ASTM D6588/D6588M-11(2016)

(Test Method)Standard Test Method for Fatigue of Tire Cords (Disc Fatigue Test)

Standard Test Method for Fatigue of Tire Cords (Disc Fatigue Test)

SIGNIFICANCE AND USE

5.1 This test method is not recommended for acceptance testing of commercial shipments in the absence of reliable information on between-laboratory precision.

5.1.1 If there are differences of practical significance between the reported test results for two laboratories (or more), a comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, test samples should be used that are as homogeneous as possible, that are drawn from a material from which the disparate test results were obtained, and that are randomly assigned in equal numbers to each laboratory for testing. Other fabrics with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

SCOPE

1.1 This test method covers the determination of fatigue of tire cords in rubber due to compression or extension, or both, using a disc fatigue tester. The fatigue is measured as a loss in strength.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6588/D6588M − 11 (Reapproved 2016)

Standard Test Method for

Fatigue of Tire Cords (Disc Fatigue Test)

This standard is issued under the fixed designation D6588/D6588M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of terms relating to tire cord and

fabrics, see Terminology D6477.

1.1 This test method covers the determination of fatigue of

3.1.2 For definitions of other terms related to textiles, see

tire cords in rubber due to compression or extension, or both,

Terminology D123.

using a disc fatigue tester. The fatigue is measured as a loss in

strength.

4. Summary of Test Method

1.2 The values stated in either SI units or inch-pound units

4.1 disc fatigue is a measure of the strength loss of a tire

are to be regarded separately as standard. The values stated in

cord, which is subjected to repeated stresses. The stresses are

each system may not be exact equivalents; therefore, each

accomplished by subjecting the tire cords, after being cured in

system shall be used independently of the other. Combining

rubber, to repeated cycles of compression and extension.

values from the two systems may result in nonconformance

4.2 The specimen of interest is the cord after it has been

with the standard.

stressed and later removed from the rubber in which it was

1.3 This standard does not purport to address all of the

imbedded. Cord specimens are placed between strips of rubber

safety concerns, if any, associated with its use. It is the

compound and molded into blocks.The specimen block is then

responsibility of the user of this standard to establish appro-

mounted between two rotating discs that are positioned in such

priatesafetyandhealthpracticestodeterminetheapplicability

a way that the specimen will undergo compression or

of regulatory limitations prior to use.

extension, or both, as the discs rotate.After a specified number

of cycles, the cords are removed from the blocks and their

2. Referenced Documents

breaking force measured on a tensile testing machine. The

2.1 ASTM Standards:

fatigue, based on the unfatigued specimen strength, is ex-

D76 Specification for Tensile Testing Machines for Textiles

pressed as a percent strength loss in fatigued specimens.

D123 Terminology Relating to Textiles

D885 Test Methods for Tire Cords, Tire Cord Fabrics, and

5. Significance and Use

Industrial Filament Yarns Made from Manufactured

5.1 This test method is not recommended for acceptance

Organic-Base Fibers

testing of commercial shipments in the absence of reliable

D1776 Practice for Conditioning and Testing Textiles

information on between-laboratory precision.

D6477 Terminology Relating to Tire Cord, Bead Wire, Hose

5.1.1 If there are differences of practical significance be-

Reinforcing Wire, and Fabrics

tween the reported test results for two laboratories (or more), a

D7269 Test Methods for Tensile Testing of Aramid Yarns

comparative test should be performed to determine if there is a

statistical bias between them, using competent statistical assis-

3. Terminology

tance. As a minimum, test samples should be used that are as

3.1 Definitions:

homogeneous as possible, that are drawn from a material from

which the disparate test results were obtained, and that are

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

randomly assigned in equal numbers to each laboratory for

and is the direct responsibility of Subcommittee D13.19 on Industrial Fibers and

testing. Other fabrics with established test values may be used

Metallic Reinforcements

for this purpose. The test results from the two laboratories

Current edition approved July 1, 2016. Published August 2016. Originally

should be compared using a statistical test for unpaired data, at

approved in 2000. Last previous edition approved in 2011 as D6588–11. DOI:

