ASTM D4749-87(2002)

(Test Method)Standard Test Method for Performing the Sieve Analysis of Coal and Designating Coal Size

Standard Test Method for Performing the Sieve Analysis of Coal and Designating Coal Size

SCOPE

1.1 This test method covers procedures for determining the sieve analysis of coal and designating the size of coal from sieve analysis data. Raw as well as prepared (crushed, cleaned or screened) coals can be tested by this test method.

1.2 This test method explains how to designate coal sizes from the results of sieve analysis data in order to represent the condition of the coal as sold. In the case of special mixtures or coals with noncontinuous ranges of sizes, a sufficiently complete sieve analysis must be made to properly describe the size distribution.

1.3 This test method is not applicable for determining the sieve analysis nor for designating the size of pulverized coal. Size fractions down to and including 38 m (No. 400 U.S.A. Standard Series) can be treated by the methods discussed in this test method. Methods for handling size fractions below 38 m (No. 400) will be developed by this committee.

1.4 The values stated in metric units shall be regarded as standard. The values shown in parentheses are provided for information only. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D4749–87(Reapproved2002)

Standard Test Method for

Performing the Sieve Analysis of Coal and Designating Coal

Size

This standard is issued under the fixed designation D4749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D2013 Practice for Preparing Coal Samples for Analysis

D2234 Practice for Collection of a Gross Sample of Coal

1.1 This test method covers procedures for determining the

D4371 TestMethodforDeterminingtheWashabilityChar-

sieve analysis of coal and designating the size of coal from

acteristics of Coal

sieve analysis data. Raw as well as prepared (crushed, cleaned

E11 Specification for Wire-Cloth and Sieves for Testing

or screened) coals can be tested by this test method.

Purposes

1.2 This test method explains how to designate coal sizes

E323 Specification for Perforated-Plate Sieves for Testing

from the results of sieve analysis data in order to represent the

Purposes

condition of the coal as sold. In the case of special mixtures or

2.2 Other Document:

coals with noncontinuous ranges of sizes, a sufficiently com-

Specification C-80 Commonwealth of Pennsylvania, De-

plete sieve analysis must be made to properly describe the size

partmentofGeneralServices,BureauofPurchases,Speci-

distribution.

fication for Coal:Anthracite

1.3 This test method is not applicable for determining the

sieve analysis nor for designating the size of pulverized coal.

3. Descriptions of Terms Specific to this Standard

Size fractions down to and including 38 µm (No. 400 U.S.A.

3.1 as-mined coal—same as ROM coal (3.8).

Standard Series) can be treated by the methods discussed in

3.2 as-shipped or produced coal—raw or prepared coal in

this test method. Methods for handling size fractions below 38

any state or condition at which it leaves the mine property or

µm (No. 400) will be developed by this committee.

loading facility.

1.4 The values stated in metric units shall be regarded as

3.3 bottomsize, nominal—the sieve designating the lower

standard. The values shown in parentheses are provided for

limit or bottomsize shall be that sieve of the series given in

information only. The values stated in each system may not be

Section 6 with the largest openings through which passes a

exact equivalents; therefore, each system must be used inde-

total of less than 15% of the sample. This defined bottomsize

pendently of the other, without combining values in any way.

is not to be confused with the size of the smallest particles in

1.5 This standard does not purport to address all of the

the lot. (Warning—In the case of a commercial, double-

safety concerns, if any, associated with its use. It is the

1 3

screened product, for example, 37.5 by 9.5 mm (1 ⁄2 by ⁄8 in.),

responsibility of the user of this standard to establish appro-

this designation may not be valid. In such commercial or

priate safety and health practices and determine the applica-

contractual situations, the amount of allowable material

bility of regulatory limitations prior to use.

smaller than the bottomsize (for example, 9.5 mm) must be

2. Referenced Documents specified by the contract under which the coal is bought and

sold.)

2.1 ASTM Standards:

3.4 dry sieving—for the purposes of this test method, the

D197 Test Method for Sampling and Fineness Test of

3 test method for the sieving of coal after the sample has been

Pulverized Coal

air-dried under prescribed conditions; this is generally used

D346 Practice for Collection and Preparation of Coke

when testing with coal particles larger than 600 µm. (No. 30

Samples for Laboratory Analysis

U.S.A. Standard Sieve Series.)

D388 Classification of Coals by Rank

3.5 opening—for the purpose of this test method, openings

and apertures shall be regarded as synonomous terms. Dimen-

sions for round and square openings shall be determined as

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke and is the direct responsibility of Subcommittee D05.07 on Physical

follows: for round holes, dimensions shall refer to the opening

Characteristics of Coal.

