ASTM D4526-96(2001)e1

(Practice)Standard Practice for Determination of Volatiles in Polymers by Static Headspace Gas Chromatography

Standard Practice for Determination of Volatiles in Polymers by Static Headspace Gas Chromatography

SIGNIFICANCE AND USE

For various reasons, one may want to measure the level of unreacted or residual monomer, water, or other volatile components in a polymer sample.

Volatiles of interest are often at trace concentrations. Headspace analysis is suited for determination of these trace components which often cannot be determined by conventional gas chromatography because of sample decomposition or interferences.

For polymer analysis, sample treatment for headspace analysis is simpler than conventional gas chromatography, where precipitation steps may be required to prevent polymer contamination of the chromatographic column.

This headspace practice will be able to determine qualitatively any component with sufficient vapor pressure. It is capable of yielding semiquantitative results and can be used for relative comparisons between samples.

SCOPE

1.1 Headspace gas chromatography (GC) involves the determination of volatile components in a polymer solution by gas chromatography of a vapor phase in thermal equilibrium with the sample matrix. Volatiles in finely ground insoluble polymers can also be determined with and without an extracting solvent.

1.2 This practice provides two procedures:

1.2.1 Procedure A--Automatic headspace analysis.

1.2.2 Procedure B--Manual injection headspace analysis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

Note 1--There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 4526 – 96 (Reapproved 2001)

Standard Practice for

Determination of Volatiles in Polymers by Static Headspace

Gas Chromatography

This standard is issued under the fixed designation D 4526; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Several sections were changed and added editorially in March 2001.

1. Scope* 3.2 Volatiles of interest are often at trace concentrations.

Headspace analysis is suited for determination of these trace

1.1 Headspace gas chromatography (GC) involves the de-

componentswhichoftencannotbedeterminedbyconventional

termination of volatile components in a polymer solution by

gas chromatography because of sample decomposition or

gas chromatography of a vapor phase in thermal equilibrium

interferences.

with the sample matrix. Volatiles in finely ground insoluble

3.3 For polymer analysis, sample treatment for headspace

polymers can also be determined with and without an extract-

analysis is simpler than conventional gas chromatography,

ing solvent.

where precipitation steps may be required to prevent polymer

1.2 This practice provides two procedures:

contamination of the chromatographic column.

1.2.1 Procedure A—Automatic headspace analysis.

3.4 This headspace practice will be able to determine

1.2.2 Procedure B—Manual injection headspace analysis.

qualitatively any component with sufficient vapor pressure. It

1.3 This standard does not purport to address all of the

is capable of yielding semiquantitative results and can be used

safety concerns, if any, associated with its use. It is the

for relative comparisons between samples.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Apparatus

bility of regulatory limitations prior to use. Specific precau-

4.1 Gas Chromatograph, equipped with an appropriate

tionary statements are given in Section 6.

detector and backflush valve.

NOTE 1—There is no equivalent ISO standard. 3

4.1.1 For ProcedureA, an Automated Headspace Sampler,

including backflush capability, thermostated sample tray, and

2. Referenced Documents

associated accessories fulfill these requirements while provid-

2.1 ASTM Standards:

ing for automatic sequential sampling of headspace vapors.

D 4322 Test Method for ResidualAcrylonitrile Monomer in

4.1.2 Procedure B requires the following additional equip-

Styrene-Acrylonytrile Copolymers and Nitrile Rubber by

ment:

Headspace Gas Chromatography

4.1.2.1 Constant-Temperature Bath, capable of maintaining

E 260 Practice for Packed Column Gas Chromatography

90 6 1°C.

E 355 Practice for Gas Chromatography Terms and Rela-

4.1.2.2 Gas-Tight Gas Chromatographic Syringes, which

tionships

can be heated to 90°C for sampling and injection.