10.1520/D6588_D6588M-11R16.

a probability level chosen prior to the testing series. If a bias is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

found, either its cause must be found and corrected, or future

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test results must be adjusted in consideration of the known

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bias.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6588/D6588M − 11 (2016)

6. Apparatus, Materials, and Reagents 6.11 Solvent, 1.1.2.2 tetrachloroethylene, CHCl CHCl or

2 2

1.1.1 trichloroethane CCl CH ) for removing cords from

3 3

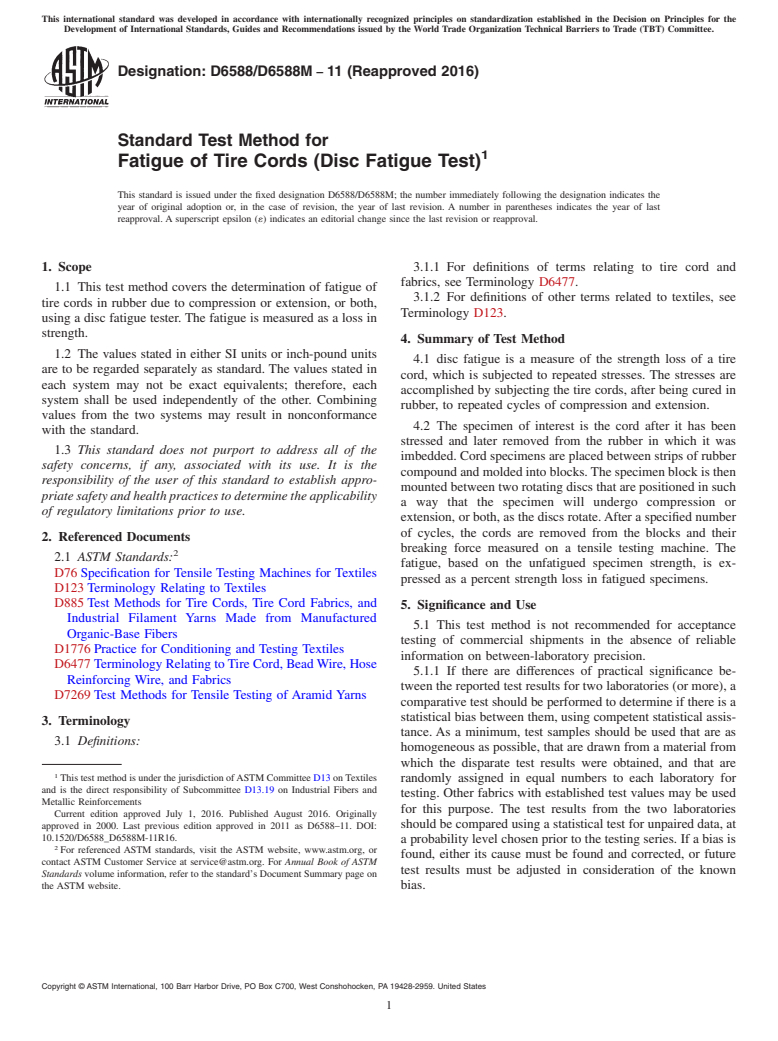

6.1 Disc Fatigue Tester (see schematic drawing in Fig. 1),

rubber.

with capacity for 12 specimens. For actual dimensions, see

patent US 2595069. Testers with different capacity are accept- 6.12 Tachometer or Stroboscope.

able.

6.13 Screwdriver, or other tightening device.

6.2 Displacement Transducer, with digital readout or dial

gage for setting distance between disc fatigue flanges to the 7. Hazards

nearest 0.01 mm [0.004 in.].

