ASTM D7277-16(2023)

(Test Method)Standard Test Method for Performance Testing of Articulating Concrete Block (ACB) Revetment Systems for Hydraulic Stability in Open Channel Flow

Standard Test Method for Performance Testing of Articulating Concrete Block (ACB) Revetment Systems for Hydraulic Stability in Open Channel Flow

SIGNIFICANCE AND USE

5.1 An articulating concrete block revetment system is comprised of a matrix of individual concrete blocks placed together to form an erosion-resistant revetment with specific hydraulic performance characteristics. The system includes a filter layer compatible with the subsoil which allows infiltration and exfiltration to occur while providing particle retention. The filter layer may be comprised of a geotextile, properly graded granular media, or both. The concrete blocks within the matrix shall be dense and durable, and the matrix shall be flexible and porous.

5.2 ACB revetment system are used to provide erosion protection to underlying soil materials from the forces of flowing water. The term “articulating,” as used in this standard, implies the ability of individual concrete blocks of the system to conform to changes in subgrade while remaining interconnected by virtue of geometric interlock, cables, ropes, geotextiles, geogrids, or combination thereof.

5.3 The definition of ACB revetment system does not distinguish between interlocking and non-interlocking block geometries, between cable-tied and non-cable-tied systems, between vegetated and non-vegetated systems or between methods of manufacturing or placement. Furthermore, the definition does not restrict or limit the block size, shape, strength, or longevity; however, guidelines and recommendations regarding these factors are incorporated into this standard. Blocks are available in either open-cell or closed-cell configurations.

SCOPE

1.1 The purpose of this test method is to provide specifications for the hydraulic testing of full-scale articulating concrete block (ACB) revetment systems under controlled laboratory conditions for purposes of identifying stability performance in steep slope, high-velocity flows. The testing protocols, including system installation, test procedures, measurement techniques, analysis techniques, and reporting requirements are described in this test method.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Reporting or use of units other than inch-pound shall not be considered non-conformance as long as the selected parameters described regarding flume construction by the inch-pound system used in this method are met as a minimum.

1.2.1 The gravitational system of inch-pound units is used when dealing with inch-pound units. In this system, the pound (lbf) represents a unit of force (weight), while the unit for mass is slugs. The rationalized slug unit is not given, unless dynamic (F = ma) calculations are involved.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3.1 The procedures used to specify how data are collected, recorded and calculated in this Guide are regarded as the industry standard. In addition they are representative of the significant digits that generally be retained. The procedures used do not consider material variation, purpose of obtaining the data, special purpose studies or any considerations for the user’s objectives; and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it and the suitability of t...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7277 − 16 (Reapproved 2023)

Standard Test Method for

Performance Testing of Articulating Concrete Block (ACB)

Revetment Systems for Hydraulic Stability in Open Channel

Flow

This standard is issued under the fixed designation D7277; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope standard to consider significant digits used in analysis methods

for engineering design.

1.1 The purpose of this test method is to provide specifica-

1.4 This standard does not purport to address all of the

tions for the hydraulic testing of full-scale articulating concrete

safety concerns, if any, associated with its use. It is the

block (ACB) revetment systems under controlled laboratory

responsibility of the user of this standard to establish appro-

conditions for purposes of identifying stability performance in

priate safety, health, and environmental practices and deter-

steep slope, high-velocity flows. The testing protocols, includ-

mine the applicability of regulatory limitations prior to use.

ing system installation, test procedures, measurement

techniques, analysis techniques, and reporting requirements are

NOTE 1—The quality of the result produced by this standard is

described in this test method.

dependent on the competence of the personnel performing it and the

suitability of the equipment and facilities used. Agencies that meet criteria

1.2 The values stated in inch-pound units are to be regarded

of Practice D3740 are generally considered capable of competent and

as standard. The values given in parentheses are mathematical

objective testing. Users of this standard are cautioned that compliance

conversions to SI units that are provided for information only

with Practice D3740 does not in itself assure reliable results. Reliable

results depend on many factors and Practice D3740 provides a means of

and are not considered standard. Reporting or use of units other

evaluating some of these factors.

than inch-pound shall not be considered non-conformance as

1.5 This international standard was developed in accor-

long as the selected parameters described regarding flume

construction by the inch-pound system used in this method are dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

met as a minimum.

