ASTM C832-00(2005)

(Test Method)Standard Test Method of Measuring Thermal Expansion and Creep of Refractories Under Load

Standard Test Method of Measuring Thermal Expansion and Creep of Refractories Under Load

SIGNIFICANCE AND USE

The thermal expansion under load and the 20 to 50 h creep properties of a refractory are useful in characterizing the load bearing capacity of a refractory that is uniformly heated. Directly applicable examples are blast furnace stoves and glass furnace checkers.

SCOPE

1.1 This test method covers the procedure for measuring the linear change of refractory specimens that are subjected to compressive stress while being heated and while being held at elevated temperatures.

1.2 This test method does not apply to materials whose strength depends on pitch or carbonaceous bonds unless appropriate atmospheric control is used (see 7.3).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C832–00 (Reapproved 2005)

Standard Test Method of

Measuring Thermal Expansion and Creep of Refractories

Under Load

This standard is issued under the fixed designation C832; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope tory the product and the better it is able to resist deformation at

elevated temperatures.

1.1 This test method covers the procedure for measuring the

3.1.3 20 to 50 h creep—the percent deformation between

linear change of refractory specimens that are subjected to

the 20 and 50 h can be used to rank products in terms of

compressive stress while being heated and while being held at

relative load bearing capacity at a particular temperature.

elevated temperatures.

Relative rankings of various products may differ at different

1.2 This test method does not apply to materials whose

temperatures.

strength depends on pitch or carbonaceous bonds unless

appropriate atmospheric control is used (see 7.3).

4. Summary of Test Method

1.3 The values stated in inch-pound units are to be regarded

4.1 Test specimens sawed from samples of refractory brick

as standard. The values given in parentheses are mathematical

or from prefabricated samples of monolithic refractories are

conversions to SI units that are provided for information only

placed in a furnace and subjected to a prescribed compressive

and are not considered standard.

stress. Sensors are positioned for continuously measuring the

1.4 This standard does not purport to address all of the

linear change of the specimens parallel to the direction of the

safety concerns, if any, associated with its use. It is the

compressive stress. The temperature and linear change of the

responsibility of the user of this standard to establish appro-

specimens are continuously recorded while heating the furnace

priate safety and health practices and determine the applica-

at a controlled rate for thermal expansion under load testing.

bility of regulatory limitations prior to use.

The time and linear change of the specimens are also continu-

2. Referenced Documents ously recorded while at soak temperature for 20 to 50 h of

creep testing.

2.1 ASTM Standards:

4.2 The user should be aware that other mechanisms,

E691 Practice for Conducting an Interlaboratory Study to

besides those related to creep, may be activated. This is

Determine the Precision of a Test Method

especially true as temperatures approach 1650°C. When other

3. Terminology material responses are activated, such as corrosion, oxidation,

sintering, etc., strong caution should be exercised when inter-

3.1 Definitions of Terms Specific to This Standard:

preting and identifying creep mechanisms.

3.1.1 maximum dilation—the percent expansion where the

4.3 Since materials tend to exhibit faster creep rates during

thermal-expansion rate equals the creep-deformation rate. It

the initial stage of deformation, the user should be cautioned

can be used in estimating thermal-expansion relief when used

when extrapolating measured creep rates beyond the normal

in conjunction with the temperature at maximum dilation.

50 h test time. The material must be in the secondary creep

3.1.2 temperature at maximum dilation—in addition to

stage in order to extrapolate to longer times.

estimating thermal-expansion relief, it can be used to rank

products in terms of relative refractoriness. In general, the

5. Significance and Use

higher the temperature at maximum dilation, the more refrac-

5.1 The thermal expansion under load and the 20 to 50 h

creep properties of a refractory are useful in characterizing the

load bearing capacity of a refractory that is uniformly heated.

This test method is under the jurisdiction of ASTM Committee C08 on

Directly applicable examples are blast furnace stoves and glass

Refractories and is the direct responsibility of Subcommittee C08.01 on Strength.

furnace checkers.

Current edition approved Dec. 1, 2005. Published December 2005. Originally

approved in 1976. Last previous edition approved in 2000 as C832 – 00. DOI:

6. Interferences

10.1520/C0832-00R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Chemical Interactions with Test Environment—The test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

environment (vacuum, inert gas, ambient air, etc.), including

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. moisture content (percent relative humidity), may have a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C832–00 (2005)

stronginfluenceonbothcreepstrainrateandcreeprupturelife. Section 8. The specimens should be equally heated on at least

In particular, refractories susceptible to slow crack growth or two opposite sides, and the temperature difference between

oxidation will be strongly influenced by the test environment. specimens in a multiple-position furnace and between the top

Testing should be conducted in environments that are either and bottom ends of single specimens should be no more than