7.1 The manufacturer’s material data sheets (MSDSs) shall

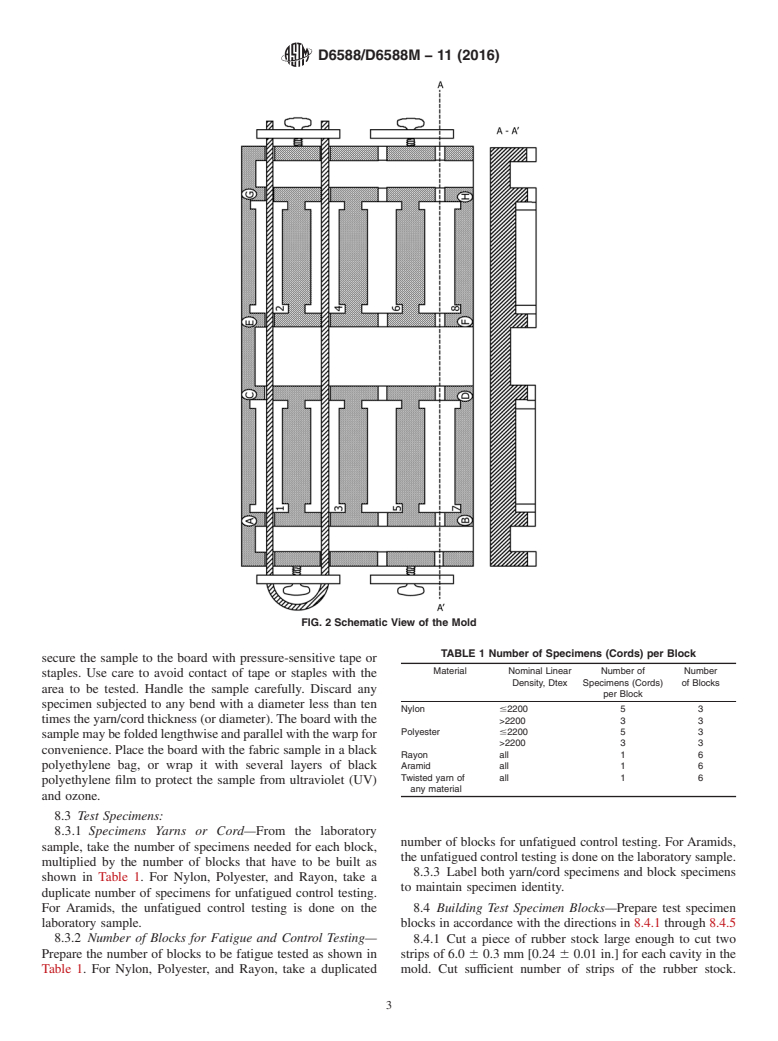

6.3 Mold, top and bottom sections with cavities in each for be used to obtain information on handling, storage, use, and

disposal of chemicals used in this test method.

12 or 24 specimens with the dimensions of 10.8 by 12.7 by

7 1

76.2 mm [ ⁄16 by ⁄2 by 3 in.]. (See schematic drawing in Fig.

8. Sampling and Test Specimens

2). All dimensions given require an accuracy of 0.1 mm [0.04

in.].The top of the mold may be coated withTFE-fluorocarbon

8.1 Primary Sampling Unit—Consider one roll of dipped

to release the specimens easily. Molds with other numbers of

tire cord fabric or a cord package as the primary sampling unit.

cavities may be used.

8.2 Laboratory Sampling Unit—As a laboratory sampling

6.4 Weights, having a mass of 50 65gor100 6 10 g, or

unit, from each primary sampling unit prepare tabby samples

both, for tensioning yarns or cords while building specimen

by taking a sample equal to the length of cord between the

blocks.

regular tabby woven at the end of the roll and a special tabby

woven a short distance from the end when the roll of fabric is

6.5 Curing press, capable of maintaining a minimum pres-

manufactured.Forrollsthatdonothaveaspecialwoventabby,

sure of 3.5 MPa [500 psi] over the total area of the mold

improvise a tabby by the use of gummed tape or strips of

surface, and capable of a platen temperature control within

cemented fabric applied across a section of the cord fabric to

63°C [65°F] of the temperature specified for curing the

give a tabby sample length at least 0.5 m [18 in.] long and at

rubber compound.

least one tenth of the roll width wide.