E 594 Practice for Testing Flame Ionization Detectors Used

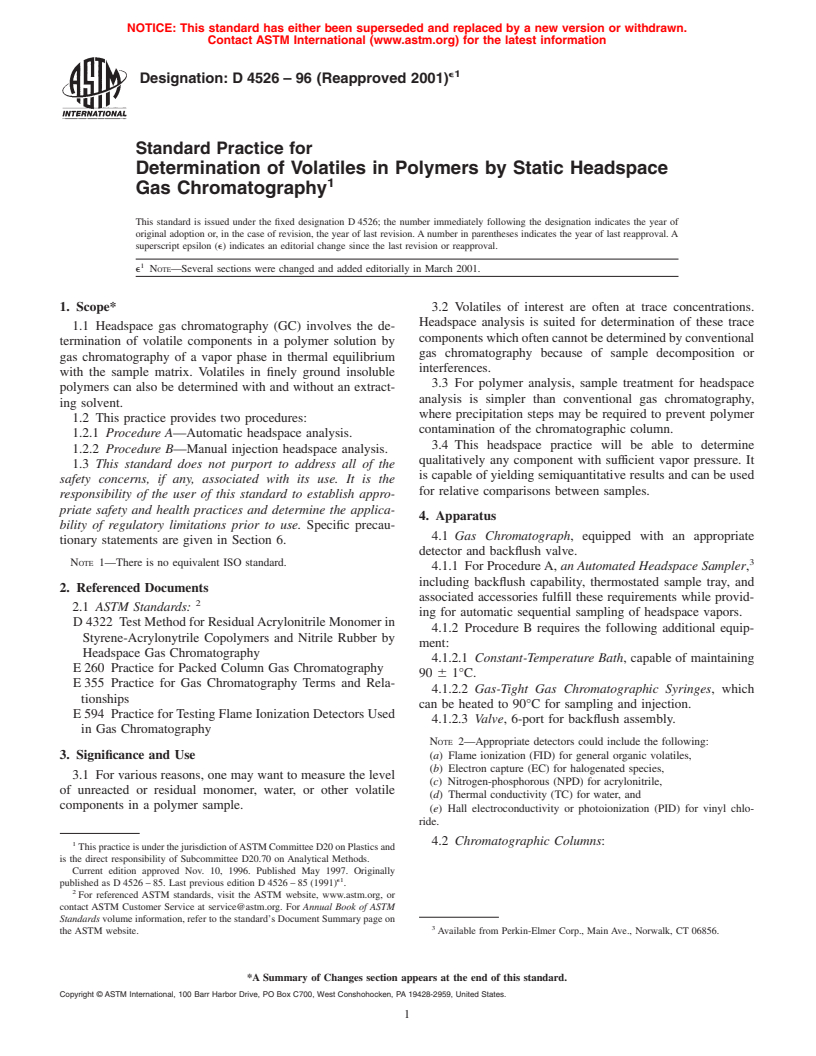

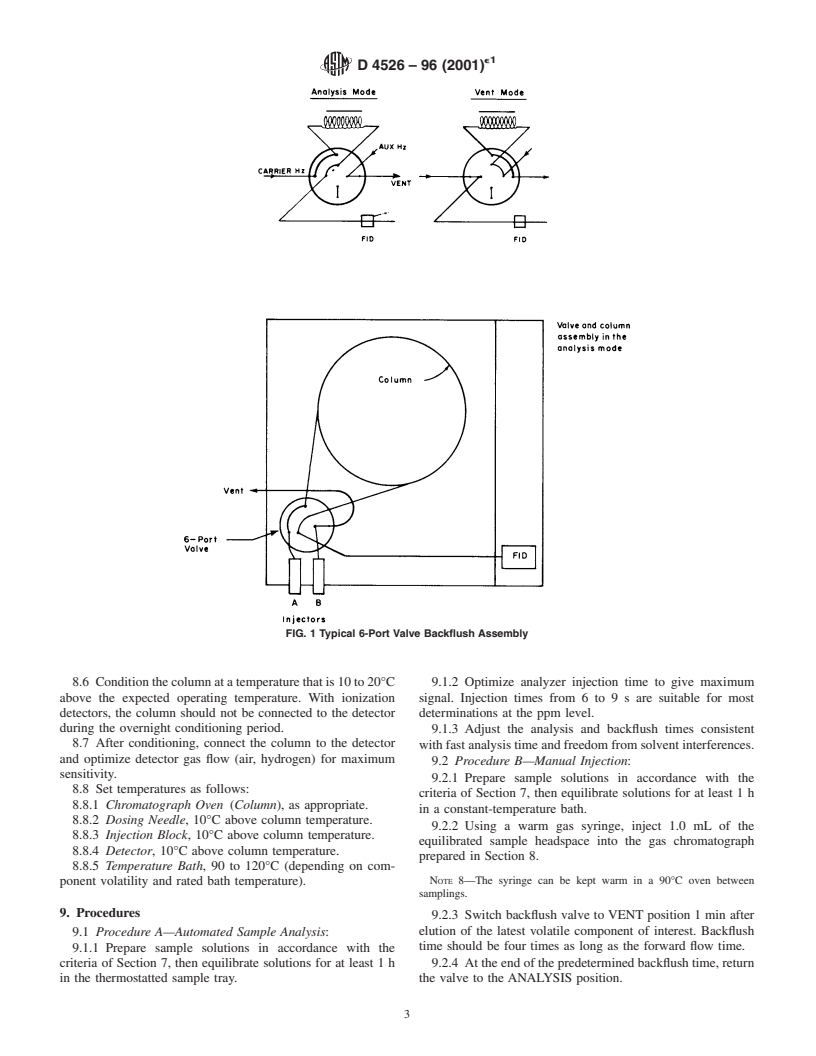

4.1.2.3 Valve, 6-port for backflush assembly.

in Gas Chromatography

NOTE 2—Appropriate detectors could include the following:

(a) Flame ionization (FID) for general organic volatiles,

3. Significance and Use

(b) Electron capture (EC) for halogenated species,

3.1 For various reasons, one may want to measure the level

(c) Nitrogen-phosphorous (NPD) for acrylonitrile,

of unreacted or residual monomer, water, or other volatile

(d) Thermal conductivity (TC) for water, and

components in a polymer sample.

(e) Hall electroconductivity or photoionization (PID) for vinyl chlo-

ride.

4.2 Chromatographic Columns:

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Nov. 10, 1996. Published May 1997. Originally

e1

published as D 4526 – 85. Last previous edition D 4526 – 85 (1991) .

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from Perkin-Elmer Corp., Main Ave., Norwalk, CT 06856.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 4526 – 96 (2001)

4.2.1 Packed Column Analysis—Column packings found 6.4 Once heated, sample vials containing polymer volatiles

to be useful for residual monomers (for example, acrylonitrile, are under pressure. After analysis, vent the pressure with a

vinyl chloride) include Chromosorb or Porapak porous poly- hypodermic syringe needle connected to a charcoal slug or

merpackings,0.4 %Carbowax1500liquidphaseonCarbopak vented hood before removing vials from the constant tempera-

C support, or 0.19 % picric acid on Carbopak C support. Other ture bath.

columns can be used after it is determined that they give the

required resolution and accuracy for the component of interest.

7. Storage and Sampling

4.2.2 Capillary Column Analysis—Choose a column ca-

