irrespective of its location.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2275 – 95 An American National Standard

Standard Test Method for

Voltage Endurance of Solid Electrical Insulating Materials

Subjected to Partial Discharges (Corona) on the Surface

This standard is issued under the fixed designation D 2275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 41 Terminology Relating to Conditioning

E 104 Practice for Maintaining Constant Relative Humidity

1.1 This test method differentiates among solid electrical

by Means of Aqueous Solutions

insulating materials for use at commercial power frequencies

E 171 Specification for Standard Atmospheres for Condi-

with respect to their voltage endurance under the action of

tioning and Testing Materials

corona (see Note 1). In general, this test method is more

2.2 Special Technical Publications:

meaningful for rating materials with respect to their resistance

Symposium on Corona, STP 198, ASTM, 1956.

to prolonged a-c stress under corona conditions than is dielec-

Corona Measurement and Interpretation, Engineering Di-

tric strength.

electrics, Vol 1, STP 669, ASTM, 1979.

NOTE 1—The term “corona” is used almost exclusively in this test

2.3 International Electrotechnical Commission (IEC)

method instead of “partial discharge”, because it is a visible glow at the

Documents:

edge of the smaller electrode. This is a difference in location, not in kind.

IEC Publication 343 Recommended Test Methods for De-

Partial discharges also occur at the edges of electrodes, and in general

termining the Relative Resistance of Insulating Materials

corona describes an electrical discharge irrespective of its location.

to Breakdown by Surface Discharges

1.2 The values stated in SI units are to be regarded as the

2.4 Institute of Electrical and Electronic Engineers (IEEE)

standard. The values given in parentheses are for information

Document:

only.

IEEE P930.7-1987 “Guide for the Statistical Analysis of

1.3 This standard does not purport to address all of the

Voltage Endurance Data”

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Descriptions of Terms:

bility of regulatory limitations prior to use. For specific hazard

3.1.1 threshold voltage—That voltage below which failure

statements, see Section 7.

will not occur under the test conditions irrespective of the

duration of the test. (Demonstration of a threshold is difficult

2. Referenced Documents

when the slope of a volt-time curve is small, and failure times

2.1 ASTM Standards:

are long. High frequency tests are often an aid in demonstra-

D 149 Test Method for Dielectric Breakdown Voltage and

tion, by reducing the time required to reach a necessary number

Dielectric Strength of Solid Electrical Insulating Materials

of voltage cycles.)

at Commercial Power Frequencies

3.1.2 voltage endurance—the time that an insulating mate-

D 618 Practice for Conditioning Plastics and Electrical

rial can withstand a prolonged alternating voltage stress under

Insulating Materials for Testing

the action of surface corona.

D 1711 Terminology Relating to Electrical Insulation

3.1.3 voltage stress-time curve—A plot of the logarithm of

D 1868 Test Method for Detection and Measurement of

the mean or median time to failure of a material against voltage

Partial Discharge (Corona) Pulses in Evaluation of Insu-

stress (or the logarithm of voltage stress) for a particular set of

lation Systems

test conditions. The plot is the quantitative depiction of the

D 5032 Practice for Maintaining Constant Relative Humid-

voltage stress endurance over a range of voltage stress for the

ity by Means of Aqueous Glycerin Solutions

conditions of test, and for the thickness tested. The curves of a

This test method is under the jurisdiction of Committee D-9 on Electrical and

Annual Book of ASTM Standards, Vol 06.01.

Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.12 on Electrical Tests. Annual Boof of ASTM Standards, Vol 11.03.

Current edition approved Sept. 10, 1995. Published November 1995. Originally Annual Book of ASTM Standards, Vol 15.09.

e1 8

published as D 2275 – 64 T. Last previous edition D 2275 – 89 (1994) . Available from ASTM Headquarters, 1916 Race St., Philadelphia, PA 19103.

2 9

Annual Book of ASTM Standards, Vol 10.01. Available from American National Standards Institute, 11 West 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

4 10

Annual Book of ASTM Standards, Vol 10.02. Available from IEEE Headquarters, 345 East 47th St., New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2275

material obtained at two thicknesses are different. should be distinguished from corona that occurs in internal

3.1.4 volt-time curve—A plot of the logarithm of the mean cavities for which no standardized test has been developed.

or median time to failure of a material against voltage (or the Evaluation of endurance by comparison of data on specimens

logarithm of voltage) for a particular set of test conditions. The of different thickness is not valid.

plot is the quantitative depiction of the voltage endurance over

5.2 The processing of the material may affect the results

a range of voltage for the conditions of the test, which includes

obtained. For instance, residual strains produced by quenching,

the particular thickness tested.

or high levels of crystallinity caused by slow cooling may

3.2 Definitions—See Terminology D 1711 and Test Method

affect the result. Also, the type of molding process, injection or

D 1868.

