ASTM F847-94(1999)

(Test Method)Standard Test Methods for Measuring Crystallographic Orientation of Flats on Single Crystal Silicon Wafers by X-Ray Techniques

Standard Test Methods for Measuring Crystallographic Orientation of Flats on Single Crystal Silicon Wafers by X-Ray Techniques

SCOPE

1.1 These test methods cover the determination of [alpha], the angular deviation between the crystallographic orientation of the direction perpendicular to the plane of a fiducial flat on a circular silicon wafer, and the specified orientation of the flat in the plane of the wafer surface.

1.2 These test methods are applicable for wafers with flat length values in the range of those specified for silicon wafers in SEMI Specification M1. They are suitable for use only on wafers with angular deviations of less than +5°.

1.3 The orientation accuracy achieved by these test methods depends directly on the accuracy with which the flat surface can be aligned with a reference fence and the accuracy of the orientation of the reference fence with respect to the X-ray beam.

1.4 Two test methods are covered as follows: Sections Test Method A---X-Ray Edge Diffraction 8 to 13 Method Test Method B---Laue Back Reflection 14 to 18 X-Ray Method

1.4.1 Test Method A is nondestructive and is similar to Test Method A of Test Methods F26 except that it uses special wafer holding fixtures to orient the wafer uniquely with respect to the X-ray goniometer. The technique is capable of measuring the crystallographic direction of flats to a greater precision than the Laue back reflection method.

1.4.2 Test Method B is also nondestructive, and is similar to Test Method E82, and to DIN 50 433, Part 3, except that it uses "instant" film and special fixturing to orient the flat with respect to the X-ray beam. Although it is simpler and more rapid, it does not have the precision of Test Method A because it uses less precise and less expensive fixturing and equipment. It produces a permanent film record of the test. Note 1-The Laue photograph may be interpreted to provide information regarding the crystallographic directions of wafer misorientation; however, this is beyond the scope of the present test method. Users desiring to carry out such interpretation should refer to Test Method E82 and to DIN 50 433, Part 3, or to a standard X-ray textbook. With different wafer holding fixturing, Test Method B is also applicable to determination of the orientation of a wafer surface.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 847 – 94 (Reapproved 1999)

Standard Test Methods for

Measuring Crystallographic Orientation of Flats on Single

Crystal Silicon Wafers by X-Ray Techniques

This standard is issued under the fixed designation F 847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

,

2 3

and to DIN 50 433, Part 3, or to a standard X-ray textbook. With

1. Scope

different wafer holding fixturing, Test Method B is also applicable to

1.1 These test methods cover the determination of a, the

determination of the orientation of a wafer surface.

angular deviation between the crystallographic orientation of

1.5 The values stated in inch-pound units are to be regarded

the direction perpendicular to the plane of a fiducial flat on a

as the standard. The values given in parentheses are for

circular silicon wafer, and the specified orientation of the flat in

information only.

the plane of the wafer surface.

1.6 This standard does not purport to address all of the

1.2 These test methods are applicable for wafers with flat

safety concerns, if any, associated with its use. It is the

length values in the range of those specified for silicon wafers

responsibility of the user of this standard to establish appro-

in SEMI Specification M 1. They are suitable for use only on

priate safety and health practices and determine the applica-

wafers with angular deviations of less than 65°.

bility of regulatory limitations prior to use. For specific hazard

1.3 The orientation accuracy achieved by these test methods

statements see Section 6.

depends directly on the accuracy with which the flat surface

can be aligned with a reference fence and the accuracy of the

2. Referenced Documents

orientation of the reference fence with respect to the X-ray

2.1 ASTM Standards:

beam.

