ASTM D6341-10

(Test Method)Standard Test Method for Determination of the Linear Coefficient of Thermal Expansion of Plastic Lumber and Plastic Lumber Shapes Between -30 and 140°F (-34.4 and 60°C)

Standard Test Method for Determination of the Linear Coefficient of Thermal Expansion of Plastic Lumber and Plastic Lumber Shapes Between -30 and 140°F (-34.4 and 60°C)

SIGNIFICANCE AND USE

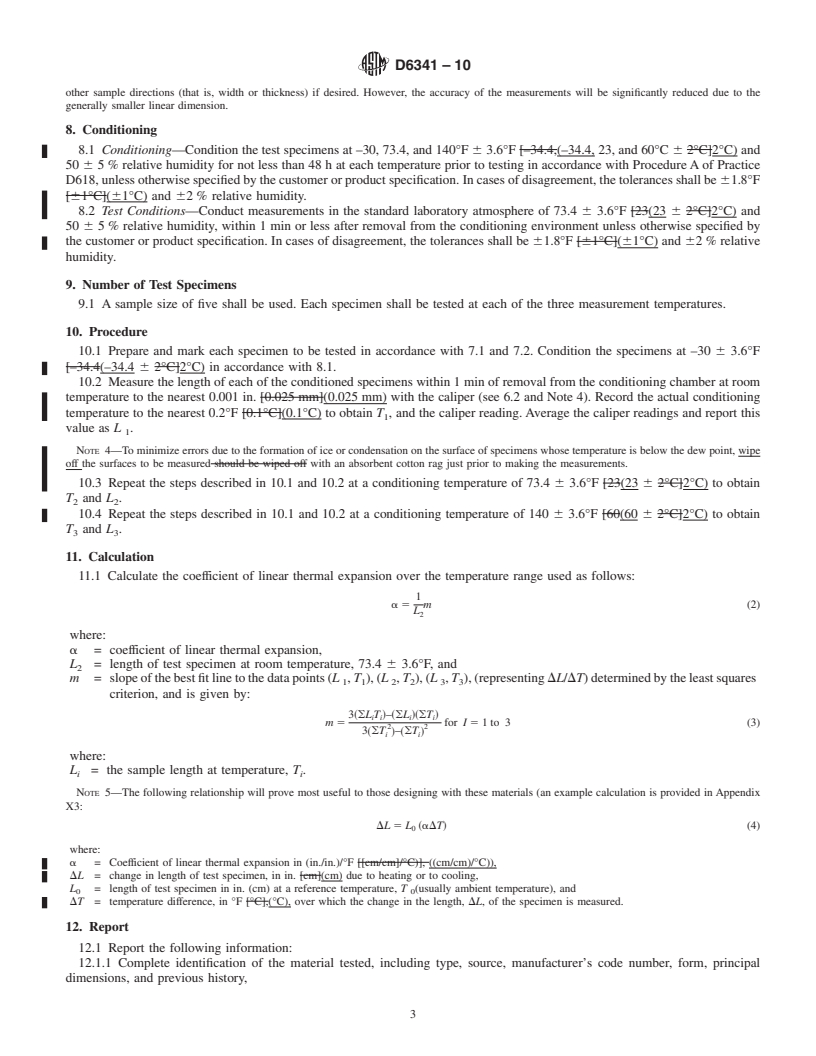

The coefficient of linear thermal expansion, α, between temperatures T1 and T2 for a specimen whose length is L0 at the reference temperature, is given by the following equation:

SCOPE

1.1 This test method covers the determination of the coefficient of linear thermal expansion for plastic lumber and plastic lumber shapes to two significant figures. The determination is made by taking measurements with a caliper at three discrete temperatures. At the test temperatures and under the stresses imposed, the plastic lumber shall have a negligible creep or elastic strain rate, or both, insofar as these properties would significantly affect the accuracy of the measurements.

1.1.1 This test method details the determination of the linear coefficient of thermal expansion of plastic lumber and plastic lumber shapes in their “as manufactured” form. As such, this is a test method for evaluating the properties of plastic lumber or shapes as a product and not a material property test method.

1.2 The thermal expansion of plastic lumber and shapes is composed of a reversible component on which it is possible to superimpose changes in length due to changes in moisture content, curing, loss of plasticizer or solvents, release of stresses, phase changes, voids, inclusions, and other factors. This test method is intended to determine the coefficient of linear thermal expansion under the exclusion of non-linear factors as far as possible. In general, it will not be possible to exclude the effect of these factors completely. For this reason, the test method can be expected to give a reasonable approximation but not necessarily precise determination of the linear coefficient of thermal expansion.

1.3 Plastic lumber and plastic lumber shapes are currently made predominately with recycled plastics where the product is non-homogeneous in the cross-section. However, it is possible that this test method will also be applicable to similar manufactured plastic products made from virgin resins or other plastic composite materials.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6341 − 10

StandardTest Method for

Determination of the Linear Coefficient of Thermal

Expansion of Plastic Lumber and Plastic Lumber Shapes

1

Between –30 and 140°F (–34.4 and 60°C)

This standard is issued under the fixed designation D6341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of the coef-

responsibility of the user of this standard to establish appro-

ficient of linear thermal expansion for plastic lumber and

priate safety and health practices and determine the applica-

plastic lumber shapes to two significant figures. The determi-

bility of regulatory limitations prior to use.

nation is made by taking measurements with a caliper at three

discrete temperatures. At the test temperatures and under the

NOTE 1—There is no known ISO equivalent to this standard.

stresses imposed, the plastic lumber shall have a negligible

creep or elastic strain rate, or both, insofar as these properties 2. Referenced Documents

2

would significantly affect the accuracy of the measurements.

