ASTM D7905/D7905M-19e1

(Test Method)Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites

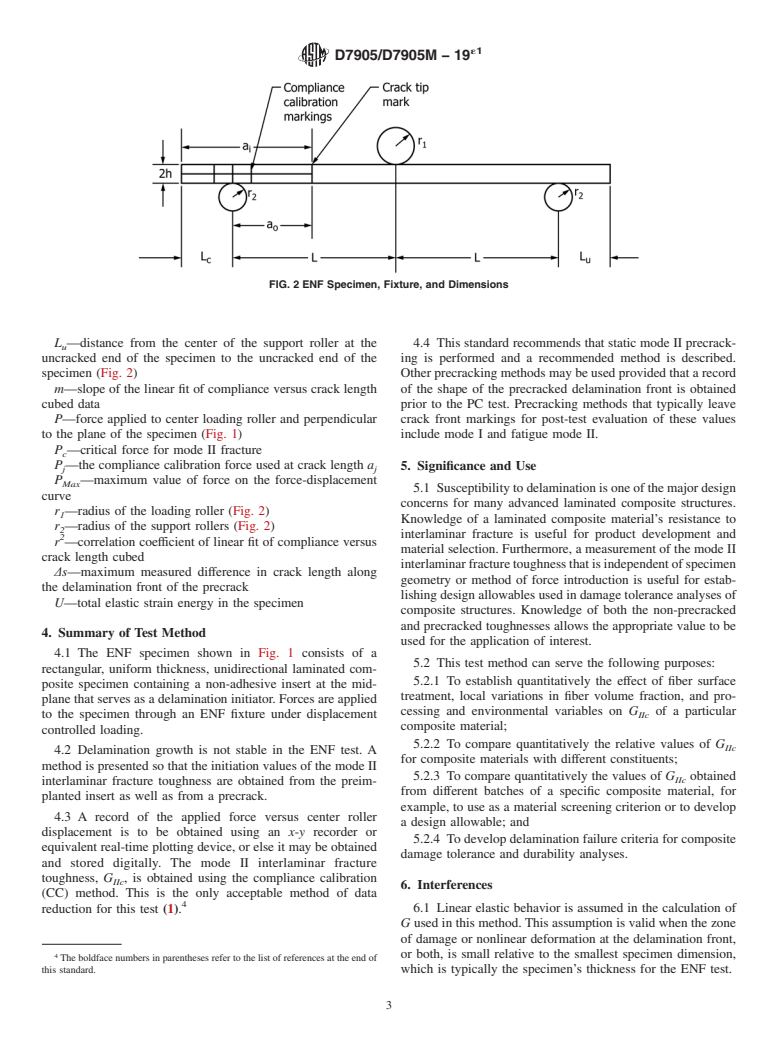

Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites

SIGNIFICANCE AND USE

5.1 Susceptibility to delamination is one of the major design concerns for many advanced laminated composite structures. Knowledge of a laminated composite material’s resistance to interlaminar fracture is useful for product development and material selection. Furthermore, a measurement of the mode II interlaminar fracture toughness that is independent of specimen geometry or method of force introduction is useful for establishing design allowables used in damage tolerance analyses of composite structures. Knowledge of both the non-precracked and precracked toughnesses allows the appropriate value to be used for the application of interest.

5.2 This test method can serve the following purposes:

5.2.1 To establish quantitatively the effect of fiber surface treatment, local variations in fiber volume fraction, and processing and environmental variables on GIIc of a particular composite material;

5.2.2 To compare quantitatively the relative values of GIIc for composite materials with different constituents;

5.2.3 To compare quantitatively the values of GIIc obtained from different batches of a specific composite material, for example, to use as a material screening criterion or to develop a design allowable; and

5.2.4 To develop delamination failure criteria for composite damage tolerance and durability analyses.

SCOPE

1.1 This test method covers the determination of the mode II interlaminar fracture toughness, GIIc, of unidirectional fiber-reinforced polymer matrix composite laminates under mode II shear loading using the end-notched flexure (ENF) test (Fig. 1).