6.6 Guillotine, Hand-operated, capable of slicing the

8.2.1 Preparation of Tabby Samples—The handling of the

sample blocks (see 11.2.2).

samples must be done with care. The person obtaining the

6.7 Tensile Testing Machine, CRE type, in accordance with

sample should wear clean gloves. Cut the warp cords of the

Specification D76.

dipped fabric along the centerline of the special tabby for a

distanceequaltothewidthofthesample.Ifthisdistanceisless

6.8 Clamps, air-actuated, flat, rubber-faced or bollard-type.

than the full width of the fabric, cut the filling yarns of the

6.9 Rubber Compound, with a thickness of 6.0 6 0.3 mm

sample and of the special and regular tabbies in the direction

[0.24 6 0.01 in.], rolled up in polyethylene liner and free from

parallel with the warp cords. The resulting section of cord

moisture and contamination.

fabric is the tabby sample. Attach the tabby sample to a piece

NOTE 1—The rubber type used, especially rubber modulus, will affect

of cardboard or fiberboard, the length of which shall be equal

the results.

toatleastthelengthofthecordwarpbetweentabbies.Foldthe

6.10 Gloves, neoprene or other solvent-resistant rubber. tabby portions of the sample over each end of the board, and

FIG. 1 Schematic Top View of the Disc Fatigue Tester with Two Specimens

D6588/D6588M − 11 (2016)

FIG. 2 Schematic View of the Mold

TABLE 1 Number of Specimens (Cords) per Block

secure the sample to the board with pressure-sensitive tape or

Material Nominal Linear Number of Number

staples. Use care to avoid contact of tape or staples with the

Density, Dtex Specimens (Cords) of Blocks

area to be tested. Handle the sample carefully. Discard any

per Block

specimen subjected to any bend with a diameter less than ten

Nylon #2200 5 3

times the yarn/cord thickness (or diameter).The board with the

>2200 3 3

Polyester #2200 5 3

samplemaybefoldedlengthwiseandparallelwiththewarpfor

>2200 3 3

convenience. Place the board with the fabric sample in a black

Rayon all 1 6

polyethylene bag, or wrap it with several layers of black Aramid all 1 6

Twisted yarn of all 1 6

polyethylene film to protect the sample from ultraviolet (UV)

any material

and ozone.

8.3 Test Specimens:

8.3.1 Specimens Yarns or Cord—From the laboratory

number of blocks for unfatigued control testing. For Aramids,

sample, take the number of specimens needed for each block,

the unfatigued control testing is done on the laboratory sample.

multiplied by the number of blocks that have to be built as

8.3.3 Label both yarn/cord specimens and block specimens

shown in Table 1. For Nylon, Polyester, and Rayon, take a

to maintain specimen identity.

duplicate number of specimens for unfatigued control testing.

For Aramids, the unfatigued control testing is done on the 8.4 Building Test Specimen Blocks—Prepare test specimen

laboratory sample. blocks in accordance with the directions in 8.4.1 through 8.4.5

8.3.2 Number of Blocks for Fatigue and Control Testing— 8.4.1 Cut a piece of rubber stock large enough to cut two

Prepare the number of blocks to be fatigue tested as shown in strips of 6.0 6 0.3 mm [0.24 6 0.01 in.] for each cavity in the

Table 1. For Nylon, Polyester, and Rayon, take a duplicated mold. Cut sufficient number of strips of the rubber stock.