2.1 ASTM Standards:

1.1.1 Thistestmethoddetailsthedeterminationofthelinear

D618 Practice for Conditioning Plastics for Testing

coefficient of thermal expansion of plastic lumber and plastic

D883 Terminology Relating to Plastics

lumber shapes in their “as manufactured” form.As such, this is

D4065 Practice for Plastics: Dynamic Mechanical Proper-

a test method for evaluating the properties of plastic lumber or

ties: Determination and Report of Procedures

shapes as a product and not a material property test method.

D5033 GuideforDevelopmentofASTMStandardsRelating

to Recycling and Use of Recycled Plastics (Withdrawn

1.2 The thermal expansion of plastic lumber and shapes is

3

composed of a reversible component on which it is possible to 2007)

E831 Test Method for Linear Thermal Expansion of Solid

superimpose changes in length due to changes in moisture

content, curing, loss of plasticizer or solvents, release of Materials by Thermomechanical Analysis

stresses, phase changes, voids, inclusions, and other factors.

3. Terminology

This test method is intended to determine the coefficient of

linear thermal expansion under the exclusion of non-linear

3.1 Definitions:

factors as far as possible. In general, it will not be possible to

3.1.1 plastic lumber, n—a manufactured product composed

exclude the effect of these factors completely. For this reason,

of more than 50 weight percent resin, in which the product

the test method can be expected to give a reasonable approxi-

generally is rectangular in cross-section and typically supplied

mation but not necessarily precise determination of the linear

in board and dimensional lumber sizes, may be filled or

coefficient of thermal expansion.

unfilled, and may be composed of single or multiple resin

blends.

1.3 Plastic lumber and plastic lumber shapes are currently

made predominately with recycled plastics where the product

3.1.2 plastic lumber shape, n—a plastic lumber product

is non-homogeneous in the cross-section. However, it is

which is generally not rectangular in cross-section.

possible that this test method will also be applicable to similar

3.1.3 resin, n—a solid or pseudosolid organic material often

manufactured plastic products made from virgin resins or other

of high molecular weight, which exhibits a tendency to flow

plastic composite materials.

when subjected to stress, usually has a softening or melting

1.4 The values stated in inch-pound units are to be regarded

range, and usually fractures conchoidally. (D883)

as the standard. The SI units given in parentheses are for

information only.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.20 on Plastic Lumber. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2010. Published September 2010. Originally the ASTM website.

3

approved in 1998. Last previous edition approved in 2005 as D6341 - 98(2005). The last approved version of this historical standard is referenced on

DOI: 10.1520/D6341-10. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6341–98 (Reapproved 2005) Designation: D6341 – 10

Standard Test Method for

Determination of the Linear Coefficient of Thermal

Expansion of Plastic Lumber and Plastic Lumber Shapes

1

Between –30 and 140°F [–34.4(–34.4 and 60°C]60°C)

This standard is issued under the fixed designation D6341; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thistestmethodcoversthedeterminationofthecoefficientoflinearthermalexpansionforplasticlumberandplasticlumber

shapes to two significant figures. The determination is made by taking measurements with a caliper at three discrete temperatures.

At the test temperatures and under the stresses imposed, the plastic lumber shall have a negligible creep or elastic strain rate, or

both, insofar as these properties would significantly affect the accuracy of the measurements.

1.1.1 This test method details the determination of the linear coefficient of thermal expansion of plastic lumber and plastic

lumber shapes in their “as manufactured” form. As such, this is a test method for evaluating the properties of plastic lumber or

shapes as a product and not a material property test method.

1.2 The thermal expansion of plastic lumber and shapes is composed of a reversible component on which may be superimposed

it is possible to superimpose changes in length due to changes in moisture content, curing, loss of plasticizer or solvents, release

of stresses, phase changes, voids, inclusions, and other factors. This test method is intended to determine the coefficient of linear

thermalexpansionundertheexclusionofnon-linearfactorsasfaraspossible.Ingeneral,itwillnotbepossibletoexcludetheeffect

of these factors completely. For this reason, the test method can be expected to give a reasonable approximation but not necessarily

precise determination of the linear coefficient of thermal expansion.

1.3 Plastic lumber and plastic lumber shapes are currently made predominately with recycled plastics where the product is

non-homogeneous in the cross-section. However, it is possible that this test method maywill also be applicable to similar

manufactured plastic products made from virgin resins or other plastic composite materials.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI units given in bracketsparentheses are for

information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—There is no similar or equivalent ISO standard. 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D4065 Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures

D5033 Guide for Development of ASTM Standards Relating to Recycling and Use of Recycled Plastics

E831 Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis

3. Terminology

3.1 Definitions:

3.1.1 plastic lumber, n—amanufacturedproductcomposedofmorethan50weightpercentresin,inwhichtheproductgenerally

is rectangular in cross-section and typically supplied in board and dimensional lumber sizes, may be filled or unfilled, and may

be composed of single or multiple resin blends.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.20 on Plastic Products.Lumber.

Current edition approved Nov.Sept. 1, 2005.2010. Published February 2006.September 2010. Originally approved in 1998. Last previous edition approved in 19982005

as D6341 - 98(2005). DOI: 10.1520/D6341-98R05.10.1520/D6341-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6341 – 10

3.1.2 plastic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.