Current edition approved Nov. 27, 1987. Published January 1988. Originally

e1

published as D4749–87. Last previous edition D4749–87 (1994) .

2 4

For powdered or pulverized coal as is fired into steam boilers, refer to Method Annual Book of ASTM Standards, Vol 14.02.

D197. Available from Commonwealth of Pennsylvania, Dept. of General Services,

Annual Book of ASTM Standards, Vol 05.06. Bureau of Purchases, 414 N. Office Building, Harrisburg, PA 17125.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D4749–87 (2002)

diameter; for square holes, dimensions shall refer to the 4.4 This test method also concerns the designation of a coal

distance between parallel wires. sample as to its upper (nominal top-size) and lower (nominal

3.6 prepared coal—any coal, regardless of its topsize, that bottom-size)limitingsizesforthepurposeofcharacterizingthe

hasbeenmanuallyormechanicallycleaned.Thisincludescoal material for further processing or for commercial purposes.

that has been processed over a picking table or air tables, This is covered in Part B of this test method.Anthracite coal is

through a breaker, jig, or other device which segregates further designated by a one word descriptive term (see 14.4).

according to size or density (specific gravity). 4.5 Enough material may not be collected by this test

3.7 raw coal—any coal, regardless of its topsize, that has method to meet subsequent test procedures, such as washabil-

not been manually or mechanically cleaned. Crushed coal that ity analyses (Test Method D4371).

has not been mechanically cleaned (including coal that has not

been through a breaker which normally rejects oversize) is

PART A. SIEVE ANALYSIS OF COAL

considered to be raw coal. Coal delivered to the surface from

an underground mine is considered to be raw coal even when

5. Apparatus

crushing and grinding is done underground. Coal removed

5.1 Sieves:

fromthepitofasurfacemineisconsideredtoberawcoaleven

5.1.1 Wire Cloth Sieves:

when breaking and crushing facilities are provided in the pit.

5.1.1.1 Standard test sieves that conform to Specification

3.8 run-of-mine(ROM)coal—inthecaseofanunderground

E11 shall always be used.

mine, it is that coal delivered to the surface by a slope belt,

5.1.1.2 Formostsievetests,wherethelargestparticleinthe

hoist,etc.Inthecaseofasurfacemine,itisthatcoalasitexists

sample does not exceed 25 mm (1 in.), standard 203-mm

afterithasbeenremovedfromthepitandplacedintotheinitial

(8-in.) diameter, 50-mm (2-in.) deep sieves or sieves with

means of transportation whether it be an on-the-road or

larger diameters (for example 300 mm (12 in.) or 450 mm (18

off-the-roadhaultruck,dumphopperwhichfeedsapit-to-plant

in.)) are recommended. For special cases, and with small

conveyor, etc. For both underground and surface mines, ROM

samples,75-mm(3-in.)and150-mm(6-in.)diametersievesare

coal is as-mined and has not been exposed to any treatment

available.

such as breaking, crushing, or cleaning except for that done by

5.1.1.3 Standard test sieves shall be made from either brass

thenormaloperationsusedtoextractthecoalfromtheground,

or stainless steel frames and either brass, phosphor bronze, or

that is, blasting, ripping, loading, cutting, etc.

stainless steel cloth.

3.9 topsize, nominal—the sieve designating the upper limit

5.1.1.4 In general, these square mesh sieves are used when

or topsize shall be that sieve of the series given in Section 6

sizing with sieves with openings smaller than 6.3 mm ( ⁄4 in.).

withthesmallestopeningsuponwhichiscumulativelyretained

U.S.A. Standard Sieve Designations shall be used.

a total of less than 5% of the sample. This defined topsize is

5.1.1.5 For more complete details of standard test sieves,

nottobeconfusedwiththesizeofthelargestparticleinthelot.

including methods of checking and calibrating the sieves, see

3.10 wet sieving—for the purposes of this test method, the

Specification E11.

testmethodforthesievingofcoalthatuseswaterasamedium

5.1.2 Perforated Plate Sieves:

forfacilitatingthesegregationofthesampleintoparticlesizes;

5.1.2.1 Perforated plate sieves, made to conform to Speci-

this is generally used when testing coal particles 600 µm (No.