1.2.1 The gravitational system of inch-pound units is used Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

when dealing with inch-pound units. In this system, the pound

Barriers to Trade (TBT) Committee.

(lbf) represents a unit of force (weight), while the unit for mass

is slugs. The rationalized slug unit is not given, unless dynamic

2. Referenced Documents

(F = ma) calculations are involved.

2.1 ASTM Standards:

1.3 All observed and calculated values shall conform to the

D422 Test Method for Particle-Size Analysis of Soils (With-

guidelines for significant digits and rounding established in

drawn 2016)

Practice D6026.

D653 Terminology Relating to Soil, Rock, and Contained

1.3.1 The procedures used to specify how data are collected,

Fluids

recorded and calculated in this Guide are regarded as the

D698 Test Methods for Laboratory Compaction Character-

industry standard. In addition they are representative of the

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

significant digits that generally be retained. The procedures

kN-m/m ))

used do not consider material variation, purpose of obtaining

D1556/D1556M Test Method for Density and Unit Weight

the data, special purpose studies or any considerations for the

of Soil in Place by Sand-Cone Method

user’s objectives; and it is common practice to increase or

D2216 Test Methods for Laboratory Determination of Water

reduce significant digits of reported data to be commensurate

(Moisture) Content of Soil and Rock by Mass

with these considerations. It is beyond the scope of this

1 2

This guide is under the jurisdiction of ASTM Committee D18 on Soil and Rock For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D18.25 on Erosion and Sediment contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Control Technology. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2023. Published August 2023. Originally the ASTM website.

approved in 2008. Last previous edition approved in 2016 as D7277 - 16. DOI: The last approved version of this historical standard is referenced on

10.1520/D7277-16R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7277 − 16 (2023)

–1

D2487 Practice for Classification of Soils for Engineering 3.1.11 uniform flow, (LT ), n—in hydraulics, the condition

Purposes (Unified Soil Classification System) of flow where the rate of energy loss due to frictional and form

D3740 Practice for Minimum Requirements for Agencies resistance is equal to the bed slope of the channel.

Engaged in Testing and/or Inspection of Soil and Rock as 3.1.11.1 Discussion—Where uniform flow exists, the slopes

Used in Engineering Design and Construction of the energy grade line, the water surface, and the channel bed

D4318 Test Methods for Liquid Limit, Plastic Limit, and are identical. Cross-sectional area and velocity of flow do not

Plasticity Index of Soils change from cross section to cross section in uniform flow.

–1

D5195 Test Method for Density of Soil and Rock In-Place at

3.1.12 velocity, V, (LT ), n—in channel flow, time rate of

Depths Below Surface by Nuclear Methods

linear motion in a given direction.

D6026 Practice for Using Significant Digits and Data Re-

cords in Geotechnical Data

4. Summary of Test Method

4.1 The test method is designed to determine the stability

3. Terminology

threshold values of shear stress and velocity of articulating

3.1 Definitions: concrete block (ACB) revetment systems under controlled

laboratory conditions of steep-slope, high-velocity flow (flume

3.1.1 For common definitions of technical terms in this test

test). Systems are tested as full-scale production units.

method, refer to Terminology D653.

3.1.2 articulating concrete block (ACB) revetment system,

4.2 The procedures associated with test set-up, testing, data

n—in erosion control, a matrix of interconnected concrete

collection, and reporting are provided in this test method.

block units for erosion protection. Units are typically con-

5. Significance and Use

nected by geometric interlock, cables, ropes, geotextile,

geogrids or a combination thereof and typically include a

5.1 An articulating concrete block revetment system is

geotextile underlayment.