E 82 Test Method for Determining the Orientation of a

1.4 Two test methods are covered as follows:

Metal Crystal

Sections

E 122 Practice for Choice of Sample Size to Estimate a

Test Method A—X-Ray Edge Diffraction Method 8 to 13

Test Method B—Laue Back Reflection X-Ray Method 14 to 18

Measure of Quality for a Lot or Process

F 26 Test Methods for Determining the Orientation of a

1.4.1 Test Method A is nondestructive and is similar to Test

Semiconductive Single Crystal

Method A of Test Methods F 26 except that it uses special

2.2 Military Standard:

wafer holding fixtures to orient the wafer uniquely with respect

MIL-STD-105D Sampling Procedures and Tables for In-

to the X-ray goniometer. The technique is capable of measur- 7

spection by Attributes

ing the crystallographic direction of flats to a greater precision

than the Laue back reflection method.

2.3 Other Standards:

1.4.2 Test Method B is also nondestructive, and is similar to

Code of Federal Regulations, Title 10, Part 20, Standards

Test Method E 82, and to DIN 50 433, Part 3, except that it 8

for Protection Against Radiation

uses“ instant” film and special fixturing to orient the flat with

SEMI Specification M 1, Polished Monocrystalline Silicon

respect to the X-ray beam. Although it is simpler and more 9

Slices

rapid, it does not have the precision of Test Method A because

DIN 50 433, Part 3, Testing of Materials for Semiconductor

it uses less precise and less expensive fixturing and equipment.

It produces a permanent film record of the test.

NOTE 1—The Laue photograph may be interpreted to provide informa-

Wood, E. A., Crystal Orientation Manual, Columbia University Press, New

tion regarding the crystallographic directions of wafer misorientation;

York, NY, 1963.

however, this is beyond the scope of the present test method. Users Barret, C. S., and Massalski, T. B., The Structure of Metals, 3rd edition

McGraw-Hill, New York, NY, 1966.

desiring to carry out such interpretation should refer to Test Method E 82

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 10.05.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

These test methods are under the jurisdiction of ASTM Committee F01 on

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Electronics and are the direct responsibility of Subcommittee F01.06 on Silicon

Published in Federal Register, Nov. 16, 1960. Available from Superintendent of

Materials and Process Control.

Documents, U.S. Government Printing Office, Washington, DC 20402.

Current edition approved Aug. 15, 1994. Published October 1994. Originally

Available from the Semiconductor Equipment and Materials Institute, Inc., 805

published as F847 – 83. Last previous edition F847 – 87.

E. Middlefield Rd., Mountain View, CA 94043.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 847

(a) Front and Side Views

(b) Photograph of Mounted Fixture (c) Detail of Wafer and Reference Fence

FIG. 1 Wafer Holding Fixture for X-Ray Edge Diffraction Method

Technology: Determining the Orientation of Single Crys- low-index plane, such as a {110} plane. In such cases the

6,10

tals Using the Laue Back-Scattering Method orientation of the flat may be described in terms of its angular

deviation from the low-index plane.

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

4. Significance and Use

3.1.1 orientation—of a single crystal surface, the crystallo-

4.1 The orientation of flats on silicon wafers is an important

graphic plane, described in terms of its Miller indices, with

materials acceptance requirement. The flats are used in semi-

which the surface is ideally coincident. The orientation of a

conductor device processing to provide consistent alignment of

wafer flat is the orientation of the surface of the flat (on the

device geometries with respect to crystallographic planes and

edge of the wafer). Flats are usually specified with respect to a

directions.