fication E323, are available with square apertures from 125

30 U.S.A. Standard Series) or smaller.

mm (5 in.) to 3.36 mm (0.132 in.) and with staggered round

4. Significance and Use

apertures from 125 mm (5 in.) to 1 mm (0.038 in.). The sizes

of successive apertures in the series follow the same ratio as in

4.1 This test method concerns the sieving of coal into

Specification E11 for sieves.

designated size fractions for the purpose of characterizing the

5.1.2.2 Standard frames for perforated plate sieves with

materialastoitsparticlesizedistributionforfurtherprocessing

apertures4.00mmandlargeraremadeofhardwoodorsteelto

or for commercial purposes. This is covered in Part A of this

hold 300-mm (12-in.), 400-mm (16-in.), or 450-mm (18-in.)

standard. Raw, as well as prepared (crushed, cleaned, or

square sieve plates. For apertures smaller than 4.00 mm,

screened), coals can be tested by this test method.

203-mm (8-in.) circular frames as well as the above larger

4.2 This test method is applicable for all types of coals,

square frames may be used.

except for pulverized coals (see Method D197) such as fed

into steam boilers. Low rank coals, that is, lignites, subbitu- 5.1.2.3 In general, round hole sieves with staggered open-

ings are used when sizing with sieves with opening diameters

minous, and high volatile bituminous C, must be dried with

cautionandhandledwithcaretominimizedeteriorationorsize of 6.3 mm ( ⁄4 in.) or larger.

5.1.2.4 Where perforated sieves and wire cloth sieves are

degradation during sieving.

4.3 This test method is applicable for the wet or dry-sieving usedinthesametest(forexample,inananalysisfrom125mm

(5 in.) to 250 µm (No. 60)) or where results with perforated

of coal at sizes from 200 mm (8 in.) to 38 µm (No. 400 U.S.A.

Standard). Methods for sizing materials below 38 µm are sieves are to be compared with results with wire cloth sieves,

it is better to use only square aperture sieves.

outside the scope of this test method.

NOTE 1—Thesizingofmaterialthatpassesthe38µmsieveisnormally NOTE 2—This action should be taken primarily while performing

performed by optical microscopy, sedimentation, centrifugation, light sieving analyses on noncommercial samples, as, for instance, in prepara-

scattering or obfuscation, surface area measurement, or other such tion plant component studies (see 6.5.1). In commerce, mixed series are

methods. Subsieve techniques are also used sometimes. still customary (see 6.1.1 and 6.3.1).

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D4749–87 (2002)