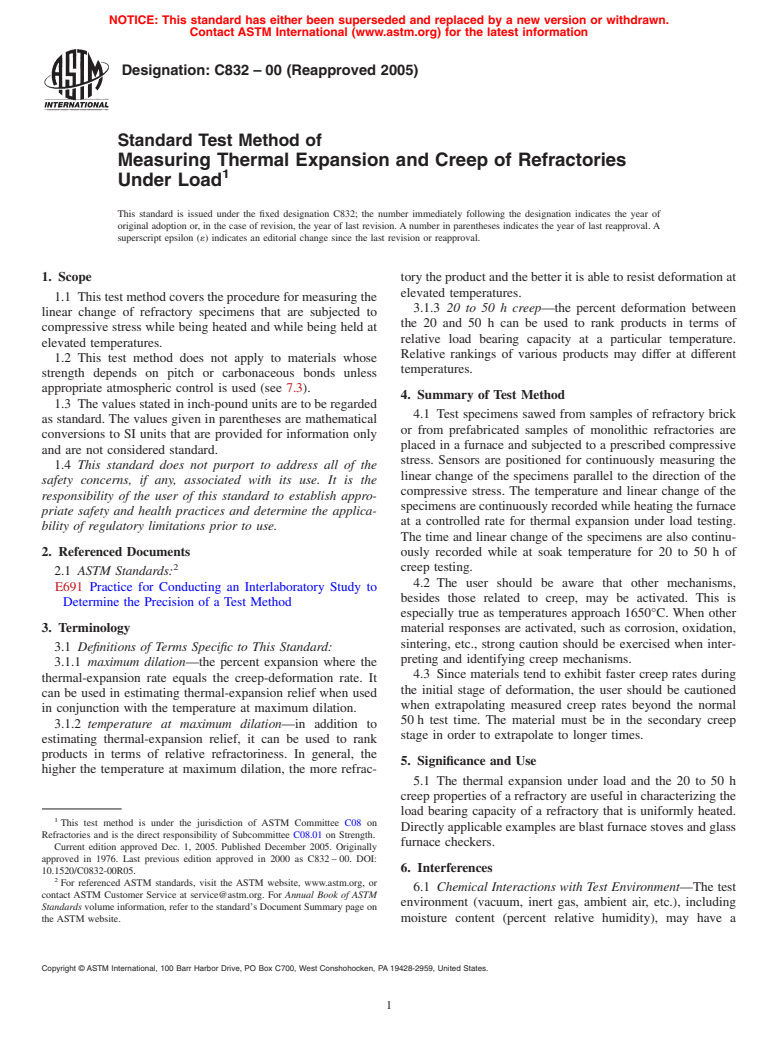

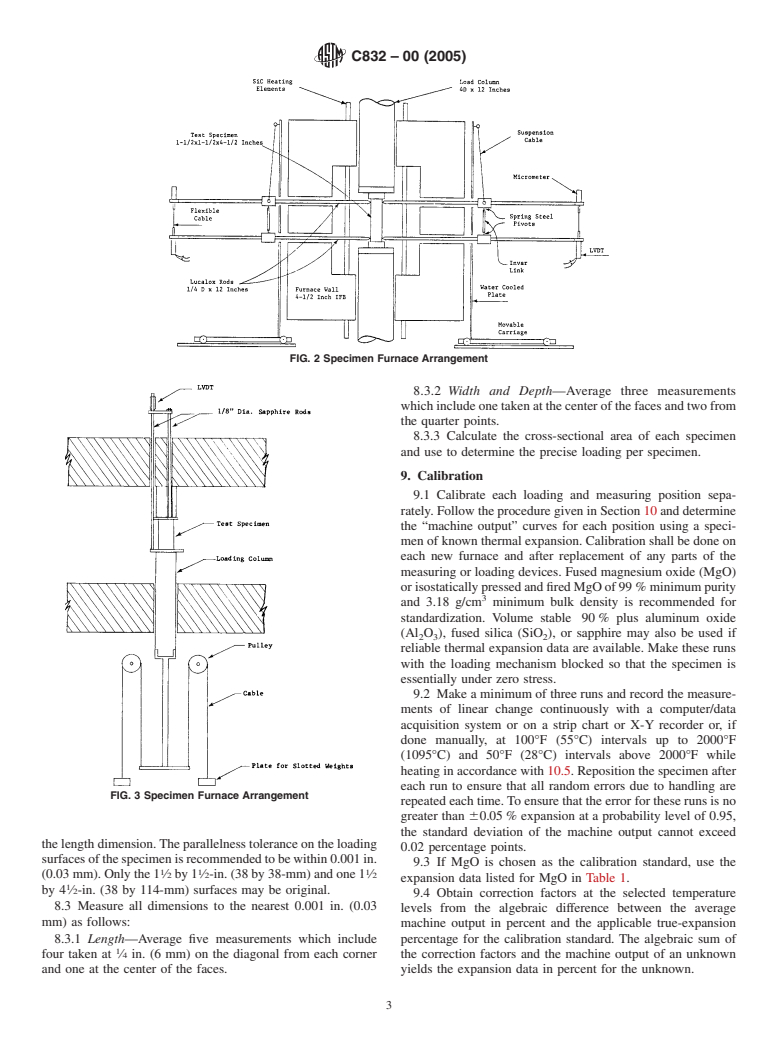

representative of service conditions or inert to the refractories 18°F (10°C). See Figs. 1-5 for sketches of five typical furnace

being tested depending on the performance being evaluated. arrangements.