comprised of a matrix of individual concrete blocks placed

3.1.3 depth of flow, y , (L), n—in hydraulics, the distance together to form an erosion-resistant revetment with specific

o

hydraulic performance characteristics. The system includes a

from the channel thalweg to the water surface, measured

normal to the direction of flow, for a given discharge. filter layer compatible with the subsoil which allows infiltration

and exfiltration to occur while providing particle retention. The

3 –1

3.1.4 design discharge, Q , (L T ), n—in erosion control,

d

filter layer may be comprised of a geotextile, properly graded

the volumetric quantity of water flow within a channel which

granular media, or both. The concrete blocks within the matrix

is typically used in determining required channel dimensions

shall be dense and durable, and the matrix shall be flexible and

and suitable lining materials for ensuring adequate channel

porous.

capacity and stability.

5.2 ACB revetment system are used to provide erosion

3.1.4.1 Discussion—The discharge associated with a speci-

protection to underlying soil materials from the forces of

fied frequency of recurrence, for example, an n-year flood. The

flowing water. The term “articulating,” as used in this standard,

n-year flood event has a probability of 1/n of being equaled or

implies the ability of individual concrete blocks of the system

exceeded in any given year.

to conform to changes in subgrade while remaining intercon-

3 –1

3.1.5 discharge, Q, (L T ), n—in channel flow, the volume

nected by virtue of geometric interlock, cables, ropes,

of water flowing through a cross-section in a unit of time,

geotextiles, geogrids, or combination thereof.

including sediment or other solids that may be dissolved in or

5.3 The definition of ACB revetment system does not

mixed with the water; usually cubic feet per second (ft /s) or

distinguish between interlocking and non-interlocking block

cubic meters per second (m /s).

geometries, between cable-tied and non-cable-tied systems,

3.1.6 hydraulic radius, (L), n—in channel flow, the cross-

between vegetated and non-vegetated systems or between

sectional area of flow divided by the wetted perimeter.

methods of manufacturing or placement. Furthermore, the

3 –1

3.1.7 local velocity, (L T ), n—in channel flow, the veloc- definition does not restrict or limit the block size, shape,

ity at a specific point in the flow region. May be defined as a strength, or longevity; however, guidelines and recommenda-

direction-dependent quantity with components V , V , or V . tions regarding these factors are incorporated into this stan-

x y z

–1 dard. Blocks are available in either open-cell or closed-cell

3.1.8 mean velocity, (LT ), n—in hydraulics, the average

configurations.

velocity throughout a channel cross section. Defined as the

discharge divided by the cross-sectional area of flow usually

6. Preparation of Test Section

expressed in meters per second (m/s) or feet per second (ft/s).