D6588/D6588M − 11 (2016)

Remove polyethylene backing from one side of rubber strips where:

just prior to using. Place a strip in each of the cavities of the

M = change of the original distance, mm [in.], if M is

two halves of the mold with the polyethylene side up. Press the

negative, the distance is decreased by that amount and

rubber firmly into the cavities. A cold press may be used.

if M is positive, the distance is increased,

Remove the polyethylene backing from the top of the rubber, D = original distance, (25.4 mm) [1 in.],

O

D = parallel testing distance of the discs,

leaving the rubber surface free of contamination and finger-

t

E = percent elongation/100, and

prints.

C = percent compression/100.

8.4.2 For packages, discard the outer layer of cord. Cut

9.1.3 Make the appropriate M change in the distance be-

approximately1m[1yd]of dipped cord. Simultaneously load

tween each pair of discs by moving the left disc in a straight

two adjacent cavities in the bottom mold by one end of a single

line toward, or away from, the right disc until the specified

cordatthefirstclamp.Positionthecordinthecenterofthefirst

parallel distance between the two discs has been achieved.

cavity, loop it through the second clamp at the end of the mold

9.1.4 Next, set the left disc to the required compression and

(hangatensioningmassonthelooptoeaseloading)thendown

extension settings as obtained from Table 2, Eq 1 , Eq 2 or by

the center of the second cavity and back through the first

changing the angle of the left disc. Read (and record) the

clamp. Tighten the first clamp on the two cord ends. Tension

maximum and minimum distances between the discs.

each cord with a tensioning mass of 50 g by hanging 100 g on

the loop end. Examine rear and front cord slots to be certain

9.2 Tensile Testing Machine Setup:

that all cords are properly aligned. Adjust cords as necessary

9.2.1 Set the gage length at 30 mm [1.2 in.], except for

then hold in position with masking tape at the ends of each

aramid where a gage length of 250 mm [10.0 in.] is required.

block. Once the cords have been tensioned and aligned, close

9.2.2 Fornylon,polyester,andrayon,useflatorbollardtype

the second clamp and remove the mass. Put an identification

clamps and set the crosshead speed at 100 % of the gage length

tag on the ends of each cord. Continue filling the remaining

per minute (Test Methods D885). For aramid, use suitable

cavities in the bottom of the mold (see schematic drawing in

bollard type clamps and set the crosshead speed at 50 % of the

Fig. 2). Place top half of the mold on the bottom half.

gage length per minute (Test Methods D7269).

8.4.3 Place the mold assembly in the press, preheated to the

10. Conditioning

specified temperature and apply a minimum pressure of 3.5

MPa [500 psi] over the total area of the mold surface.

10.1 Rubber compound properties are best maintained by

Vulcanize for the specified time at the temperature.

storage in a cool, dry atmosphere. Excessive rubber compound

moisture may lower adhesion of some fiber/rubber composites.

8.4.4 Reduce the pressure and remove the mold.

8.4.5 Openthemoldandremovethespecimenblocks.Mark

10.2 Store samples (tabbies) or adhesive-treated cord in

each block with identification. Trim the rubber overflow and

moisture-proof, UV, and ozone protective bags (aluminum-

cut the cords so that the total length in rubber and length

coated or black polythene bags may be sufficient) at tempera-

extending on each side will be not less than 150 mm [6 in.].

tures below 24°C [75°F].

Condition the specimen blocks for at least 16 h at ambient

10.3 Condition fatigued cords and non-fatigued control

room temperature

cords for at least 16 h in the standard atmosphere for testing

textiles, as described for tire cords (see Practice D1776) prior

9. Preparation of Apparatus

to determining breaking force.

9.1 Disc Fatigue Tester:

11. Procedure

9.1.1 Set disc in the tester parallel and 25.40 6 0.02 mm [1

11.1 Flexing Specimen Blocks:

6 0.001 in.] apart. Do this by setting the angle of the right disc

11.1.1 Determine the 25.4-mm [1.0-in.] position (loading

at 0 rad [0°] and adjusting the left disc to the proper distance.

position) for the discs and load the specimens (blocks) in this

9.1.2 Set the tester for compression and extension condi-

position. Distribute blocks of one sampl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.