FIG. 1 ENF Test Fixture and Specimen Nomenclature

1.2 This method is limited to use with composites consisting of unidirectional carbon-fiber- and glass-fiber-reinforced laminates. This limited scope reflects the experience gained in round robin testing. This test method may prove useful for other types and classes of composite materials; however, certain interferences have been noted (see Section 6).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3.1 Within the text the inch-pound units are shown in brackets.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D7905/D7905M − 19

Standard Test Method for

Determination of the Mode II Interlaminar Fracture

Toughness of Unidirectional Fiber-Reinforced Polymer

1

Matrix Composites

This standard is issued under the fixed designation D7905/D7905M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial changes were made to Table 1 in November 2019.

1. Scope 2. Referenced Documents

2

1.1 ThistestmethodcoversthedeterminationofthemodeII 2.1 ASTM Standards:

interlaminar fracture toughness, G , of unidirectional fiber- D792 Test Methods for Density and Specific Gravity (Rela-

IIc

tive Density) of Plastics by Displacement

reinforced polymer matrix composite laminates under mode II

shearloadingusingtheend-notchedflexure(ENF)test(Fig.1). D883 Terminology Relating to Plastics

D2584 Test Method for Ignition Loss of Cured Reinforced

1.2 Thismethodislimitedtousewithcompositesconsisting

Resins

of unidirectional carbon-fiber- and glass-fiber-reinforced lami-

D2734 TestMethodsforVoidContentofReinforcedPlastics

nates. This limited scope reflects the experience gained in

D3171 Test Methods for Constituent Content of Composite

round robin testing. This test method may prove useful for

Materials

other types and classes of composite materials; however,

D3878 Terminology for Composite Materials

certain interferences have been noted (see Section 6).

D5229/D5229M TestMethodforMoistureAbsorptionProp-

erties and Equilibrium Conditioning of Polymer Matrix

1.3 The values stated in either SI units or inch-pound units

Composite Materials

are to be regarded separately as standard. The values stated in

D5687/D5687M Guide for Preparation of Flat Composite

each system are not necessarily exact equivalents; therefore, to

Panels with Processing Guidelines for Specimen Prepara-

ensure conformance with the standard, each system shall be

tion

used independently of the other, and values from the two

D7264/D7264M Test Method for Flexural Properties of

systems shall not be combined.

Polymer Matrix Composite Materials

1.3.1 Within the text the inch-pound units are shown in

E4 Practices for Force Verification of Testing Machines

brackets.

E6 Terminology Relating to Methods of Mechanical Testing

1.4 This standard does not purport to address all of the

E122 Practice for Calculating Sample Size to Estimate,With

safety concerns, if any, associated with its use. It is the

Specified Precision, the Average for a Characteristic of a

responsibility of the user of this standard to establish appro-

Lot or Process

priate safety, health, and environmental practices and deter-

E177 Practice for Use of the Terms Precision and Bias in

mine the applicability of regulatory limitations prior to use.

ASTM Test Methods

1.5 This international standard was developed in accor- E456 Terminology Relating to Quality and Statistics

dance with internationally recognized principles on standard-

E691 Practice for Conducting an Interlaboratory Study to

ization established in the Decision on Principles for the Determine the Precision of a Test Method

Development of International Standards, Guides and Recom- E1309 Guide for Identification of Fiber-Reinforced

mendations issued by the World Trade Organization Technical Polymer-Matrix Composite Materials in Databases (With-

3

Barriers to Trade (TBT) Committee. drawn 2015)

1 2

This test method is under the jurisdiction of ASTM Committee D30 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Composite Materials and is the direct responsibility of Subcommittee D30.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Interlaminar Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 15, 2019. Published June 2019. Originally the ASTM website.

3

approved in 2014. Last previous edition approved in 2014 as D7905/D7905M – 14. The last approved version of this historical standard is referenced on

DOI: 10.1520/D7905_D7905M-19E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D7905/D7905M − 19

FIG. 1 ENF Test Fixture and Specimen Nomenclature

E1434 Guide for Recording Mechanical Test Data of Fiber- width [L] for an infinitesimal increase in delamination length,

ReinforcedCompositeMaterialsinDatabases(Withdrawn da [L], fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.