6.1 Soil Subgrade Construction:

–1

3.1.9 subcritical flow, (LT ), n—in channel flow, a charac-

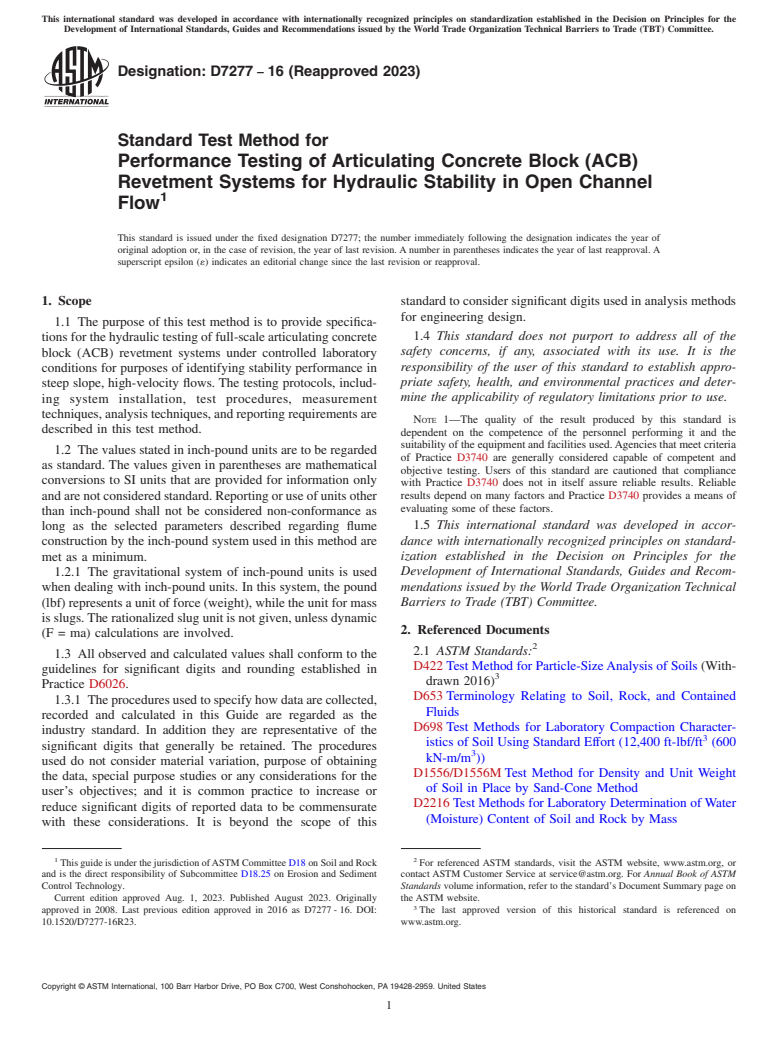

6.1.1 The testing program includes the construction of an

teristic of flowing water whereby gravitational forces dominate

earthen test subgrade compacted between vertical walls of the

over inertial forces, quantified by a Froude Number less than 1.

testing flume (Fig. 1). The soil subgrade shall be placed and

–1

3.1.10 supercritical flow, (LT ), n—in channel flow, a compacted in horizontal lifts of 4 to 6 in. (100 to 150 mm) in

characteristic of flowing water whereby inertial forces domi- thickness to a minimum subgrade thickness of 12 in. (300 mm).

nate over gravitational forces, quantified by a Froude Number The distance between the walls shall be a minimum of 4.0 ft

greater than 1. (1.2 m); installation shall be reflective of standard field usage

D7277 − 16 (2023)

NOTE 1—Drawing not to scale, and slope, as shown, is not 2H:1V.

NOTE 2—1 ft = 0.305 m.

FIG. 1 Schematic Profile of Typical Testing Flume

and shall accommodate full-scale block units such that at least 6.1.3.4 Atterberg Limits (liquid limit, plastic limit), Test

one block is not adjacent to a sidewall, at least every other row Methods D4318.

of the revetment matrix.

6.1.4 Following the preparation of the soil subgrade, the

6.1.2 The soil subgrade shall consist of a silty sand with a

following information is determined within 24 h prior to

plasticity index (PI) in the range of 2 to 6 %, and will be

installation of the revetment system. This information shall

compacted at optimum water content to between 90 and 95 %

include as a minimum the soil water (moisture) content (Test

of Standard Effort density (Test Methods D698). The embank-

Methods D2216) and density/unit weight determined by sand

ment shall be constructed to a height such that the finished

cone (Test Method D1556/D1556M) or nuclear gauge (Test

surface of the revetment consists of a horizontal crest section at

Method D5195) at a minimum of two locations along the

least 6 ft (1.8 m) in length followed by a downstream slope

centerline of the test embankment.

angle typically set at 2H:1V.

6.2 Installation of ACB Revetment System:

NOTE 2—Test conditions may incorporate slopes other that the 2H:1V

6.2.1 A properly designed filter (geotextile, granular filter,

identified as the benchmark. Variations from the procedures identified

or both), properly engineered or selected for the soil subgrade

must be included in the report. Additionally, engineering judgment must

accompany utilizing and interpreting the results from tests varying from

utilized for testing, and the ACBs shall be placed on the crest

the proposed test method.