7.1 To prevent loss of volatiles from polymer pellets, or

pable of achieving the required resolution for the components

resin, store in tightly sealed jars with minimal headspace or

ofinterest.Forexample,foracrylonitrilemonomer,thecolumn

heat-sealed pouches constructed of an outer polyester layer, an

of choice is a Quadrex 007–2, 25m 3 0.32–mm internal

aluminum foil middle layer, and a polyolefin inner sealing

diameter fused silica.

layer.

4.3 Integrator, recorder (5–mV full scale), computing inte-

7.2 Forrolledpolymerfilmsamples,discard3to5moffilm

grator or appropriate computer data station and software

before taking the sample for headspace analysis because

capable of measuring and storing peak area data.

volatiles can be lost by diffusion through the outer film layers.

4.4 Headspace Vials, septa, ring closures, and vial sealer.

7.3 Powdered resin samples (for example, poly(vinyl chlo-

4.5 Analytical Balance, capable of weighing to 60.0001 g.

ride)) can be weighed directly into a tared headspace vial. A

4.6 Soap Film Flowmeter and Stopwatch, or other means of

4-g sample (weighed to the nearest 0.0001 g) should be

measuring gas flow rates.

adequate for determination of many volatiles at the parts per

4.7 Pressure Regulators for all required gas cylinders.

million (ppm) levels using sensitive ionization detectors.

4.8 Filter-Dryer Assemblies for each required gas cylinder.

7.4 Polymer pellets or granules and film samples can be

dissolved, depending on chemistry of polymer, to facilitate

5. Reagents and Materials

attaining thermal equilibrium in a reasonable period of time.

5.1 Solvent,ReagentGrade,orBestAvailable—Thesolvent

These samples are weighed (0.56 0.001 g) into headspace

should be free of interferences at th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.