compression, may be important especially if the mixing of

fillers or the concentration and sizes of gas-filled cavities are

4. Summary of Test Method

controlled in any degree by the process. Indeed, this test

4.1 In this test method, voltage sufficient to produce corona

method may be used to examine the effects of processing.

is applied to the specimen until failure occurs. Comparative

5.3 The data are generated in the form of a set of values of

voltage endurance is the relative time to failure of two different

lifetimes at a voltage. The dispersion of failure times can be

materials of the same thickness when tested with similar

analyzed using Weibull or extreme value statistics to yield an

electrodes at the same voltage. Comparison is also possible in

estimate of the central value of the distribution and its standard

terms of the magnitude of voltage stress (kV/mm or kV/in.)

deviation. This is particularly recommended when the disper-

required to produce failure in a specified number of hours.

sion of failure times is large, and a comparison of lifetimes of

4.2 Surface corona exists in the electrically stressed gas

two materials must be made at a specified level of confidence.

where electrodes are near insulation surfaces.

5.4 This test is often used to demonstrate the differences

4.3 As with most tests at constant stress, there may be a

between different classes of materials, and to illustrate the

large dispersion of times to failure for a given sample. The

importance of eliminating corona in any application of a

median time of nine specimens (time of fifth failure) may be

particular material. When the test is used for such purposes or

used as the failure time for the sample. This removes the

other similar ones, the need for precision is reduced, and

necessity of waiting for the last few to fail. The mean may also

certain time saving techniques, such as truncating a test at the

be determined statistically (see IEEE P930.7 for additional

time of the fifth failure of a set of nine, and using that time as

information).

the measure of the central tendency, are recommended. Two

4.4 Under the proper conditions, the test may be accelerated

such techniques are described in 10.2. Both techniques remove

by increasing the frequency of the applied voltage (see

the necessity of testing beyond median failure, and reduce the

Appendix X1).

required testing time to approximately half of that required to

4.5 Standardized test conditions and conditioning prior to

obtain failures on all specimens.

testing are important. In particular, tests with specified air flow

5.5 Insulating materials operating in a gaseous medium are

at both low and moderate humidities may be informative. In

subjected to corona attack at operating voltage on some types

special cases, where a service condition is thought to alter the

of electrical apparatus in those regions where the voltage

corona endurance, this factor should be introduced as part of

gradient in the gas exceeds the corona inception level. On other

the test and reported. Such conditions might include elonga-

types of equipment, where detectable corona is absent initially,

tion, elevated temperature, high humidity, other gases besides

it may appear later due to transient over-voltages or changes in

air, pollution, etc.

insulation properties attending aging. Certain inorganic mate-

4.6 Additional information from the test may be obtained if

rials can tolerate corona for a long time. Many organic

corona-voltage levels and corona intensity are measured at the

materials are damaged quickly by corona, and for these,

start of the test and monitored at various stages of deterioration

operation with no detectable corona is imperative. This test

of the insulation. The voltage levels include corona-inception

method intensifies some of the more commonly met conditions

voltage, corona-extinction voltage, and corona intensity using

of corona attack so that materials may be evaluated in a time

Test Method D 1868. Also, comparative measurements of

that is relatively short compared to the life of the equipment.

corona power or energy by bridge and oscilloscope techniques

As with most accelerated life tests, caution is necessary in

can be informative (see ASTM STP 198 and STP 669).

extrapolation from the indicated life to actual life under various

4.7 If elevated frequencies are used to accelerate the test, it

operating conditions in the field.

is recommended that the corona-discharge pulse heights and

energy per cycle at the test frequency be compared with these 5.6 The failure produced by corona may be due to one of

several possible factors. The corona may erode the insulation

values at rated power frequency. If the energy per cycle is the

until the remaining insulation can no longer withstand the

same, it can be concluded that failure time is inversely

applied voltage. The corona may cause the insulation surface to

proportional to frequency.

become conducting. For instance, carbonization may occur, so

5. Significance and Use

that failure occurs quickly. On the other hand, compounds such

5.1 This test method is used to compare the endurance of as oxalic acid crystals may be formed, as with polyethylene, in

different materials to the action of corona on the external which case the surface conductance will vary with ambient

surfaces. A poor result on this test does not indicate that the humidity, and at moderate humidities the conductance may be

material is a poor selection for use at high voltage or at high at the proper level to reduce the potential gradient at the

voltage stress in the absence of surface corona. Surface corona electrode edge, and thus cause either a reduction in the amount

D 2275

of corona, or its cessation, thus retarding failure. The corona required for the curve to reach the threshold produced by

may cause a “treeing” within the insulation, which may

corona may be greater by many orders of magnitude than the

progress to failure. It may release gases within the insulation

time required for materials such as polyethylene, polyethylene

that change its physical dimensions. It may change the physical

terephthalate, or polytetrafluoroethylene.