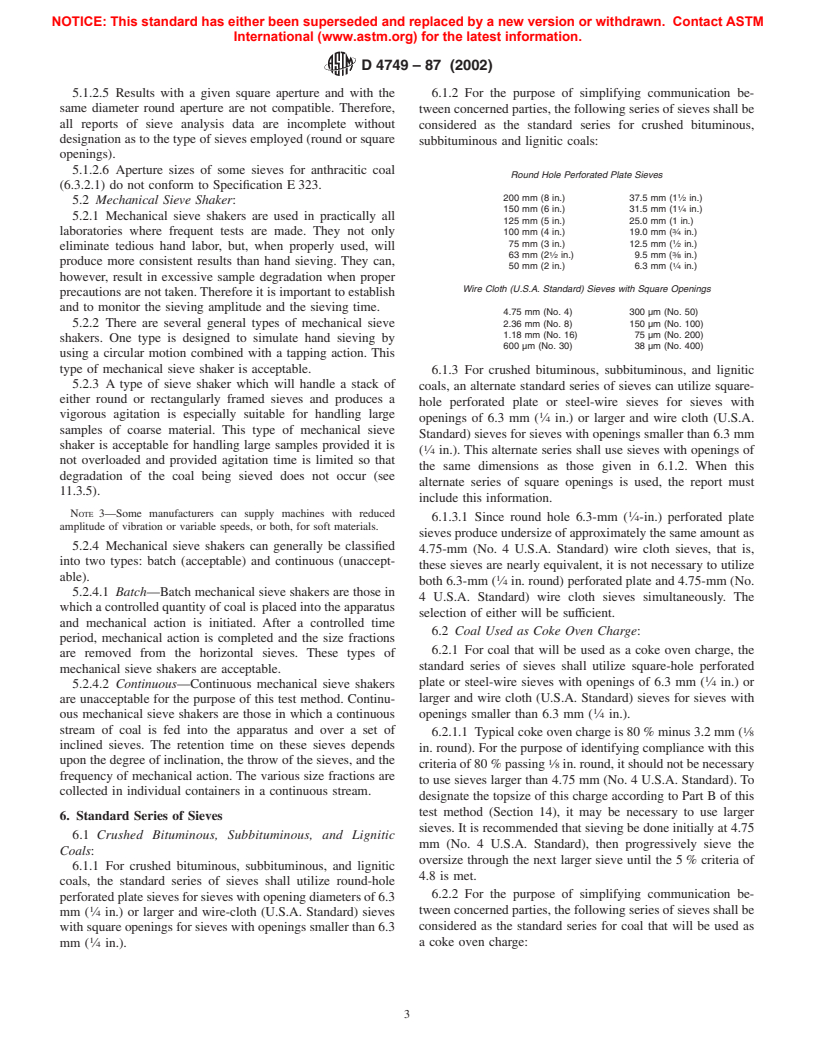

5.1.2.5 Results with a given square aperture and with the 6.1.2 For the purpose of simplifying communication be-

same diameter round aperture are not compatible. Therefore, tweenconcernedparties,thefollowingseriesofsievesshallbe

all reports of sieve analysis data are incomplete without

considered as the standard series for crushed bituminous,

designation as to the type of sieves employed (round or square

subbituminous and lignitic coals:

openings).

5.1.2.6 Aperture sizes of some sieves for anthracitic coal

Round Hole Perforated Plate Sieves

(6.3.2.1) do not conform to Specification E323.

200 mm (8 in.) 37.5 mm (1 ⁄2 in.)

5.2 Mechanical Sieve Shaker:

150 mm (6 in.) 31.5 mm (1 ⁄4 in.)

5.2.1 Mechanical sieve shakers are used in practically all

125 mm (5 in.) 25.0 mm (1 in.)

laboratories where frequent tests are made. They not only 100 mm (4 in.) 19.0 mm ( ⁄4 in.)

75 mm (3 in.) 12.5 mm ( ⁄2 in.)

eliminate tedious hand labor, but, when properly used, will

1 3

63 mm (2 ⁄2 in.) 9.5 mm ( ⁄8 in.)

produce more consistent results than hand sieving. They can,

50 mm (2 in.) 6.3 mm ( ⁄4 in.)

however, result in excessive sample degradation when proper

Wire Cloth (U.S.A. Standard) Sieves with Square Openings

precautions are not taken.Therefore it is important to establish

and to monitor the sieving amplitude and the sieving time.

4.75 mm (No. 4) 300 µm (No. 50)

5.2.2 There are several general types of mechanical sieve 2.36 mm (No. 8) 150 µm (No. 100)

1.18 mm (No. 16) 75 µm (No. 200)

shakers. One type is designed to simulate hand sieving by

600 µm (No. 30) 38 µm (No. 400)

using a circular motion combined with a tapping action. This

type of mechanical sieve shaker is acceptable.

6.1.3 For crushed bituminous, subbituminous, and lignitic

5.2.3 A type of sieve shaker which will handle a stack of

coals, an alternate standard series of sieves can utilize square-

either round or rectangularly framed sieves and produces a

hole perforated plate or steel-wire sieves for sieves with

vigorous agitation is especially suitable for handling large 1

openings of 6.3 mm ( ⁄4 in.) or larger and wire cloth (U.S.A.

samples of coarse material. This type of mechanical sieve

Standard) sieves for sieves with openings smaller than 6.3 mm

shaker is acceptable for handling large samples provided it is

( ⁄4 in.). This alternate series shall use sieves with openings of

not overloaded and provided agitation time is limited so that

the same dimensions as those given in 6.1.2. When this

degradation of the coal being sieved does not occur (see

alternate series of square openings is used, the report must

11.3.5).

include this information.

NOTE 3—Some manufacturers can supply machines with reduced 1

6.1.3.1 Since round hole 6.3-mm ( ⁄4-in.) perforated plate

amplitude of vibration or variable speeds, or both, for soft materials.

sievesproduceundersizeofapproximatelythesameamountas

5.2.4 Mechanical sieve shakers can generally be classified

4.75-mm (No. 4 U.S.A. Standard) wire cloth sieves, that is,

into two types: batch (acceptable) and continuous (unaccept-

these sieves are nearly equivalent, it is not necessary to utilize

able). 1

both 6.3-mm ( ⁄4 in. round) perforated plate and 4.75-mm (No.

5.2.4.1 Batch—Batch mechanical sieve shakers are those in

4 U.S.A. Standard) wire cloth sieves simultaneously. The

which a controlled quantity of coal is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.