4.2 Either one of these test methods is appropriate for

10 process development and quality assurance applications. Until

Available from Beuth Verlag GmbH Burgrafenstrasse 4-10, D-1000 Berlin 30,

Germany. the interlaboratory precision of these test methods has been

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 847

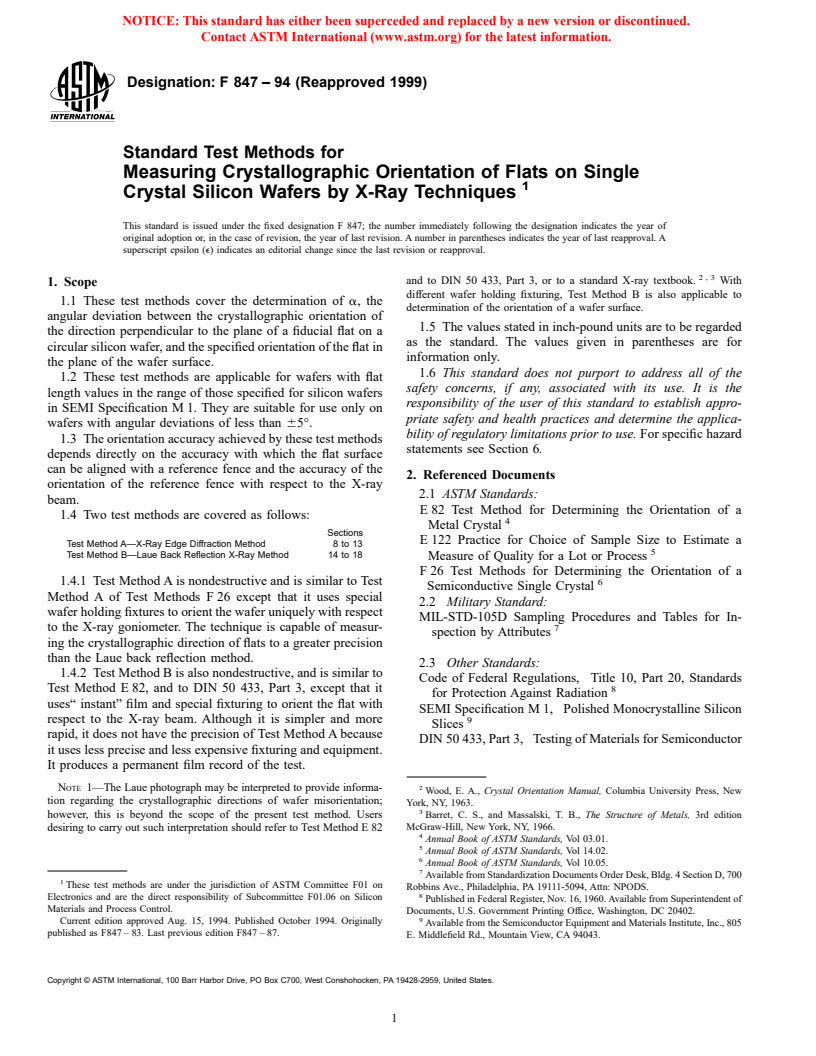

FIG. 2 Schematic of the Diffraction Geometry for the X-Ray Edge Diffraction Method

