ASTM C637-98a

(Specification)Standard Specification for Aggregates for Radiation-Shielding Concrete

Standard Specification for Aggregates for Radiation-Shielding Concrete

SCOPE

1.1 This specification covers special aggregates for use in radiation-shielding concretes in which composition or high specific gravity, or both, are of prime consideration.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 637 – 98a

Standard Specification for

Aggregates for Radiation-Shielding Concrete

This standard is issued under the fixed designation C 637; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Classification

1.1 This specification covers special aggregates for use in 3.1 Aggregates covered by this specification include:

radiation-shielding concretes in which composition or high 3.1.1 Natural mineral aggregates of either high density or

specific gravity, or both, are of prime consideration. highfixedwatercontent,orboth.Theseincludeaggregatesthat

1.2 The values stated in SI units are to be regarded as the contain or consist predominately of materials such as barite,

standard. The values given in parentheses are for information magnetite, hematite, ilmenite, and serpentine.

only. 3.1.2 Synthetic aggregates such as iron, steel, ferrophospho-

1.3 The following precautionary caveat pertains only to the rus and boron frit or other boron compounds (see Descriptive

test method portion, Section 8, of this specification:This Nomenclature C 638).

standard does not purport to address all of the safety concerns, 3.1.3 Fine aggregate consisting of natural or manufactured

if any, associated with its use. It is the responsibility of the user sand including high-density minerals. Coarse aggregate may

of this standard to establish appropriate safety and health consist of crushed ore, crushed stone, or synthetic products, or

practices and determine the applicability of regulatory limita- combinations or mixtures thereof.

tions prior to use.

4. Composition and Specific Gravity

2. Referenced Documents

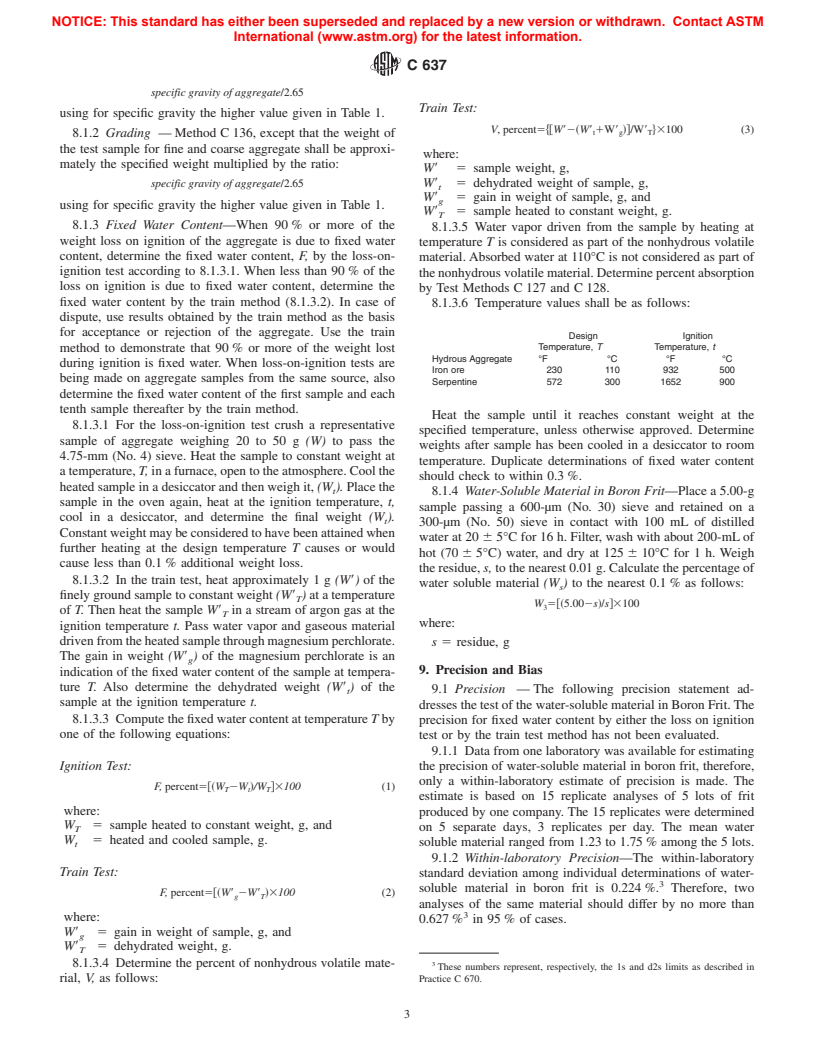

4.1 Table1givesdataonchemicalcompositionandspecific

2.1 ASTM Standards: gravity of aggregate materials covered by this specification.

C 33 Specification for Concrete Aggregates 4.2 The purchaser shall specify the minimum specific grav-

C 127 Test Method for Specific Gravity and Absorption of ity for each size and type of aggregate.

Coarse Aggregate 4.2.1 Uniformity of Specific Gravity—The bulk specific

C 128 Test Method for Specific Gravity and Absorption of gravity (saturated surface-dry) of successive shipments of

Fine Aggregate aggregate shall not differ by more than 3 % from that of the

C 131 Test Method for Resistance to Degradation of Small- sample submitted for source approval tests. The average

Size CoarseAggregate byAbrasion and Impact in the Los specificgravityofthetotalshipmentshallbeequaltoorgreater

Angeles Machine than the specified minimum.