and downstream slope in accordance with the manufacturer’s

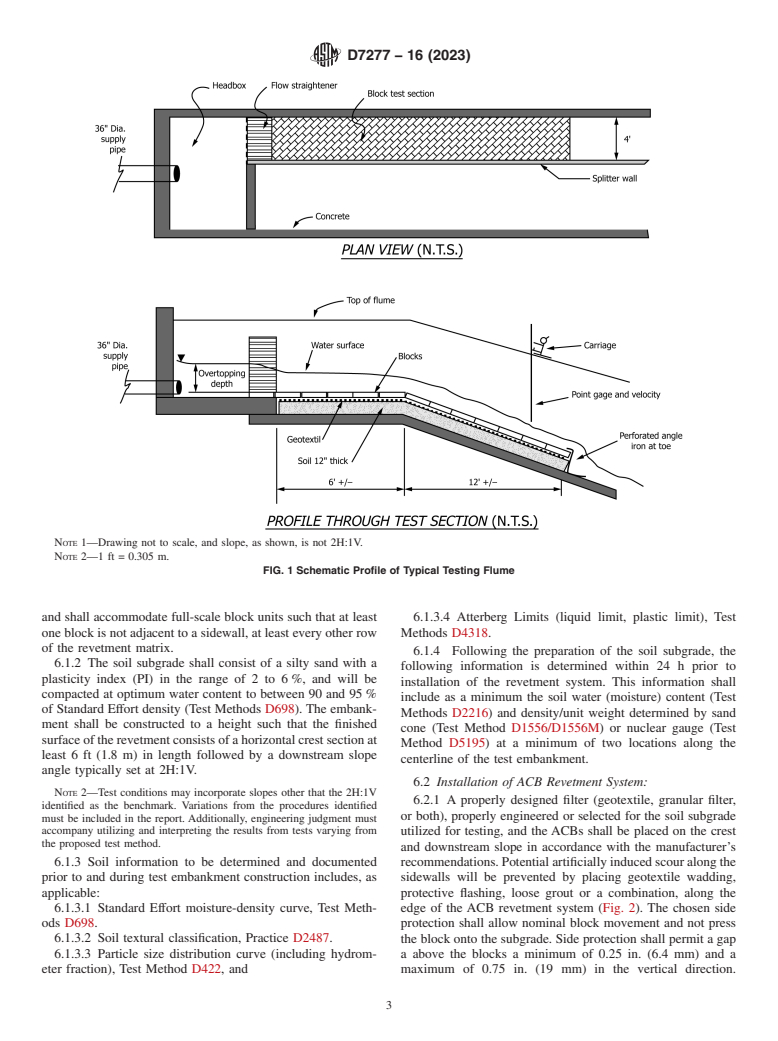

6.1.3 Soil information to be determined and documented recommendations. Potential artificially induced scour along the

prior to and during test embankment construction includes, as sidewalls will be prevented by placing geotextile wadding,

applicable: protective flashing, loose grout or a combination, along the

6.1.3.1 Standard Effort moisture-density curve, Test Meth- edge of the ACB revetment system (Fig. 2). The chosen side

ods D698. protection shall allow nominal block movement and not press

6.1.3.2 Soil textural classification, Practice D2487. the block onto the subgrade. Side protection shall permit a gap

6.1.3.3 Particle size distribution curve (including hydrom- a above the blocks a minimum of 0.25 in. (6.4 mm) and a

eter fraction), Test Method D422, and maximum of 0.75 in. (19 mm) in the vertical direction.

D7277 − 16 (2023)

FIG. 2 Recommended Sidewall Detail (Cross Section View)

Horizontal projection of the side protection shall extend a 7.2 Water Surface and Bed Elevation Profiles—Hourly mea-

minimum of 0.5 in. (13 mm) and a maximum of 2.5 in. (64 surements of water surface elevation will be made at 2-ft

mm) into the flume. The ACB revetment system will be (0.6-m) intervals (stations) along the centerline of the embank-

secured at the embankment toe by means of a bolted or welded ment during each test. Bed elevations (top of ACB revetment

toe retention system designed for the specific system to be surface) shall be established prior to each test and again after

tested (Fig. 3). Depending on the geometry of the system being the cessation of each test, at the same measurement stations as

tested, void spaces next to the sidewalls greater than 3 in. (75 the water surface readings. When testing ACBs that exhibit a

mm) should be filled with partial blocks specially cut

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.