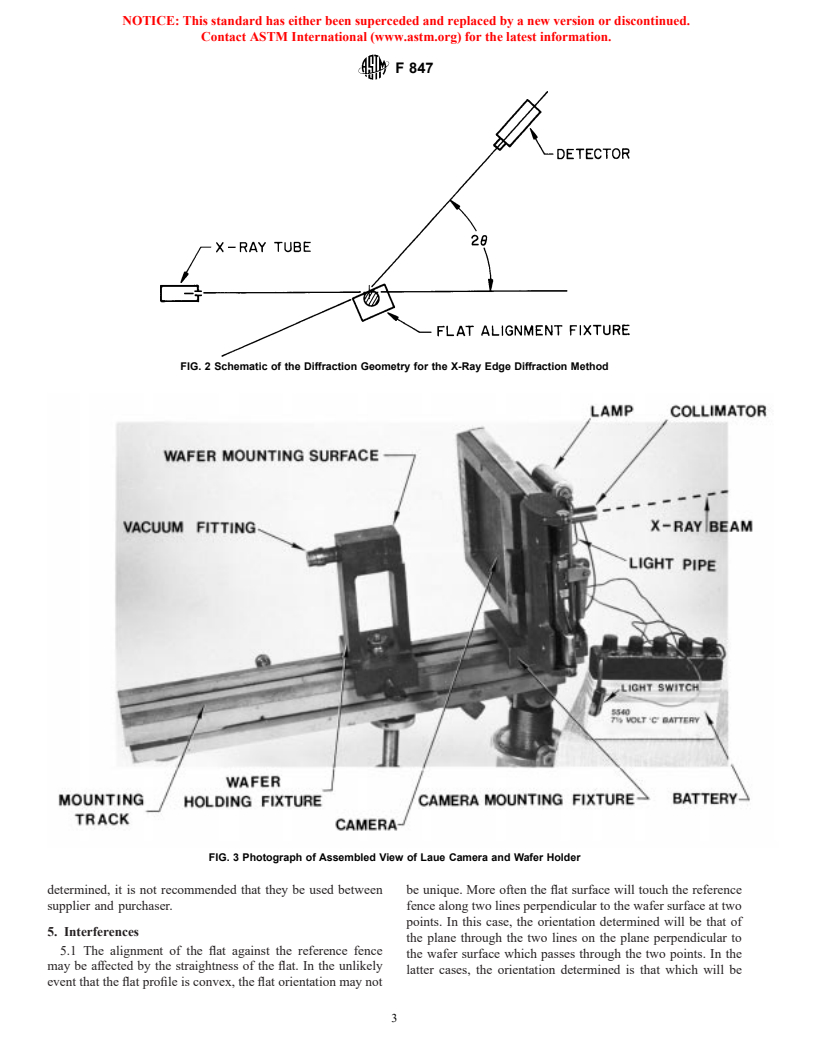

FIG. 3 Photograph of Assembled View of Laue Camera and Wafer Holder

determined, it is not recommended that they be used between be unique. More often the flat surface will touch the reference

supplier and purchaser. fence along two lines perpendicular to the wafer surface at two

points. In this case, the orientation determined will be that of

5. Interferences

the plane through the two lines on the plane perpendicular to

5.1 The alignment of the flat against the reference fence

the wafer surface which passes through the two points. In the

may be affected by the straightness of the flat. In the unlikely

latter cases, the orientation determined is that which will be

event that the flat profile is convex, the flat orientation may not

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 847

FIG. 4 Photograph of Wafer Holding Fixture and Mounting Track

obtained in subsequent processing of the wafer when the to external X-radiation of quantum energy less than 3 MeV

−4

alignment is between the flat and a reference fence. over an indefinite period is 1.25 R (3.22 3 10 C/kg) per

−7

5.2 Misalignment of the various fixtures will degrade both calendar quarter (equivalent to 0.6 mR/h (1.5 3 10 C/kg·h))

the interlaboratory reproducibility and the absolute accuracy of as established in the Code of Federal Regulations, Title 10,

both test methods. The single-instrument repeatability will not Part 20. The present maximum permissible dose of hand and

be degraded provided the fixturing is rigid. forearm exposure under the same conditions is 18.75 R

−3

(4.85 3 10 C/kg) per calendar quarter (equivalent to 9.3

−6

6. Hazards

mR/h (2.4 3 10 C/kg·h)). Besides the above stated regula-

6.1 These test methods use X-radiation; it is absolutely tions, various other government and regulatory organizations

have their own safety requirements. It is the responsibility of

necessary to avoid personal exposure to X rays. It is especially

important to keep hands or fingers out of the path of the X rays the user to make sure that the equipment and the conditions

under which it is used meet these regulations.

and to protect the eyes from scattered secondary radiation. The

use of commercial film badge or dosimeter service is recom-

7. Sampling

mended, together with periodic checks of the radiation level at

the hand and body positions with a Geiger-Muller counter 7.1 Unless otherwise specified, Practice E 122 shall be used.

calibrated with a standard nuclear source. The present maxi- When so specified, appropriate sample sizes shall be selected

mum permissible dose for total body exposure of an individual from each lot according to MIL-STD-105D. Inspection levels

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 847

FIG. 5 Section of Laue Camera Platen Showing Light Pipe and Collimating Tube

shall be agreed upon between the parties to the test. 9.2.2 Both the side of the reference fence against which the

wafer flat is located, and the fixture surface to which the

TEST METHOD A—X-RAY EDGE

reference fence mates, must be flat to within one part per

DIFFRACTION METHOD

10 000.

8. Summary of Test Method

10. Procedure

8.1 In this test method a holding fixture which uniquely

10.1 Position the detector so that the angle between the

orients the wafer being tested with respect to its geometric

extension of the incident X-ray beam and the line joining the

features is used to position the wafers with r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.