C 136 Test Method for Sieve Analysis of Fine and Coarse 4.3 The purchaser shall specify the minimum fixed water

Aggregates content of hydrous ores. If the design temperature, T, is

C 535 Test Method for Resistance to Degradation of Large- different from that given in 8.1.3.5, the purchaser shall specify

Size CoarseAggregate byAbrasion and Impact in the Los the value of T.

Angeles Machine 4.3.1 Uniformity of Fixed Water Content—For hydrous

C 638 Descriptive Nomenclature of Constituents of Aggre- aggregates the fixed water content of successive shipments of

gates for Radiation-Shielding Concrete aggregate shall not be less than 95 % of the specified minimum

value. The average fixed water content of the total shipment

shall be equal to or exceed the specified minimum value.

5. Aggregate Grading

This specification is under the jurisdiction of ASTM Committee C-9 on

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

5.1 Sieve Analysis—Fine and coarse aggregates for conven-

C09.41on Concrete for Radiation Shielding.

tionally placed concrete shall be graded within the limits given

Current edition approved May 10, 1998. Published December 1998. Originally

in Specification C 33, except that with the approval of the

published as C 637 – 69 T. Last previous edition C 637 – 98.

Annual Book of ASTM Standards, Vol 04.02. purchaser, as much as 20 % of the material passing the 9.5-mm

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C 637

TABLE 1 Composition and Specilc Gravity of Aggregates Covered by This Speciflcation

Specific Gravity of

Predominant Chemical Composition of

Class of Material Available

A

Constituent Principal Constituent

Aggregates

B

Serpentine crushed stone, hydrous siliente Mg Si O (OH) 2.4to2.65

3 2 5 4

C

Limonite crushed stone, hydrous iron ore (HFeO ) (H O) 3.4to3.8

2 x 2 y

C

Goethite crushed stone, hydrous iron ore HFeO 3.5to4.5

Barite gravel or crushed stone BaSO 4.0to4.4

Ilmenite crushed stone, iron ore FeTiO 4.2to4.8

Hematite crushed stone, iron ore Fe O 4.6to5.2

2 3

Magnetite crushed stone, iron ore FeFe O 4.6to5.2

2 4

Iron manufactured from iron/steel Fe 6.5 to 7.5

D

Ferrophosphorous synthetic Fe P 5.8 to 6.3

n

E

Boron Frit synthetic B O ,Al O ,SiO , CaO 2.6 to 2.8

2 3 2 3 2

Boron Carbide synthetic B C, B O ,C 2.5

4 2 3

Calcium Boride synthetic C B ,C 2.5

a 6

A

When it is necessary to minimize the production of long-lived secondary radiation in the shield, or to avoid using materials having inherent radioactivity, the purchaser

should specify limits on the contents of objectionable elements.

B

The fixed water content of serpentine ranges from 10 to 13 percent by weight.

C

The fixed water content of limonite and goethite ranges from 8 to 12 percent by weight.

D

Ferrophosphorus when used in Portland cement concrete will generate flammable and possibly toxic gases which can develop high pressures if confined. See

Clendenning,T.G.,Kellam,B.,andMacInnis,C.,“HydrogenEvolutionfromFerrophosphorousAggregateinPortlandCementConcrete,”JournaloftheAmericanConcrete

Institute, No. 12, December 1968. (Proceedings, Vol 65, pp. 1021–1028), and Mather, Bryant, discussion of Davis, Harold S., “Concrete for Radiation Shielding—In

Perspective,” and closure by author in “Concrete for Nuclear Reactors,” Journal of the American Concrete Institute SP-34, Vol 1, 1972, pp. 11–13.

E

The fixed water content of boron frit is less than 0.5 %.

( ⁄8 -in.) sieve may also pass the 150-µm (No. 100) sieve, with 5.1.2 When boron frit is used as part of the fine aggregate,

up to 10 % passing the 75-µm (No. 200) sieve if the material the grading shall be such that 100 % passes the 4.75-mm (No.

passing the 75-µm (No. 200) sieve is essentially free of clay or 4) sieve and not more than 5 % passes the 600-µm (No. 30)

shale. sieve.

5.1.1 Fine and coarse aggregates for preplaced aggregate 5.2 Fineness Modulus—If the fineness modulus of the fine

concreteshallbegradedaccordingtotherequirementsofTable aggregatevariesmorethan0.2fromthevaluecorrespondingto

2 and as follows: that of the sample submitted for acceptance, the fine aggregate

shall be rejected unless suitable adjustments are made in

concrete proportions to compensate for the difference in

Grading of Aggregate

Specific Gravity Coarse Fine

grading.

of Fine Aggregate Aggregate Aggregate

Up to 3.0 Grading 1 Grading 1

6. Deleterious Substances

Greater than 3.0 Grading 1 Grading 2

Full range Grading 2 Grading 2 6.1 Fine and coarse aggregates shall meet the requirements

of Specification C 33.

6.2 Boron frit shall not contain more than 2.0 % of water

soluble material.

NOTE 1—This limit is based on concrete mixtures containing no more

TABLE 2 Grading Requirements for Coarse and Fine Aggregates

3 3

for Preplaced Aggregate Concrete than 300 kg/m (500 lb/yd ) of boron frit.

Percentage Passing

7. Abrasion Resistance of Coarse Aggregate

Grading 2

Grading 1

Sieve Size

7.1 Coarse aggregate shall have an abrasion loss not greater

For 25-mm (1-in.) Nominal

For 37.5-mm (1 ⁄2 -in.)

Maximum Size

than 50 % when tested in accordance with Test Method C 131,

Nominal Maximum Size Aggregate

A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.