6.2 Specimen Surface Preparation—Surface preparation of 7.2 Temperature Controllers,thatcontrolheatingatarateof

specimens can introduce machining flaws that may affect the 100 6 9°F/h (55 6 5°C/h) over the temperature range from

creep strain rate and creep rupture life. Machining damage 500 to 3000°F (260 to 1650°C) and can control soak tempera-

imposed during specimen preparation will most likely result in tures within 69°F (65°C).

premature failure of the specimen, but may also introduce 7.3 Air Atmosphere, unless otherwise specified. If pitch or

flaws that can grow by slow crack growth. Surface preparation carbonaceous-bonded materials are tested, specify the atmo-

can also lead to residual stresses, which can be released during sphere used when reporting results.

the test. 7.4 Linear Measuring Device, that records the difference in

6.3 Specimen/Extensometer Chemical Interactions—If the length dimension of each specimen parallel to the direction of

strain measurement technique relies on physical contact be- stress and yields the desired precision and reproducibility.

tween the extensometer components (contacting probes or 7.5 Recorders, that display linear change readings to

optical method flags) and the specimen, then the flag attach- 60.0005 in. (0.013 mm).

ment methods and extensometer contact materials must be 7.6 Loading Devices, that apply at least 100 psi (689 kPa)

1 1

chosen with care to ensure that no adverse chemical reactions compressive stress within 61%, on a 1 ⁄2 by 1 ⁄2-in. (38 by

occur during testing. This should not be a problem if the probe 38-mm) cross section.

or specimen materials are mutually chemically inert. The user

should also be aware that impurities or second phases in the 8. Specimen Preparation

probes and flags or specimens may be mutually chemically

1 1 1

8.1 Cut or form specimens nominally 1 ⁄2 by 1 ⁄2 by 4 ⁄2 in.

reactive and could influence the results.

(38 by 38 by 114 mm) (Note 1) with the 4 ⁄2-in. dimension

6.4 Temperature Variations—Creep strain is related to tem-

perpendicular to the pressing direction of a brick, the ramming

perature through an exponential function. Thus, fluctuations in

direction of a plastic, or the position of the vibrator used in

test temperature or changes in temperature profile along the

forming a castable. The 4 ⁄2-in. dimension may be parallel to

length of the specimen can cause fluctuations in strain mea-

the length or width of the original shape.

surements or changes in creep rate (see 7.1 and 7.2).

NOTE 1—Specimens of different geometry (for example, cylindrical)

may be used upon agreement between the parties concerned.

7. Apparatus

1 1

7.1 Electrically Heated Furnace, with a setting space suffi- 8.2 Grind or sand both 1 ⁄2 by 1 ⁄2-in. (38 by 38-mm)

cient to contain one or more specimens of the size specified in surfaces so that they are nominally plane and perpendicular to

FIG. 1 Specimen Furnace Arrangement

C832–00 (2005)

FIG. 2 Specimen Furnace Arrangement

8.3.2 Width and Depth—Average three measurements

whichincludeonetakenatthecenterofthefacesandtwofrom

the quarter points.

8.3.3 Calculate the cross-sectional area of each specimen

and use to determine the precise loading per specimen.

9. Calibration

9.1 Calibrate each loading and measuring position sepa-

rately. Follow the procedure given in Section 10 and determine

the “machine output” curves for each position using a speci-

men of known thermal expansion. Calibration shall be done on

each new furnace and after replacement of any parts of the

measuring or loading devices. Fused magnesium oxide (MgO)

orisostaticallypressedandfiredMgOof99 %minimumpurity

and 3.18 g/cm minimum bulk density is recommended for

standardization. Volume stable 90 % plus aluminum oxide

(Al O ), fused silica (SiO ), or sapphire may also be used if

2 3 2

reliable thermal expansion data are available. Make these runs

with the loading mechanism blocked so that the specimen is

essentially under zero stress.

9.2 Make a minimum of three runs and record the measure-

ments of linear change continuously with a computer/data

acquisition system or on a strip chart or X-Y recorder or, if

done manually, at 100°F (55°C) intervals up to 2000°F

(1095°C) and 50°F (28°C) intervals above 2000°F while

heating in accordance with 10.5. Reposition the specimen after

each run to ensure that all random errors due to handling are

FIG.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.