properties of an insulating material; for instance, it may cause

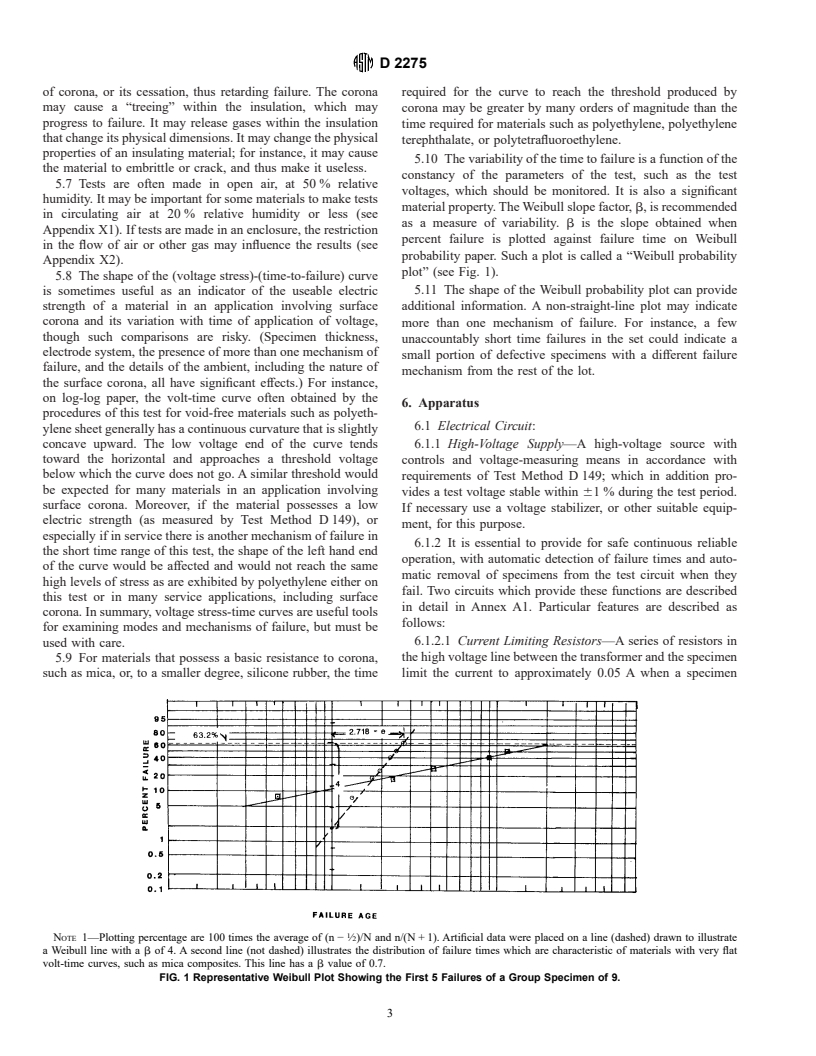

5.10 The variability of the time to failure is a function of the

the material to embrittle or crack, and thus make it useless.

constancy of the parameters of the test, such as the test

5.7 Tests are often made in open air, at 50 % relative

voltages, which should be monitored. It is also a significant

humidity. It may be important for some materials to make tests

material property. The Weibull slope factor, b, is recommended

in circulating air at 20 % relative humidity or less (see

as a measure of variability. b is the slope obtained when

Appendix X1). If tests are made in an enclosure, the restriction

percent failure is plotted against failure time on Weibull

in the flow of air or other gas may influence the results (see

probability paper. Such a plot is called a “Weibull probability

Appendix X2).

plot” (see Fig. 1).

5.8 The shape of the (voltage stress)-(time-to-failure) curve

5.11 The shape of the Weibull probability plot can provide

is sometimes useful as an indicator of the useable electric

strength of a material in an application involving surface additional information. A non-straight-line plot may indicate

corona and its variation with time of application of voltage, more than one mechanism of failure. For instance, a few

though such comparisons are risky. (Specimen thickness,

unaccountably short time failures in the set could indicate a

electrode system, the presence of more than one mechanism of

small portion of defective specimens with a different failure

failure, and the details of the ambient, including the nature of

mechanism from the rest of the lot.

the surface corona, all have significant effects.) For instance,

on log-log paper, the volt-time curve often obtained by the

6. Apparatus

procedures of this test for void-free materials such as polyeth-

6.1 Electrical Circuit:

ylene sheet generally has a continuous curvature that is slightly

concave upward. The low voltage end of the curve tends

6.1.1 High-Voltage Supply—A high-voltage source with

toward the horizontal and approaches a threshold voltage

controls and voltage-measuring means in accordance with

below which the curve does not go. A similar threshold would

requirements of Test Method D 149; which in addition pro-

be expected for many materials in an application involving

vides a test voltage stable within 61 % during the test period.

surface corona. Moreover, if the material possesses a low

If necessary use a voltage stabilizer, or other suitable equip-

electric strength (as measured by Test Method D 14

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.